Patents

Literature

54results about How to "Reduce or avoid the generation of" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

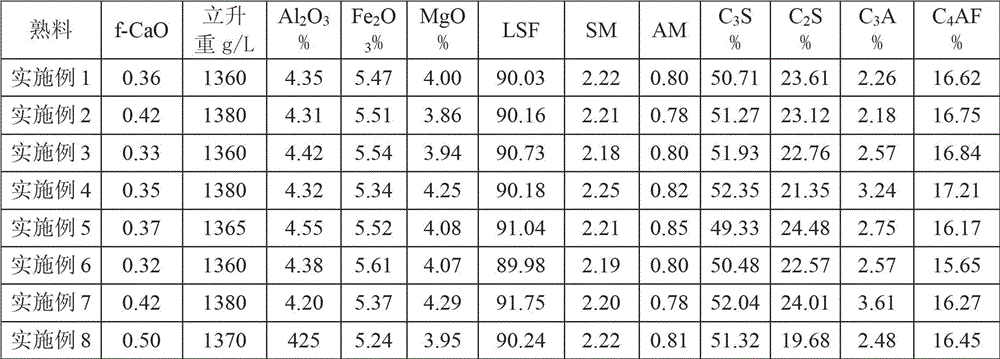

Micro-expansive moderate-heat Portland cement and production method thereof

InactiveCN102976641AHigh strengthHeat of hydration controlClinker productionHigh magnesiumPortland cement

The invention discloses a micro-expansive moderate-heat Portland cement and a production method thereof. The cement contains micro-expansive moderate-heat Portland cement clinker and gypsum in a weight ratio of 92:8-98:2, and also comprises grinding aid which accounts for 0-0.1 wt% of the sum of micro-expansive moderate-heat Portland cement clinker and gypsum. The raw meal of the micro-expansive moderate-heat Portland cement clinker is prepared from the following raw materials in percentage by weight: 65-80% of calcium raw material, 5-20% of silicon correction raw material, 5-15% of iron correction raw material and 3-10% of magnesium correction raw material. The micro-expansive moderate-heat Portland cement clinker is prepared by the following steps: grinding the raw meal, dehydrating the slurry, drying and crushing the filter cake, and firing to obtain the clinker. By adopting the low-aluminum high-iron high-magnesium low-saturation-ratio formula, the invention effectively controls the hydration heat of cement, displays the micro-expansive property, and can compensate the volume shrinkage in the concrete cooling process, thereby reducing or avoiding cracks.

Owner:GUANGXI YUFENG CEMENT

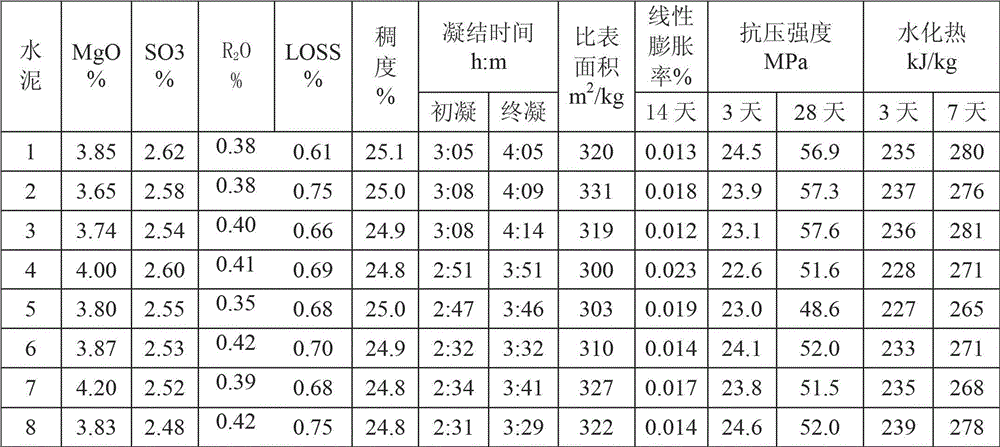

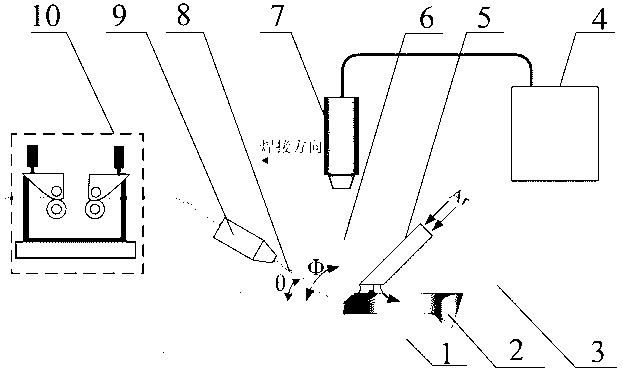

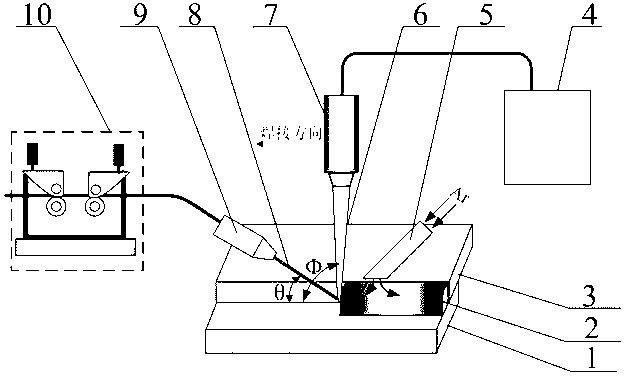

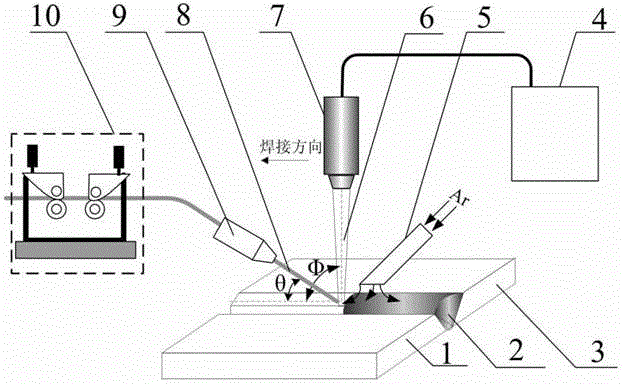

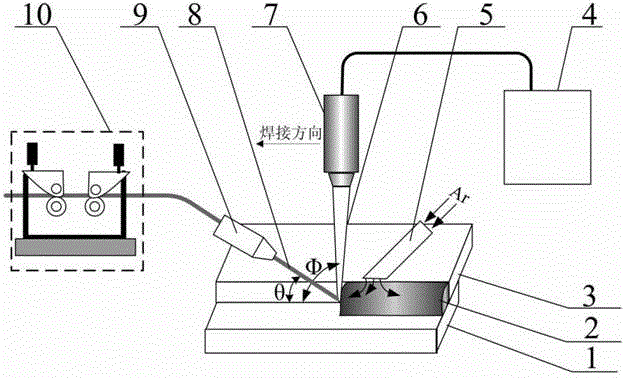

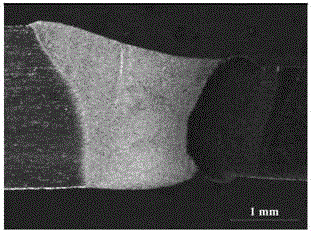

Magnesium and steel special metal superaudio frequency pulse laser smelting braze-welding wire and welding method

ActiveCN102699535AFull overflowReduce or avoid the generation ofWelding/cutting media/materialsWelding/soldering/cutting articlesLaser beamsMaterials science

The invention provides a magnesium and steel special metal superaudio frequency pulse laser smelting braze-welding wire and a welding method. The welding method comprises the following steps of: forming a beveled edge on a part to be welded of a magnesium alloy and a steel workpiece, and removing oil dirt and an oxidation film from the surface of the workpiece; fixing the magnesium alloy and the steel workpiece on a welding fixture, adjusting the position and the angle of a wire feeding device, automatically feeding the welding wire at a certain angle in front of a laser beam, and protecting a welding seam through argon, wherein the welding wire comprises the following components in percentage by weight: 2 to 10 percent of Al, 0.5 to 5 percent of Zn, 0.1 to 1 percent of Sr, 0.05 to 0.2 percent of B, 0.5 to 2 percent of RE and the balance of Mg; and placing the laser beam on one side of the magnesium alloy workpiece in a slightly deviating way, and heating the welding wire and the magnesium alloy workpiece by using superaudio frequency pulse laser to form a smelting pool, wherein the steel workpiece is kept in a solid state substantially in a welding process and acts with liquid magnesium alloy to form a welding joint. The key and common problem that the improvement of the welding quality of Mg / Fe and Mg / Ti immiscible heterogeneous metal is limited is solved, and the application range of laser smelting braze-welding is expanded.

Owner:哈尔滨哈船特装科技发展有限公司

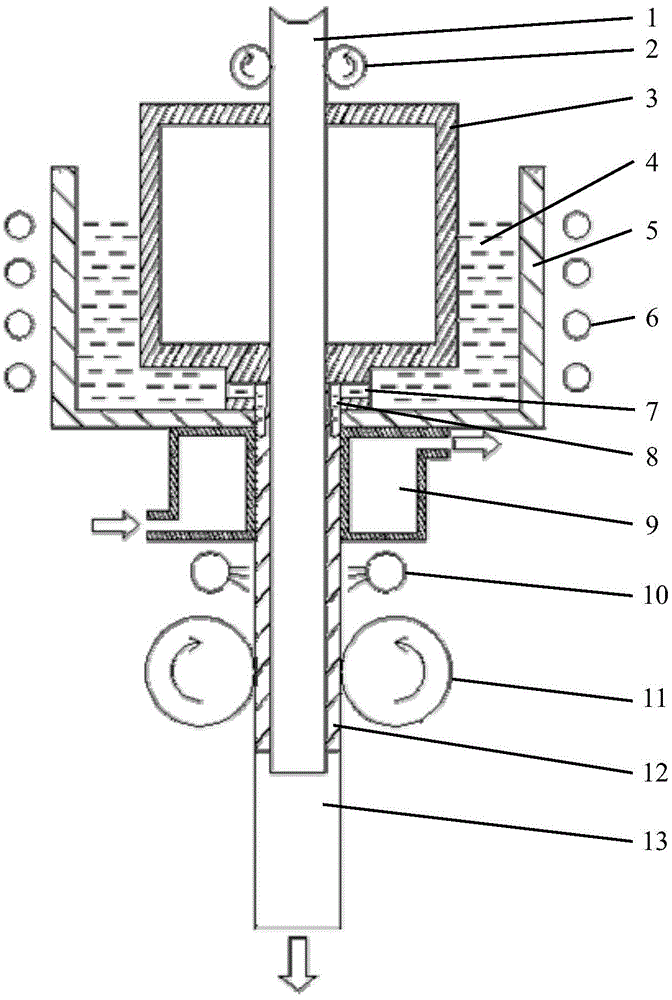

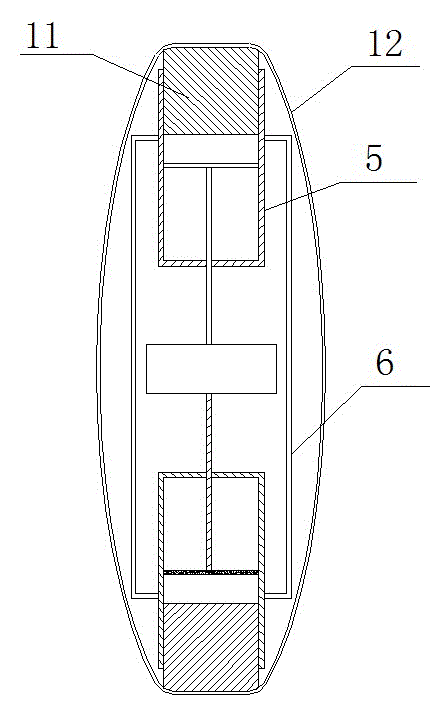

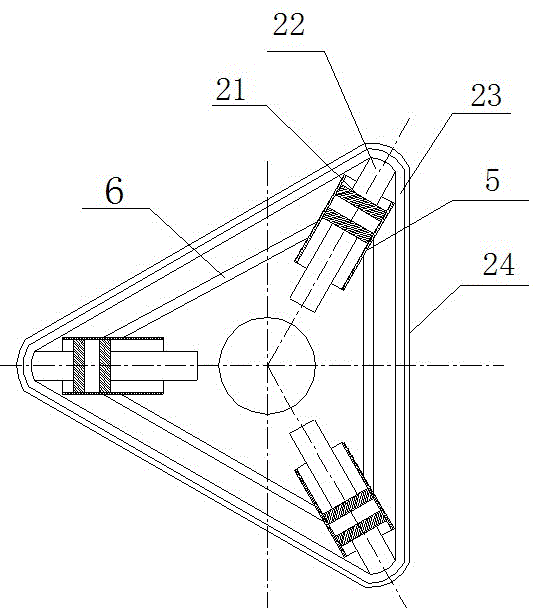

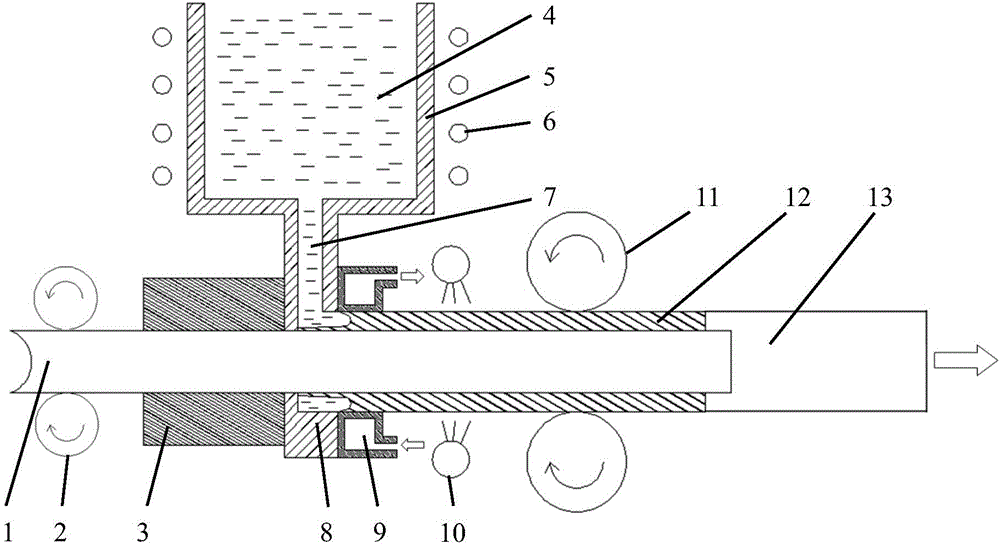

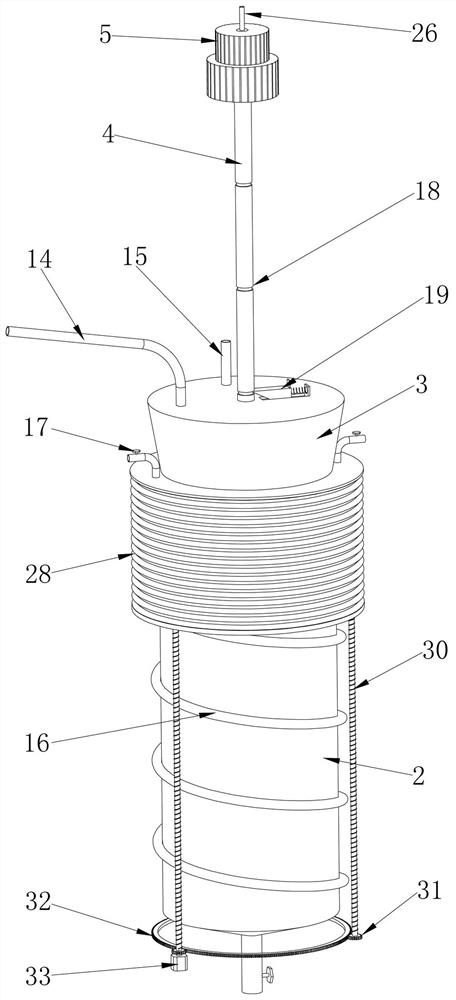

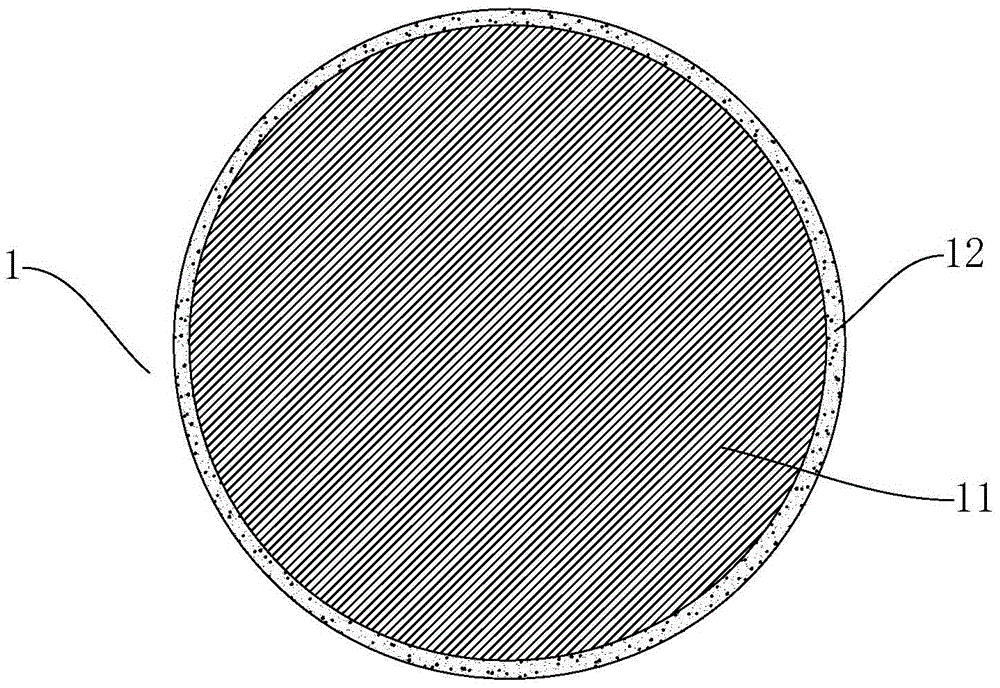

Clad material solid/liquid composite dual-solidification continuous casting and forming equipment and method

The invention belongs to the technical field of clad material continuous casting, in particular to clad material solid / liquid composite dual-solidification continuous casting and forming equipment and method. The clad material solid / liquid composite dual-solidification continuous casting and forming equipment and method are characterized in that inversion solidification and forward solidification continuous casting and forming are combined, the measures that core materials are not heated in advance, an inversion solidification device with small capacity is designed, the core materials are prevented from penetrating through clad layer melt metal for a long time, the melt metal flows out from the bottom of a crucible by relying on self-weight, and the size of the inversion solidification device and the size of a water-cooled crystallizer are controlled effectively are taken, the high quality clad materials of needed shapes and sizes are formed through continuous casting, and the equipment and the method are especially suitable for continuous casting forming of the high quality clad materials with the melting point of the clad layer metal lower than that of the core material metal. The equipment and method have the advantages that the equipment is simple in structure, parts are easy to replace, operation and maintenance are convenient to carry out, layout is reasonable and compact, investment is small, industrialized application and popularization are facilitated, the procedure of the forming process is short, energy is saved, environment is protected, cost is low, the combination freedom of the clad layer metal and the core material metal is large, and the prepared clad materials are good in quality and performance.

