Bio-ethylene caustic wash tower

A technology of ethylene alkali washing tower and alkali washing tower, which is applied in the field of biological ethylene alkali washing tower, can solve the problems of uneven spraying, blocking tower of alkali washing tower, intensified polymerization of aldehydes, etc., and achieves improved removal efficiency, gas-liquid contact Fully and reduce the effect of aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

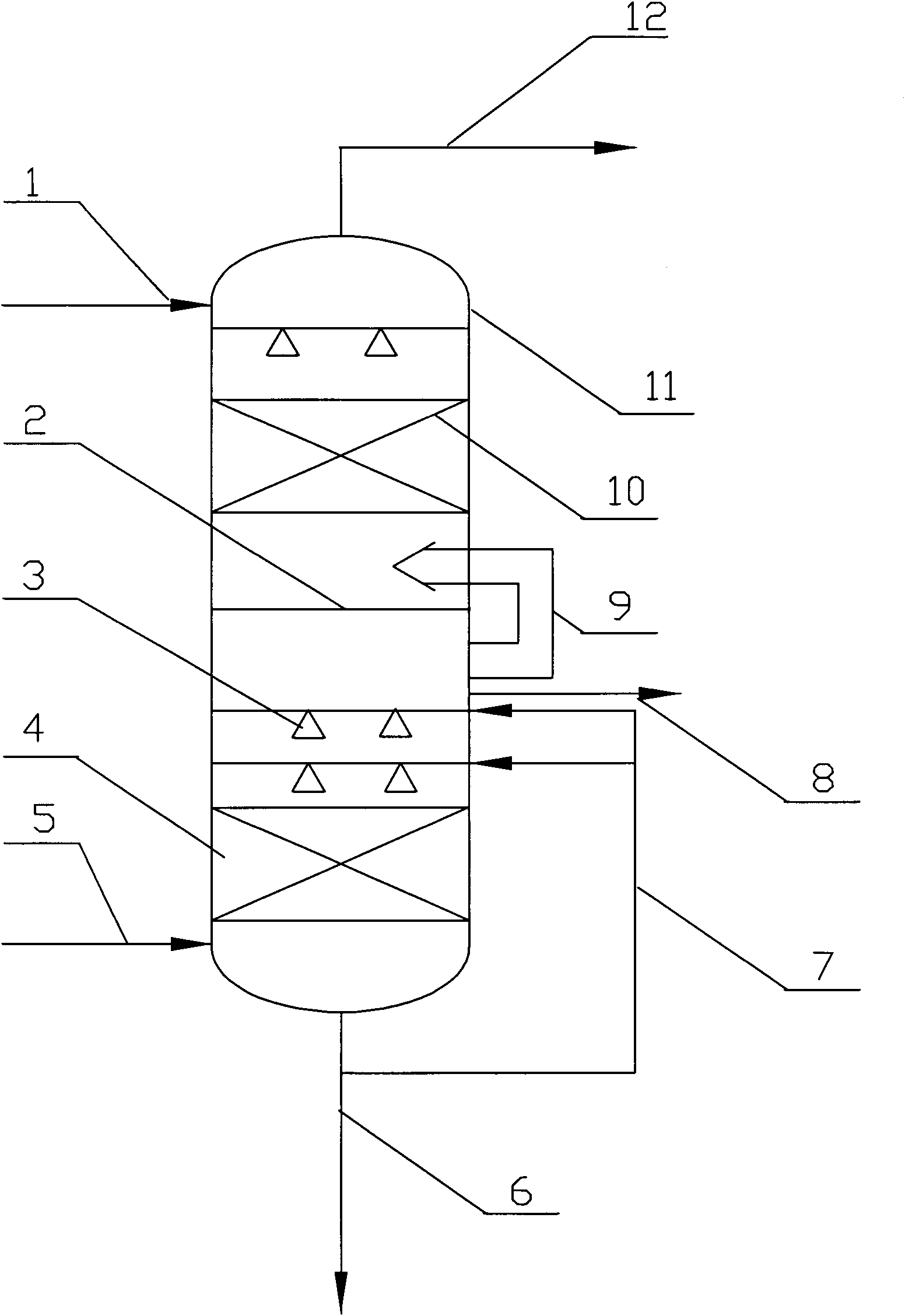

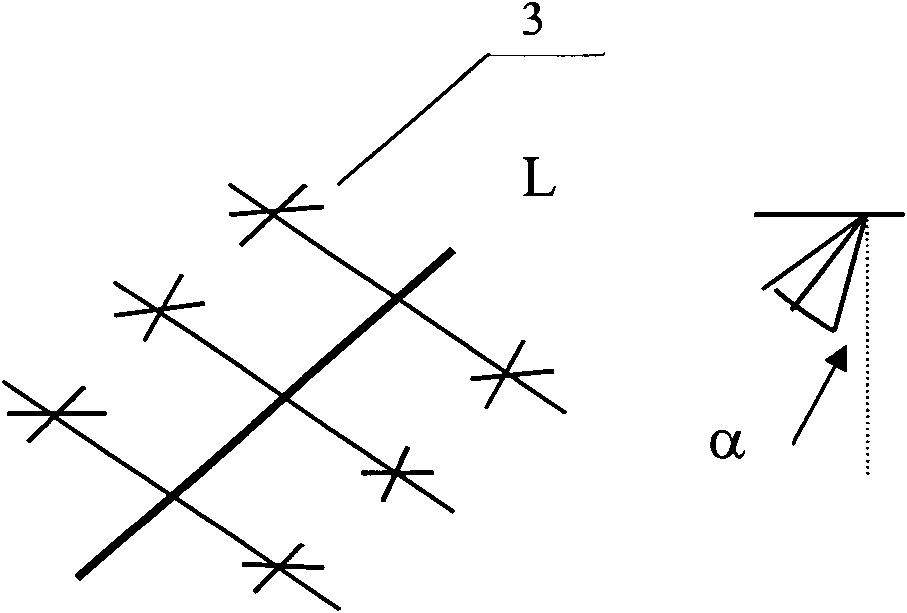

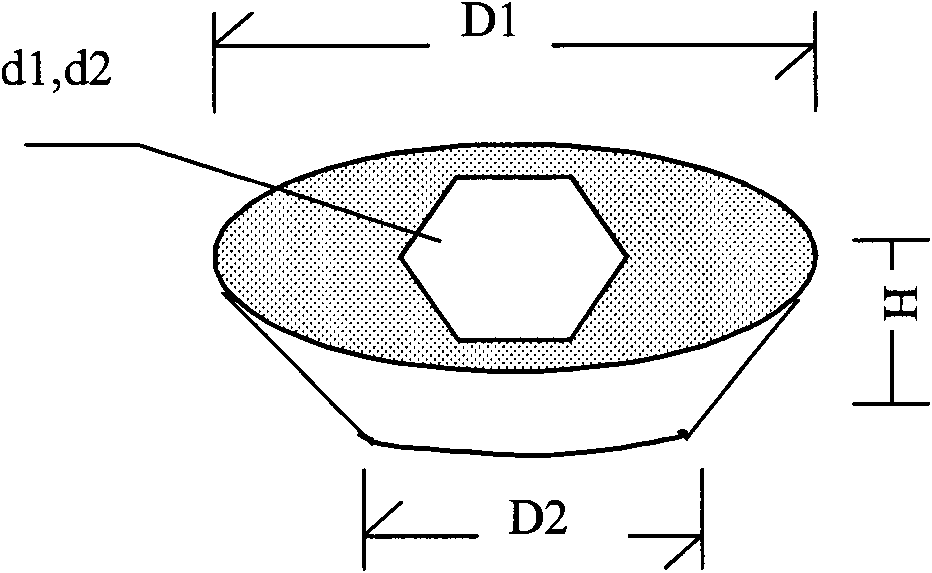

[0017] Such as figure 1 , The reactor effluent enters the alkali washing tower from the lower part of the alkali washing tower, and the composition (weight %) of the reactor effluent is: bioethylene 96.69, ethane 0.24, acetaldehyde 0.17, carbon dioxide 0.05, and other 2.85. The flow rate is 4 tons / hour, and the feed temperature is 42°C. The lower part of the alkali washing tower also has the following image 3 Internal components shown. The inner member of the lower section is composed of packing units whose exterior is circular and whose internal passages are regular triangles. The number of packing units is 7, D2 = 0.5D1, d2 = 0.5d1, and the arithmetic average cross-sectional area of the internal passages of all packing units is the cross-sectional area of the tower. 75%; the outer circulating liquid in the lower section of the alkali washing tower is sprayed with 5 layers, and the installation is as follows figure 2 The nozzles shown are installed at three angles of...

Embodiment 2

