Four-drill auger miner

A technology of shearer and drill bit, which is applied to earth-moving drilling, cutting machinery and other directions, can solve the problems of time-consuming connection of drill pipes, poor coal conveying effect, low cutting efficiency, etc., and achieves easy maintenance, convenient coal loading, The effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

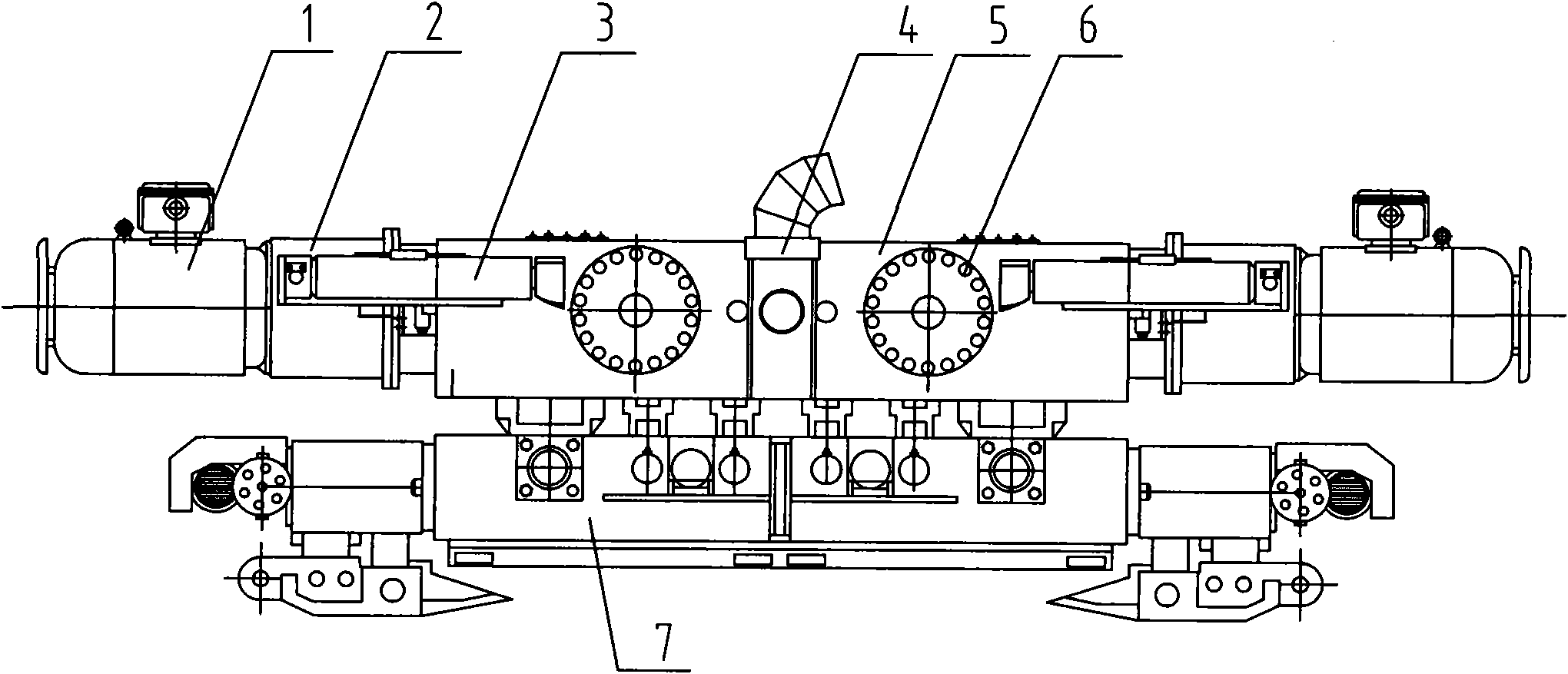

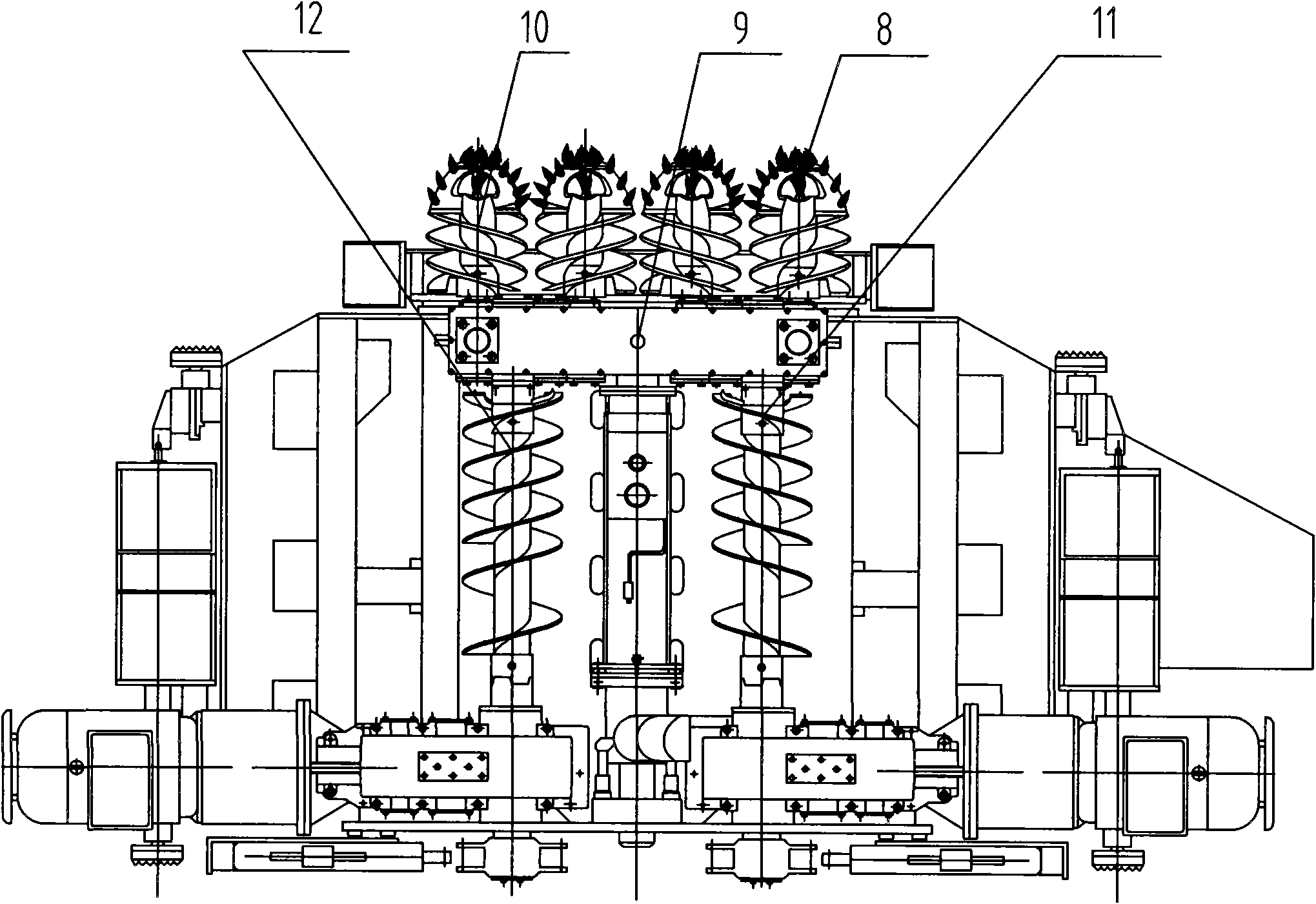

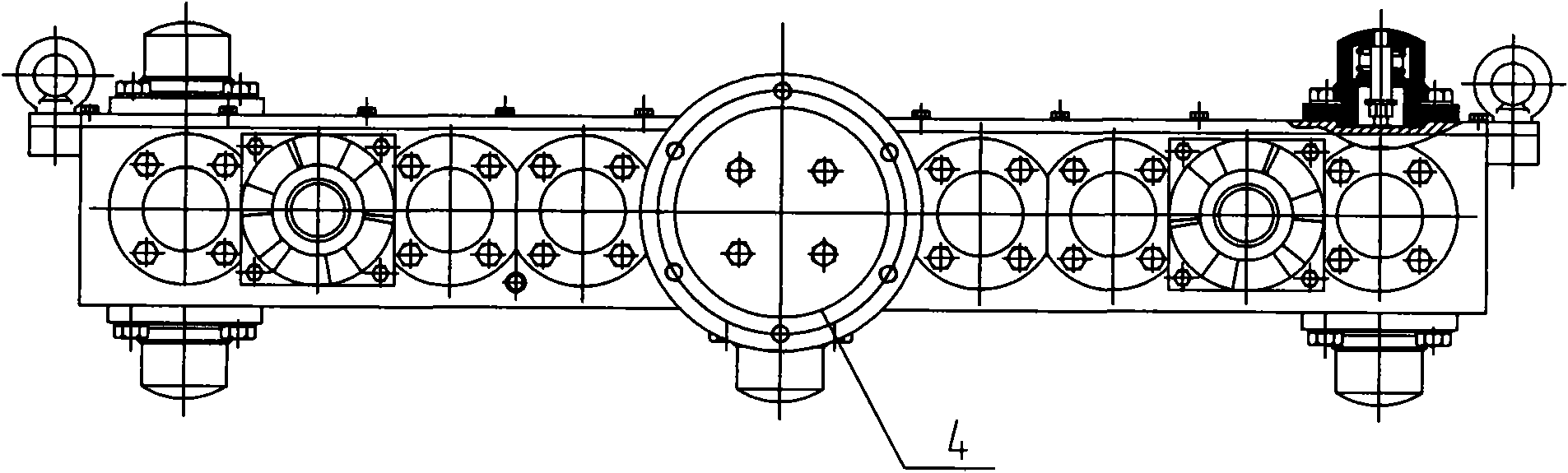

[0014] The four-bit drilling shearer of the present invention is mainly composed of a symmetrically arranged explosion-proof motor 1, a hydraulic coupling 2, a fine-tuning hydraulic cylinder 3, an air cylinder 4, a reducer 5, a fine-tuning device 6, a frame 7, and a fixed box 9 , drill bits, and drill pipes; the explosion-proof motor 1 is arranged at the rear of the frame 7, and the symmetrically arranged explosion-proof motor 1 is respectively connected with the symmetrically arranged reducer 5 through the hydraulic coupling 2, and the hydraulic coupling 2 is provided with fine-tuning The oil cylinder 3 and the reducer 5 are provided with a fine-tuning device 6, and the output shafts of the symmetrically arranged reducer 5 are respectively connected with a left-handed drill rod 11 and a right-handed drill rod 12; the fixed box 9 is fixed on the front part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com