High efficiency cereal flotation, dust removing and sand gravel removing device

A grain and high-efficiency technology, applied in the directions of sieves, grilles, wet separation, etc., can solve the problems of affecting product quality, greatly increasing dust concentration, and difficult to separate, and achieve the effect of ensuring product quality, ensuring health, and being easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

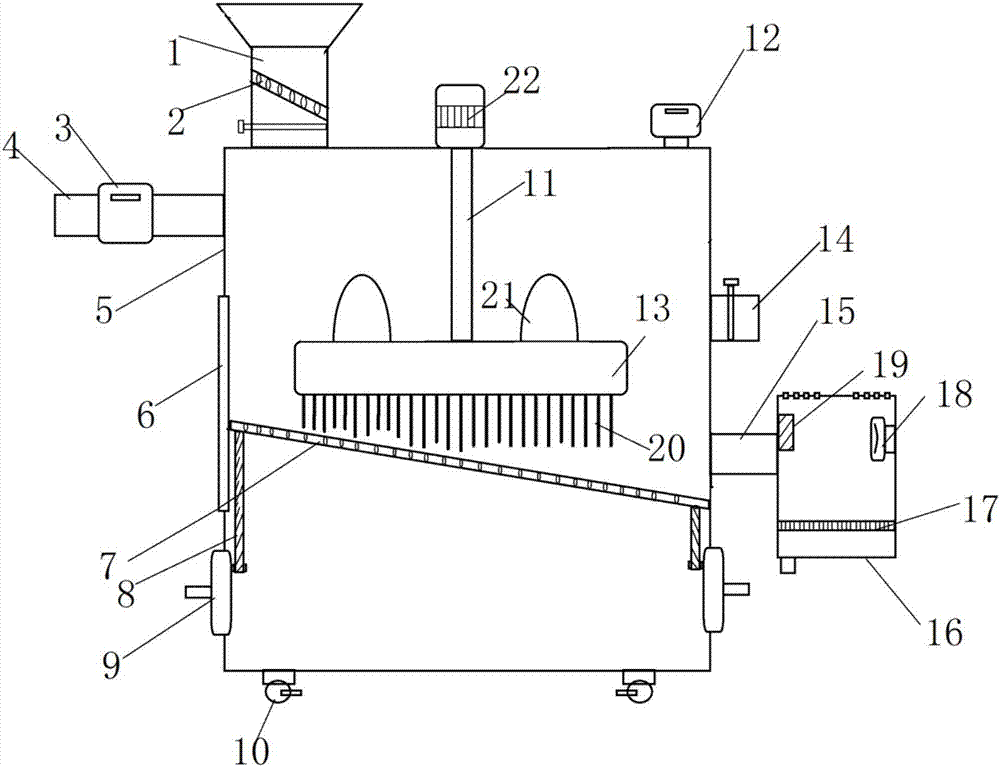

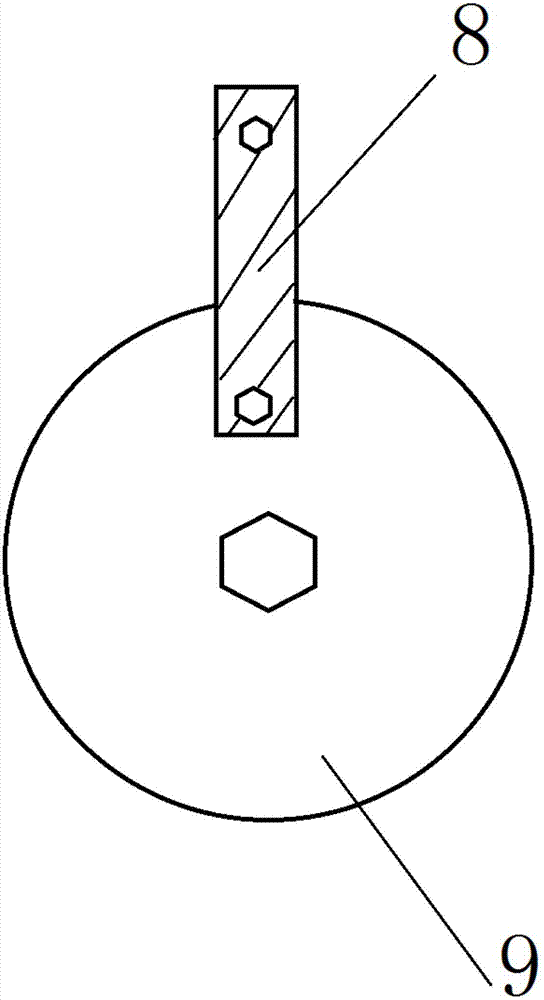

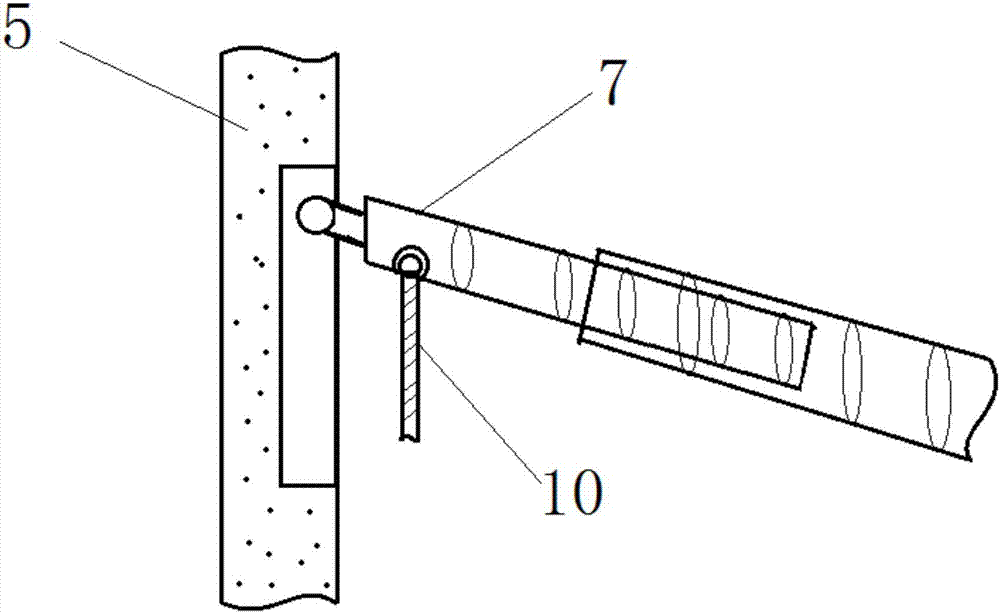

[0019] see Figure 1-3 , a high-efficiency grain flotation dedusting and sand removal device, including a feed pipe 1, a flow meter 3, a water inlet pipe 4, a screening box 5, a vibrating sieve plate 7, a runner 9, a guide wheel 10, a rotating shaft 11, and a liquid level gauge 12. The impeller 13, the debris discharge pipe 14, the grain discharge pipe 15 and the drying box 16, the feed pipe 1 is connected to the screening box 5, and the top of the feed pipe 1 is provided with a feeding port, which is convenient for feeding and feeding. The material pipe 1 is provided with an inclined filter screen 2. The inclined filter screen 2 prevents the weeds in the grain from entering the screening box 5, and initially cleans the grain. The water inlet pipe 4 communicates with the upper part of the screen box 5. 3. The flowmeter 3 records and controls the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com