A kind of stable modified silica sol and preparation method thereof

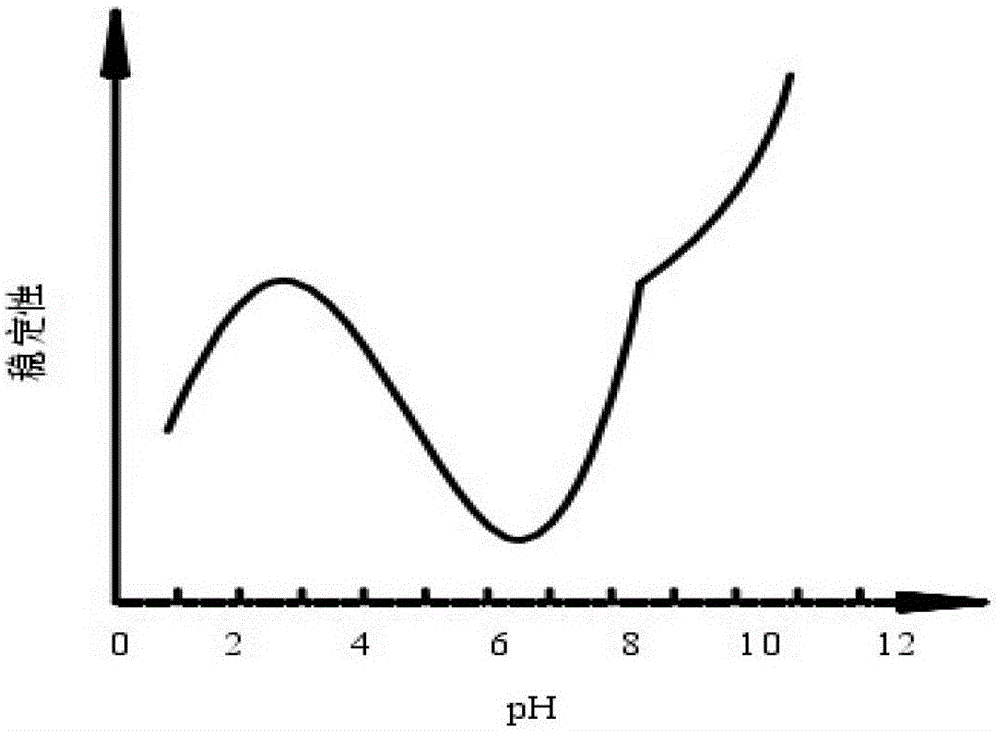

A silica sol modification technology, applied in the field of chemical engineering, can solve problems such as easy gelation, poor stability of silica sol, short stable period, etc., and achieve the effect of reducing the probability of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

