Patents

Literature

130results about How to "Reduce depletion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

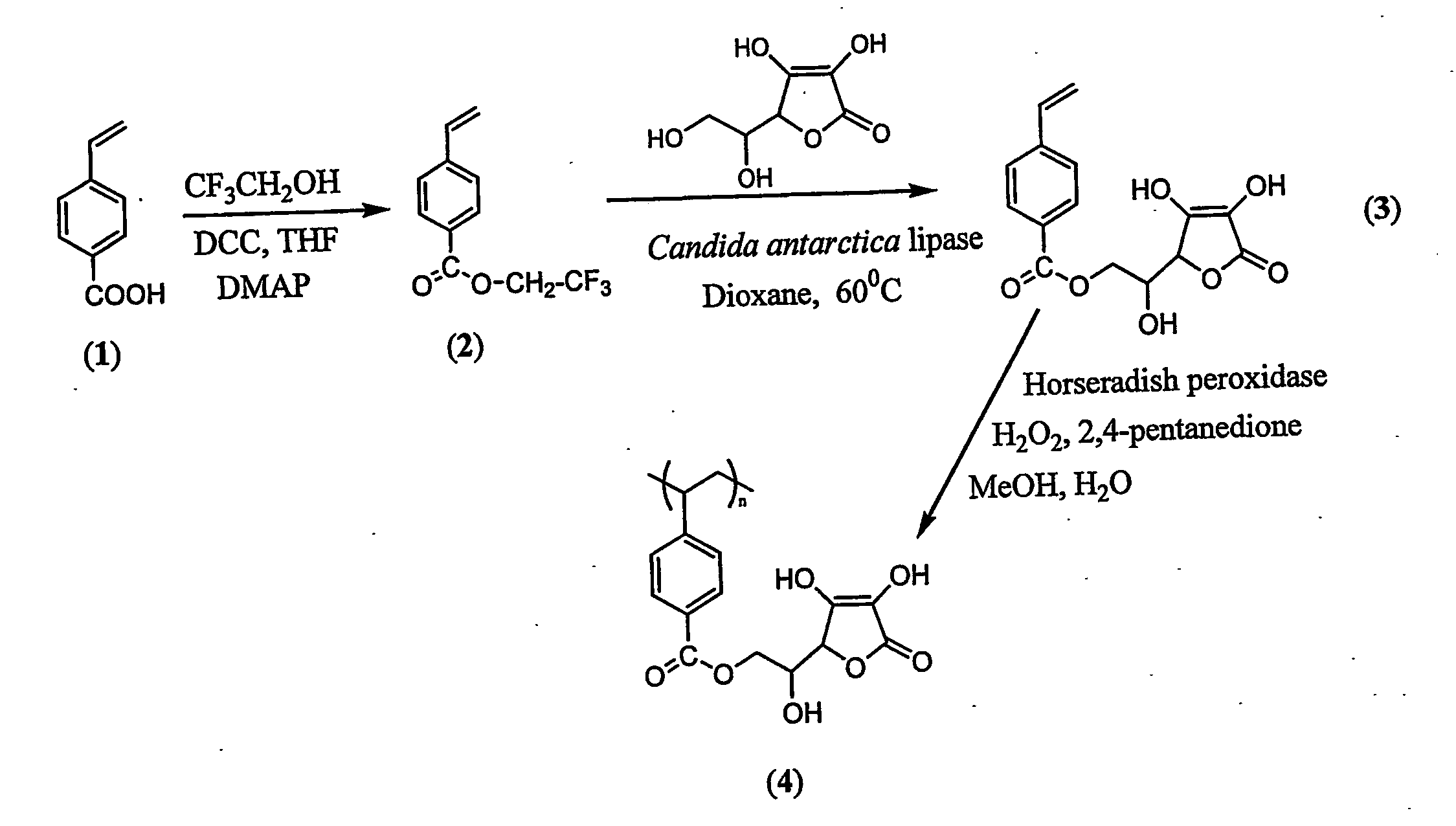

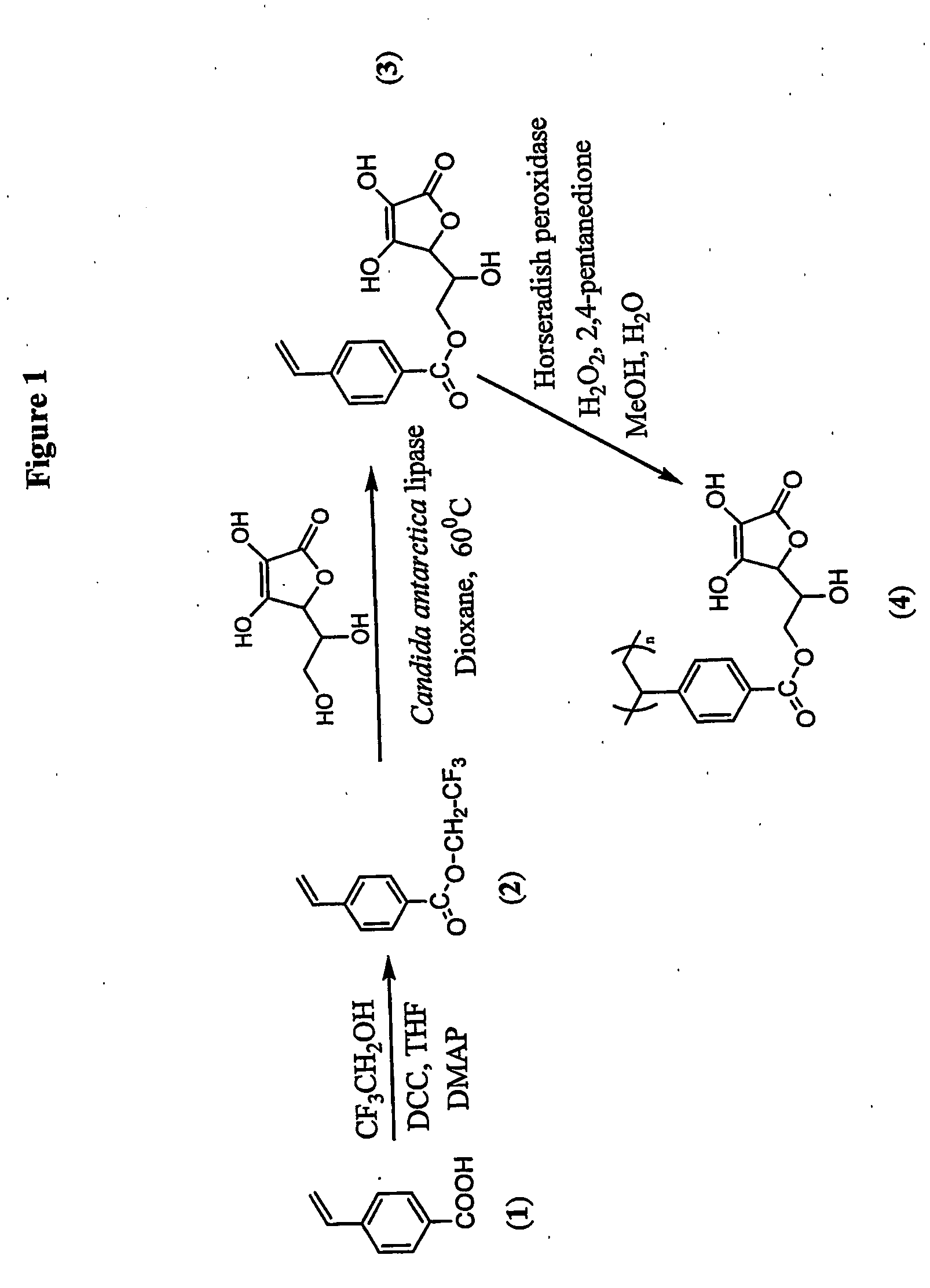

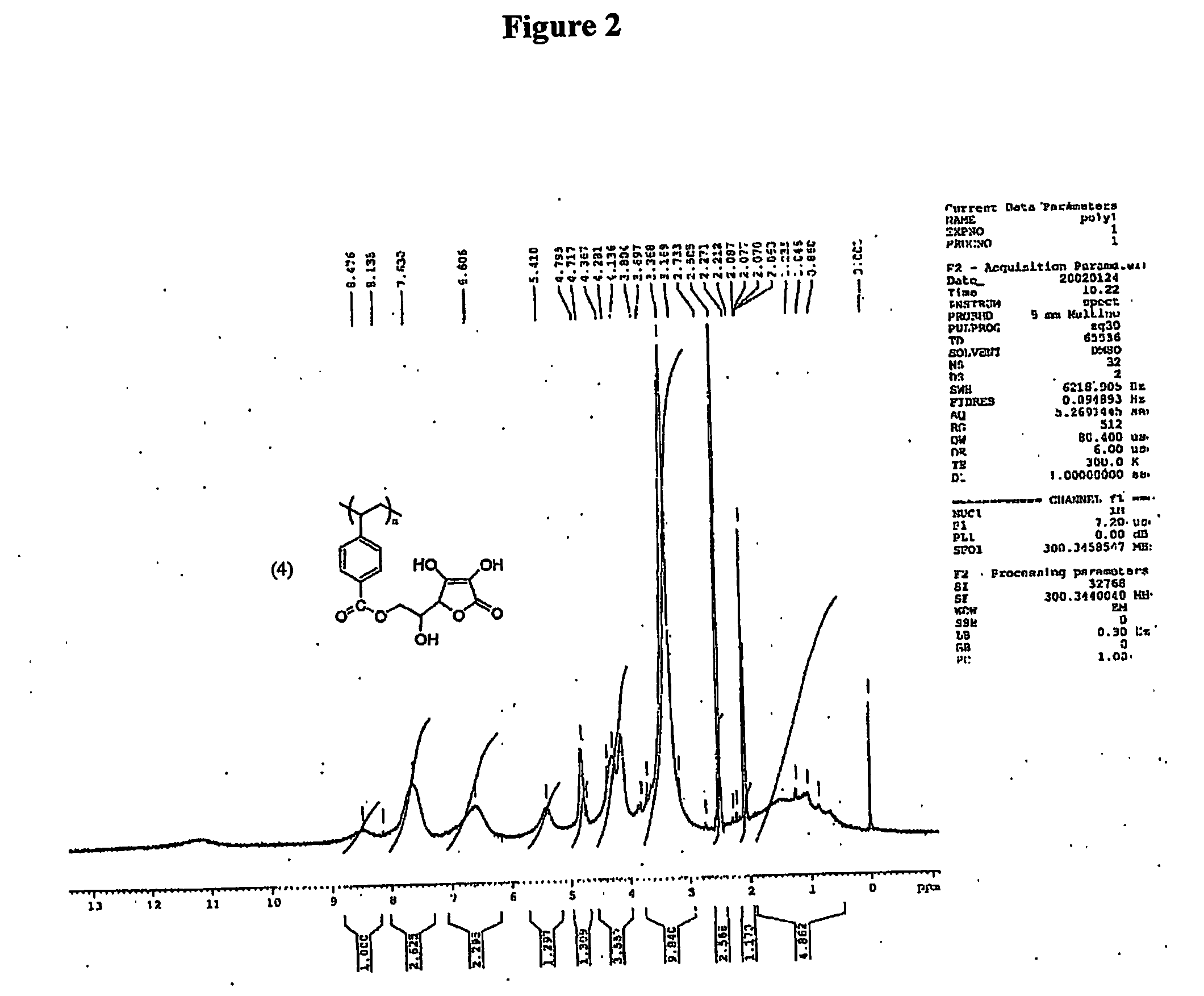

Antioxidant-functionalized polymers

InactiveUS20070010632A1Low yieldReduce sensitivitySuture equipmentsOrganic chemistryAntioxidantOxygen

Methods and compositions are disclosed for the preparation of free radical scavenging polymers and polymer films functionalized with antioxidants. Enzymatic and chemical tailoring of monomers with antioxidants followed by enzymatic polymerization is described. These antioxidant functionalized polymers can increase shelf life and quality of food products, as well as, increase effectiveness of pharmaceutical agents when used as packaging or as coatings on packaging for oxygen sensitive materials. The novel enzymatic covalent coupling of antioxidants to a polymer enhances the free radical scavenging ability of packaging while also inhibiting the escape of the antioxidants, and thus limiting exposure and / or absorption by an individual. In addition to its use in food or pharmaceutical packaging, methods are disclosed for using the antioxidant coupled polymers in a variety of applications including as coatings on the inside of medical devices, such as stents and catheters, which would substantially reduce free radical damage and / or oxygen depletion during medical procedures. Furthermore, through the coupling of antioxidants to biodegradable polymers, controlled delivery and sustained release of an antioxidant to a subject is possible.

