Robot joint torque sensor

A technology of torque sensor and robot joints, which is applied in the direction of instruments, torque measurement, power measurement, etc., can solve the problems of low measurement accuracy, sensor hysteresis error temperature drift, large error, etc., achieve high measurement efficiency, eliminate vibration, real-time good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objectives, technical solutions and advantages of the present invention clearer, the invention is further described below with reference to the accompanying drawings.

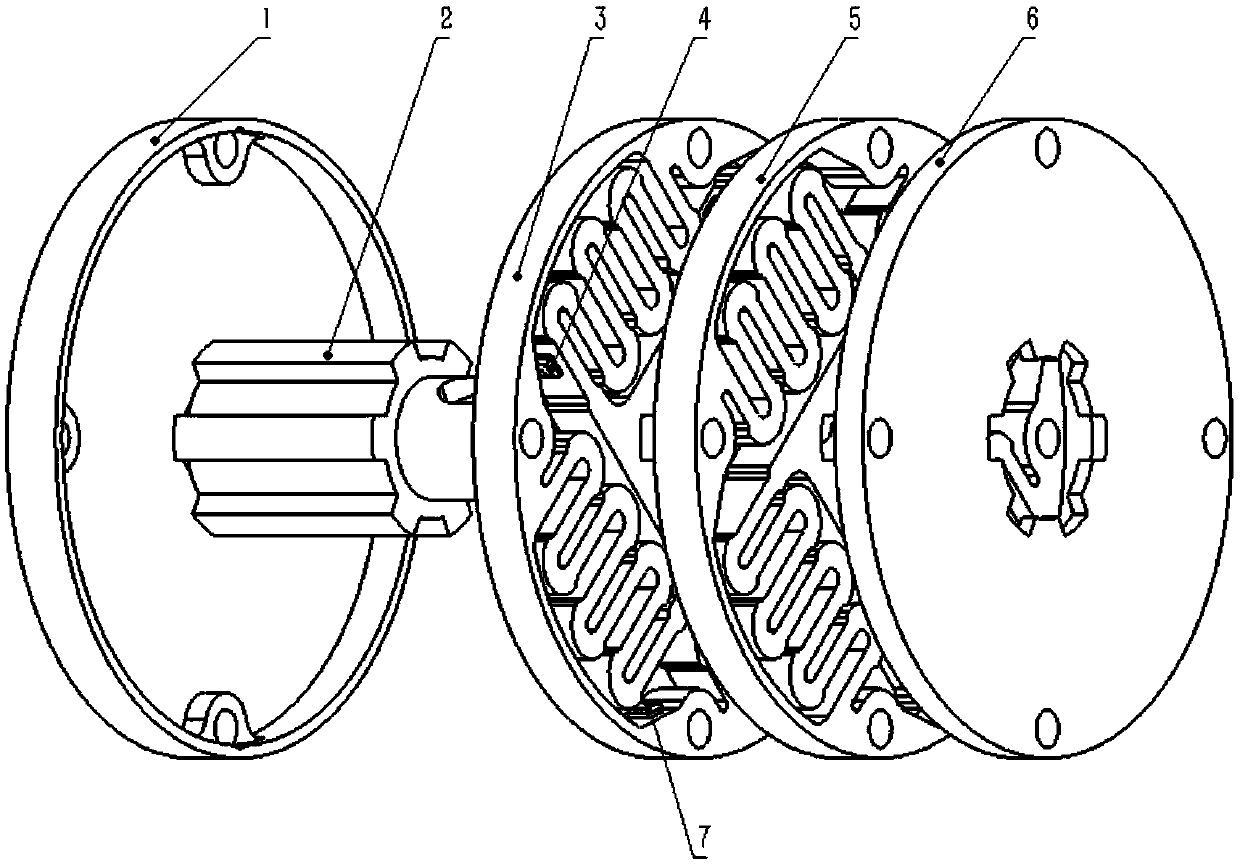

[0038] like figure 1 As shown in the figure, a robot joint torque sensor of the present invention is composed of an end cover 1, a spline shaft 2, a first plane torsion spring 3, a second plane torsion spring 5, an end cover 2 6, a PCB signal processing circuit board and a photosensitive device. Composition; end cap 1 is used to install the PCB signal processing circuit board.

