Sticking method for decorative brick

A technology of facing bricks and adhesives, applied in the field of building decoration, can solve the problems of easy hollowing, unstable pasting quality, low work efficiency, etc., and achieves the effect of simple cleaning, ideal pasting effect, and ensuring clean and hygienic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

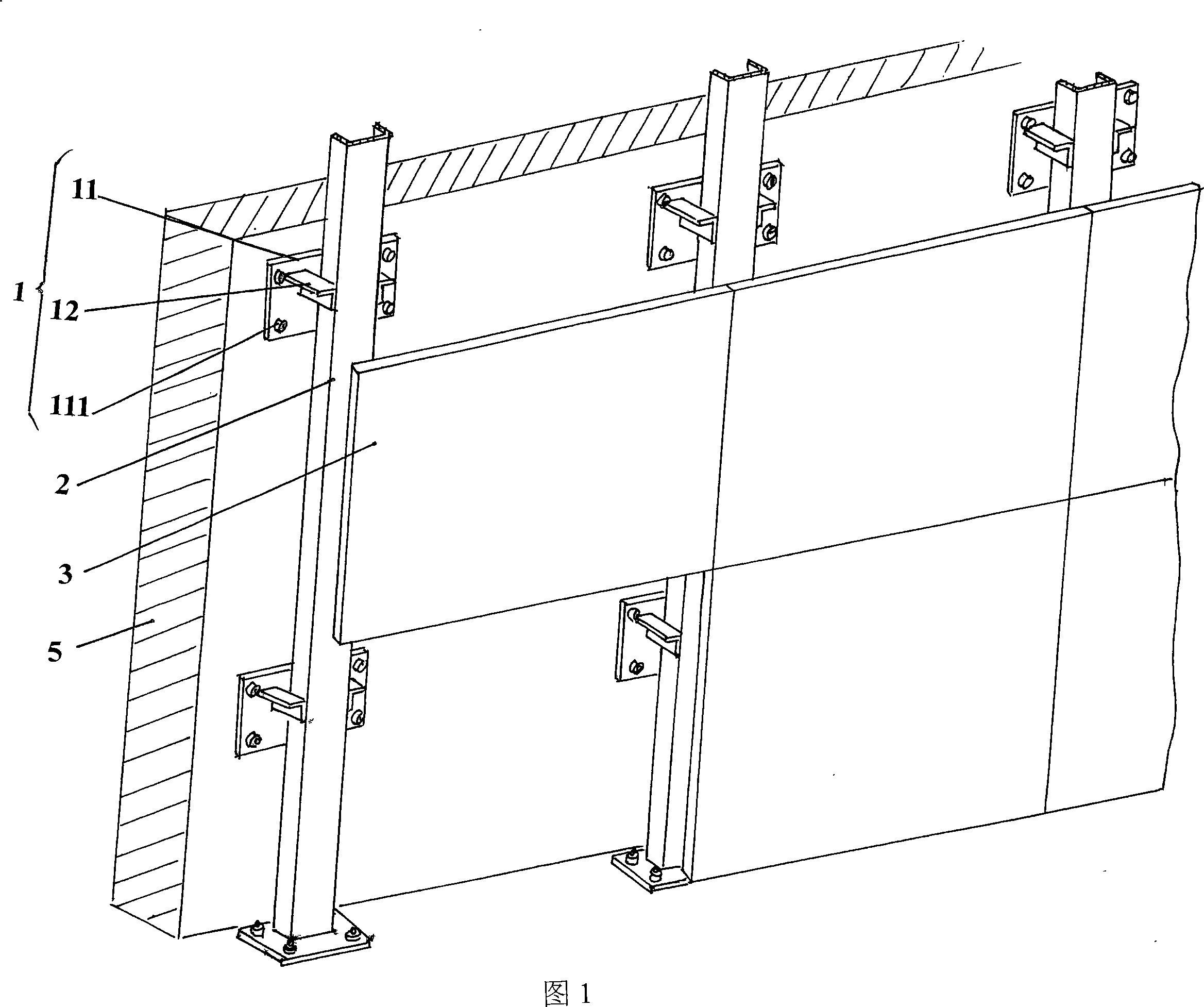

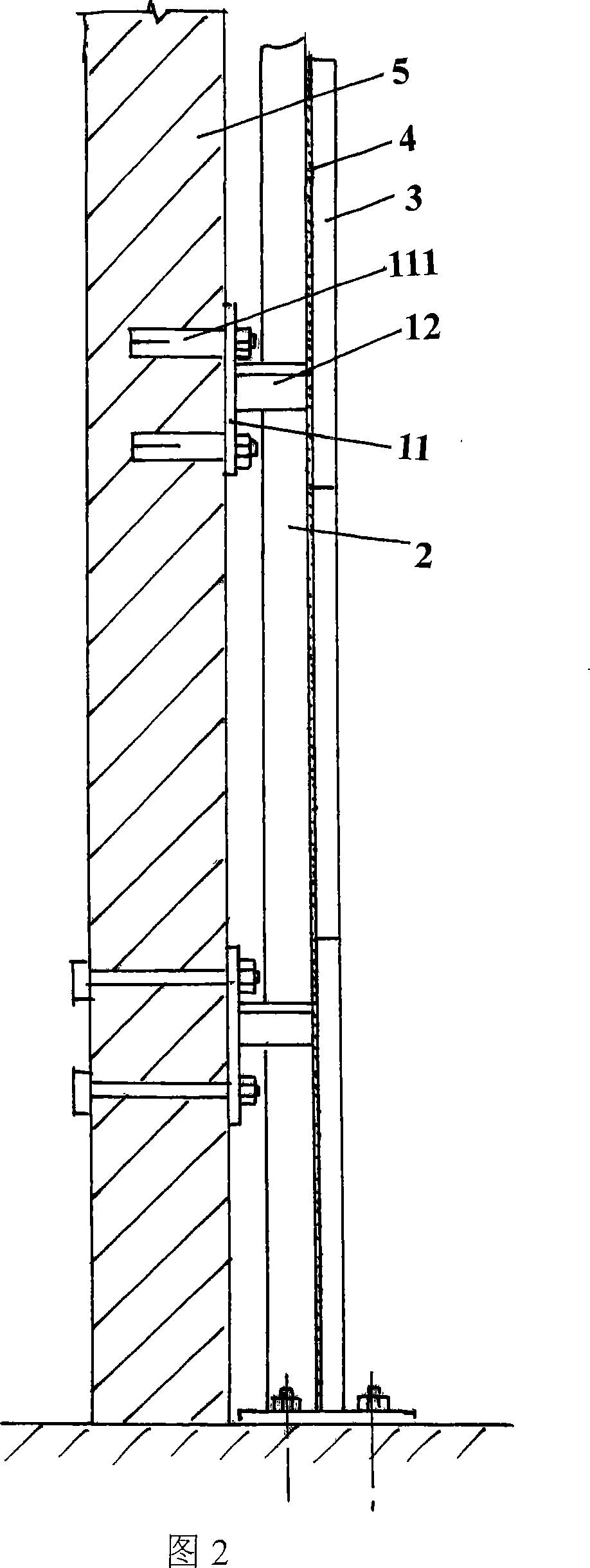

[0023] Please refer to Figure 1 and Figure 2.

[0024] A) The first adapter 1 is first arranged on the wall, and the galvanized steel plate 11 with a shape of preferably rectangular 15×20×0.8 cm is fixed to the concrete wall 5 with expansion bolts 111 of Φ12 mm. The upper and lower spacing of the steel plates 11 is 1m, and the left and right spacing is 40cm, and the consistency of the vertical and horizontal positions of each steel plate 11 is ensured, that is, the same horizontal position or the same horizontal axis should be ensured between the steel plates 11 on the same row , and the steel plates 11 on the same column should be guaranteed to be on the same longitudinal axis. The preferred but not limited specification for welding on each steel plate 11 is No. 5 (5 # ) angle steel 12, the size of all angle steel 12 welded on the steel plate 11 should be consistent, and the angle steel 12 and steel plate 11 maintain vertical relationship, thereby form the first adapter 1 on ...

Embodiment 2

[0030] sketches.

[0031] Change the decorative brick 3 to a 60×120×1.2cm mirror brick; change the wall 5 to a block wall; fix the steel plate 11 to the wall 5 with Φ12mm wall-through bolts, and the steel plate 11 should be opposite to the inside and outside The way is to implement alignment and fixation on both sides of the wall 5, and use caulking agent instead of cement slurry pointing treatment. For the caulking agent, it is preferred but not limited to use, for example, produced and sold by Shanghai Ruirui Waterproof Material Co., Ltd., Shanghai, China. The grade is FL-11, and the product name is construction caulking putty. All the other are the same as the description to embodiment 1.

[0032] Utilize the scheme of the present invention to also be able to paste facing brick 3 on the surface that is pure steel frame, that is to say when using steel frame to separate indoor space, the method of the present invention can be applied equally, as long as implement double-sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com