Owner:TRUSTEES OF TUFTS COLLEGE

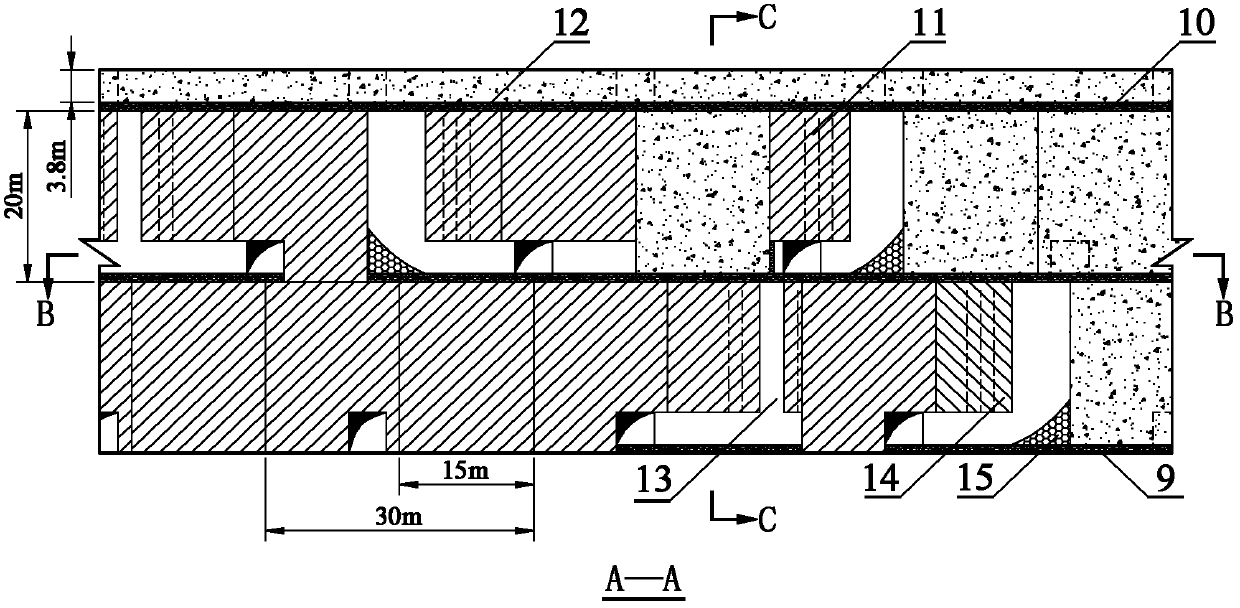

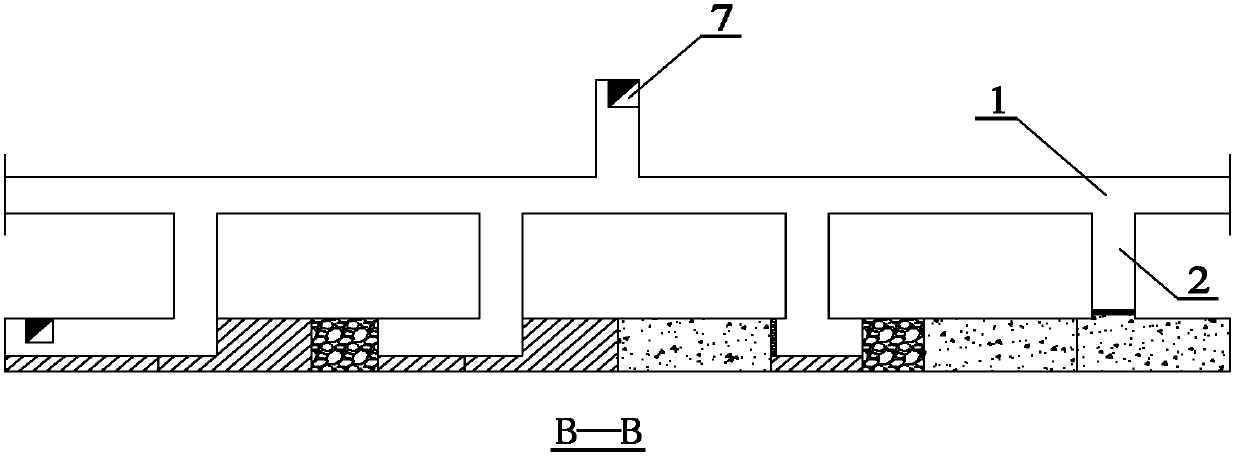

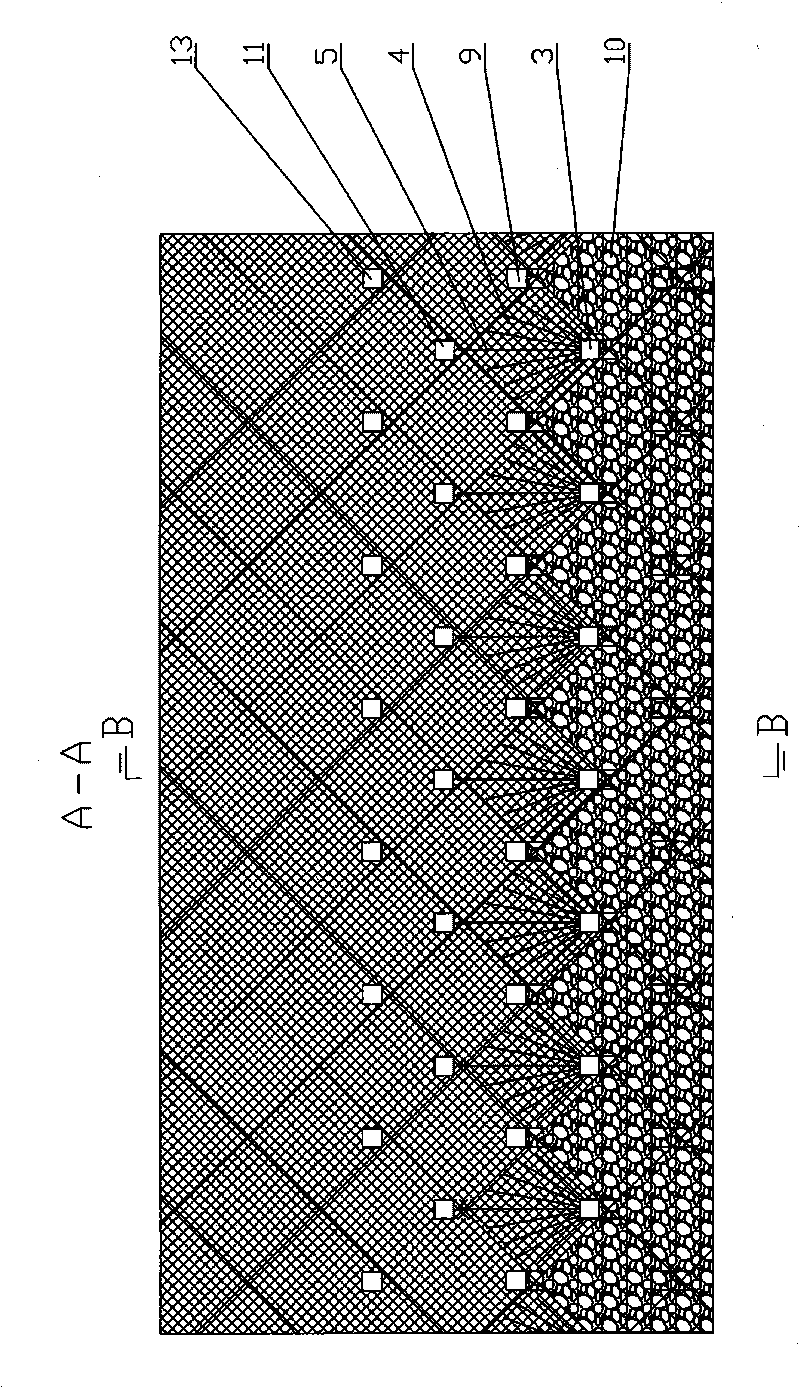

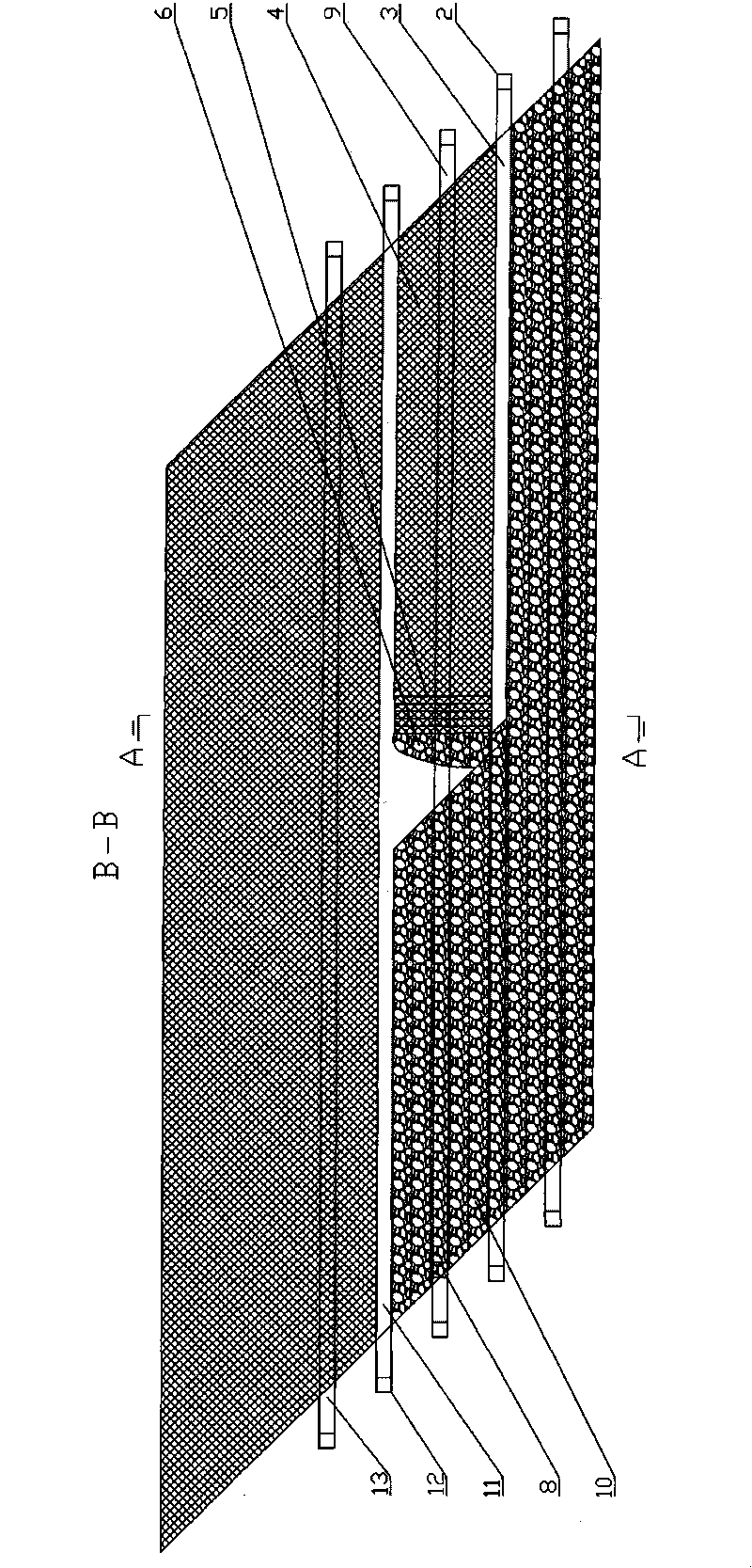

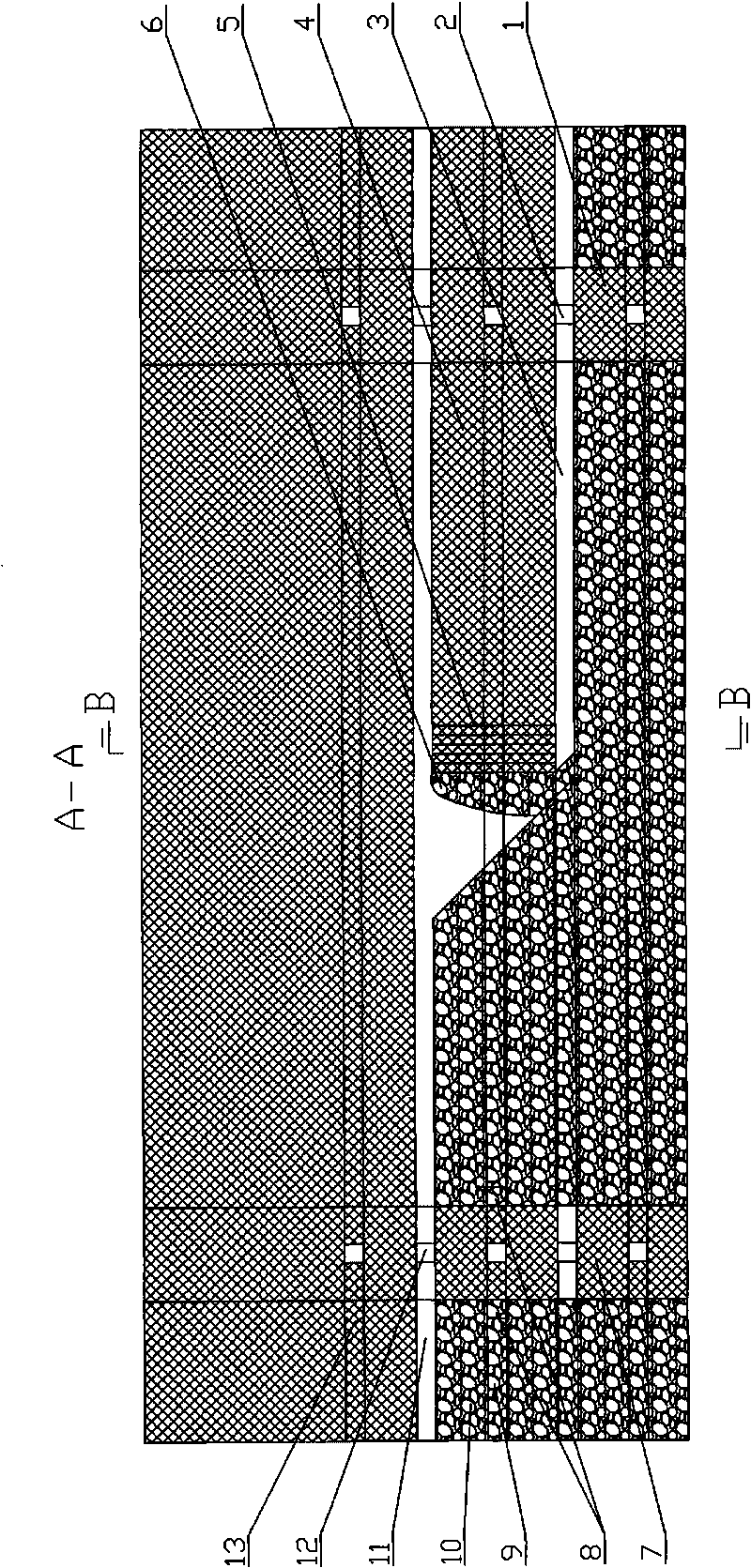

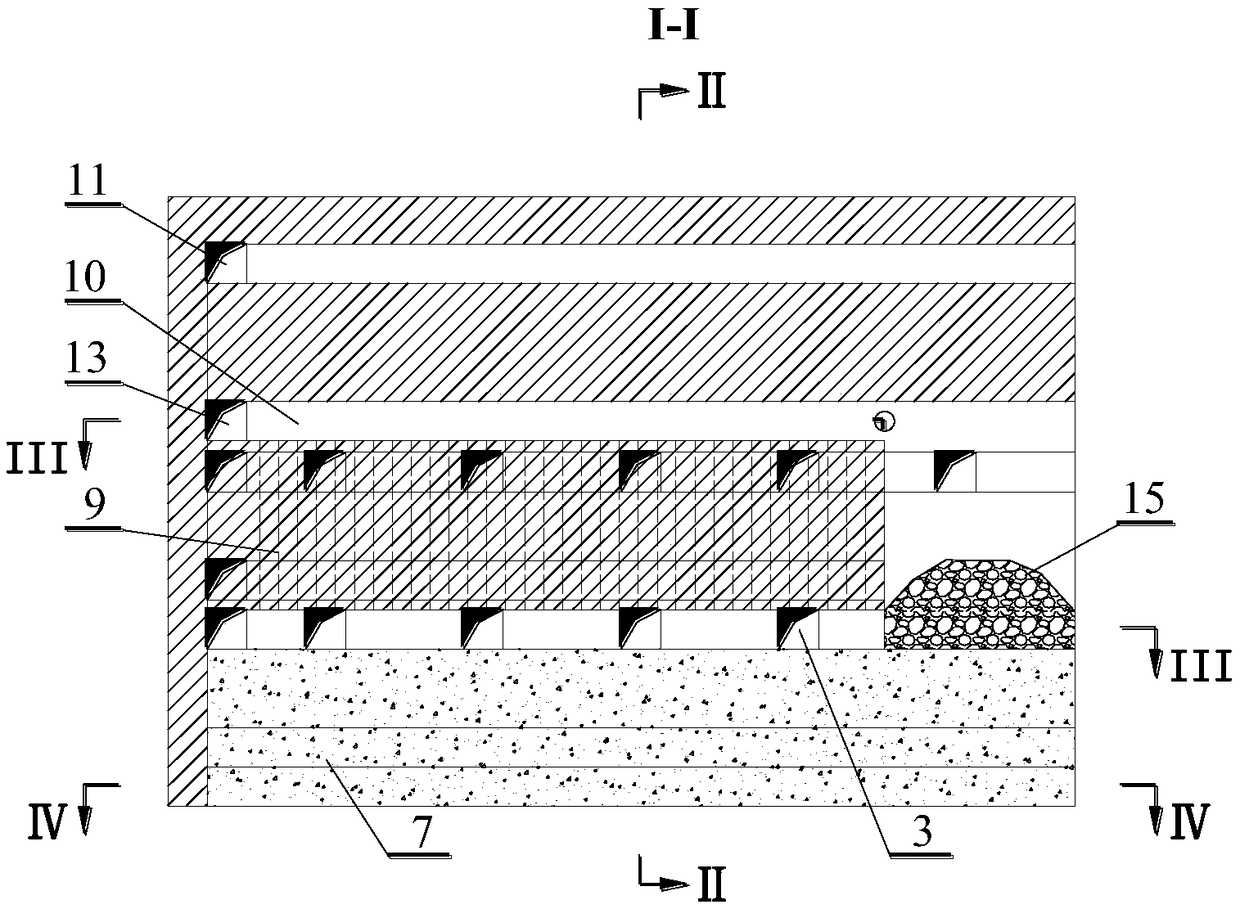

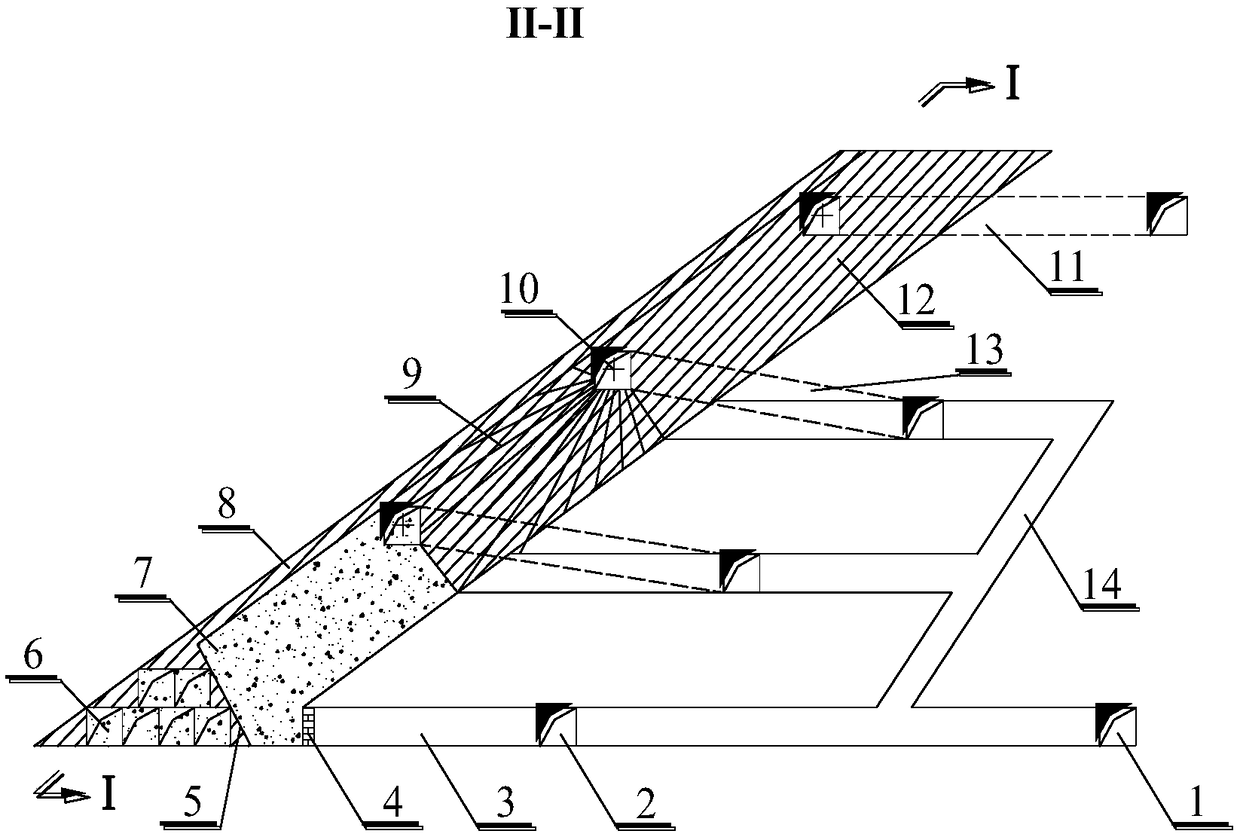

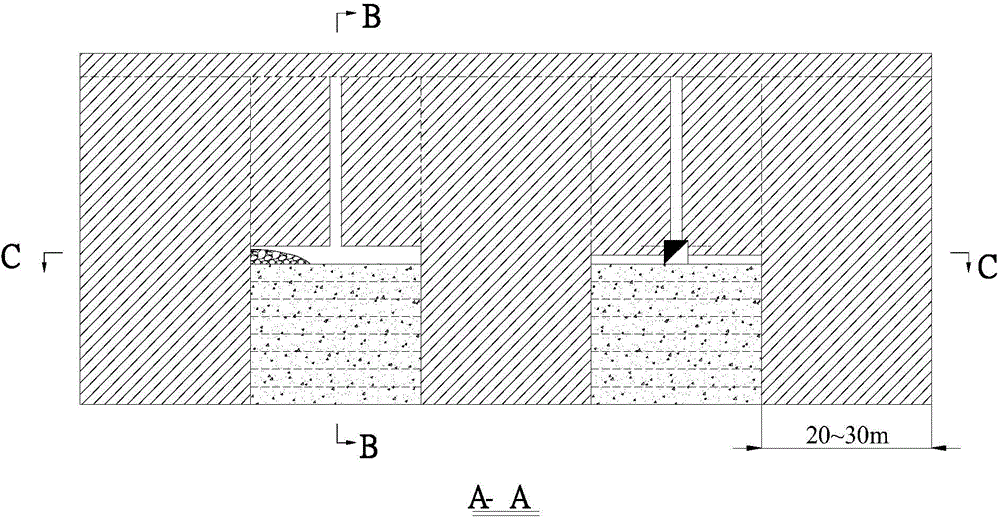