Owner:UNIV OF SCI & TECH BEIJING

Lactating sow compound feed capable of improving piglet sow production performance

InactiveCN104855721AImprove survival rateIncrease feed intakeAnimal feeding stuffAccessory food factorsFiberMonosodium glutamate

The invention discloses a lactating sow compound feed capable of improving piglet sow production performance. The lactating sow compound feed is prepared from the following raw materials in parts by weight: 50-55 parts of corn, 8-10 parts of ordinary bean pulp, 17-19 parts of wheat middling, 3-5 parts of extruded soybeans, 1-2 parts of fermented bean pulp, 1-2 parts of fish meal, 3-5 parts of wheat sprouts, 3-5 parts of kelp powder, 1-2 parts of fish oil, 1-2 parts of glucose, 2-3 parts of rice hull powder, 1-2 parts of soybean fiber, 0.3-0.5 part of table salt, 0.1-0.2 part of monosodium glutamate, 1-2 parts of a premix, 0.5-1 part of mountain flour, 0.5-1 part of monocalcium phosphate, 0.3-0.5 part of lysine, 0.05-0.1 part of valine, and 0.1-0.2 part of an enzyme preparation. When ate by the sow in the lactating period, the lactating sow compound feed disclosed by the invention can improve the food consumption of the lactating sow, increases the lactation yield and improves the milk quality, so that the piglet can suck sufficient high-quality breast milk, the daily gain of the piglet can reach up to above 250 g, and the weight of the piglet which is weaned on the 28th day can reach up to above 9 kg.

Owner:青岛大信饲料有限公司

Method for recycling lithium cobalt oxide from waste positive electrode of lithium cobalt oxide battery

ActiveCN103199319ANot very tightly boundReduce the binding forceWaste accumulators reclaimingProcess efficiency improvementLithiumMass ratio

The invention discloses a method for recycling lithium cobalt oxide from a waste positive electrode of a lithium cobalt oxide battery. The method comprises the following steps of: (1) feeding the waste positive electrode of the lithium cobalt oxide battery into a 1-2mol / L hydrochloric acid lixivium in which citric acid is dissolved, and reacting for 4-6 hours at 60-80 DEG C; (2) filtering the lixivium in the step (1) so as to separate aluminum foil and solid grains; and (3) washing and drying the solid grains; and (4) adding a lithium source into the solid grains to adjust the mass ratio of Co / Li in the solid grains, uniformly mixing, calcining and cooling so as to obtain lithium cobalt oxide. The method adopts the mixed acid of citric acid and hydrochloric acid as the lixivium so as to effectively separate a positive electrode material and the aluminum foil, the process is simple, and no toxic or harmful gases are generated. The first discharge capacity of recovered lithium cobalt oxide can still be 140mAh / g, and the discharge capacity after 40 times of charge and discharge circulation is not less than 90%.

Owner:河南省冶金研究所有限责任公司

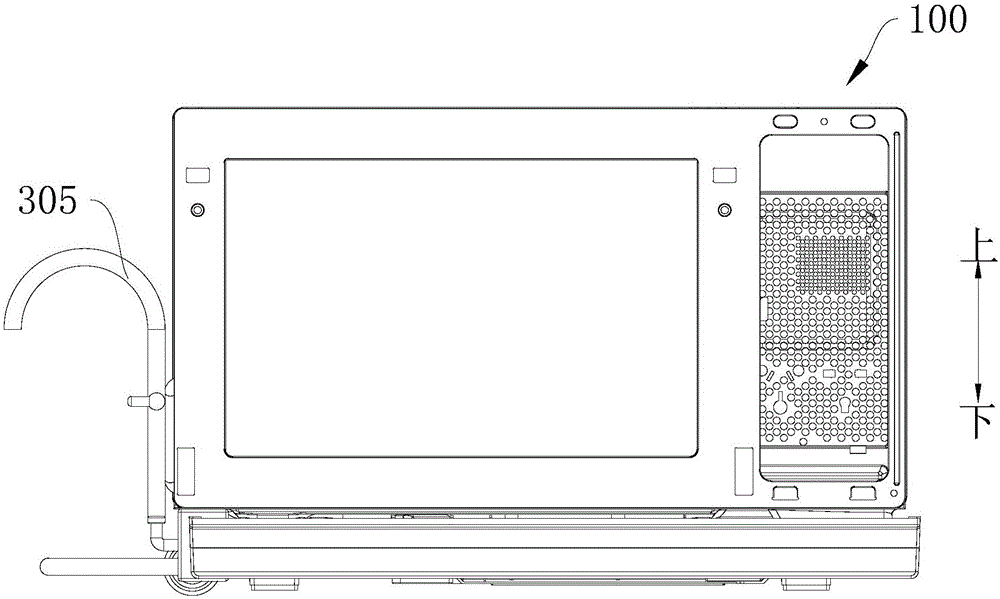

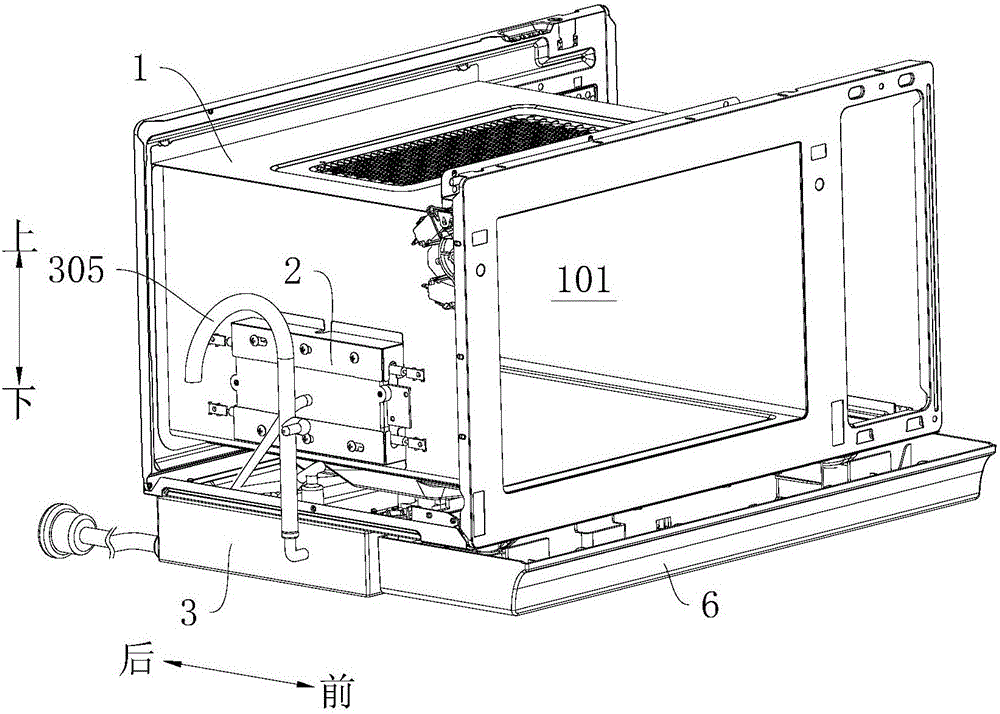

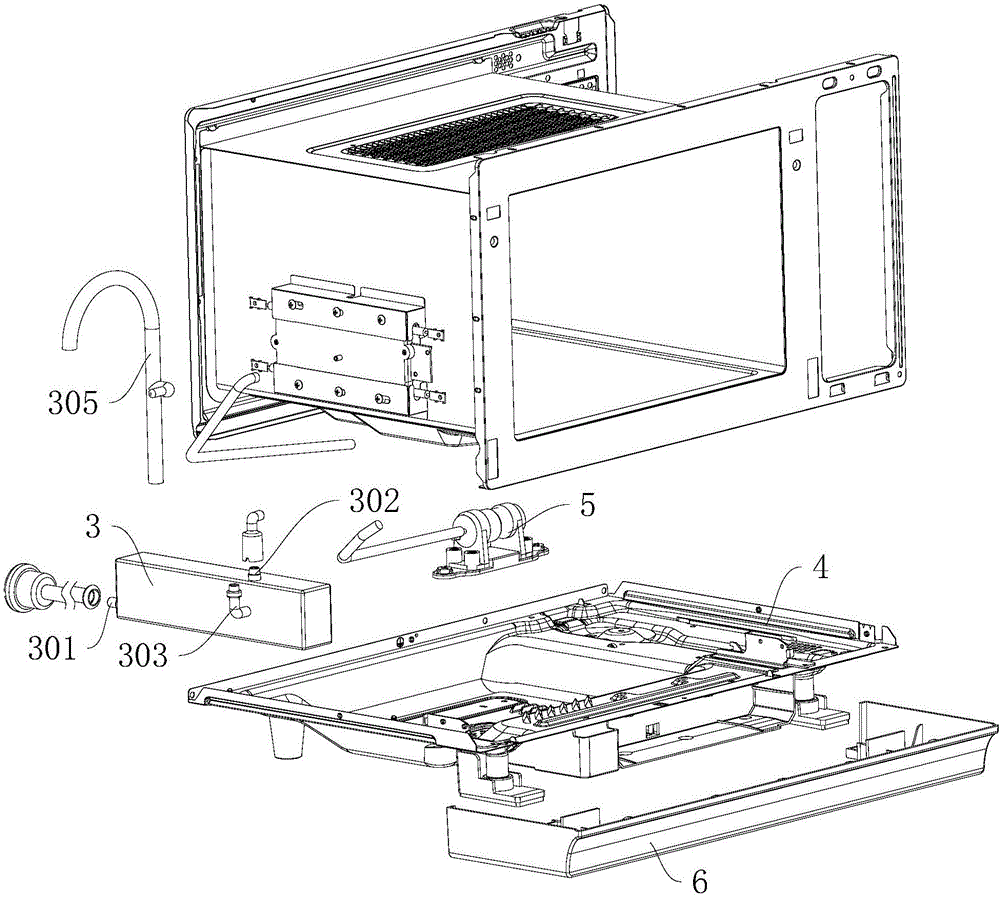

Electric cooking appliance

InactiveCN106264089AReduce or avoid the generation ofImprove cooking efficiencyDomestic stoves or rangesLighting and heating apparatusEngineeringPurified water

The invention discloses an electric cooking appliance and belongs to the field of household appliances. The electric cooking appliance comprises a chamber, a steam generator and a water purifier, wherein a cooking cavity is defined in the chamber; the steam generator communicates with the cooking cavity and is used for providing steam into the chamber; the water purifier is provided with a raw water inlet and a first purified water outlet which is connected with the steam generator. According to the embodiment of the invention, the electric cooking appliance is high in cooking efficiency, clean and sanitary.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

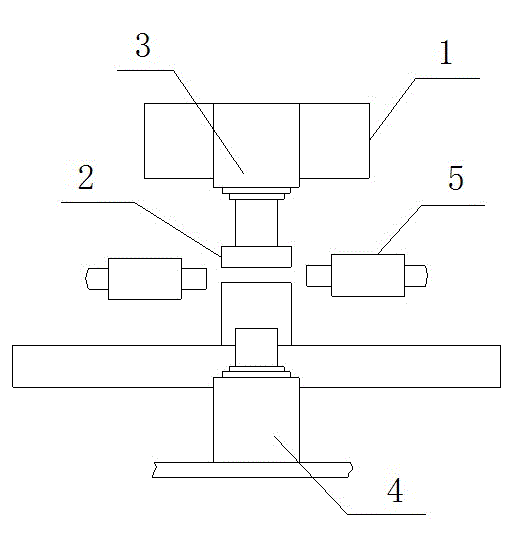

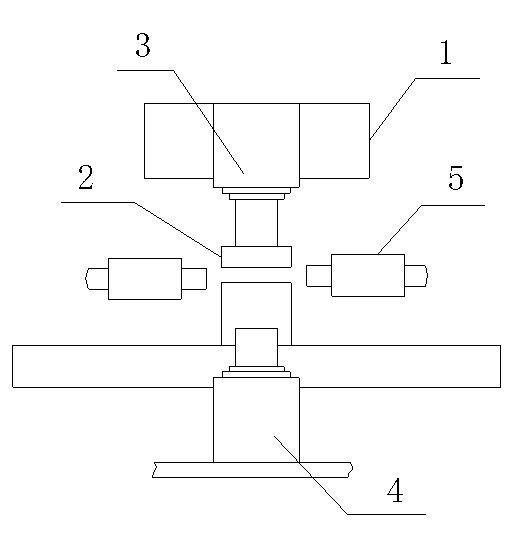

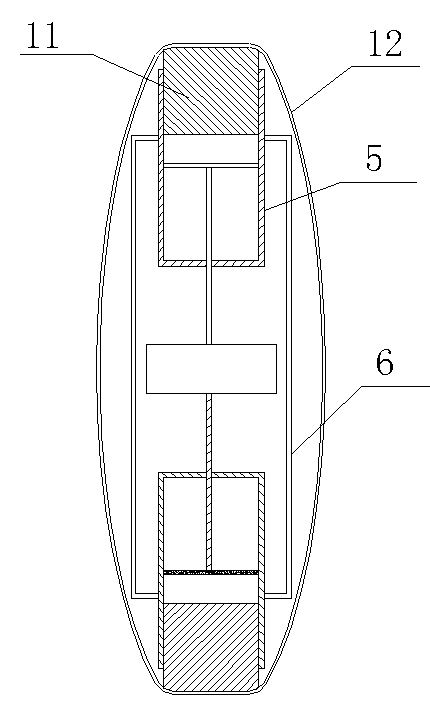

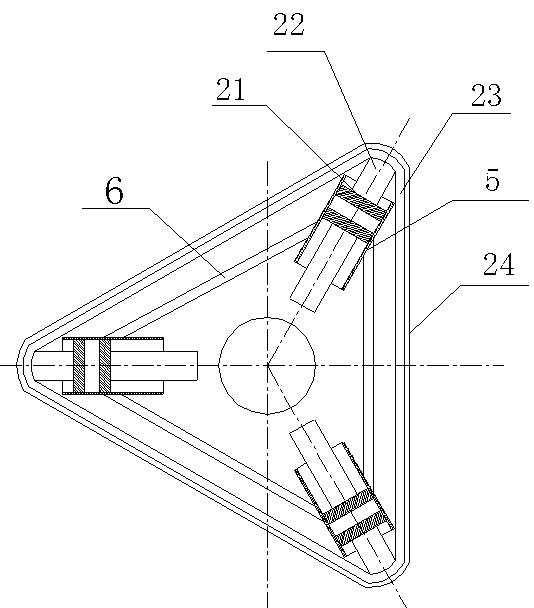

Block type multidirectional forging device

ActiveCN102794380AForce balanceReduce or avoid the generation ofForging/hammering/pressing machinesForging press detailsEngineeringBlock type

The invention discloses a block type multidirectional forging device, which comprises a frame, a die for forming a product and a hydraulic transmission device. The hydraulic transmission device comprises a main cylinder, a jacking cylinder and at least two lateral extrusion cylinders, wherein a movable element is arranged at the rear end of each lateral extrusion cylinder; and the frame comprisesa bracket and fasteners in wrapped connection with the outer sides of the movable elements and used for fixedly connecting a plurality of movable elements sequentially, and each fastener has a closedannular structure. According to the device, the movable elements are arranged at the rear ends of the lateral extrusion cylinders and fixedly connected with the fasteners, and when each lateral extrusion cylinder extrudes a workpiece, a force reacting on the frame can directly act on the fasteners; and because the fasteners have the closed annular structures, stress balance at each position of the fasteners is ensured, the forging precision is effectively ensured, degraded products are reduced or avoided, the working efficiency is improved, and the production cost is reduced.

Owner:山东格新精工有限公司

Tin plating electrolyte and preparation method and application thereof

The invention relates to a tin plating electrolyte which contains a solvent and the materials with following concentration: 10-20g / L of tin methane sulfonate, 30-60g / L of methanesulfonic acid, 0.4-5g / L of compound additive, and a proper amount of PH regulator; and the compound additive is formed by thiourea, hydroquinone, 2-mercapto benzimidazole and propylene glycol block polyether. For the tin plating electrolyte, by reasonably selecting types and use amount of additives, the problems of instable plating solution and high cost in the methanesulfonic acid system are solved, and by using the tin plating electrolyte, a high-mass plating layer is acquired beneficially.

