A kind of liquid preparation of lipoic acid and preparation method thereof

A technology of liquid preparations and lipoic acid, which is applied in the field of medicine, can solve the problems of increasing the risk of adverse reactions and clinical medication, low content of lipoic acid injection, and unsatisfactory stability effects, etc., to achieve faster dissolution and environmental tolerance Good resistance, prevent degradation and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

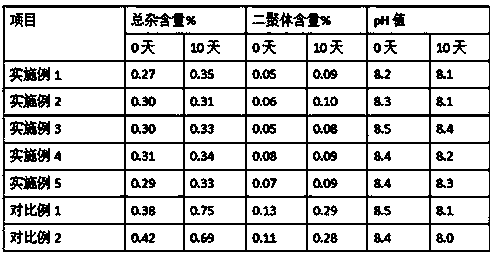

Examples

Embodiment 1

[0033] Example 1 Each 0.3g / 10mL, 1000

[0034] Alpha Lipoic Acid 300g

[0035] Lysine 350g

[0036] Disodium hydrogen phosphate 25g

[0037] Phosphoric acid to adjust pH 8.0 to 8.5

[0038] The balance of water for injection is made up to 10L.

[0039] Preparation:

[0040] 1) Mix lipoic acid and lysine in a blender evenly, set aside;

[0041] 2) Fill the liquid mixing tank with nitrogen saturation for 10-20 minutes, then add 70% of the prescription water for injection, add disodium hydrogen phosphate and stir to dissolve, control the temperature at 35-40°C, and then inject nitrogen saturation, Control the residual oxygen to be less than 2%;

[0042] 3) Add the mixture of lipoic acid and lysine in step 1 under stirring, after it is completely dissolved, add 0.1mol / L phosphoric acid dropwise to adjust the pH value to 8.0-8.5, add medicinal activated carbon and stir for 15 minutes, decarburize, Make up the water for injection to the full amount;

[0043] 4) After fine filt...

Embodiment 2

[0044] Example 2 0.3g / 10mL per tube, 1000 tubes

[0045] Alpha Lipoic Acid 300g

[0046] Lysine 400g

[0047] Disodium hydrogen phosphate 25g

[0048] Phosphoric acid to adjust pH 8.0 to 8.5

[0049] D-Sorbitol 30g

[0050] The balance of water for injection is made up to 10L.

[0051] Preparation:

[0052] 1) Mix lipoic acid and lysine in a blender evenly, set aside;

[0053] 2) Fill the liquid mixing tank with nitrogen saturation for 10-20 minutes, then add 70% of the prescription amount of water for injection, add disodium hydrogen phosphate and D-sorbitol and stir to dissolve, control the temperature at 35-40°C, and then add Saturated with nitrogen, control the residual oxygen to less than 2%;

[0054] 3) Add the mixture of lipoic acid and lysine in step 1 under stirring, after it is completely dissolved, add 0.1mol / L phosphoric acid dropwise to adjust the pH value to 8.1-8.3, add medicinal activated carbon and stir for 15 minutes, decarburize, Make up the water fo...

Embodiment 3

[0056] Example 3 0.3g / 10mL per tube, 1000 tubes

[0057] R-lipoic acid 300g

[0058] Lysine 360g

[0059] Disodium hydrogen phosphate 24g

[0060] Phosphoric acid to adjust pH 8.1~8.3

[0061] D-Sorbitol 30g

[0062] The balance of water for injection is made up to 10L.

[0063] Preparation:

[0064] 1) Mix D-lipoic acid and lysine in a blender evenly, set aside;

[0065] 2) Fill the liquid mixing tank with nitrogen saturation for 10-20 minutes, then add 70% of the prescription amount of water for injection, add disodium hydrogen phosphate and D-sorbitol and stir to dissolve, control the temperature at 35-40°C, and then add Saturated with nitrogen, control the residual oxygen to less than 2%;

[0066] 3) Add the mixture of D-lipoic acid and lysine in step 1 under stirring, after it is completely dissolved, add 0.1mol / L phosphoric acid dropwise to adjust the pH value to 8.1-8.3, add medicinal activated carbon and stir for 15 minutes, remove Carbon, make up water for inj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com