Molybdenum catalyst preparation method and application thereof

A catalyst and application technology, applied in the field of fine chemicals, can solve the problems of high cost, restriction of industrialization process, difficult separation and purification of products, etc., and achieve the effects of easy recovery, improved intrinsic safety level, and excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of molybdenum catalyst is as follows:

[0038] First, add 208 g of suberic acid, 34 g of ammonium dimolybdate, and 208 g of toluene into the reaction kettle. After nitrogen replacement, heat to 100° C. and react for 90 hours to remove the water and ammonia generated by the reaction to obtain a catalyst precursor.

[0039] Take the catalyst precursor obtained above and add it to another reaction kettle, add 81.6g of ammonia water (25wt%) dropwise to it within 1h at 10°C, then continue the reaction for 5h, cool down to room temperature after the reaction, filter and dry , to obtain a molybdenum catalyst, numbered Mo-1.

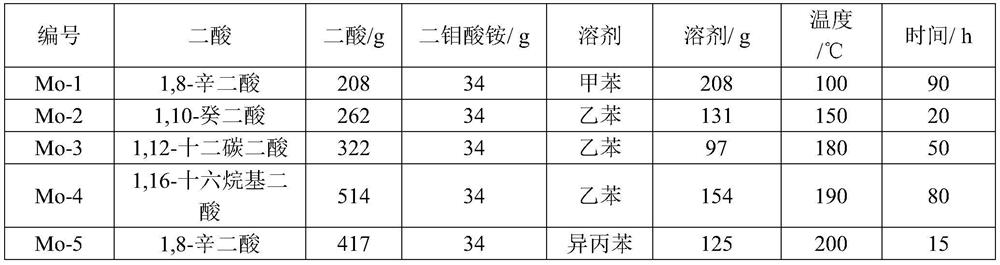

[0040] The preparation of other catalysts is the same as the above method, and the specific feeding amount and conditions are controlled in Table 1 and Table 2 below.

[0041] Table 1 Catalyst precursor synthesis conditions

[0042]

[0043] Table 2 Catalyst precursor treatment process

Embodiment 2-6

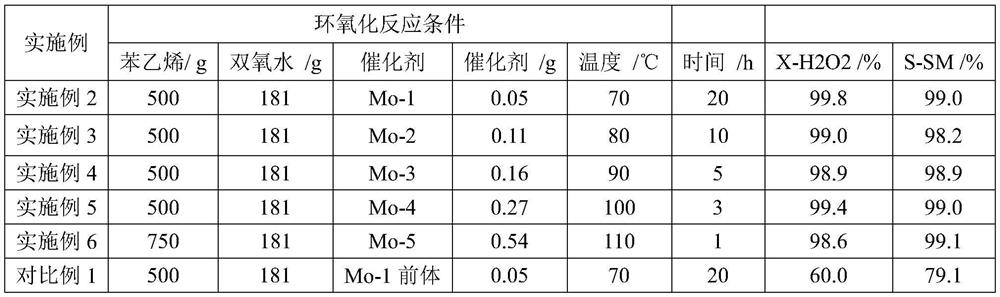

[0046] For five catalysts prepared in embodiment 1, carry out epoxidation reaction evaluation respectively:

[0047] Take the evaluation of catalyst Mo-1 as an example (embodiment 2) to introduce the evaluation method:

[0048] Add 500g of styrene, 5g of phenothiazine, and 0.05g of catalyst Mo-1 in the epoxidation reactor, then after the nitrogen replacement is complete, heat up to a reaction temperature of 70°C, and add 181g of hydrogen peroxide (concentration is 30wt% ), the reaction was continued for 20 h after the addition was completed. After the reaction was completed, the temperature was not lowered, and the phases were separated to obtain an oil phase and an aqueous phase, and then the temperature was lowered to 10°C.

[0049] After analysis, the conversion rate of hydrogen peroxide was 99.8%, and the selectivity of styrene oxide was 99.0%.

[0050] After the temperature of the water phase is lowered, the molybdenum catalyst is precipitated, and the catalyst is obtain...

Embodiment 7-11

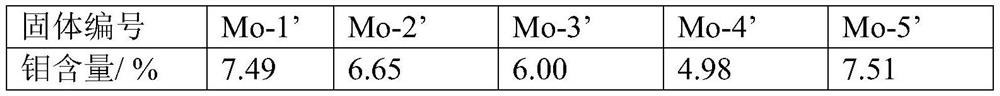

[0058]After the water phase of Examples 2-6 was cooled, solids were precipitated, and solid substances could be obtained by simple settling and decanting. After uniform and simple drying treatment (drying at 100°C for 4h), 0.0482g of solid substances were obtained in Examples 2-6, respectively. 0.1051g, 0.1509g, 0.2580g, 0.5258g. The five solids are numbered Mo-1', Mo-2', Mo-3', Mo-4', Mo-5' respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com