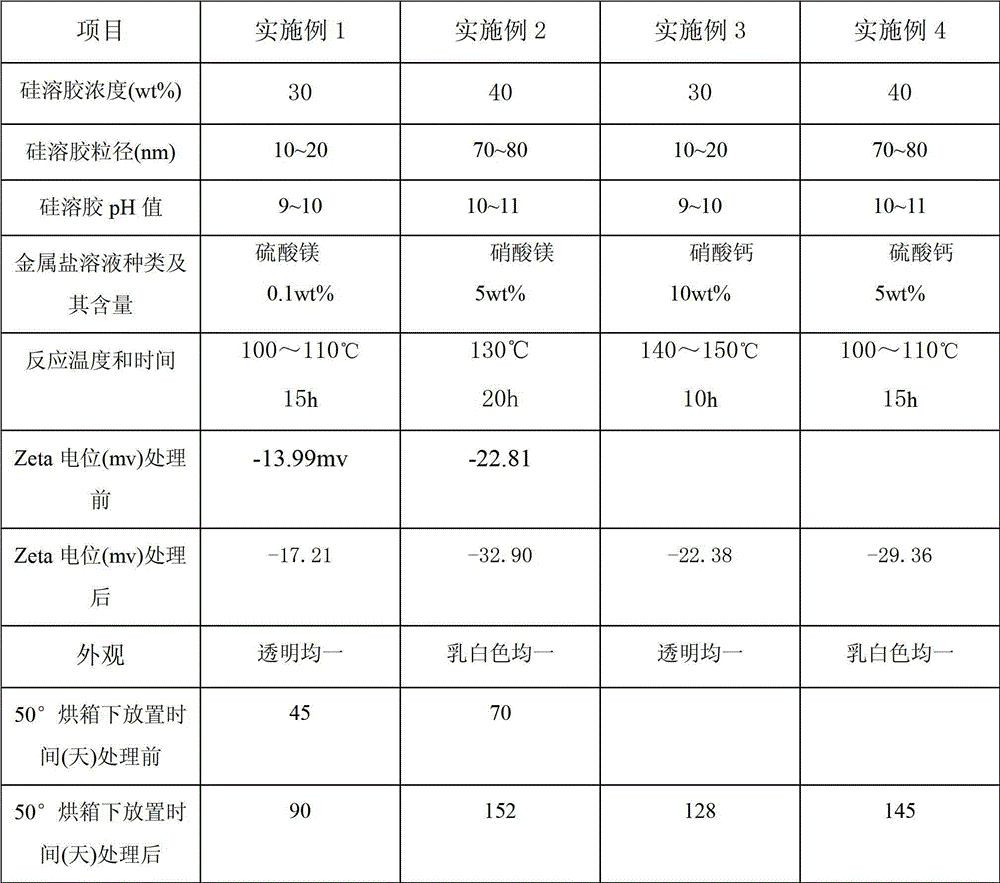

Embodiment 1

[0034] 1. Experimental instruments and reagents

[0035] 1) Instruments:

[0036] D-7401-W electric stirrer

[0037] BT300-1FLongerpump

[0038] HDM-5000 digital temperature control electric heating mantle

[0039] HH.BII-420-S-II Electric Heating Constant Temperature Incubator

[0040] NicompTM380 / ZLS ξ Potential / Particle Size Meter

[0041] 2) Conditions: Atmospheric pressure

[0042] 3) Reaction raw materials:

[0043] Silica sol: particle size 10~20nm, concentration 30wt%, pH 9~10.

[0044] Metal salt solution: magnesium sulfate 0.1wt%;

[0045] Solvent: deionized water;

[0046] 2. Experimental methods and results

[0047] The alkaline silica sol to be modified (particle size 10~20nm, concentration 30wt%, pH 9~10) is mixed with anion exchange resin for exchange reaction to obtain anion-removed silica sol; Heating to make it boil, under boiling conditions, add 0.1wt% magnesium sulfate dropwise to the anion-removing silica sol while stirring, the addition of 0.1wt...

Embodiment 2

[0050] 1. Experimental instruments and reagents

[0051] 1) Instrument:

[0052] D-7401-W electric stirrer

[0053] BT300-1FLongerpump

[0054] HDM-5000 digital temperature control electric heating mantle

[0055] HH.BII-420-S-II Electric Heating Constant Temperature Incubator

[0056] NicompTM380 / ZLS ξ Potential / Particle Size Meter

[0057] 2) Conditions: Atmospheric pressure

[0058] 3) Reaction raw materials:

[0059] Silica sol: particle size 70~80nm, concentration 40wt%, pH 10~11.

[0060] Metal salt solution: magnesium nitrate 5wt%;

[0061] Solvent: deionized water;

[0062] 2. Experimental methods and results

[0063] Mix the alkaline silica sol to be modified (particle size 70~80nm, concentration 40wt%, pH 10~11) with anion exchange resin for exchange reaction to obtain anion-removed silica sol; Heating to make it boil, while stirring under boiling conditions, add 5wt% magnesium nitrate dropwise to the anion-removing silica sol, the addition of 5wt% magnesium ...

Embodiment 3

[0066] 1. Experimental instruments and reagents

[0067] 1) Instrument:

[0068] D-7401-W electric stirrer

[0069] BT300-1FLongerpump

[0070] HDM-5000 digital temperature control electric heating mantle

[0071] HH.BII-420-S-II Electric Heating Constant Temperature Incubator

[0072] NicompTM380 / ZLS ξ Potential / Particle Size Meter

[0073] 2) Conditions: Atmospheric pressure

[0074] 3) Reaction raw materials:

[0075] Silica sol: particle size 10~20nm, concentration 30wt%, pH 9~10.

[0076] Metal salt solution: calcium nitrate 10wt%;

[0077] Solvent: deionized water;

[0078] 2. Experimental methods and results

[0079] The alkaline silica sol to be modified (particle size 10~20nm, concentration 30wt%, pH 9~10) is mixed with anion exchange resin for exchange reaction to obtain anion-removed silica sol; Heat to make it boil, and add 10wt% calcium nitrate dropwise to the anion-removing silica sol while stirring under boiling conditions, the addition of 10wt% calciu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com