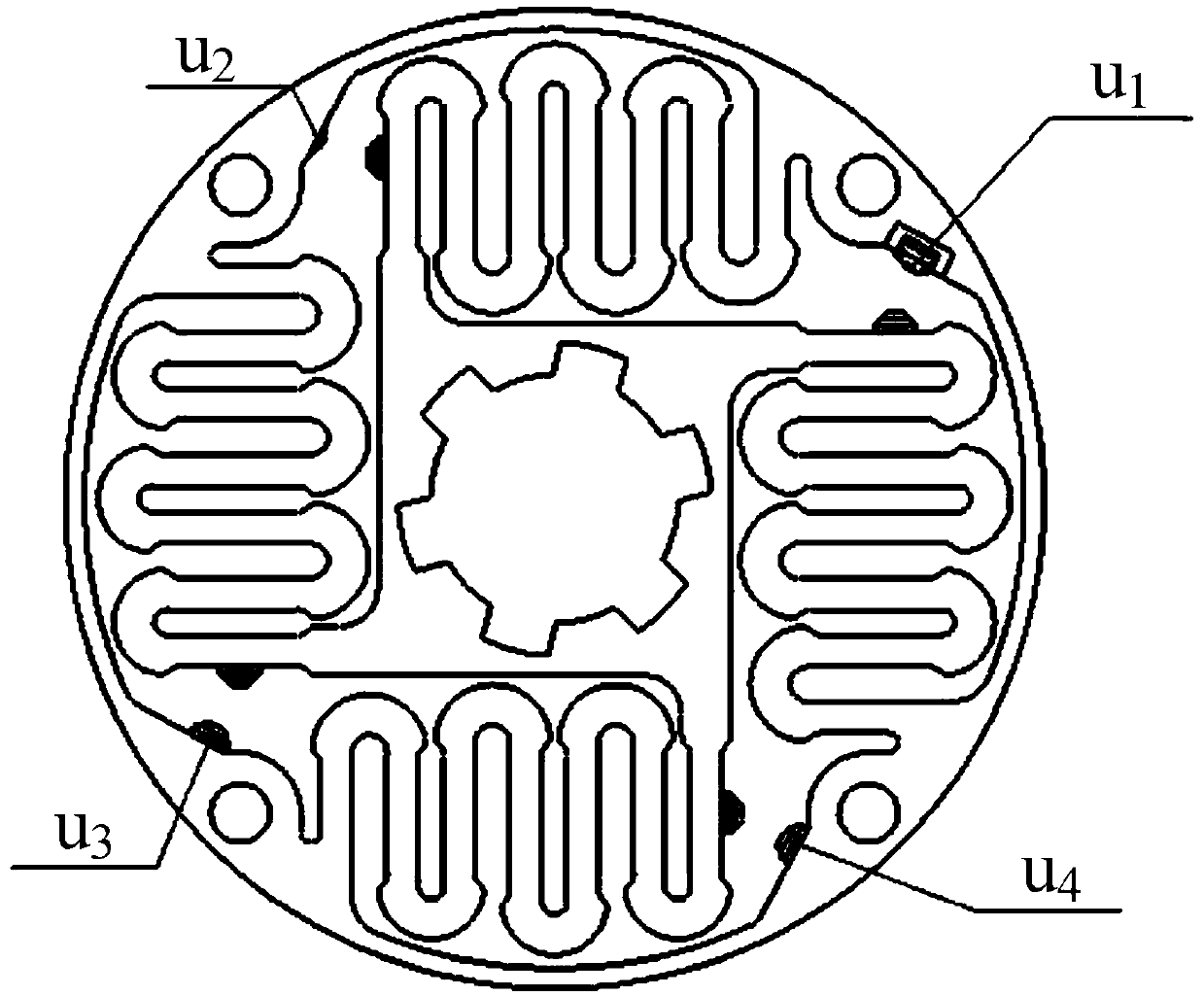

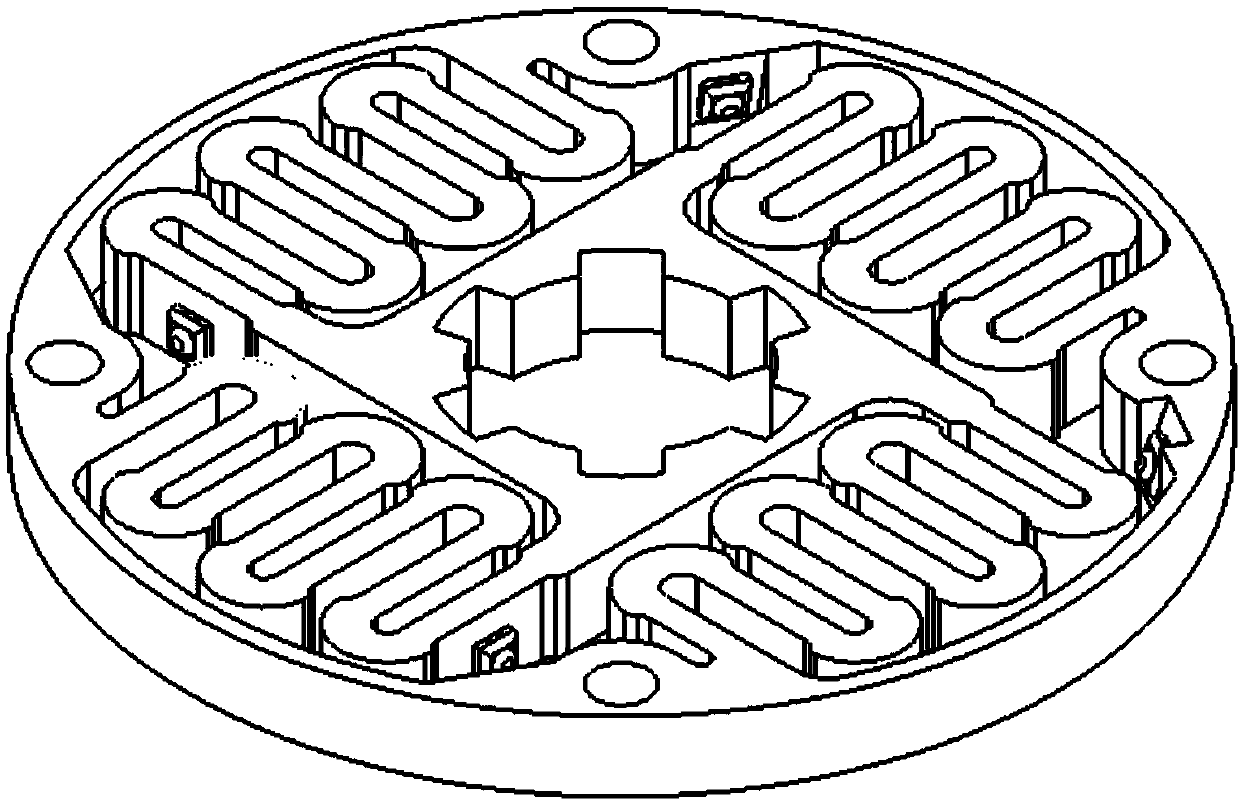

[0039] like figure 2 and 3 As shown, the structures of the first plane torsion spring 3 and the second plane torsion spring 5 are completely the same, and they are both improved structures for the first plane torsion spring or the second plane torsion spring in the patent application No. 201611059925.9, that is, they both include internal The ring, the outer ring and the elastomer unit, but not the limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com