Owner:GUANGDONG GUANGHUA SCI TECH

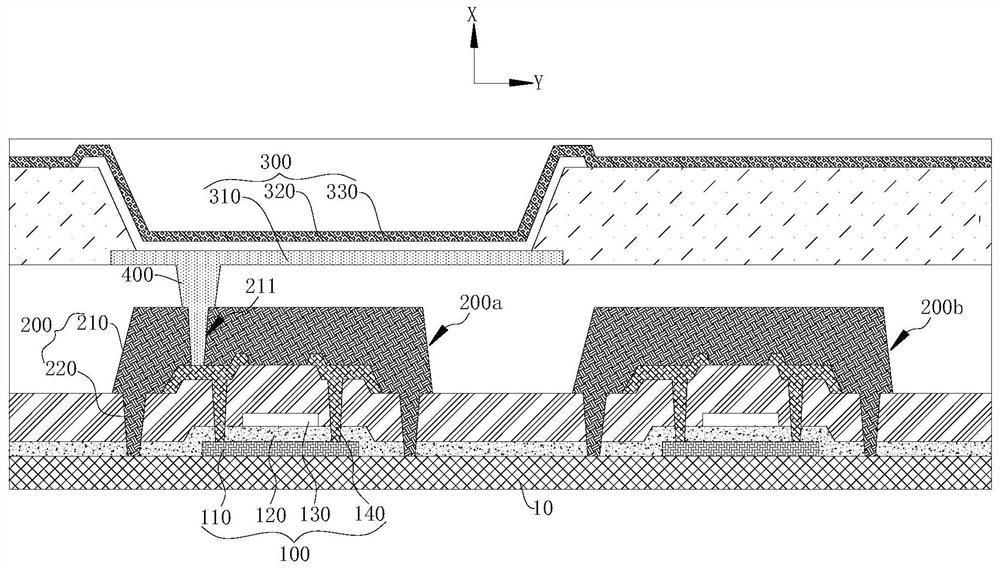

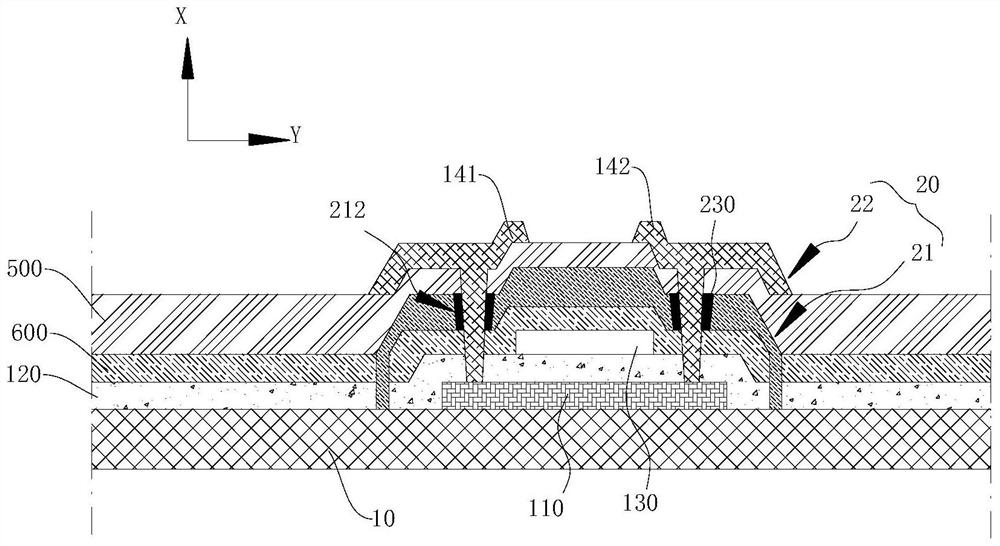

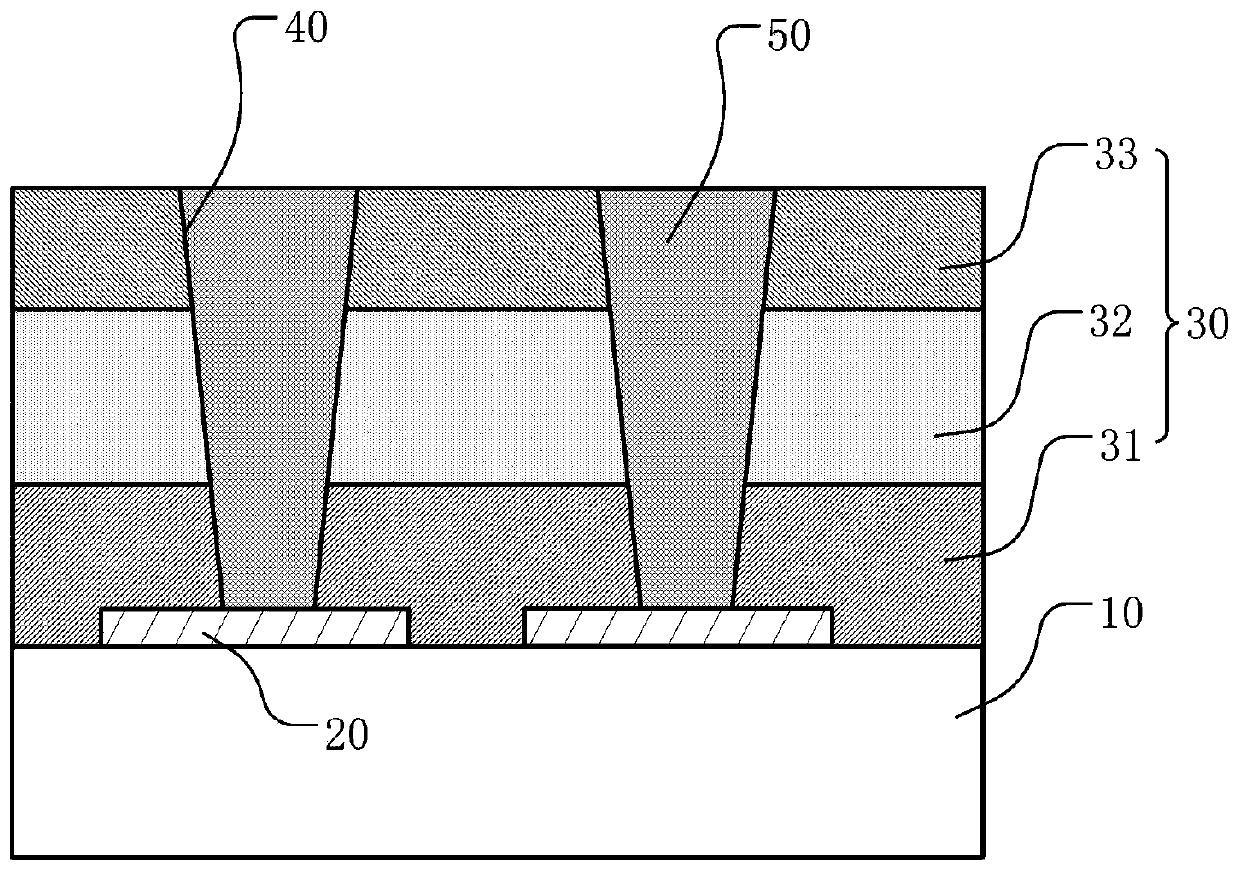

Array substrate, display panel and display device

PendingCN111834465AGuaranteed uptimeExtended service lifeTransistorSolid-state devicesDisplay deviceActive layer

The embodiment of the invention provides an array substrate, a display panel and a display device. The array substrate comprises a substrate, a transistor, a light shielding component, wherein the transistor includes an active layer disposed on the substrate; and at least part of the light shielding component is located on the active layer, and the light shielding component covers at least part ofthe active layer. According to the array substrate provided by the embodiment of the invention, photon-generated carriers generated by external light in a channel of the transistor can be reduced oravoided, normal and stable operation of the transistor is ensured, and the service life of the array substrate is prolonged. When the array substrate provided by the embodiment of the invention is applied to the display panel, light transmission and display of the display panel can be realized, and under-screen integration of a photosensitive assembly is facilitated.

