Undamaged disassembling device of windscreen of scraped car

A technology for windshields and scrapped cars, which can be applied to the recycling of scrapped vehicles, the removal of solid waste, motor vehicles, etc., and can solve the time-consuming and labor-intensive problems of windshields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

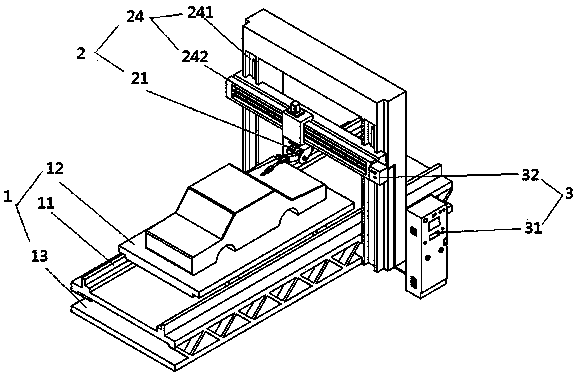

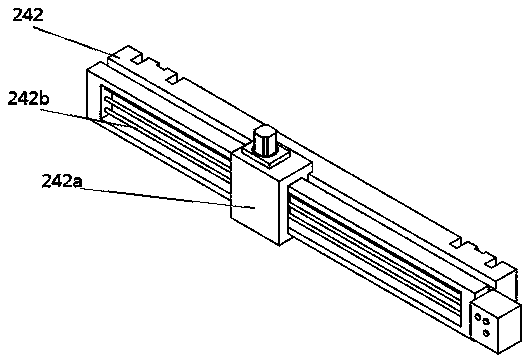

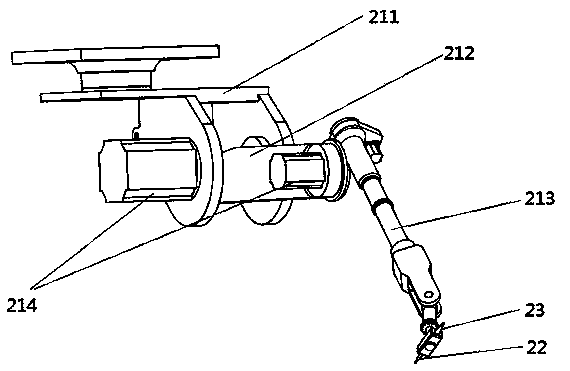

[0024] See Figure 1 to Figure 3 , the non-destructive dismantling device for windshields of scrapped automobiles disclosed in this embodiment includes a conveying unit 1 for transporting vehicles to be dismantled, a mechanical arm 2 for detecting the edge of the windshield and cutting it, and a mechanical arm unit 2 for controlling the cutting The control unit 3 of parameters and cutting path. The conveying part 1 includes a guide rail 11, a conveying trolley 12 and a steel stand 13, the guide rail 11 is fixed on the steel stand 13, and the conveying trolley 12 runs back and forth on the guide rail 11, and can transport the pre-disassembled scrapped cars to the position of the mechanical arm Disassemble. The mechanical arm part 2 includes a gantry frame 24, and the gantry frame 24 includes a column 241 and a crossbeam 242 arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com