Cutting machine capable of collecting residues

A cutting machine and residue technology, which is applied in the direction of metal sawing equipment, sawing machine accessories, metal processing machinery parts, etc., can solve the problems of entering the equipment, reducing the cleanliness of the equipment, and difficult to clean the residue, so as to maintain the cleanliness and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

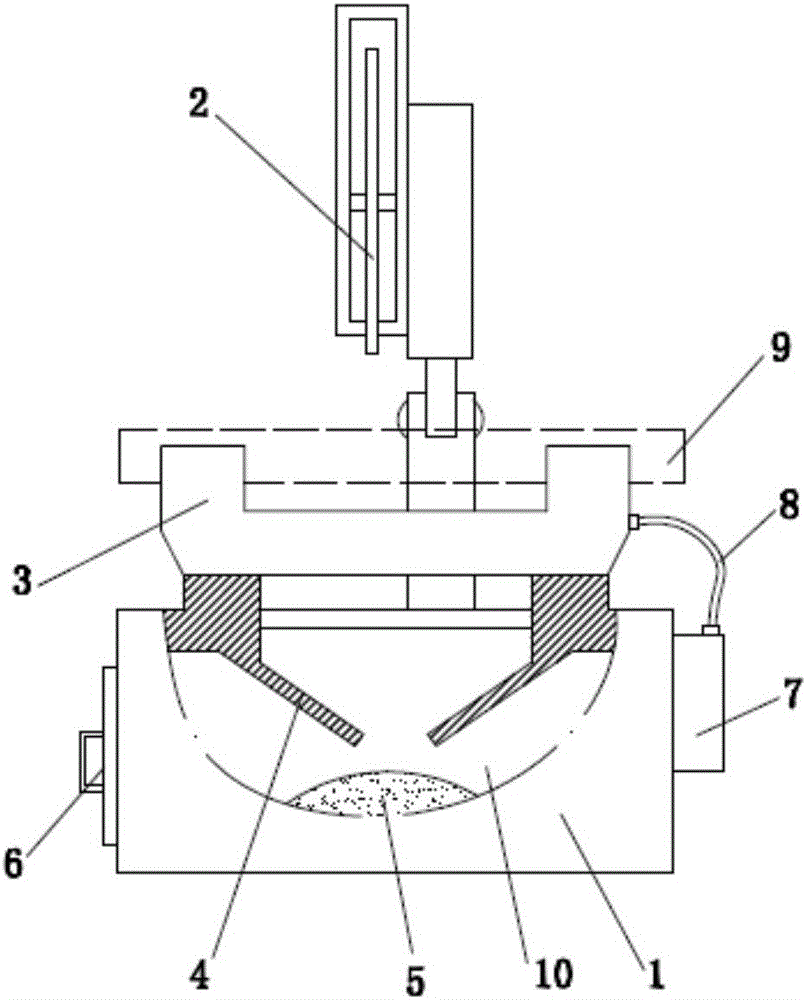

[0015] The specific embodiment of the present invention is as figure 1 As shown, a cutting machine capable of collecting residues includes a base 1 on which an electric saw 2 is arranged. A fixing frame 3 for clamping the cutting piece 8 is also provided on the base 1, and a cavity 10 is provided in the base 1, and the cavity 10 is used for collecting the residue 5 falling from the cutting piece 9 during the cutting process. The upper part of the base 1 is provided with two symmetrically arranged inclined plates 4 . The inclined plate 4 can allow the residue 5 to slide down into the cavity 10 . It collects the residue 5 accumulated on the base 1 after cutting through the cavity 10 in the base 1, and the inclined plate 4 on the base 1 allows the residue 5 to fall into the cavity 10 under the action of gravity without manual treatment. Maintain the cleanliness of the equipment.

[0016] The fixed frame 3 clamps the cutting piece 9 by means of pneumatic drive. An air pump 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com