Owner:YUNGU GUAN TECH CO LTD

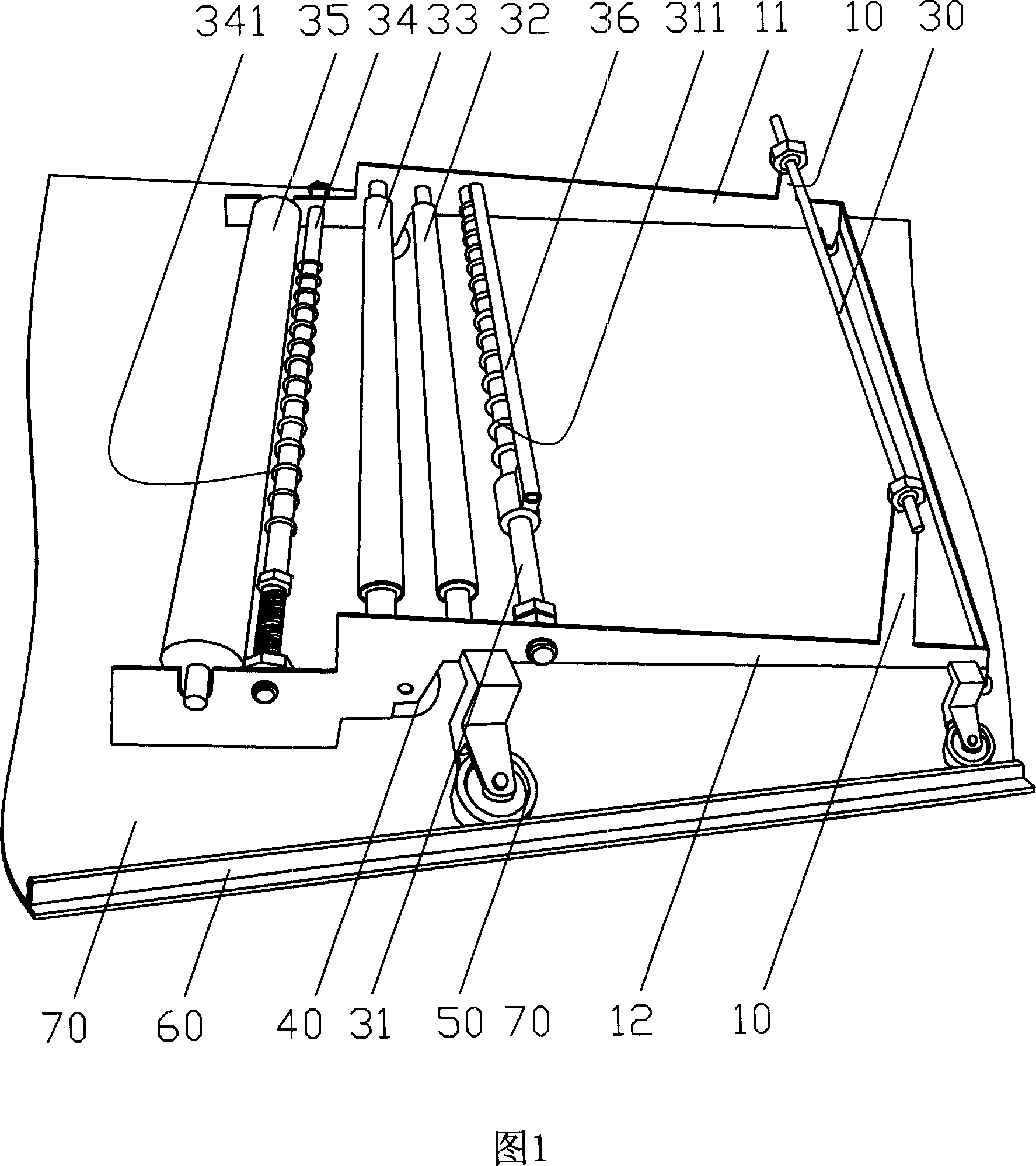

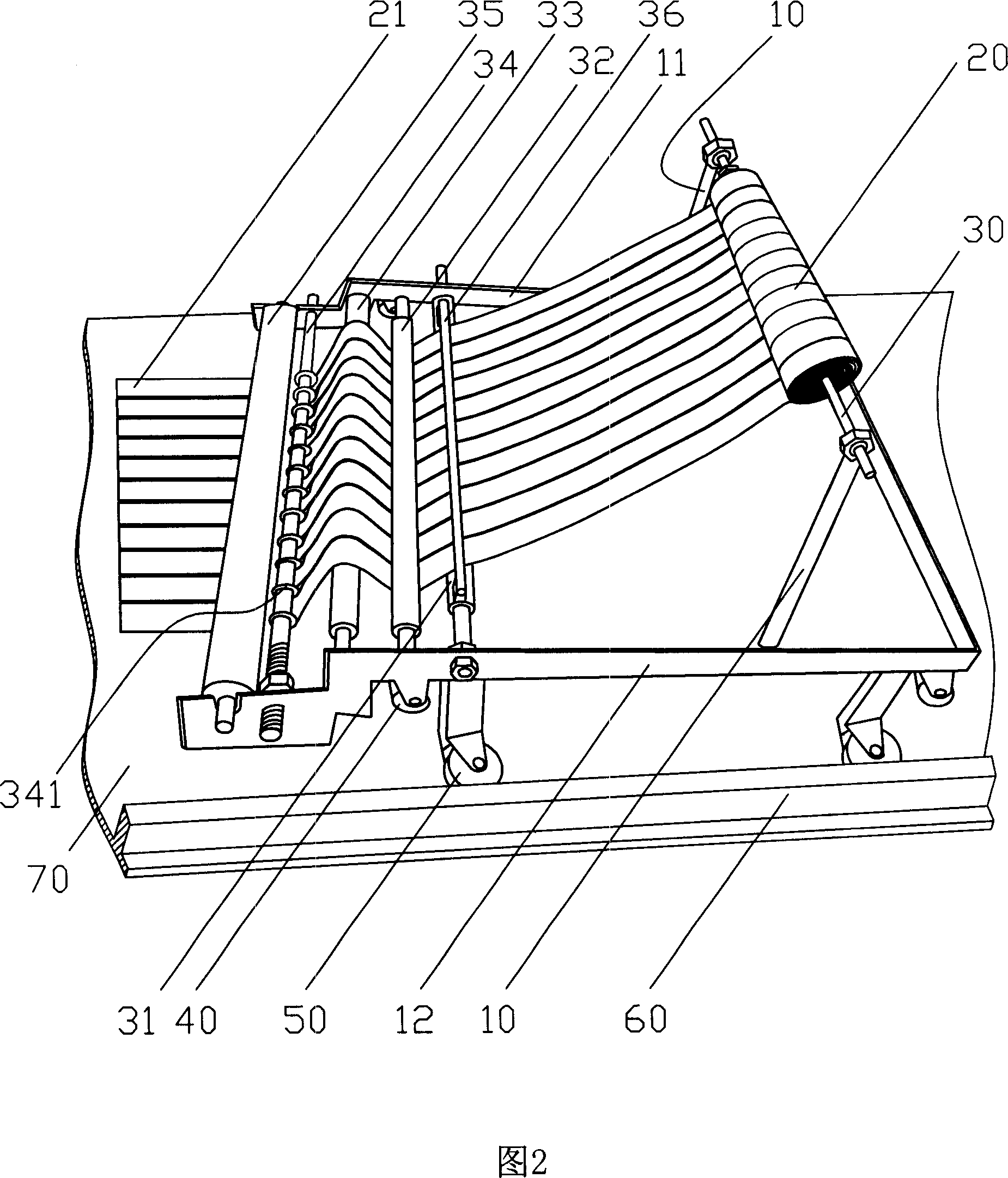

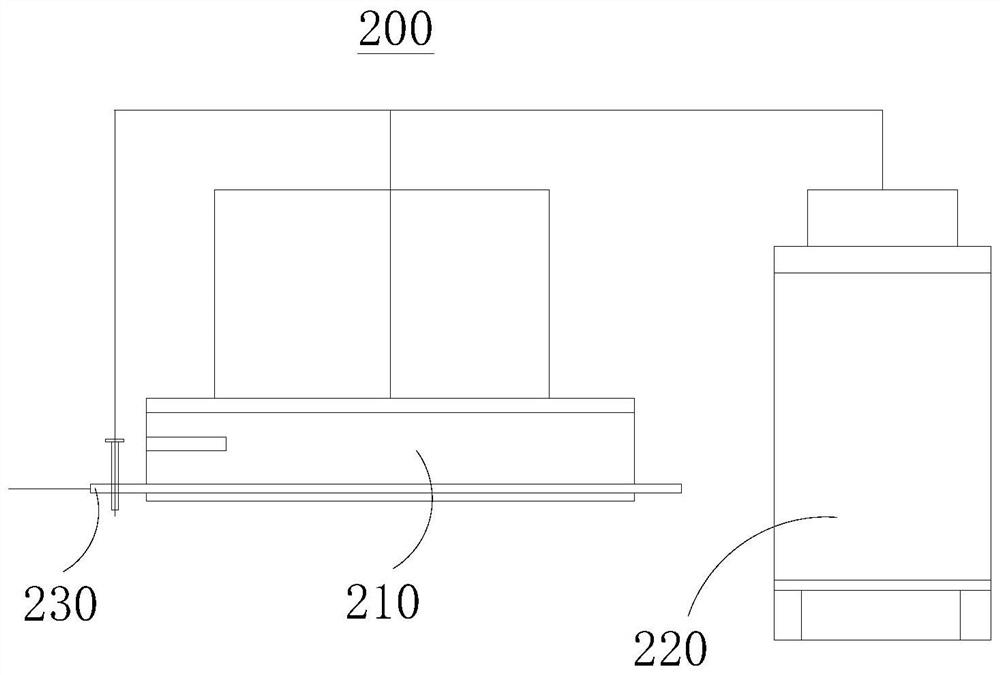

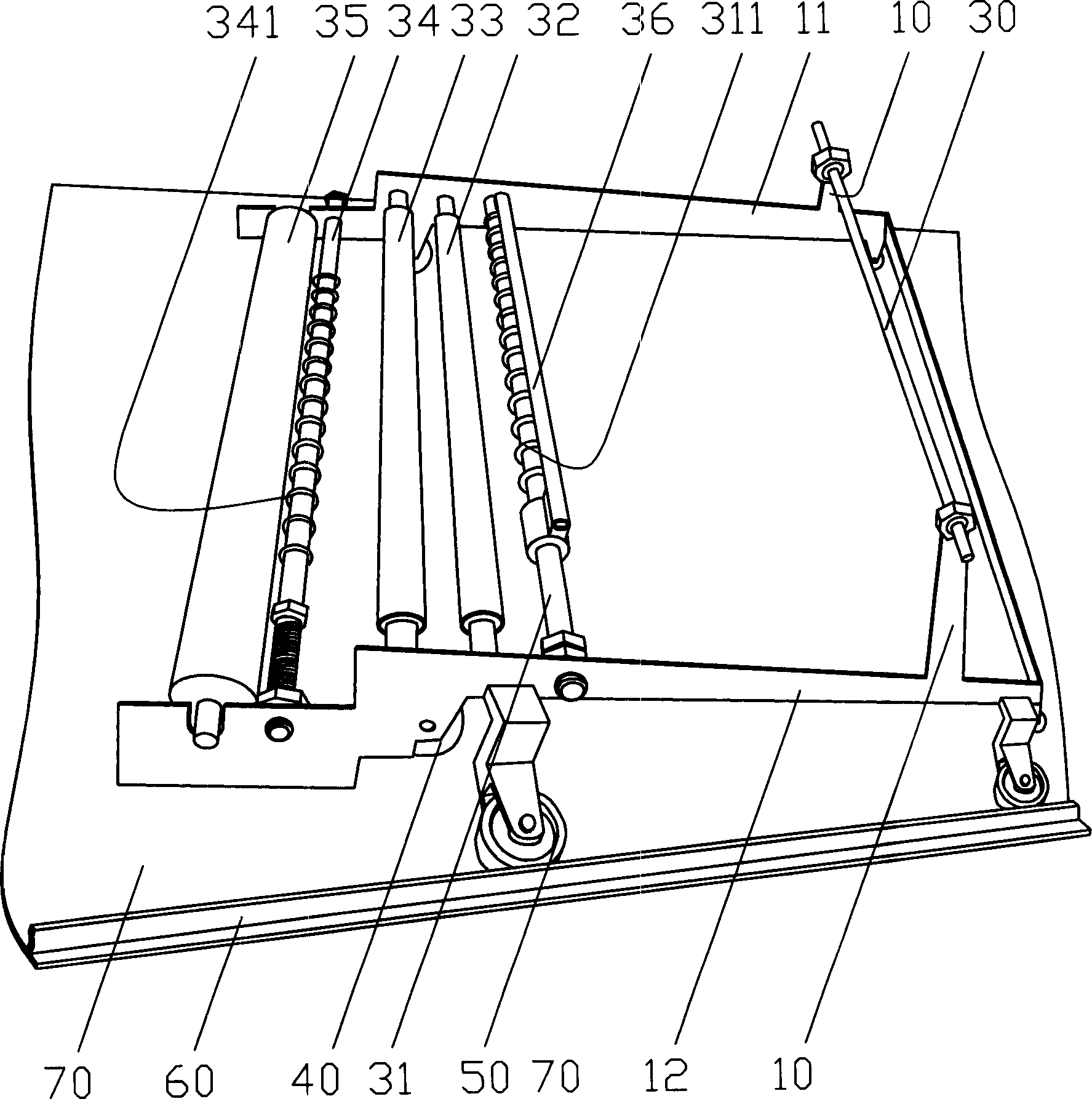

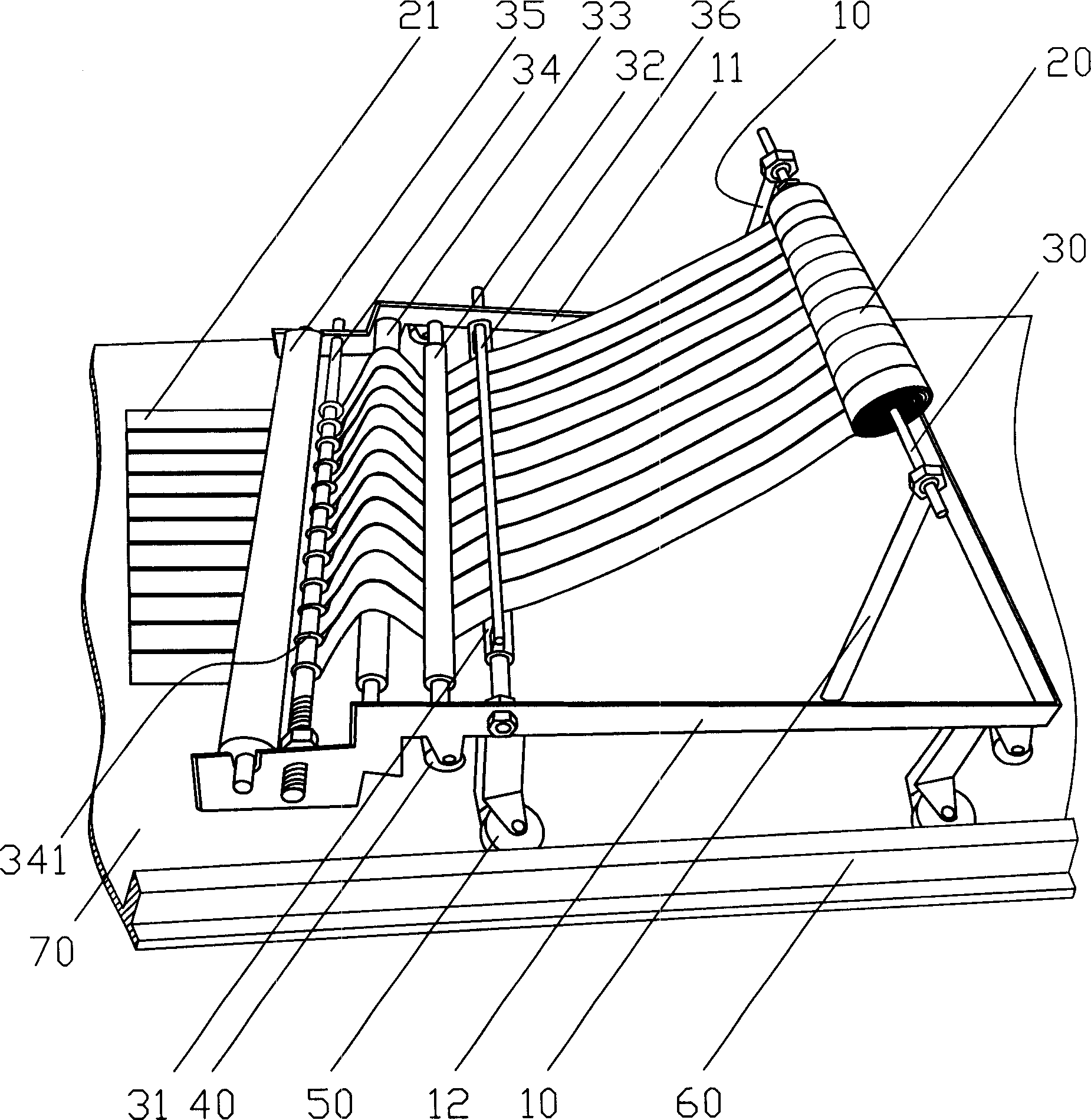

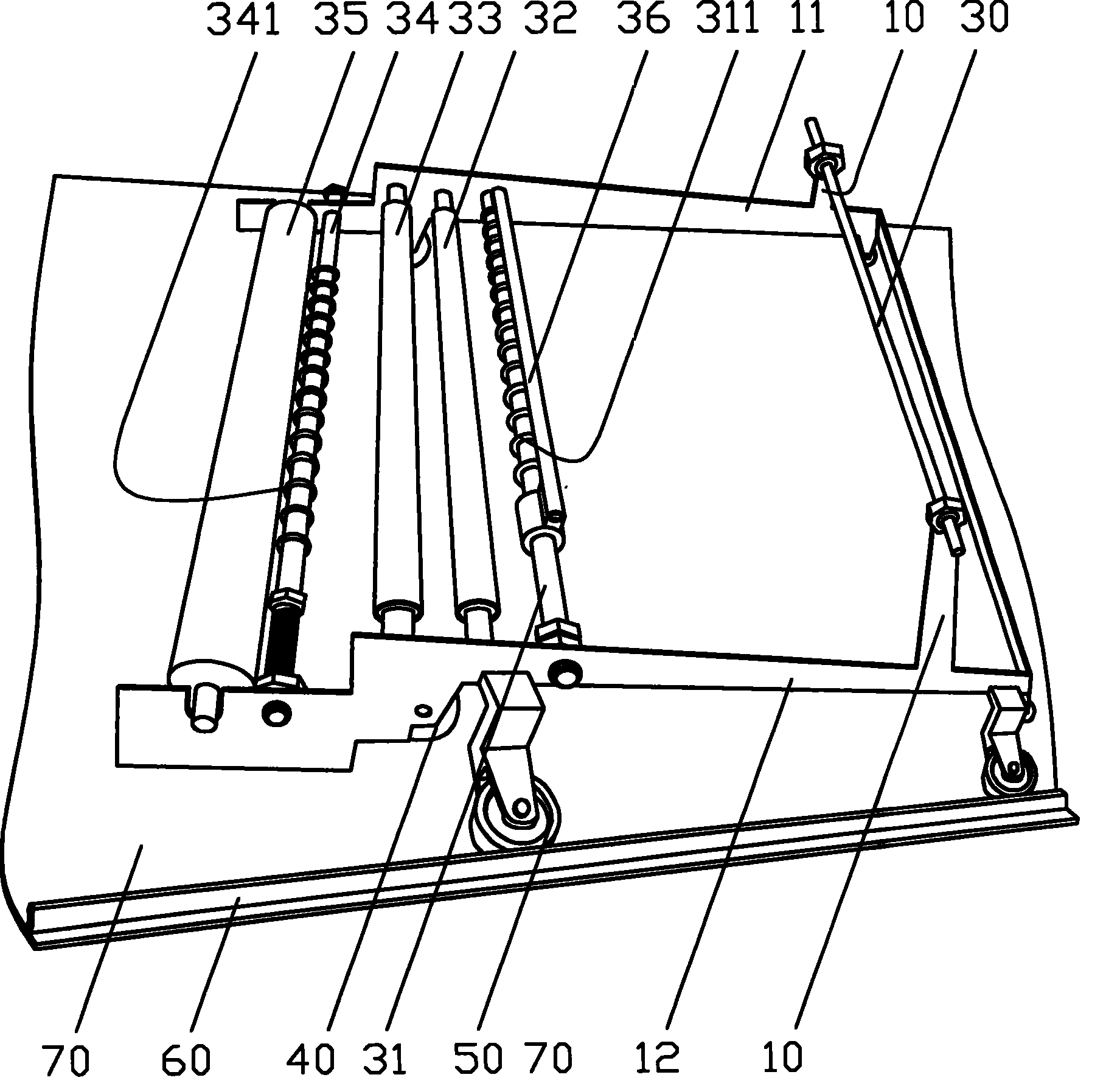

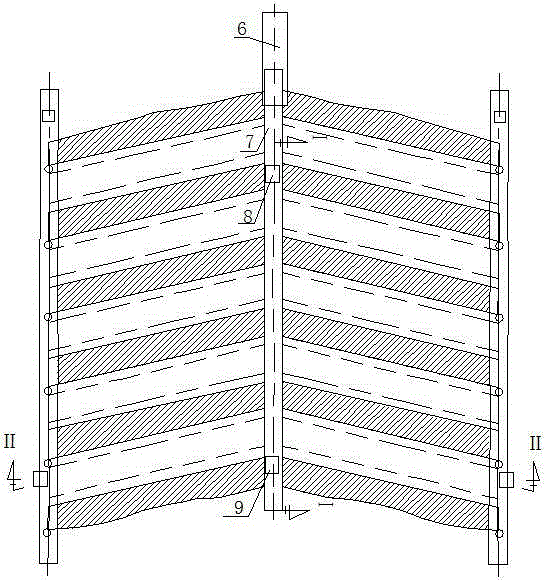

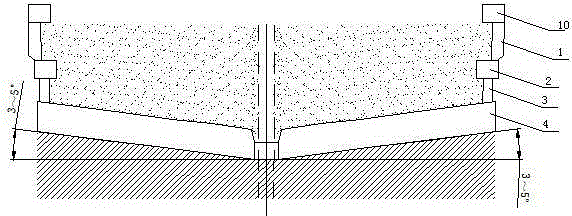

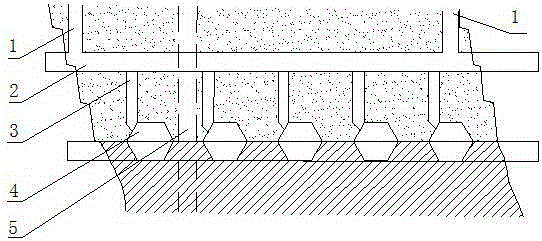

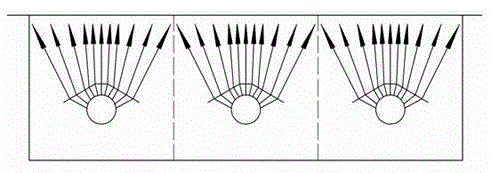

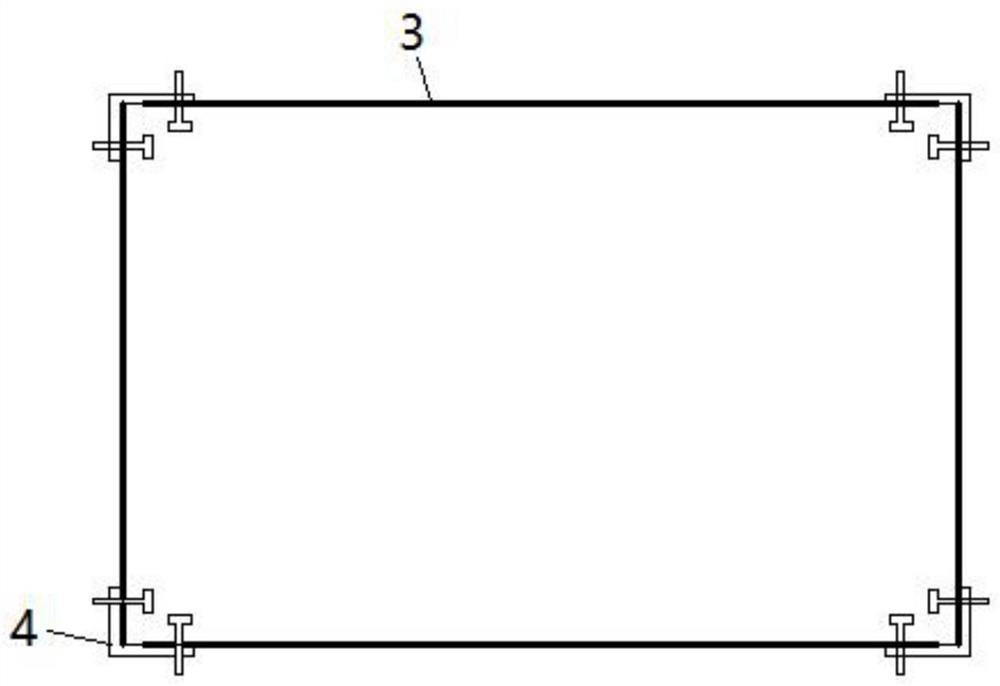

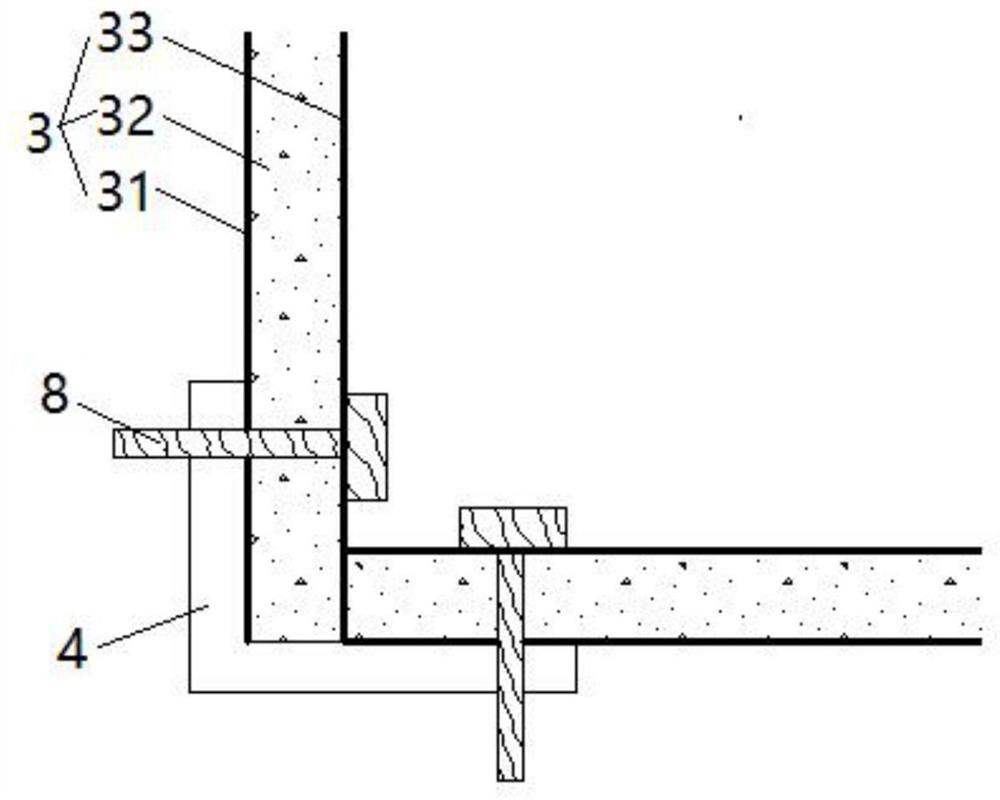

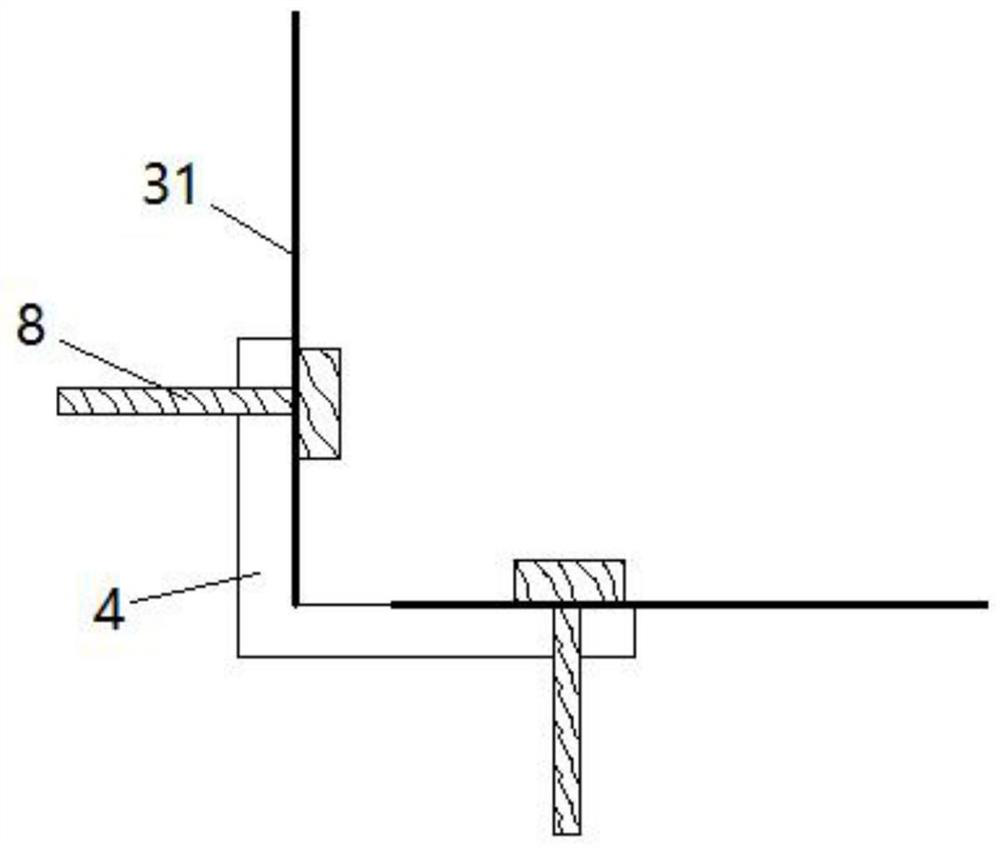

Semiautomatic ribbon sprealing machine and its spreading technology

InactiveCN100999149AIncrease productivityReduce labor intensityScreen printersScreen printingSemi automatic

The present invention belongs to the field of silk-screen printing matched equipment technology, in the concrete, it relates to a semi-automatic screen-laying machine and screen-laying process. It is characterized by that said screen-laying machine mainly includes the following several portions: rectangular frame, supporting frames, screen roll, screen roll hanger shaft, first screen-dividing shaft, second screen-dividing shaft, first screen-pressing roller, second screen-pressing roller, third screen-pressing roller, bearing running wheel and running guide wheel. Said invention also provides the connection mode of all the above-mentioned portion and the concrete steps of its screen-laying method.