[0019] The alkali washing process is the same as in Example 1, and the reactor effluent composition (weight %) is: bioethylene 96.69, ethane 0.24, acetaldehyde 0.17, carbon dioxide 0.05, and others 2.85. The flow rate is 4 tons / hour, and the feed temperature is 42°C. Using the alkali washing tower of the present invention, the outer circulating liquid in the lower section is sprayed into three layers, and the installation angles of the nozzles are 0°, 120°, and 180°. The internal components in the lower section are composed of The outside is circular, and the internal channel is composed of regular pentagonal packing units. The number of packing units is 4, D2=0.75D1, d2=075d1, and the arithmetic average cross-sectional area of the internal passages of all packing units is 45% of the cross-sectional area of the tower; The upper section is filler. The carbon dioxide removal rate of the alkali washing tower is 99.0%, and the carbon dioxide removal rate of the industrial devi...

Embodiment 3

[0021] The alkali washing process is the same as in Example 1, and the reactor effluent composition (weight %) is: bioethylene 96.69, ethane 0.24, acetaldehyde 0.17, carbon dioxide 0.05, and others 2.85. The flow rate is 4 tons per hour, and the feed temperature is 42°C. Using the alkali washing tower of the present invention, the outer circulating liquid in the lower section is sprayed into two layers, and the installation angles of the nozzles are 30° and 150°. Shape, the inner channel is also composed of circular packing units, the number of packing units is 6, D2=D1, d2=d1, the arithmetic mean cross-sectional area of the internal passages of all packing units is 25% of the cross-sectional area of the tower; the upper section is packing. The carbon dioxide removal rate of the alkali washing tower is 99.6%, and the carbon dioxide removal rate of the industrial device is 95.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com