Exterior wall fluorocarbon paint and preparation method thereof

A fluorocarbon paint and exterior wall technology, applied in the coating and other directions, can solve the problems of poor air permeability, foaming, cracks, etc., and achieve the effect of strong crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

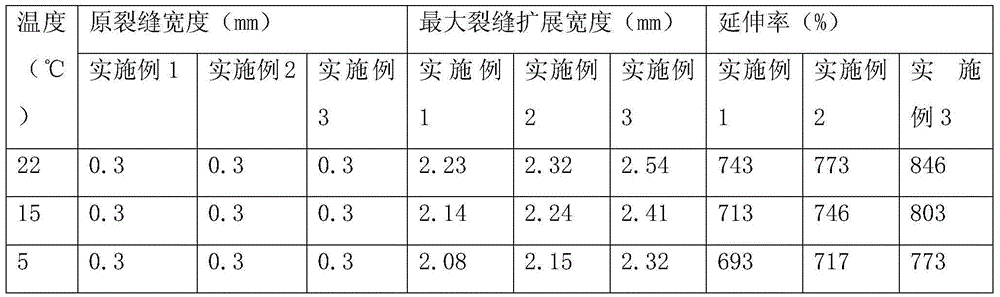

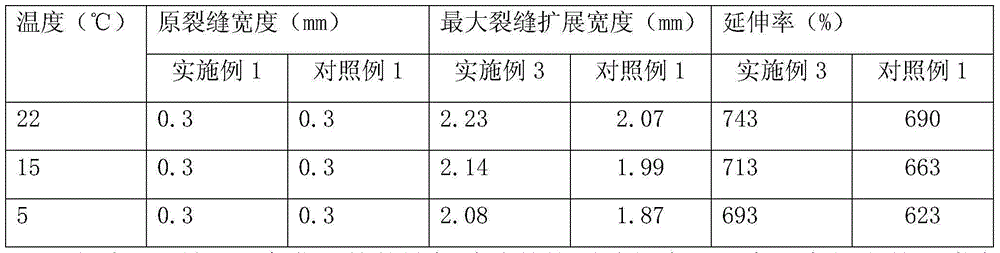

Examples

Embodiment 1

[0063] The exterior wall fluorocarbon paint of the present embodiment comprises the components of following weight fraction:

[0064] 35 parts of water-based fluorocarbon resin

[0065]Coalescing aid 2 parts

[0066] Diethylenediamine 1.2 parts

[0067] Thickener 0.5 parts

[0068] pH adjuster 0.1 parts

[0069] 1 part dispersant

[0070] Titanium dioxide 10 parts

[0071] 10 parts cellulose acetate paddle

[0072] 3 parts butyl acetate

[0073] Preservative 0.8 parts

[0074] Defoamer 4 parts

[0075] 20 parts of pure water.

[0076] Wherein, the film-forming aid includes the following components by weight fraction: 5 parts of propylene glycol phenol, 12 parts of paraffin, 15 parts of polyvinyl alcohol, 2 parts of ethyl oleate, 2.5 parts of sodium stearoyl lactylate, monostearic acid 1 part of glycerol ester, 1.2 parts of polyacrylic acid, 3 parts of glyoxal modified acrylamide, 10 parts of melamine formaldehyde resin, 10 parts of nylon bisisobutyrate.

[0077] Cor...

Embodiment 2

[0084] The exterior wall fluorocarbon paint of the present embodiment comprises the components of following weight fraction:

[0085] Water-based fluorocarbon resin 45 parts

[0086] Coalescing aid 1 part

[0087] Diethylenediamine 1.5 parts

[0088] 1 part thickener

[0089] 0.3 parts of pH regulator

[0090] Dispersant 0.5 parts

[0091] Titanium dioxide 16 parts

[0092] 5 parts cellulose acetate paddle

[0093] Butyl acetate 5 parts

[0094] Preservative 0.5 parts

[0095] 3.5 parts of defoamer

[0096] 30 parts of pure water.

[0097] Wherein, the film-forming aid includes the following components by weight fraction: 20 parts of propylene glycol phenol, 7 parts of paraffin, 20 parts of polyvinyl alcohol, 1 part of ethyl oleate, 2 parts of sodium stearoyl lactylate, monostearic acid 1.5 parts of glyceride, 1.5 parts of polyacrylic acid, 6 parts of glyoxal modified acrylamide, 13 parts of melamine formaldehyde resin, 12 parts of nylon acid bisisobutyrate.

[0098...

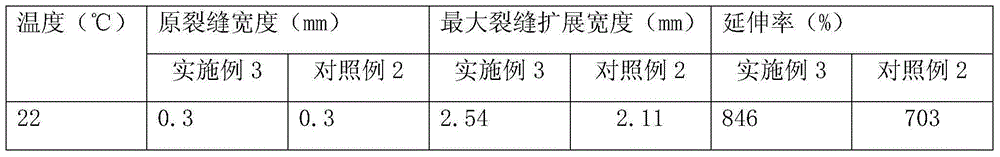

Embodiment 3

[0105] The exterior wall fluorocarbon paint of the present embodiment comprises the components of following weight fraction:

[0106] 42 parts of water-based fluorocarbon resin

[0107] Coalescing aid 1.5 parts

[0108] Diethylenediamine 1 part

[0109] Thickener 0.6 parts

[0110] pH adjuster 0.2 parts

[0111] Dispersant 0.8 parts

[0112] Titanium dioxide 14 parts

[0113] 7 parts cellulose acetate paddle

[0114] 4 parts butyl acetate

[0115] 1 part preservative

[0116] Defoamer 3 parts

[0117] 28 parts of pure water;

[0118] Wherein: the film-forming aid comprises the following components by weight: 8 parts of propylene glycol phenol, 9 parts of paraffin, 16 parts of polyvinyl alcohol, 3 parts of ethyl oleate, 2.3 parts of sodium stearoyl lactylate, glyceryl monostearate 1.2 parts, polyacrylic acid 1.3 parts, glyoxal modified acrylamide 4 parts, melamine formaldehyde resin 12 parts, nylon acid bisisobutyrate 8 parts.

[0119] Corresponding to the components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com