Owner:陈杰民

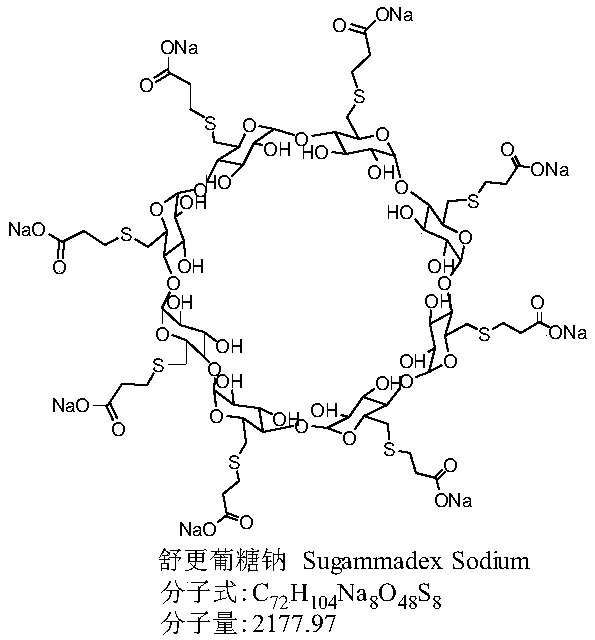

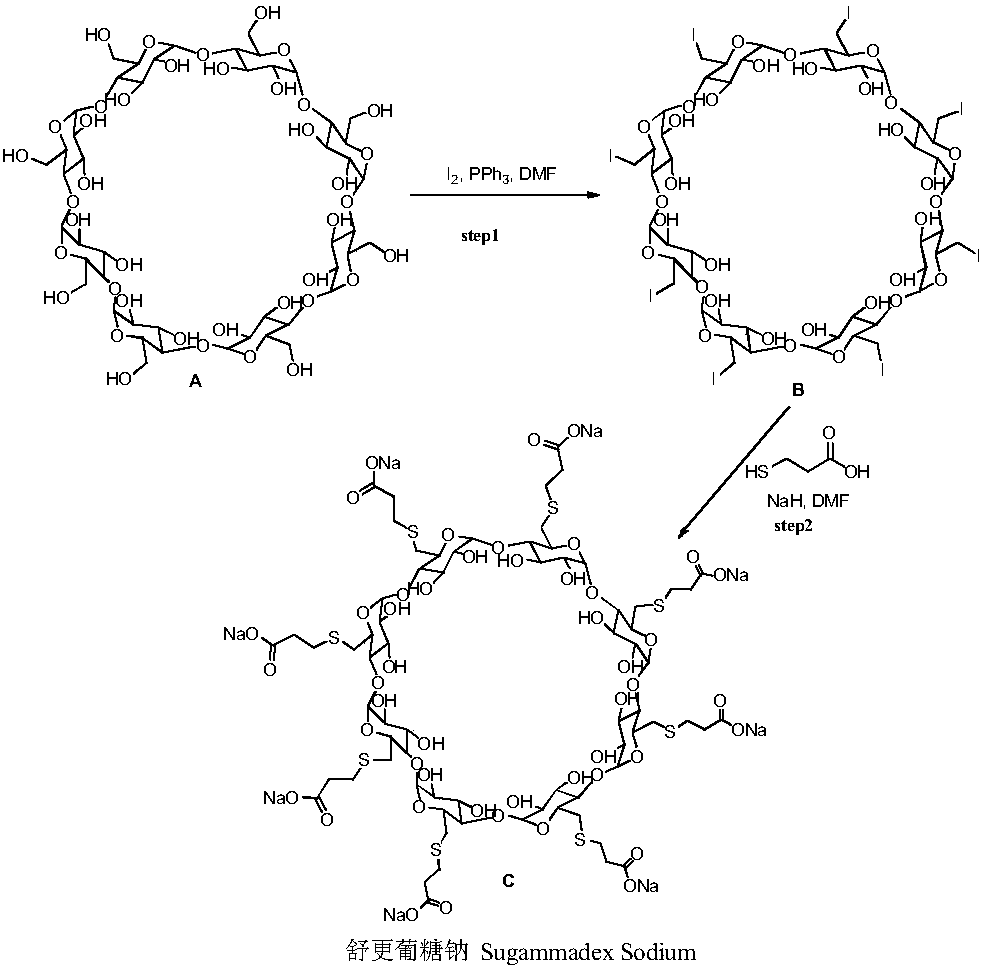

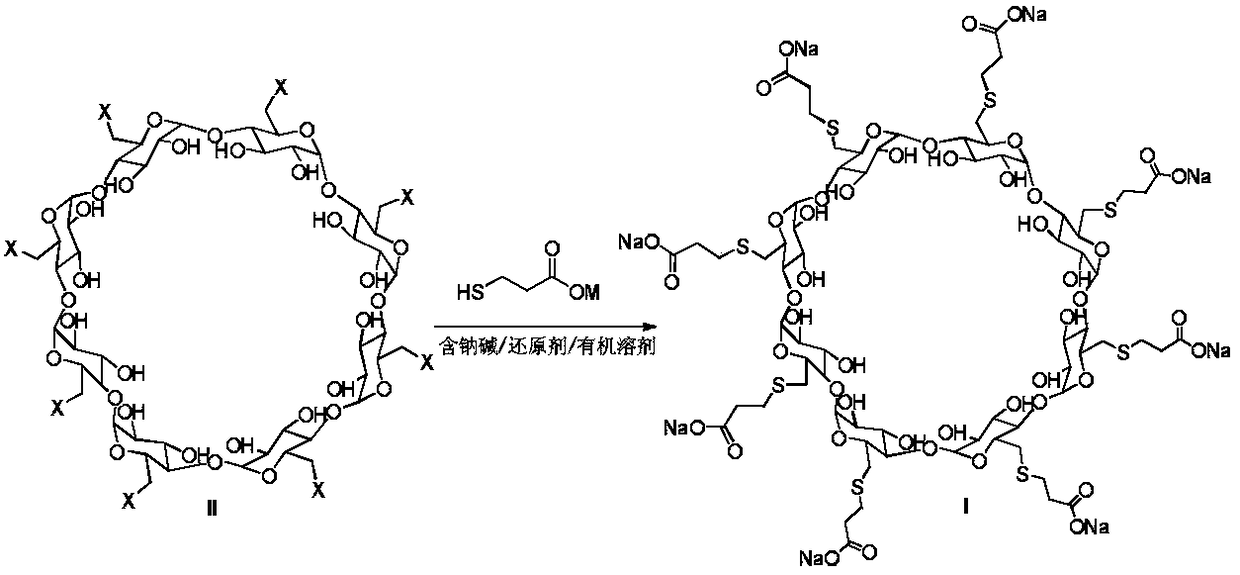

Method for preparing sugammadex sodium

The invention discloses a method for preparing sugammadex sodium. The method is characterized in that perhalogeno gamma-cyclodextrin and 3-mercaptopropionic acid or / and a sodium salt thereof are subjected to a replacement reaction in a sodium base-reducing agent-organic solvent system for preparing sugammadex sodium, the method effectively controls the formation of process impurities with similarstructure of sugammadex sodium from a reaction process, and obtains high-yield and high-purity product after simple post-treatment. The invention further provides a method for purifying of a crude product of the sugammadex sodium and conversion of impurities to the target product in a one-step reaction, which is simple, efficient and wasteful, the method improves the yield and purity from variousaspects, and solves the problems of complex operation, high requirements on instruments and low yield in the prior art method, and is suitable for industrial mass production of the sugammadex sodium.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

A solid/liquid composite horizontal continuous casting forming equipment and method for coating material

The invention discloses clad material solid / liquid composite horizontal continuous casting and forming equipment and method, and belongs to the technical field of clad material continuous casting. According to the clad material solid / liquid composite horizontal continuous casting and forming equipment and method, the measures that a core material protection device, a flow guide pipe, an inversion solidification device and the like are adopted and mounted below a crucible, core materials are not heated in advance, the inversion solidification device with small capacity is designed, the core materials are prevented from penetrating through clad layer melt metal for a long time, the melt metal flows out from the bottom of the crucible by relying on self-weight, and the size of the inversion solidification device and the size of a water-cooled crystallizer are controlled effectively are taken, the high quality clad materials of needed shapes and sizes are formed through horizontal continuous casting, and the equipment and the method are especially suitable for horizontal continuous casting forming of the large-size clad materials which are hard to reel up and has the melting point of the clad layer metal lower than that of the core material metal. The equipment and method have the advantages that the equipment is simple in structure, parts are easy to replace, operation and maintenance are convenient to carry out, layout is reasonable and compact, production efficiency is high, investment is small, automatic control is easy to achieve, large-scale industrial production is facilitated, the procedure of the forming process is short, energy is saved, environment is protected, efficiency is high, cost is low, the combination freedom of the clad layer metal and the core material metal is large, and the prepared clad materials are good in quality and performance.

Owner:UNIV OF SCI & TECH BEIJING

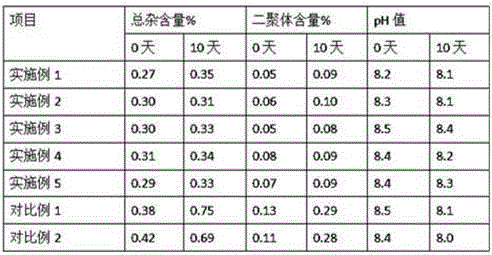

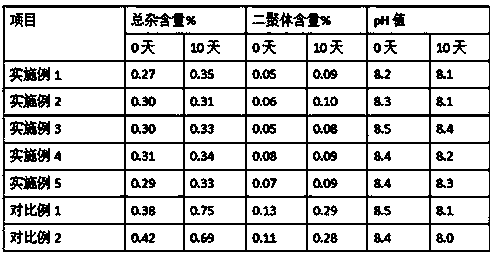

Lipoic acid liquid preparation and preparation method thereof

ActiveCN105125480AStable pHReduce dosageOrganic active ingredientsNervous disorderLight exposureBiomedical engineering

The invention discloses a lipoic acid liquid preparation and a preparation method thereof. The lipoic acid liquid preparation comprises main lipoic-acid ingredients, polymerization inhibitor lysine and a pH (potential of hydrogen) modifier. Though simple in component, the preparation can obviously improve stability of liquid medicine under high-temperature sterilization and high-light exposure, and generation of impurities of lipoic acid dimmers can be particularly greatly lowered. The effect of stabilizing the quality of the liquid medicine is further enhanced by adding an auxiliary stabilizer D-sorbitol. The preparation technology of injection is strictly controlled by performing entire nitrogen protection during liquid dosing, dissolution and potting and timely monitoring the oxygen volume of the liquid medicine, degradation of lipoic acid in water solution is effectively controlled, and the lipoic acid liquid preparation is ensured to be safe and effective in clinical application.

Owner:NANJING HERON PHARM CO LTD +1

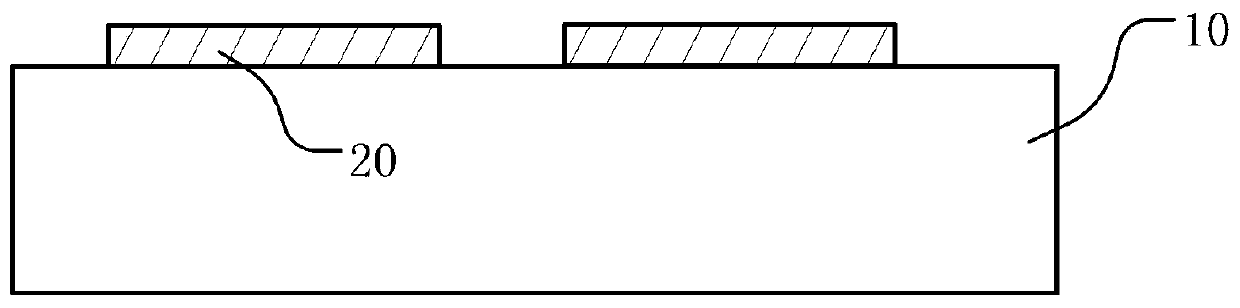

Semiconductor device and forming method

InactiveCN110120382AIncrease etch rateThe total doping concentration is reducedSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceDopant

The invention provides a semiconductor device and a forming method. The semiconductor device comprises a semiconductor substrate, a dielectric layer and a conductive plug, wherein the dielectric layeris located on the semiconductor substrate. The dielectric layer comprises a dopant, and the total doping concentration of the dopant in the dielectric layer is gradually reduced in the direction faraway from the surface of the semiconductor substrate. A through hole for exposing the conductive structure is formed in the dielectric layer, and the conductive plug is disposed in the through hole. The total doping concentration of the dopant in the dielectric layer of the semiconductor device provided by the invention is gradually reduced in the direction far away from the semiconductor substrate; due to the fact that the dielectric layer with the large doping concentration can be etched and removed more easily, when the dielectric layer is etched to form the through hole, the etching rate cannot be obviously reduced along with the increase of the etching depth, the bottom appearance of the through hole can be improved, the through hole meeting the requirement is formed, and then the performance of the semiconductor device is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

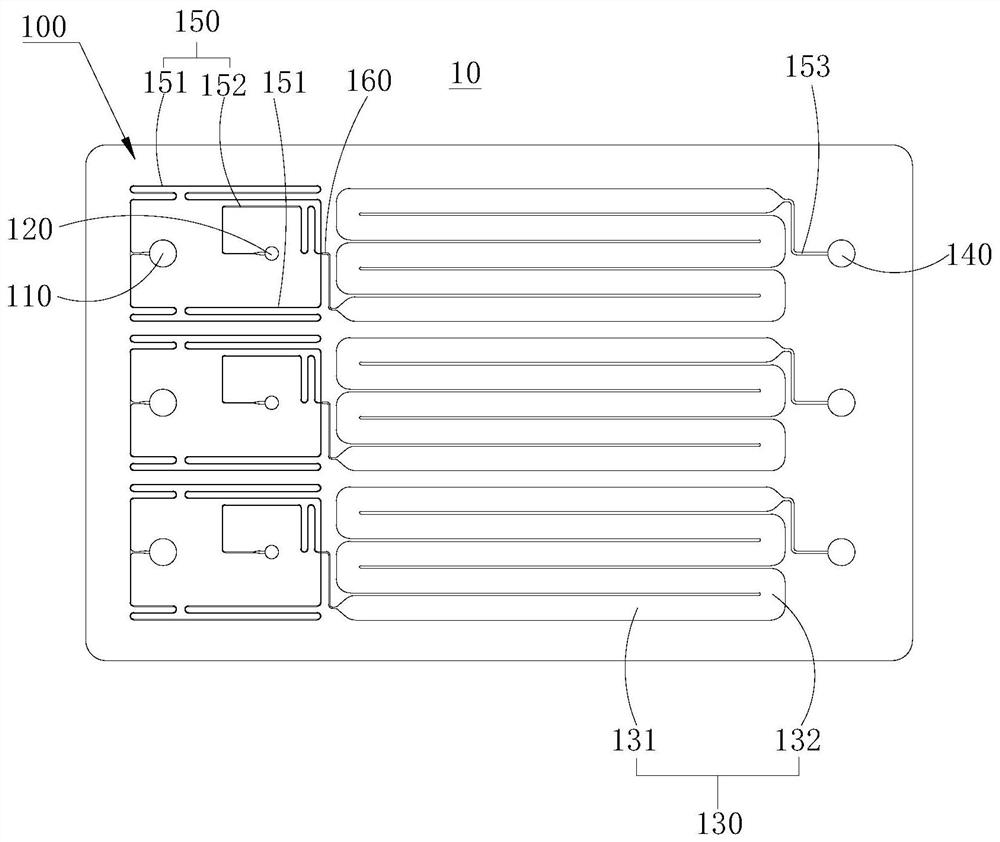

Liquid drop type PCR chip and liquid drop type PCR detection system

PendingCN113073028AAvoid crowding outIncrease vapor pressureBioreactor/fermenter combinationsBiological substance pretreatmentsPcr chipLiquid storage tank

The invention discloses a liquid drop type PCR (Polymerase Chain Reaction) chip and a liquid drop type PCR detection system. The liquid drop type PCR chip comprises at least one unit, wherein each unit comprises an oil phase liquid storage tank, a PCR reagent liquid storage tank, a liquid drop tiling cavity and an outlet liquid storage tank; the PCR reagent liquid storage tank and the oil phase liquid storage tank are converged through a fluid flow path and converge to a droplet generation channel; one end of the liquid drop tiling cavity communicates with the liquid drop generation channel so as to receive the generated liquid drops, and the liquid drop tiling cavity provides a PCR amplification reaction place for the liquid drops; the outlet liquid storage tank is connected to the other end of the liquid drop tiling cavity so as to discharge air extruded by the liquid drops in the liquid drop tiling cavity; and each liquid storage tank is also used for receiving mineral oil so as to seal the liquid drop tiling cavity. Therefore, liquid drops are prevented from being squeezed out of the liquid drop tiling cavity due to leakage of bubbles generated by heating in oil phase; and in addition, the vapor pressure generated by heating in the oil phase is retained in the liquid drop type PCR chip after sealing, so that the vapor pressure in the liquid drop tiling cavity is improved, and bubbles generated in the liquid drop type PCR chip can be reduced or avoided.

