Method for relieving nodulation of furnace roller of continuous annealing furnace

A continuous annealing furnace and furnace roll technology, which is applied in the direction of furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of continuous annealing furnace rolls that are easy to nodulate, so as to ensure the cleanliness and stability of furnace rolls and relieve furnace roll nodulation , Reduce the effect of high foreign matter concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

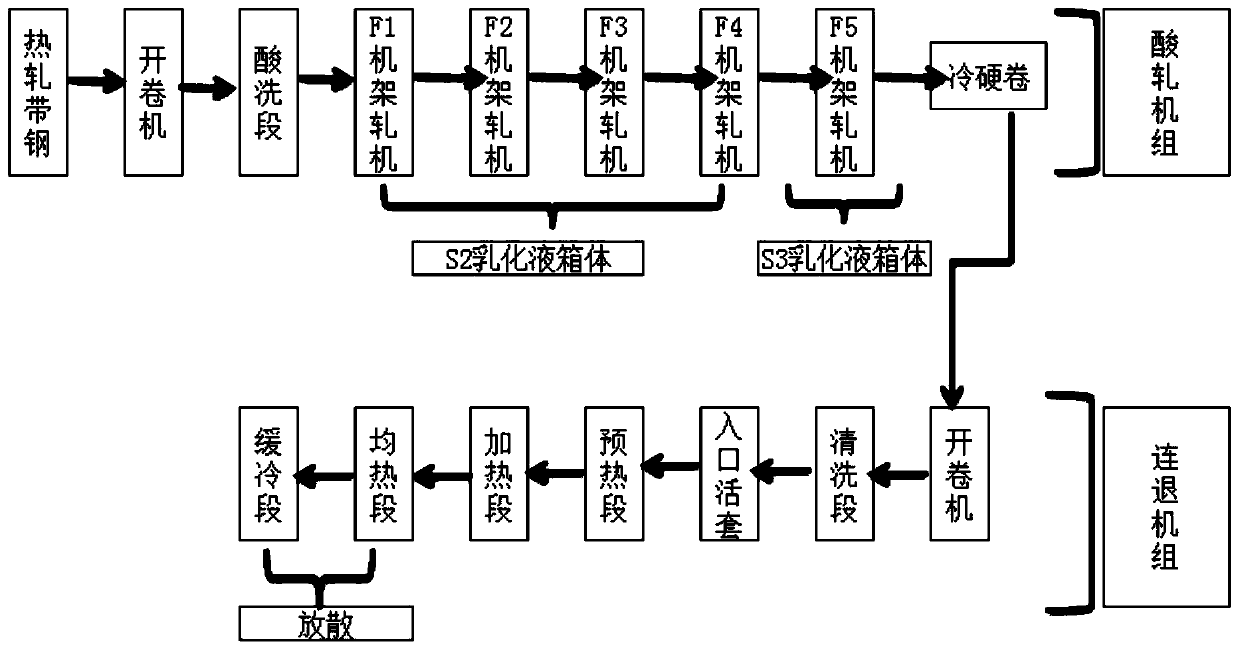

[0055] A method for alleviating nodulation of rollers in continuous annealing furnaces, the steel type is M250P1, and the layout plan is 180 tons.

[0056] The relationship between the nominal roll diameter b of the furnace roll set in the PLC program and the actual roll diameter a of the furnace roll is: b=a+5mm.

[0057] The inner wall of the furnace roll is coated with LC056, the thickness of the coating is 0.05mm, and the hardness of the coating is HV=900. The manufacturer is Shanghai Junshan Surface Technology Co., Ltd.

[0058] During the strip steel production process, it is processed as follows:

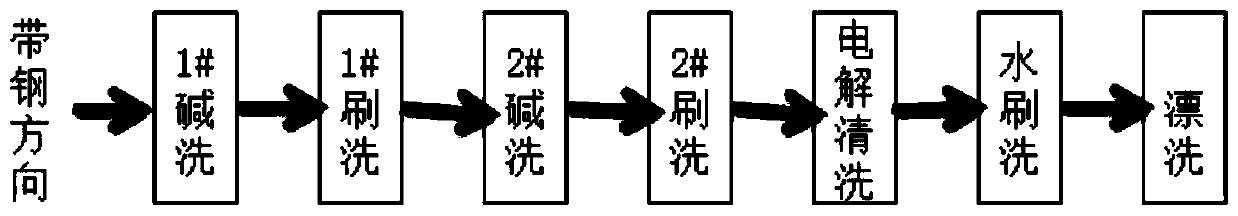

[0059] (1) the emulsion concentration of acid rolling group control S2 is 2.0%, and the emulsion concentration of S3 is 0.7%; The iron powder content of the emulsion of F1-F4 is 300ppm, and the iron powder content of the emulsion of F5 stand rolling mill is 100ppm; the flow rate of the emulsion in the F1-F5 stand rolling mill is 5000L / min; the temperature control of the emul...

Embodiment 2

[0068] A method for alleviating nodulation of rollers in continuous annealing furnaces, the steel type is M210P1, and the layout plan is 200 tons.

[0069] The relationship between the nominal roll diameter b of the furnace roll set in the PLC program and the actual roll diameter a of the furnace roll is: b=a-5mm.

[0070] The inner wall of the furnace roll is coated with LC056, the thickness of the coating is 0.07mm, and the hardness of the coating is HV=1000. The manufacturer is Shanghai Junshan Surface Technology Co., Ltd.

[0071] During the strip steel production process, it is processed as follows:

[0072] (1) the emulsion concentration of acid rolling group control S2 is 3.0%, and the emulsion concentration of S3 is 0.6%; The iron powder content of the emulsion of F1-F4 is 250ppm, and the iron powder content of the emulsion of F5 stand rolling mill is 80ppm; the flow rate of the emulsion in the F1-F5 stand rolling mill is 6000L / min; the temperature control of the emul...

Embodiment 3

[0080] A method for alleviating nodulation of furnace rolls in continuous annealing furnaces. The steel type is DC04, and the layout plan is 210 tons.

[0081] The relationship between the nominal roll diameter b of the furnace roll set in the PLC program and the actual roll diameter a of the furnace roll is b=a+3mm.

[0082] The inner wall of the furnace roll is coated with LC056, the thickness of the coating is 0.06mm, and the hardness of the coating is HV=950. The manufacturer is Shanghai Junshan Surface Technology Co., Ltd.

[0083] During the strip steel production process, it is processed as follows:

[0084] (1) the emulsion concentration of acid rolling group control S2 is 2.5%, and the emulsion concentration of S3 is 0.5%; The iron powder content of the emulsion of F1-F4 is 270ppm, and the iron powder content of the emulsion of F5 stand rolling mill is 90ppm; the flow rate of the emulsion in the F1-F5 stand rolling mill is 5500L / min; the temperature control of the em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com