A downward approach layered cemented filling mining method

A technology of cemented filling and mining methods, which is applied in underground mining, filling materials, surface mining, etc., and can solve problems such as the collapse of both sides of the filling body, the difficulty of separating rubble, and the danger of filling small wells 3 up and down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

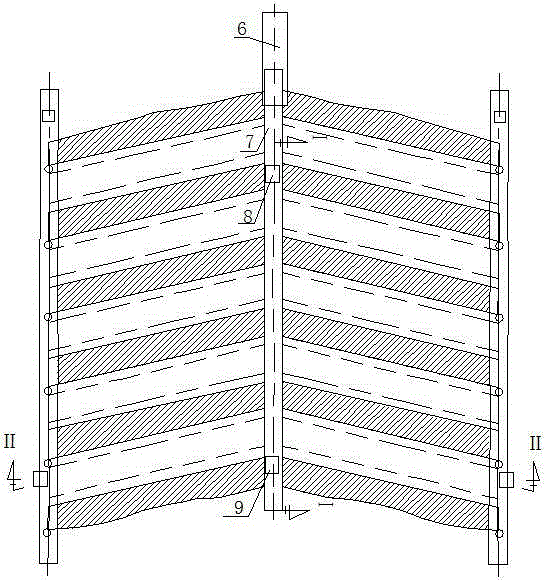

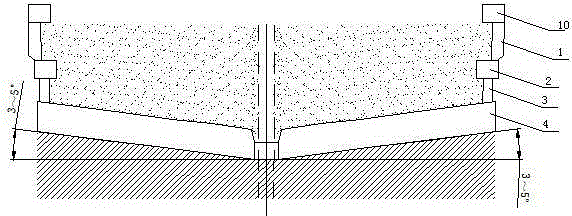

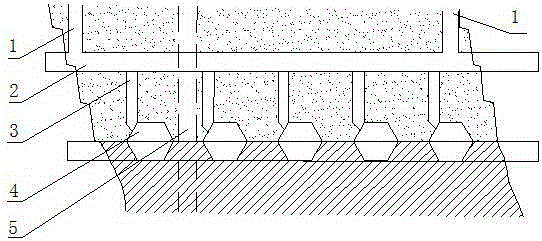

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0019] Such as Figure 4-6 As shown, a mining method of layered cemented filling with downward approach, the stope approach 4 is a vertical layered road with two wings, 21m long, hexagonal cross-section, 2.6m wide at the top and bottom, 5.4m wide at the waist, and 5.4m high. 4m, stope approach 4 is arranged in such a way that the adjacent stope approach 4 is staggered by half a layer in vertical height, that is, 2.0m, the stope approach 4 is mined one by one, and the height of each mining layer is lowered by 2.0m. A vein-piercing approach 11 is respectively arranged on both wings of the vertical ore body in the stope. The height of the vein-piercing approach 11 is 2-3 meters and the width is 3-5 meters. When back mining after the layer is opened, the stope approach 4 facing the mine shaft 8 is back mined earlier, and the layered road 7 is dug ahead at the same time. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com