Alkali washing method of bio-ethylene

A bio-ethylene and alkaline washing technology, applied in the direction of chemical change purification/separation, organic chemistry, etc., can solve the problems of intensified polymerization of aldehydes, blockage of alkali washing towers, uneven spraying, etc., to reduce the chance of polymerization, gas-liquid The effect of sufficient contact and improved removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

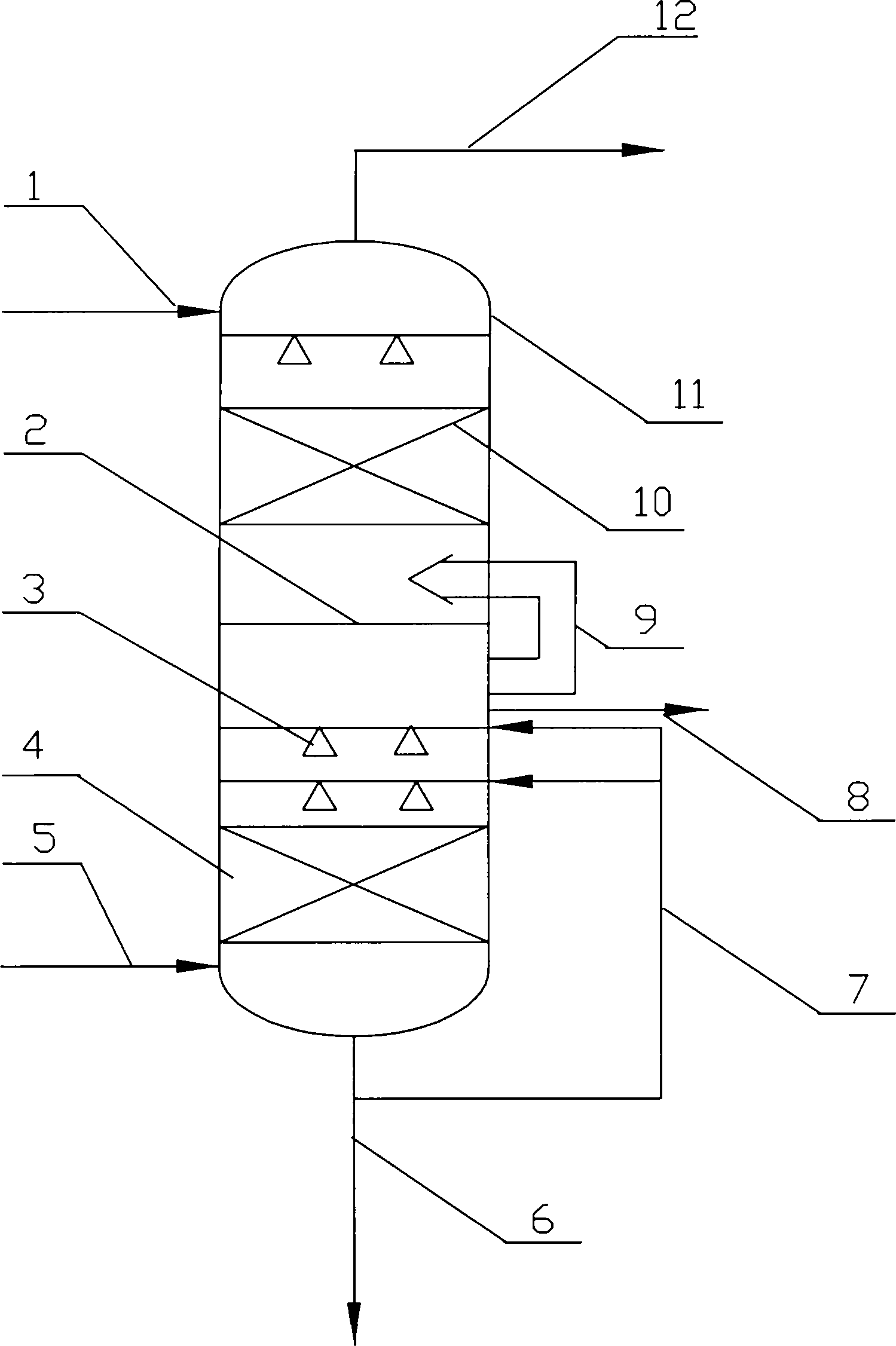

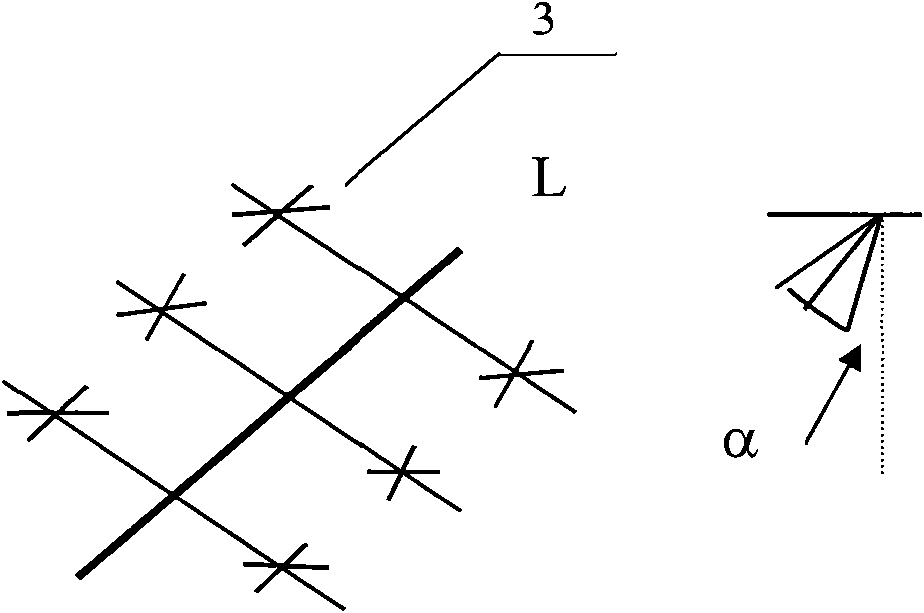

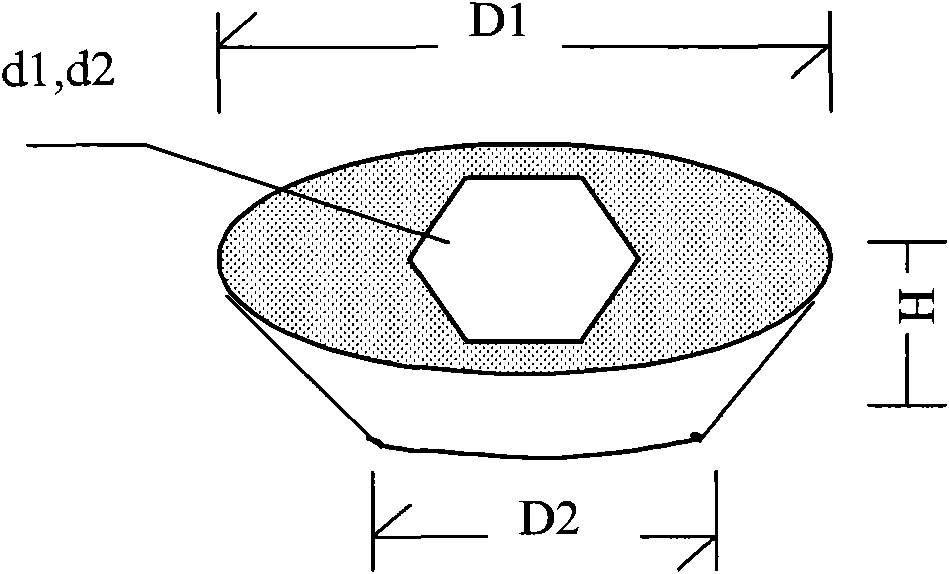

[0019] Such as figure 1 , The reactor effluent enters the caustic scrubber from the lower part of the caustic scrubber, and the composition (weight%) of the reactor effluent is: bioethylene 96.69, ethane 0.24, acetaldehyde 0.17, carbon dioxide 0.05, and others 2.85. The flow rate is 4 tons / hour, and the feed temperature is 42°C. The lower part of the caustic washing tower image 3 The internals shown. The lower internal components are composed of packing units with a circular exterior and an equilateral triangle in the internal channel. The number of packing units is 7, D2=0.5D1, d2=0.5d1. The arithmetic average cross-sectional area of the internal channels of all packing units is the cross-sectional area of the tower. 75%; the outer circulating liquid spray in the lower section of the caustic washing tower is 5 layers, the installation is like figure 2 The nozzle shown has three installation angles of 0°, 30°, and 150°. The effluent from the reactor and the circulating l...

Embodiment 2