Owner:中山百慧生物科技有限公司

Semiautomatic ribbon spreading machine and its spreading technology

InactiveCN100999149BIncrease productivityReduce labor intensityScreen printersScreen printingSemi automatic

The present invention belongs to the field of silk-screen printing matched equipment technology, in the concrete, it relates to a semi-automatic screen-laying machine and screen-laying process. It is characterized by that said screen-laying machine mainly includes the following several portions: rectangular frame, supporting frames, screen roll, screen roll hanger shaft, first screen-dividing shaft, second screen-dividing shaft, first screen-pressing roller, second screen-pressing roller, third screen-pressing roller, bearing running wheel and running guide wheel. Said invention also providesthe connection mode of all the above-mentioned portion and the concrete steps of its screen-laying method.

Owner:陈杰民

A downward approach layered cemented filling mining method

ActiveCN103953344BReduce or avoid the generation ofAvoid it happening againUnderground miningSurface miningMineralogy

The invention provides a downward drift layered cemented filling mining method, and belongs to the technical field of layered cemented filling mining methods. The downward drift layered cemented filling mining method provided by the invention avoids tunnelling of a filling tunnel and a small filling well, reduces or avoids a large quantity of rubbles and improves the filling height of a mined-out stope access. By adopting the mining method, the small filling well and the filling tunnel are not tunnelled, so that waste stone produced by tunnelling the small filling well and the filling tunnel is eliminated, ore dilution is reduced, and blasting fume poisoning accidents and susceptible dampness syndromes produced during upward tunnelling are prevented; filling pipes are not erected over the stope access, so that overhead operation is avoided, and the filling pipes are omitted; meanwhile, the stope access can be fully filled to the top, and the safety of stope top plates is improved.

Owner:JINCHUAN GROUP LIMITED

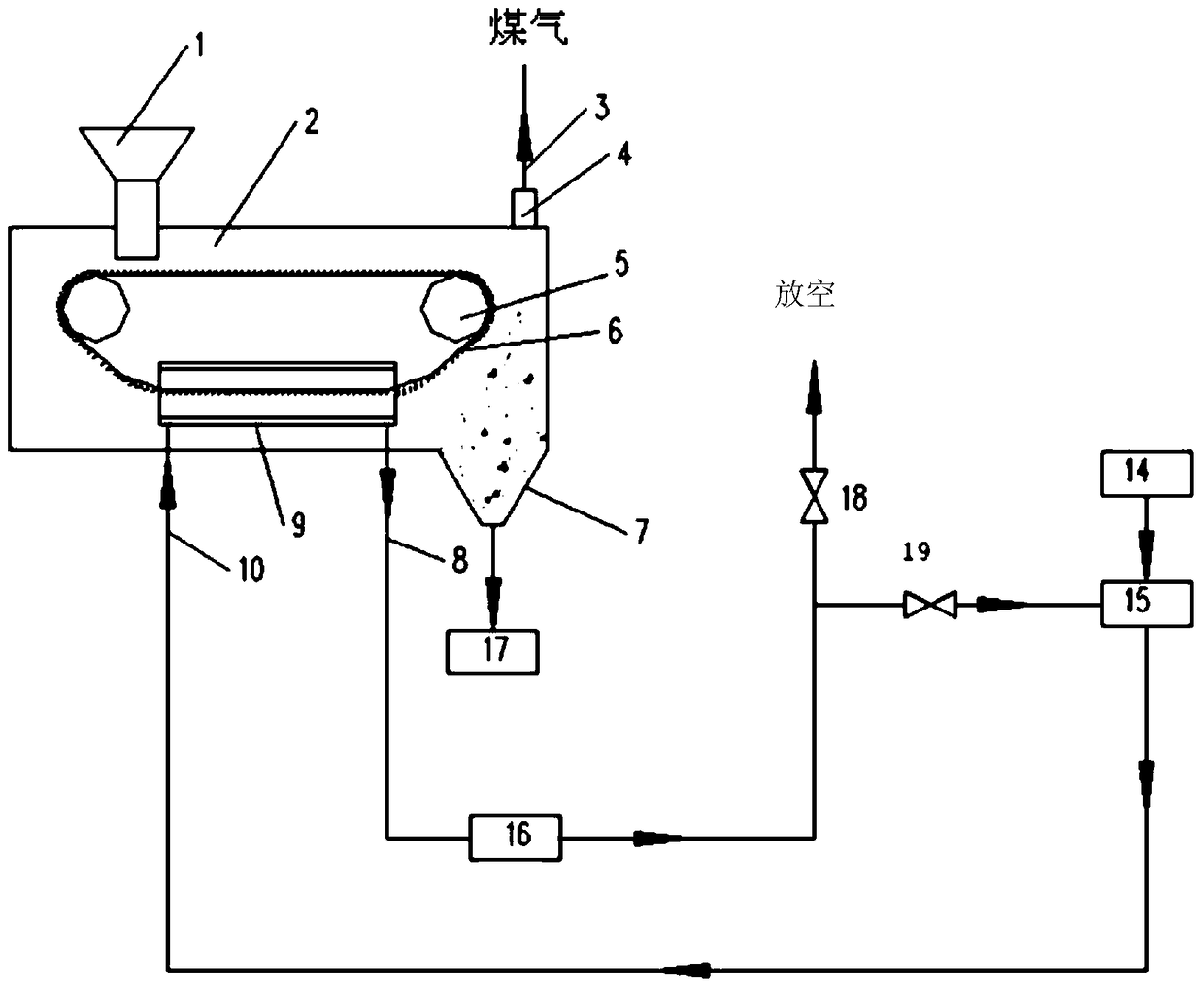

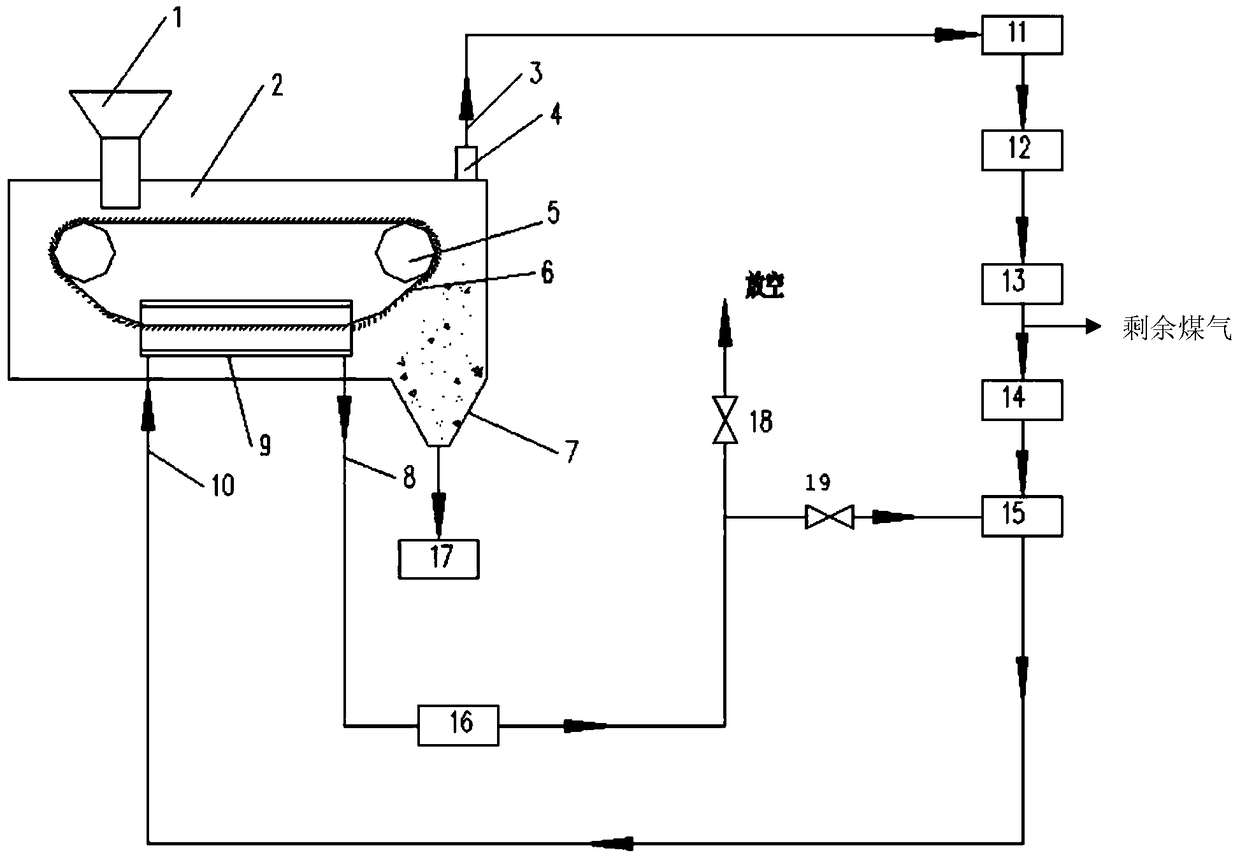

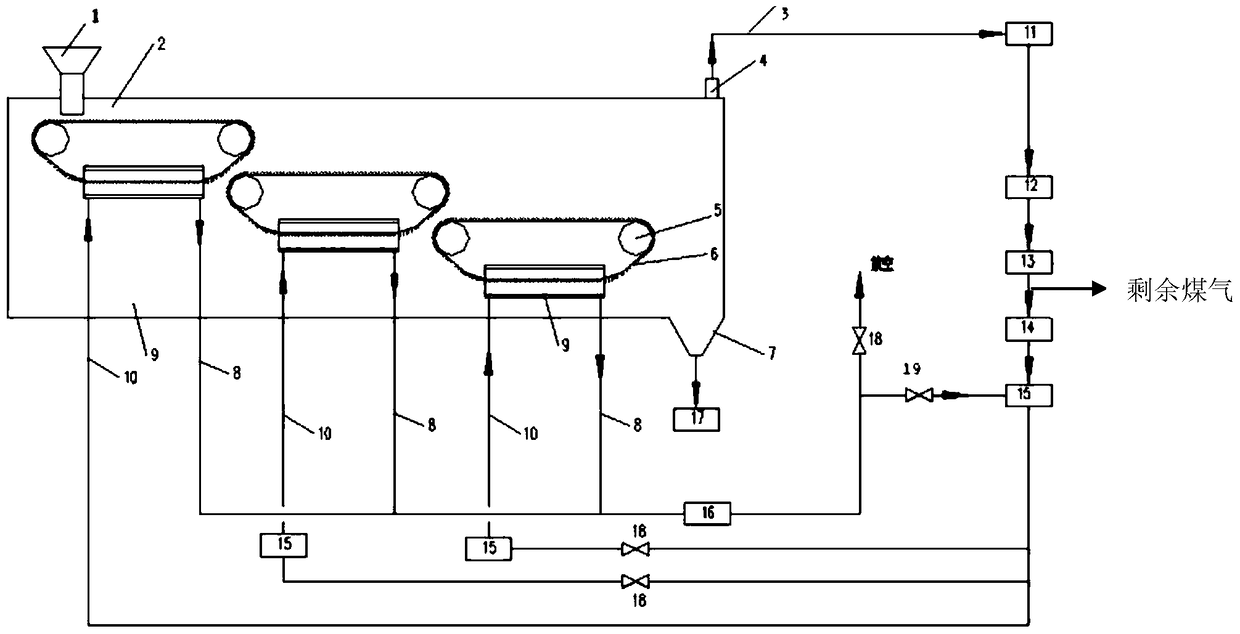

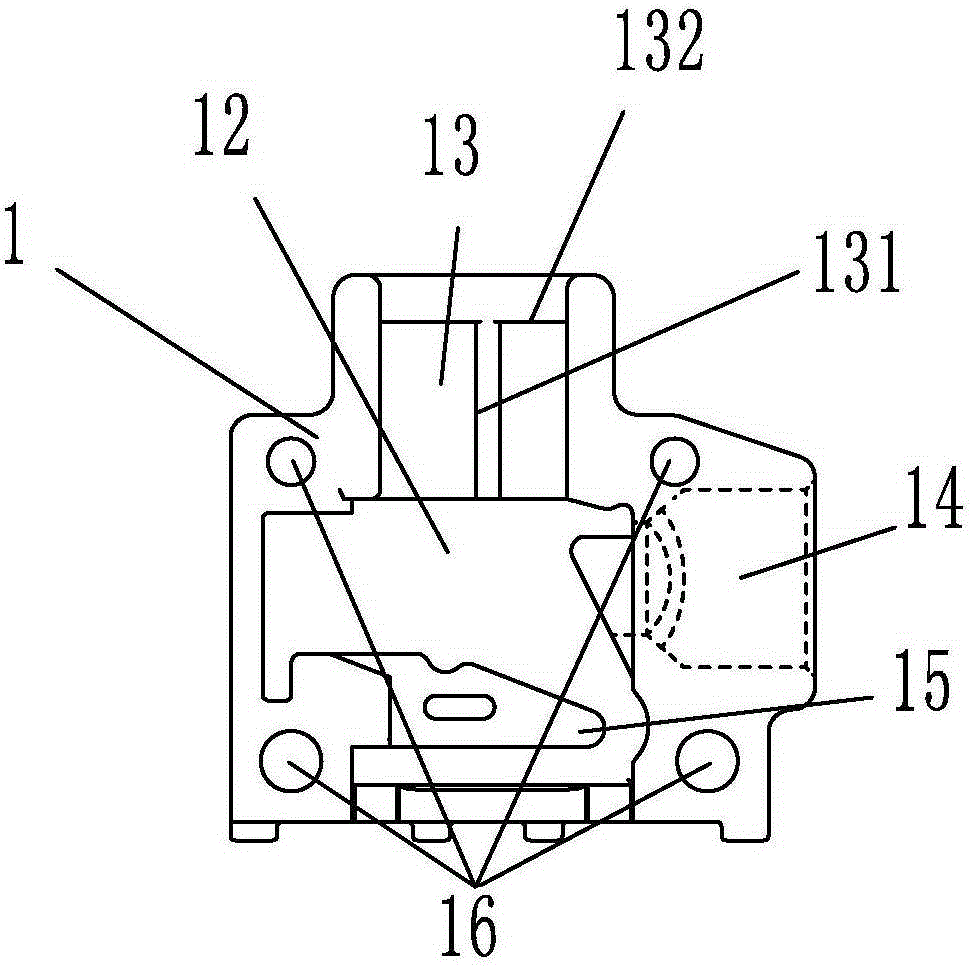

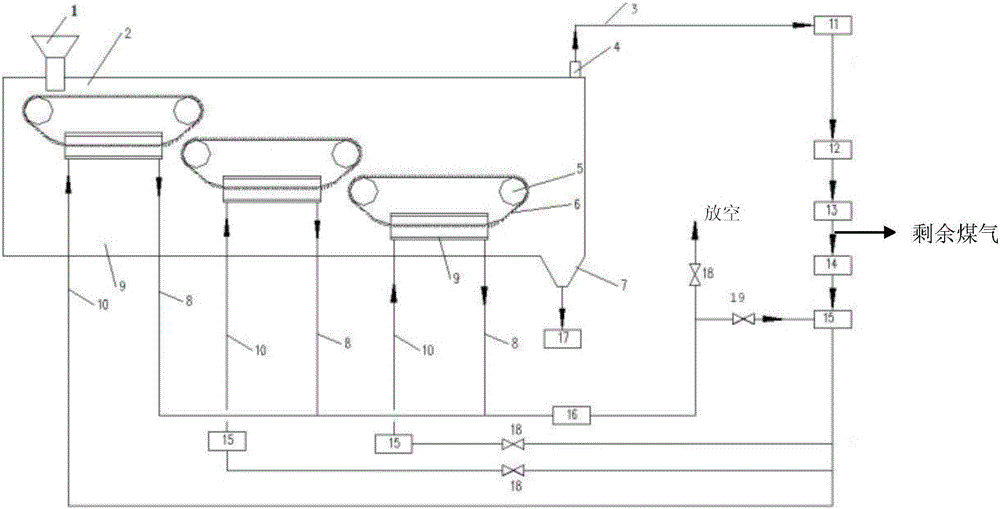

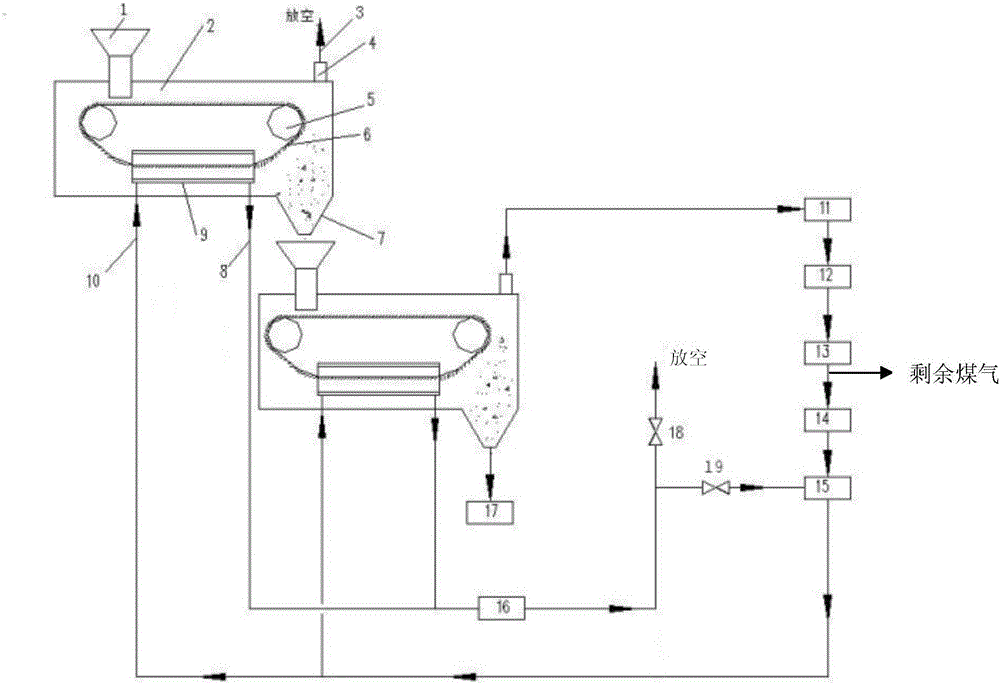

A pulverized coal upgrading pyrolysis device and upgrading pyrolysis process

ActiveCN105062523BImprove quality improvement efficiencyFull heat exchangeSpecial form destructive distillationThermodynamicsCombustion

