Double-vane hydraulic self-servo oscillating cylinder

A self-servo, swing cylinder technology, applied in the field of double-blade hydraulic self-servo swing cylinder, can solve the problems of complex structure, small flow, poor dynamic characteristics of the valve core, etc., and achieve the effect of simple oil channel structure, simple structure and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

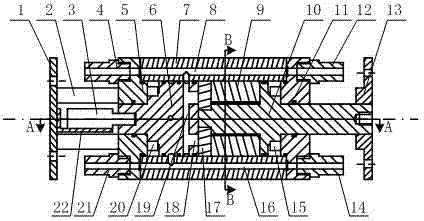

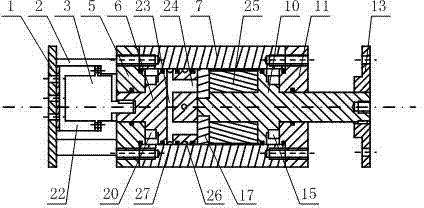

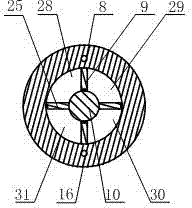

[0041]A double vane hydraulic self-servo swing cylinder. The double vane hydraulic self-servo swing cylinder as figure 1 and figure 2 As shown, it includes a motor 3, a cylinder body 7, a valve body 6, a swing output shaft 10, a flow plate 17, a fixed block 9, a vane 25, a left end cover 5 and a right end cover 11.

[0042] Such as figure 1 and figure 2 As shown, the left end of cylinder block 7 is equipped with left end cover 5, and left bearing 20 is housed in cylinder block 7, and left bearing 20 is close to the inner side of left end cover 5, and the stepped shaft on the left side of valve body 6 passes through left bearing 20 and left end cover 5 The center hole of the valve body is installed in the cylinder body 7, the left end of the valve body 6 is fixedly connected with the output shaft of the motor 3, the motor 3 is fixedly connected with the left flange 1 through the bracket plate 22, and the left flange 1 is connected with the left end through the bracket rod ...

Embodiment 2

[0055] A double vane hydraulic self-servo swing cylinder. Except following situation, all the other are with embodiment 1.

[0056] When the double-blade hydraulic self-servo swing cylinder adopts multi-stage series connection, the plug 14 installed at the outlet of the high-pressure oil passage of the right end cover 11 is replaced with a high-pressure oil outlet pipe joint 14, and the high-pressure oil outlet pipe joint 14 passes through the pipeline and the lower The high-pressure oil inlet pipe joint 21 of the first stage is connected; the plug 12 installed at the inlet of the low-pressure oil passage of the right end cover 11 is replaced with the low-pressure oil inlet pipe joint 12, and the low-pressure oil inlet pipe joint 14 is connected to the low-pressure oil outlet pipe of the next stage through the pipeline. Connector 4 is connected. A plug 14 is installed at the high-pressure oil passage outlet of the right end cover 11 of the last-stage double-blade hydraulic se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com