[0021] The alkaline washing process is the same as in Example 1. The reactor effluent composition (weight %) is: bioethylene 96.69, ethane 0.24, acetaldehyde 0.17, carbon dioxide 0.05, and others 2.85. The flow rate is 4 tons / hour, the feed temperature is 42°C, and the caustic washing tower of the present invention is adopted. The lower internal components are composed of packing units with a circular exterior and a regular pentagonal channel. The number of packing units is 4, D2= 0.75D1, d2=0.75d1, the arithmetic average cross-sectional area of the internal channels of all packing units is 45% of the cross-sectional area of the tower, the lower section of the external circulation liquid sprays in 3 layers, and the nozzle installation angles are 0°, 120°, and 180° ; The upper section is packing. The carbon dioxide removal rate of the caustic scrubber is 99.0%, and the carbon dioxide removal rate of the industrial plant is 94.6%.

Embodiment 3

[0023] The alkaline washing process is the same as in Example 1. The reactor effluent composition (weight %) is: bioethylene 96.69, ethane 0.24, acetaldehyde 0.17, carbon dioxide 0.05, and others 2.85. The flow rate is 4 tons / hour, and the feed temperature is 42°C. The caustic washing tower of the present invention is adopted. The lower section of the external circulating liquid sprays in two layers. The nozzle installation angles are 30° and 150°. The inner parts of the lower section are round from the outside. The internal channel is also composed of circular packing units, the number of packing units is 6, D2=D1, d2=d1, the arithmetic average cross-sectional area of the internal channels of all packing units is 25% of the tower cross-sectional area; the upper section is the packing. The carbon dioxide removal rate of the caustic scrubber is 99.6%, and the carbon dioxide removal rate of the industrial plant is 95.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com