The invention relates to the field of coal chemical industry, in particular to the field of energy utilization. The invention provides a pulverized coal quality upgrading pyrolysis device and a process using the device, which includes a coal drop port, including a coal drop port, a upgrading furnace body, a gas outlet pipeline, and a gas outlet. It is characterized in that the quality upgrading A toothed driving wheel and a toothed steel belt are arranged inside the furnace body, and the toothed steel belt is used as a heating medium; the pulverized coal enters the upgrading furnace body through the coal drop port and falls into the hot toothed steel belt. belt, and along with the movement of the toothed steel belt, is sent to the other end of the upgrade furnace body to realize the upgrade pyrolysis reaction of pulverized coal. The invention can solve the technical problems of low utilization efficiency, easy combustion and serious loss in the pulverized coal upgrading process.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

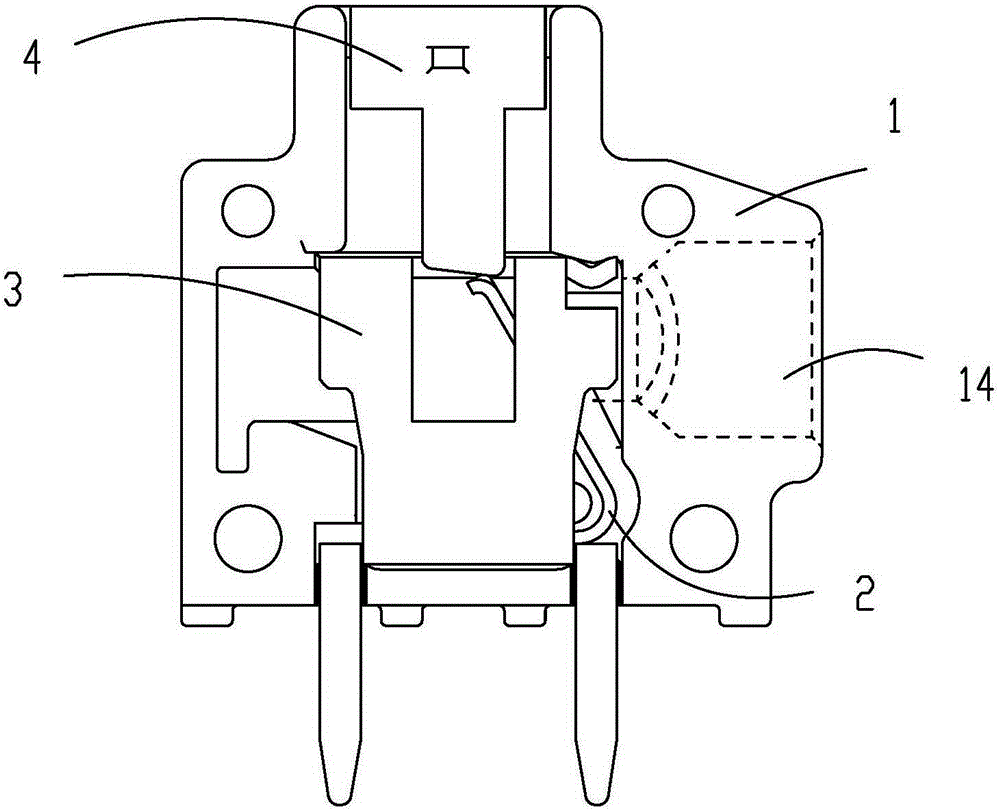

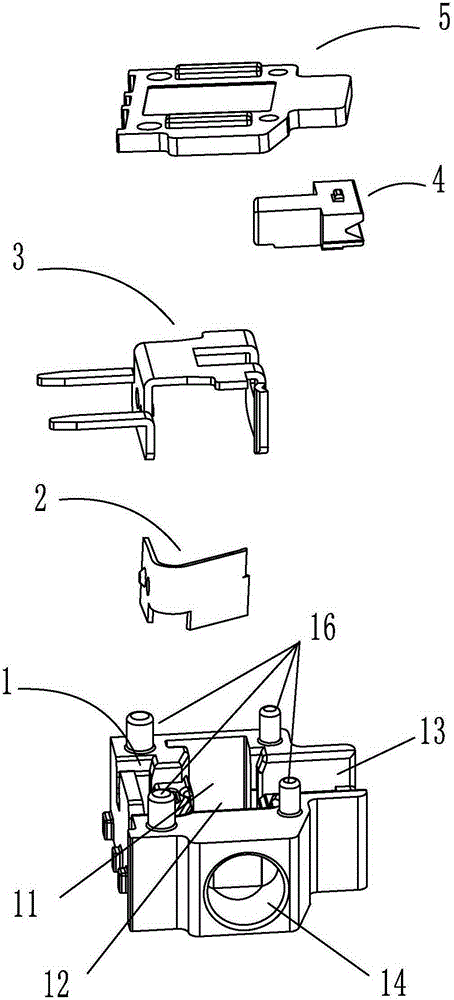

Bolt-free PCB wiring terminal provided with button

ActiveCN105390862AIncrease wiring capacitySolve the anti-warping phenomenonCoupling device detailsFixed connectionsEngineeringElectrical and Electronics engineering

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

Pulverized coal upgrading pyrolysis device and upgrading pyrolysis process

ActiveCN105062523AImprove quality improvement efficiencyFull heat exchangeSpecial form destructive distillationThermodynamicsCombustion

The invention relates to the field of coal chemical industry, in particular to the field of energy utilization. The invention provides a pulverized coal upgrading pyrolysis device and a process using the device. The device comprises a coal drop port, an upgrading furnace body, a gas outlet pipeline and a gas outlet. The device is characterized in that the upgrading furnace body is internally provided with toothed driving wheels and a toothed steel strip, and the toothed steel strip is a heating medium. Pulverized coal enters the upgrading furnace body through the coal drop port, drops onto the hot toothed steel strip, and is sent to the other end of the upgrading furnace body along with the movement of the toothed steel strip, thus realizing the upgrading pyrolysis reaction of pulverized coal. The device and the process provided by the invention can solve the technical problems of low utilization efficiency, easy combustion and serious loss in a pulverized coal upgrading process.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

Magnesium and steel special metal superaudio frequency pulse laser smelting braze-welding wire and welding method

ActiveCN102699535BEffect of Surface Energy StateGood wetting and spreadingWelding/cutting media/materialsWelding/soldering/cutting articlesMelting tankWeld seam

The invention provides a magnesium and steel special metal superaudio frequency pulse laser smelting braze-welding wire and a welding method. The welding method comprises the following steps of: forming a beveled edge on a part to be welded of a magnesium alloy and a steel workpiece, and removing oil dirt and an oxidation film from the surface of the workpiece; fixing the magnesium alloy and the steel workpiece on a welding fixture, adjusting the position and the angle of a wire feeding device, automatically feeding the welding wire at a certain angle in front of a laser beam, and protecting a welding seam through argon, wherein the welding wire comprises the following components in percentage by weight: 2 to 10 percent of Al, 0.5 to 5 percent of Zn, 0.1 to 1 percent of Sr, 0.05 to 0.2 percent of B, 0.5 to 2 percent of RE and the balance of Mg; and placing the laser beam on one side of the magnesium alloy workpiece in a slightly deviating way, and heating the welding wire and the magnesium alloy workpiece by using superaudio frequency pulse laser to form a smelting pool, wherein the steel workpiece is kept in a solid state substantially in a welding process and acts with liquid magnesium alloy to form a welding joint. The key and common problem that the improvement of the welding quality of Mg / Fe and Mg / Ti immiscible heterogeneous metal is limited is solved, and the application range of laser smelting braze-welding is expanded.

Owner:哈尔滨哈船特装科技发展有限公司

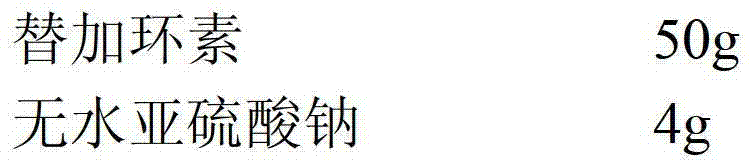

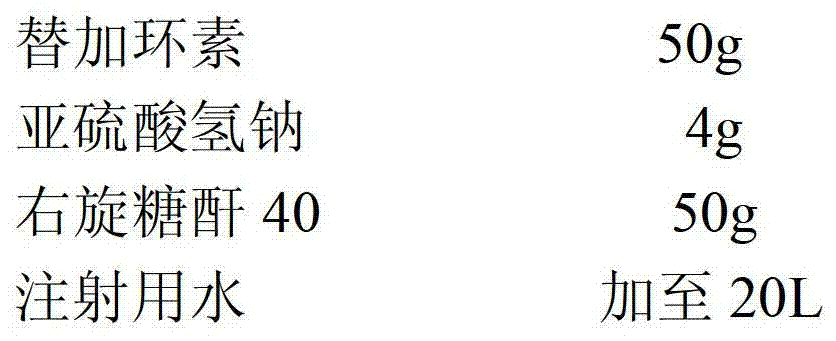

Method for preparing tigecycline for injection

InactiveCN103202814AReduce contentReduce or avoid the generation ofAntibacterial agentsPowder deliveryVitamin CAntioxidant

The invention discloses a method for preparing tigecycline for injection. The method comprises the following steps: (1) taking water for injection, adding an excipient and an antioxidant, and dissolving; (2) adding tigecycline at the temperature of 2-10 DEG C, regulating the pH value to be 4.5-5.5 after complete dissolving, and fixing the volume; (3) filtering until the solution is clarified after activated carbon adsorption; and (4) filling, performing freeze drying, and packaging to obtain the powder injection, wherein nitrogen is filled until the residual oxygen in the water is less than or equal to 2mg / L in the steps (1) to (3), the antioxidant is sodium hydrogen sulfite, anhydrous sodium sulfite, sodium pyrosulfite and vitamin C, and the excipient is dextran or lactose. In the process of preparing the tigecycline freeze-dried powder injection, various process parameters are controlled and adjusted, the content of impurities and epimers in the product is obviously reduced, the mass of the preparation for injection is ensured, the impurities are reduced or avoided, and the administration safety of the injection product is guaranteed.

Owner:CHENGDU BAIYU PHARMA CO LTD

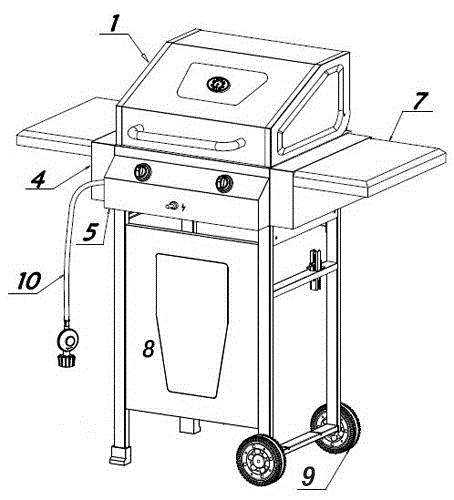

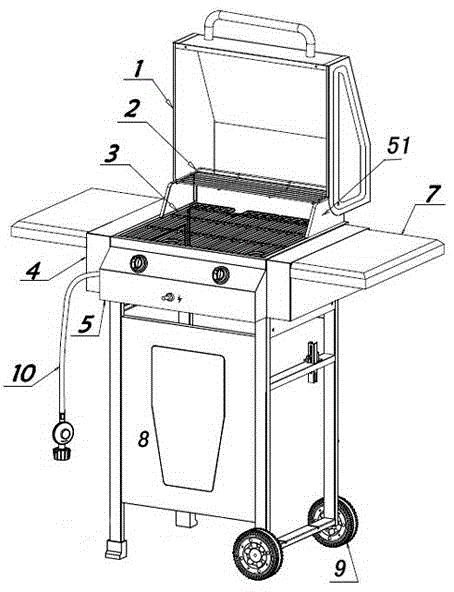

Barbecue oven

InactiveCN104013311AAvoid direct contactReduce or avoid the generation ofRoasters/grillsEngineeringSmoke

The invention discloses roasting equipment, and particularly relates to a barbecue oven which comprises a hollow oven body, infrared oven heads and a roasting net, wherein the oven heads are arranged on the left and right side walls in the oven body, respectively; the roasting net is arranged above the oven heads. When the barbecue oven is in use, oil drops generated by food freely drips to the bottom of the oven body; since the infrared oven heads are arranged on the side walls of the oven body, the oil drops do not touch the infrared oven heads, much smoke generated by the oil drops vaporized instantly at high temperature is avoided, and thus environmental pollution is reduced. The barbecue oven provided by the invention is reasonable in structure and convenient to use, and roasted food generates little smoke; moreover, the temperature in the oven is uniform, the roasting quality of heated food is effectively guaranteed, and the heat efficiency of roasting is greatly improved.

Owner:阳江市汉能工业有限公司

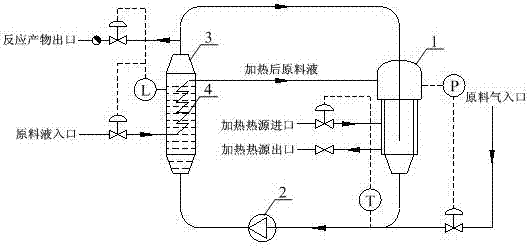

Gas-liquid reaction method and special device

ActiveCN107233851ASame flow rateRaise the temperature of the liquidSequential/parallel process reactionsChemical/physical/physico-chemical stationary reactorsGas liquid reactionMixed flow

The invention discloses a gas-liquid reaction method and a special device. During the reaction, a raw material liquid enters a tubular reactor from a raw material liquid inlet of the tubular reactor, and raw material gas is fully mixed with a reaction liquid or the raw material liquid at a mixed flow circulating pump inlet and subjected to a gas-liquid reaction in a circulating pipeline and the tubular reactor along the flow path; energy supplement is performed by the aid of a ripening reactor outer jacket at the initial stage of the reaction, and automatic energy supplement is set after the reaction system is stabilized; forced circulating reaction is adopted. The working performance is good, the yield is effectively increased, and byproducts are reduced or avoided.

