Block type multidirectional forging device

A multi-directional forging and blocking technology, applied in forging/pressing/hammer devices, forging presses, forging presses, etc., can solve problems such as frame or base deformation, low work efficiency, and workpiece processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

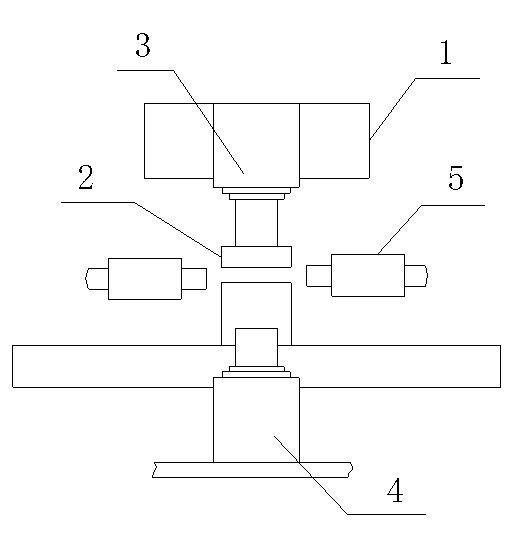

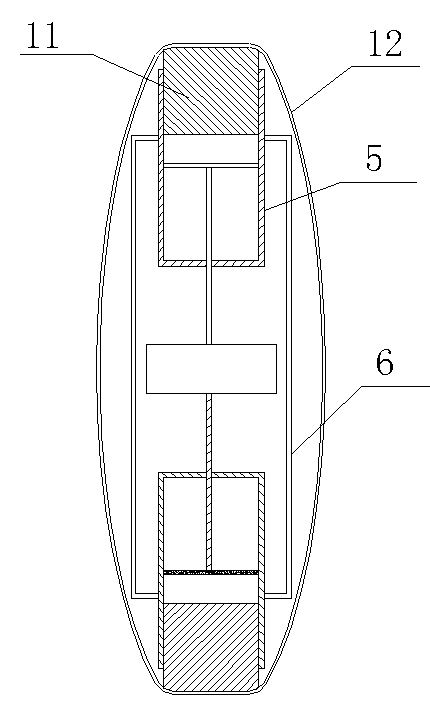

[0025] like figure 1 , 2 As shown, a closed-type multi-directional forging device includes a frame 1, a mold 2 for forming products, and a hydraulic transmission device fixedly arranged on the frame 1 and acting on the mold 2; the hydraulic transmission device includes a The main cylinder 3 above the mold 2, the jacking cylinder 4 arranged under the mold 2 for blanking, and the lateral extrusion cylinder 5 for laterally extruding the workpiece, there are two lateral extrusion cylinders 5, The rear end of the lateral extruding cylinder 5 is provided with movable elements that can move along the inner wall of the lateral extruding cylinder 5; The outside is a fastener that fixedly connects multiple movable elements in turn, and the fastener is a closed ring structure.

[0026] By setting movable elements at the rear end of the lateral extrusion cylinders and making the movable elements fixedly connected with the fasteners, when each lateral extrusion cylinder is extruding the ...

Embodiment 2

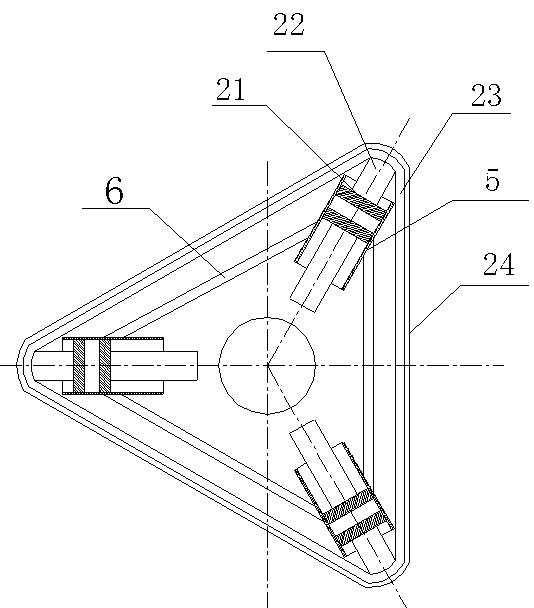

[0030] like image 3 As shown, the rest are the same as in Embodiment 1, the difference is that the lateral extruding cylinders 5 are 3 evenly distributed, and the movable element is the lower piston 21 arranged on the inner side of the lateral extruding cylinders 5, and the lower piston 21 is provided with Connecting rod 22 is arranged, and connecting rod 22 stretches out and fixes with fastener on the outside of lateral extruding oil cylinder 5. The fastener is a polygonal frame 23, or a wound steel belt 24 or a steel wire rope, or a polygonal frame 23 with a steel belt 24 or a steel wire rope wound outside. The frame 23 is a triangular frame, and the fasteners are inscribed to the movable elements. When the lateral extrusion oil cylinder 5 does work, the reaction force produced will push the lower piston 21 and the connecting rod 22 to move. The force produced by each lateral extrusion cylinder is balanced, and the force does not act on the frame, which reduces the load-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com