Smoke generator and method of controlling a smoke generation

A smoke generator and generator technology, applied in the direction of artificial fog/smoke devices, ratio control, control/regulation systems, etc., can solve the problems of reducing the possibility of machine performance, blockage, etc., to reduce gas consumption, smoke The effect of low liquid flow and smooth smoke generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

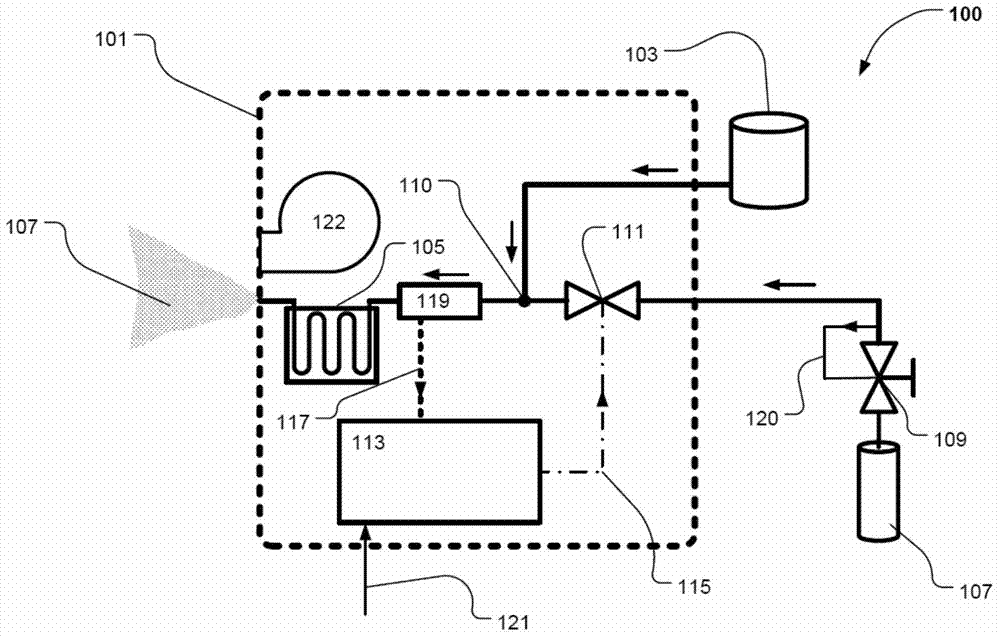

[0052] figure 1 Illustrated is an aerosol generating system 100 comprising an aerosol generator 101 according to an embodiment of the invention connected to a supply of smoke liquid 103 and a supply of pressurized gas 107 . In one embodiment, gas pressure is throttled through a manually operable valve 109 . Such valves can be omitted. Such valve 109 may further include an internal F / B indicating regulator 120 for enhanced safety and control of the pressure level of the supplied gas.

[0053] The flow of smoke liquid and pressurized gas is indicated by arrows.

[0054] The smoke liquid 103 is driven to the mixing unit 110 where it mixes with gas. The mixture is directed into the heat exchanger 105 causing the smoke liquid to evaporate and upon exiting the smoke generator 101 to form smoke 107 in contact with the surrounding air. The smoke generator may further include a fan (122) at the smoke outlet, which may be controlled to regulate the flow of smoke from the generator. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com