Owner:JIANGSU JIUJIUJIU TECH

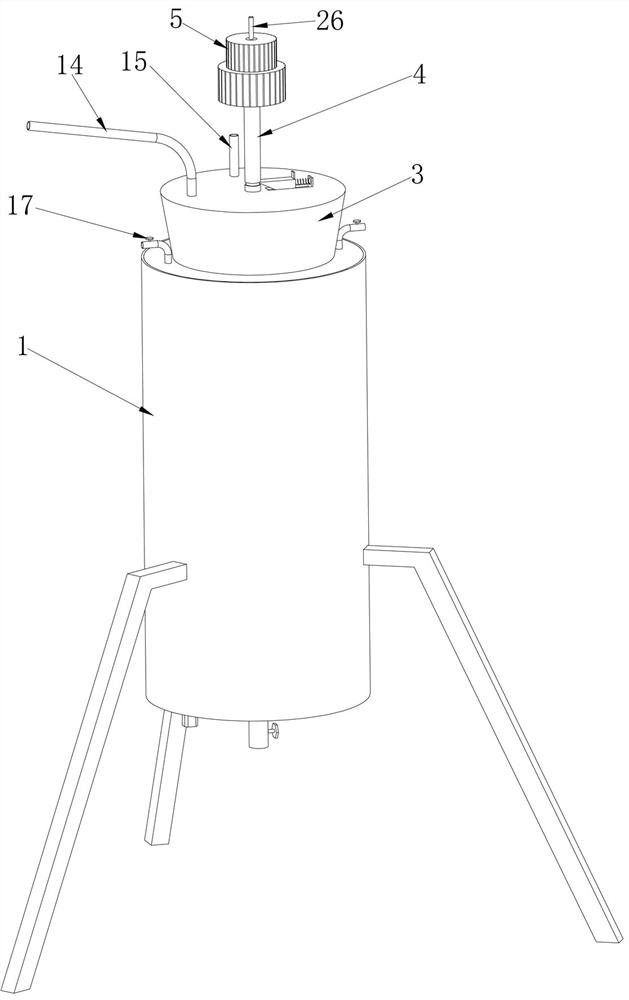

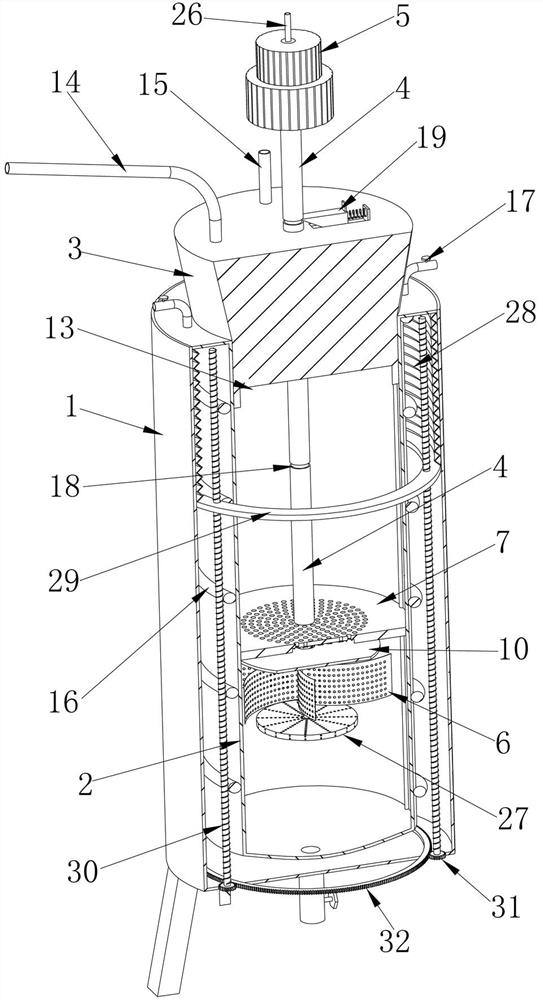

Biological reaction device for bioengineering and use method thereof

InactiveCN113122444AWill not be damagedReduce or avoid the generation ofBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismEngineering

The invention provides a biological reaction device for bioengineering and a use method thereof, and solves the problems that foam is accumulated on the liquid level of reaction liquid, so that the exhaust of gas such as carbon dioxide is influenced, and the fermentation effect is influenced. The biological reaction device for bioengineering comprises an outer cylinder, wherein an inner cylinder is fixed in the outer cylinder; a cylinder cover is fixed to the top of the inner cylinder; an isolation rod penetrates through the middle of the cylinder cover; a stirring rod is rotatably arranged inside the isolation rod; stirring blades positioned under the isolation rod are arranged at the bottom of the stirring rod; an isolation plate is arranged inside the inner cylinder in a vertically sliding manner; a sealing plate is connected to the bottom of the isolation plate in a vertically sliding manner; a spiral groove is formed in the outer surface of the bottom end of the isolation rod; the bottom end of the isolation rod penetrates through the sealing plate, and a driving pin glidingly arranged in the spiral groove is arranged on the inner side surface of the sealing plate; and a round storage groove is formed in the bottom of the cylinder cover. The reaction liquid is stirred through a plurality of arc-shaped stirring blades, microbial cells cannot be damaged, and bubbles in the reaction liquid can be broken through a plurality of stirring holes in the stirring blades, so that the number of the bubbles is reduced.

Owner:河南胜凡信息科技有限公司

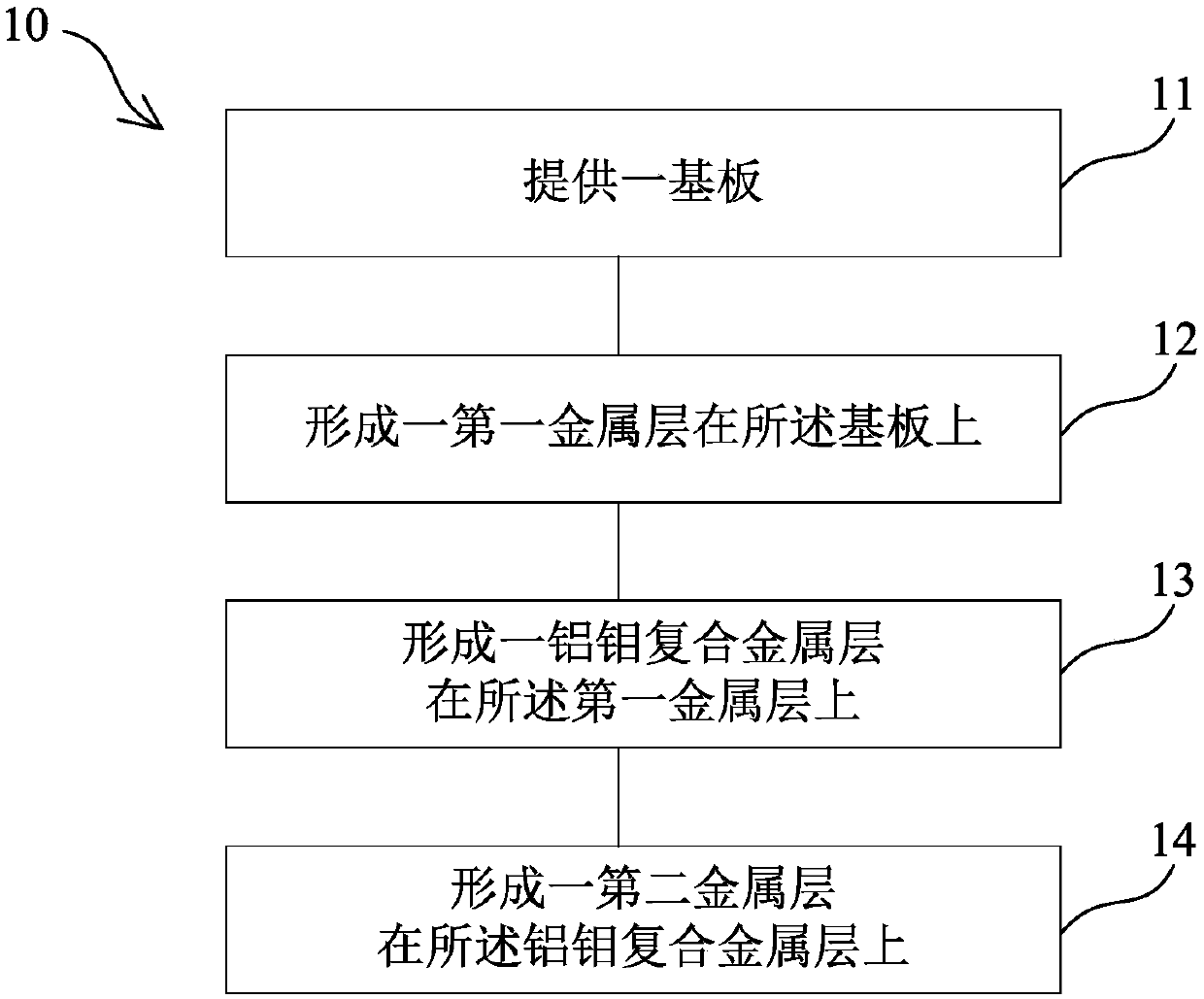

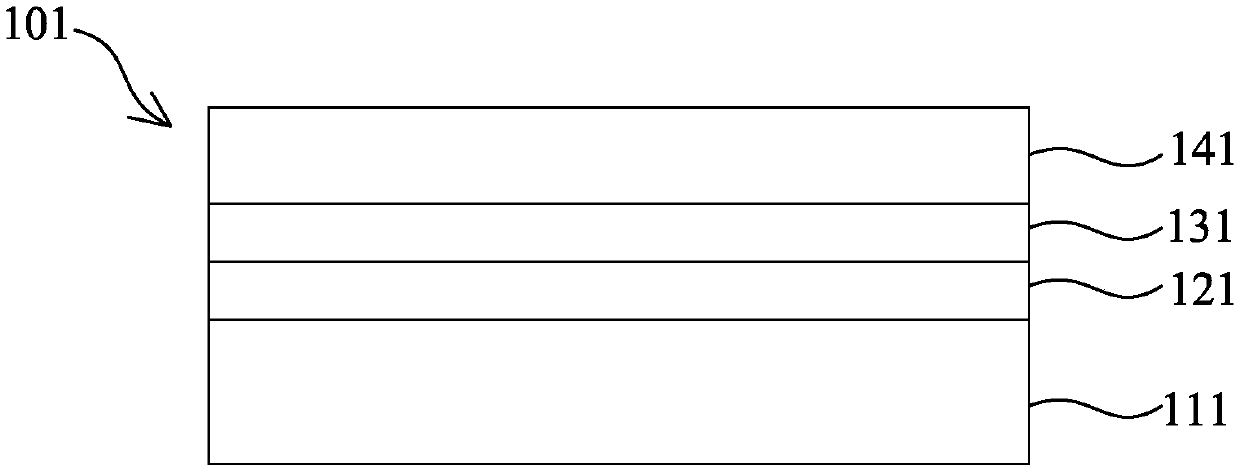

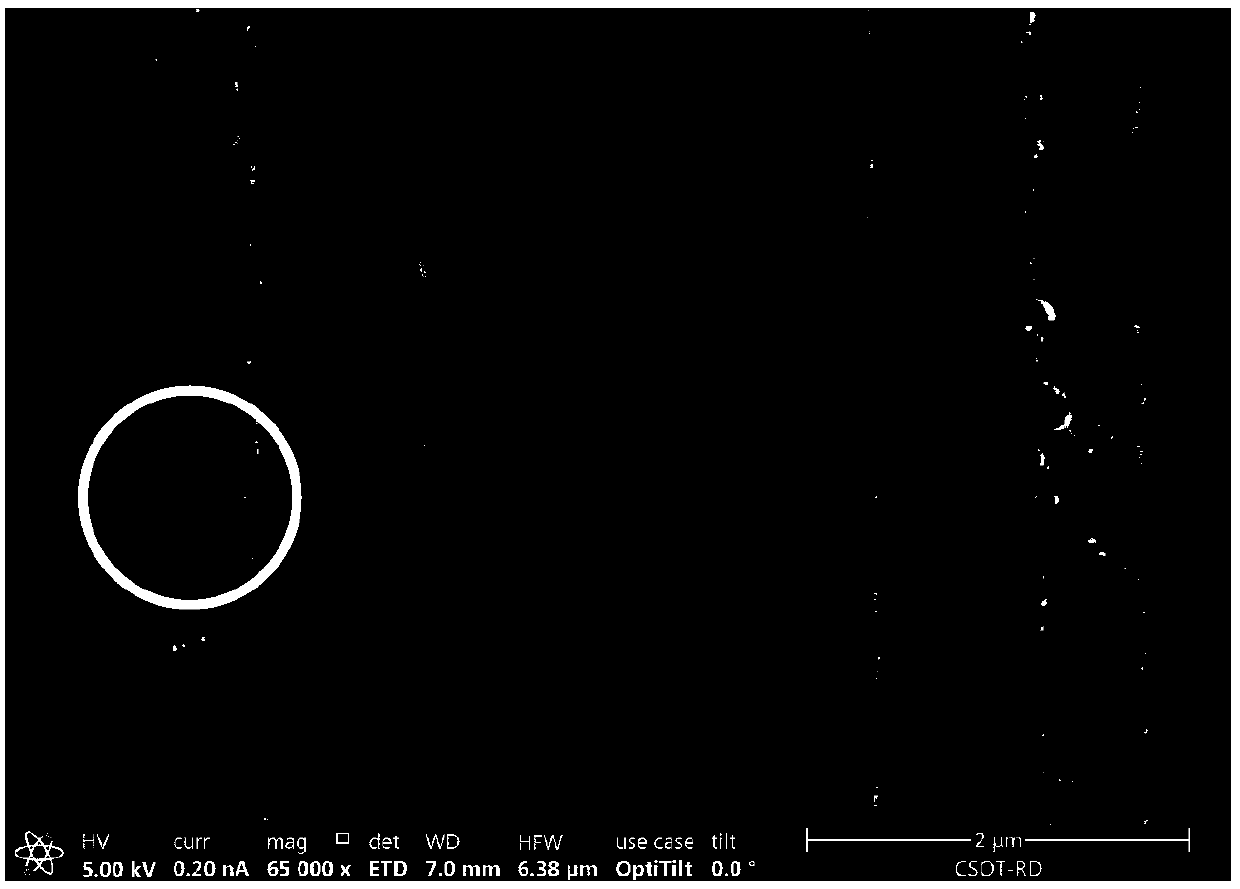

Making methods of grid electrode and thin film transistor

ActiveCN109671623AAvoid glitchy structuresImprove work efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesAluminiumOptoelectronics

The invention discloses making methods of a grid electrode and a thin film transistor. The making method of the grid electrode comprises the following steps of providing a base plate; forming a firstmetal layer on the base plate; forming an aluminum and molybdenum composite metal layer on the first metal layer; forming a second metal layer on the aluminum and molybdenum composite metal layer so as to form the grid electrode. The making methods of the grid electrode and the thin film transistor provided by the embodiment of the invention have the advantages that the generation of a burr structure of the grid electrode can be reduced or avoided; the work efficiency of the thin film transistor is further improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

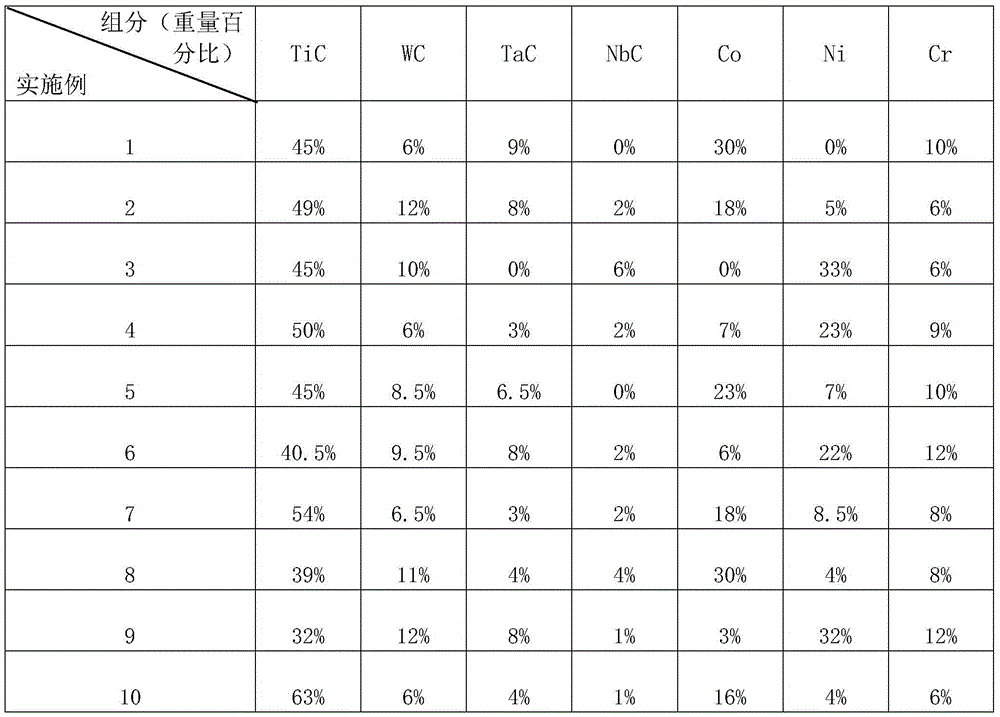

Corrosion-resistant roller and manufacturing method thereof

ActiveCN104120376BAvoid corrosionAvoid it happening againMolten spray coatingProduction lineSheet steel

The invention discloses a corrosion-resistant roll which is characterized by comprising a base and a corrosion-resistant coating coated on the base surface, wherein the corrosion-resistant coating is prepared by spraying a corrosion-resistant spraying powder. The corrosion-resistant roll can be widely used as a sink roll, guide roll or support roll in a hot-galvanizing or hot-aluminizing production line, and has favorable corrosion resistance. The corrosion-resistant layer on the roll surface has the advantages of favorable thermal shock resistance, low tendency to cracking or shedding and long service life, and the produced galvanized or aluminized steel plate and the like have higher quality.

Owner:SHANGHAI JUSN SURFACE TECH ENG

A kind of liquid preparation of lipoic acid and preparation method thereof

ActiveCN105125480BReduce chance of aggregationLow impurity contentOrganic active ingredientsNervous disorderNitrogenAqueous solution

Owner:NANJING HERON PHARM CO LTD +1

Moisture-proof distribution box

InactiveCN112886422AEasy to rustImprove the problem of circuit failureSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringMechanical engineering

The invention discloses a moisture-proof distribution box comprising a bottom plate, a top plate and four side plates, four angle steels vertically distributed at four corners are detachably fixed on the bottom plate, the side plates are detachably connected among the angle steels to form four box walls of the distribution box, and the top plate detachably covers the tops of the angle steels. Each side plate is formed by detachably combining an outer plate body, a heat preservation plate and an inner plate body, the heat preservation plate is located between the outer plate body and the inner plate body, a grid-shaped window is formed in the outer plate body, and a movable blocking cover is arranged on the outer side of the window. The side plates of the distribution box are formed by combining the outer plate bodies, the inner plate bodies and the middle heat insulation plates, and heat exchange between the outside and the interior of the distribution box is blocked by the heat insulation plates at night in winter, so that the condition that hot air in the distribution box is cooled and liquefied is well improved, and fog water generated on the inner wall of the distribution box is reduced or avoided. Therefore, the problems of corrosion and circuit faults in the distribution box are solved, and the service life of the distribution box is prolonged.

Owner:湖北西迈电气设备有限公司

Block type multidirectional forging device

ActiveCN102794380BForce balanceReduce or avoid the generation ofForging/hammering/pressing machinesForging press detailsEngineeringBlock type

The invention discloses a block type multidirectional forging device, which comprises a frame, a die for forming a product and a hydraulic transmission device. The hydraulic transmission device comprises a main cylinder, a jacking cylinder and at least two lateral extrusion cylinders, wherein a movable element is arranged at the rear end of each lateral extrusion cylinder; and the frame comprisesa bracket and fasteners in wrapped connection with the outer sides of the movable elements and used for fixedly connecting a plurality of movable elements sequentially, and each fastener has a closedannular structure. According to the device, the movable elements are arranged at the rear ends of the lateral extrusion cylinders and fixedly connected with the fasteners, and when each lateral extrusion cylinder extrudes a workpiece, a force reacting on the frame can directly act on the fasteners; and because the fasteners have the closed annular structures, stress balance at each position of the fasteners is ensured, the forging precision is effectively ensured, degraded products are reduced or avoided, the working efficiency is improved, and the production cost is reduced.

Owner:江西国瑞重工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com