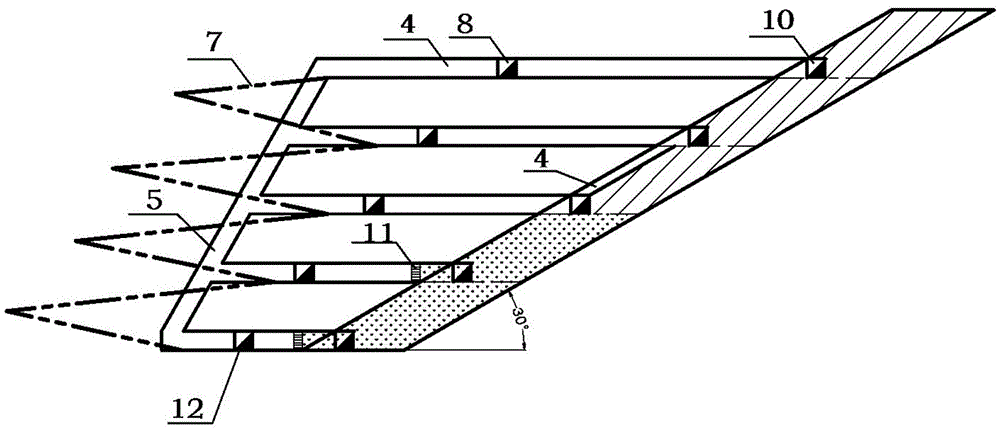

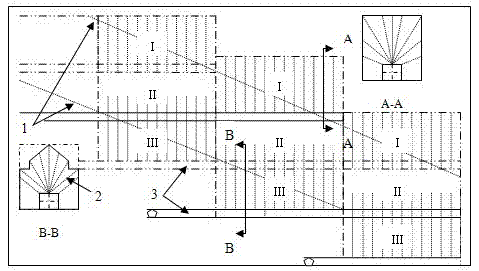

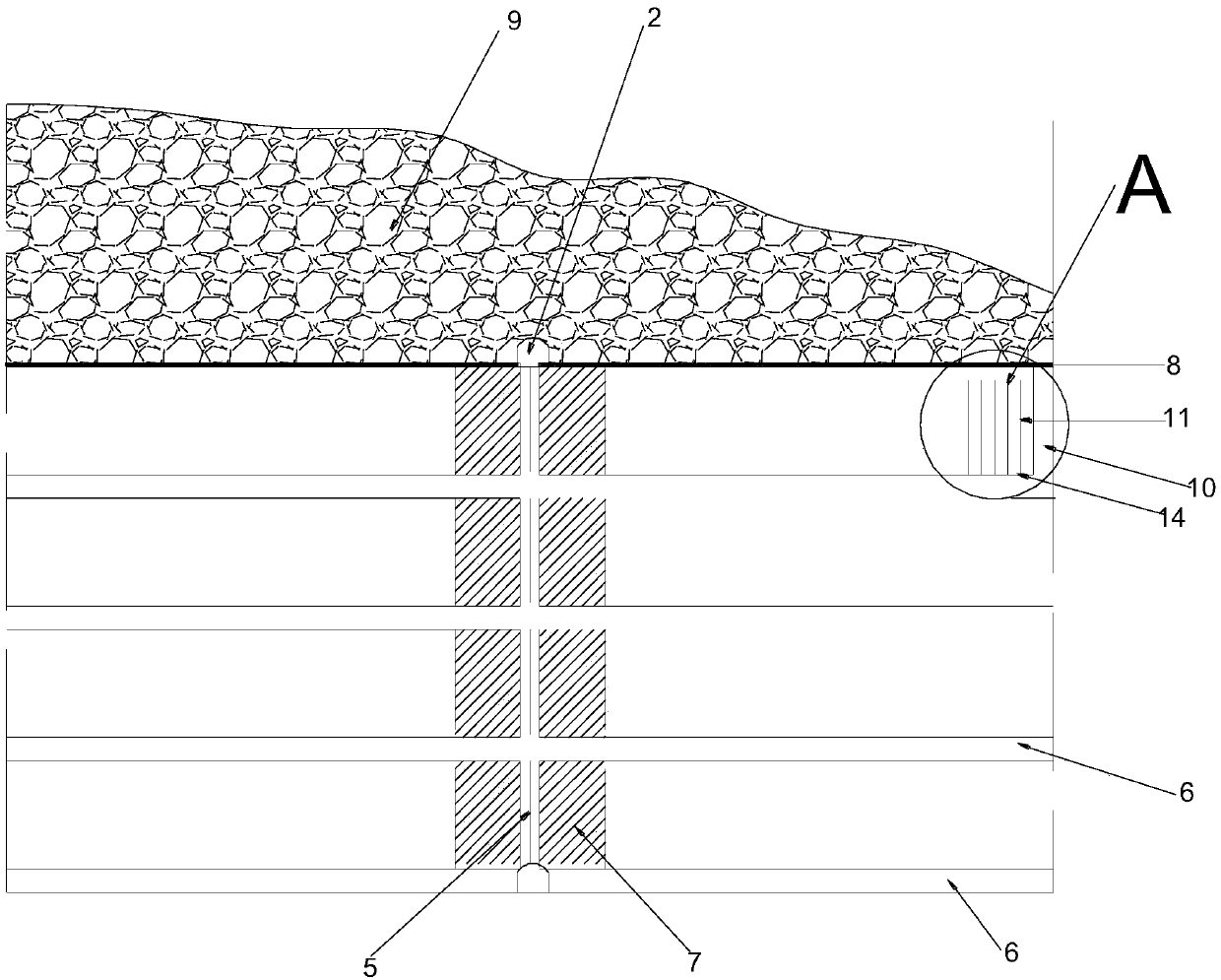

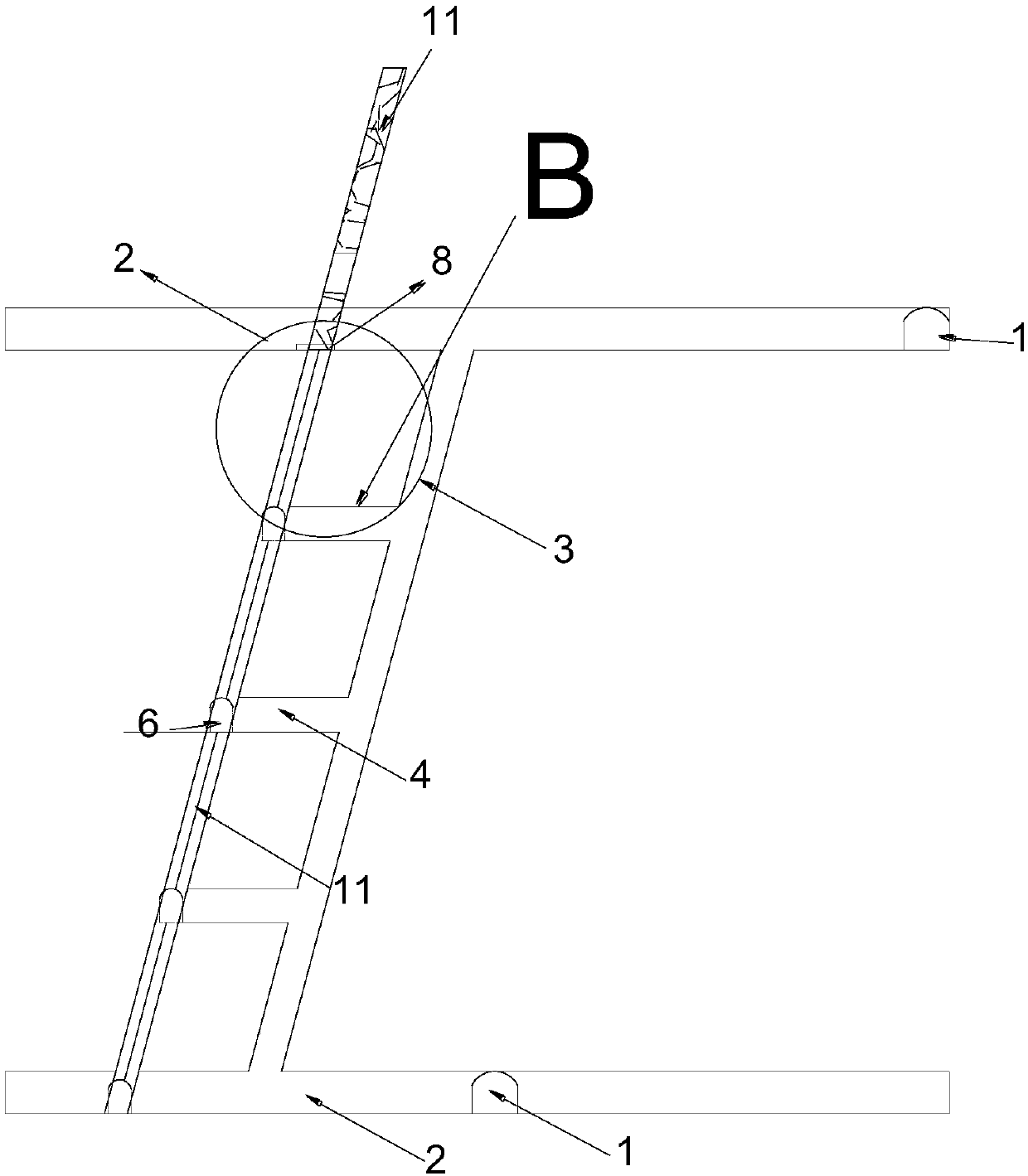

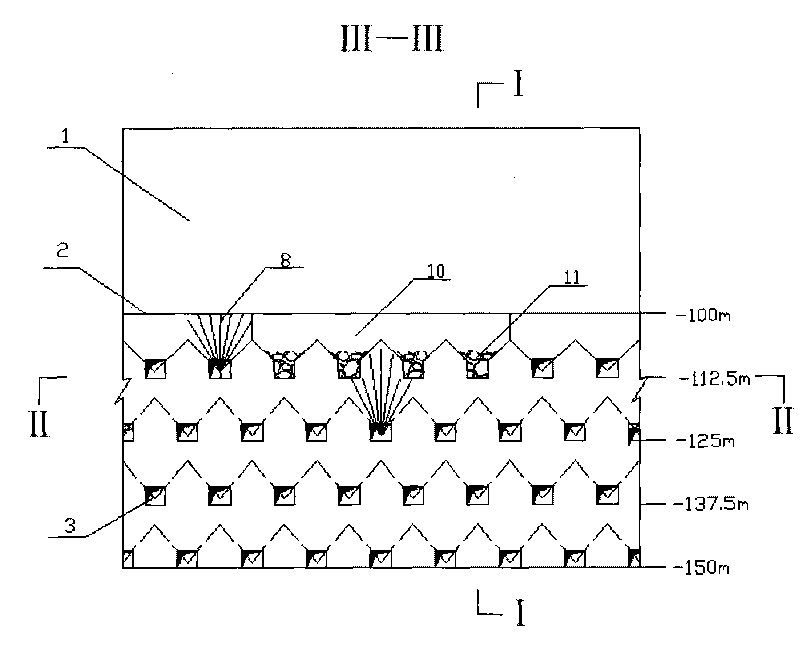

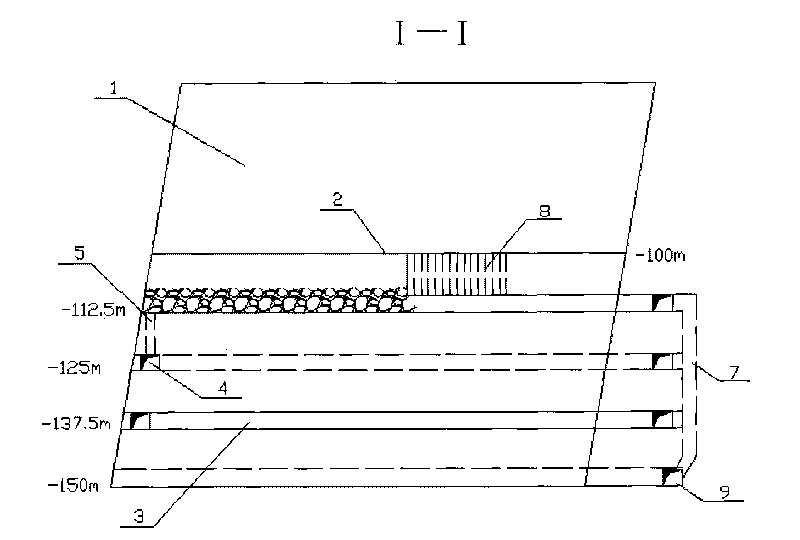

Medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method

InactiveCN102606159AImprove efficiencyImprove securityUnderground miningTunnel/mines ventillationRoom and pillar miningReinforced concrete

The invention discloses a medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method which comprises the following steps: dividing chamber jambs along the trend of an ore body; adopting a rail-less mining aligning system; pre-constructing a high-strength reinforced concrete artificial top in a segmented drilling lane; adopting a stoping sequence from up to down; performing drilling and blasting ore removal on the ore body through the segmented drilling lane at bottom; adopting medium-length hole drilling and remotely controlling a scraper to discharge ore; after finishing the mining of the chamber, utilizing concrete tailings to perform cemented filling; after finishing the mining of the jambs, utilizing concrete tailings or pure tailings to perform cemented filling; after completely stoping the mine chamber in the frame under the protection of the concrete artificial top, starting to stope the jamb adjacent to the segment, and meanwhile stoping the corresponding mine chamber in the frame of the next segment, and then stoping the corresponding jamb of the next segment; and after completely mining the chamber jamb in the middle segment, immediately turning towards the lower middle segment for stoping. The method provided by the invention has the advantages that the safety for mining the heavy-pitch medium thick crushed or ultra-crushed ore body is high, the resource depletion loss rate is low, the mechanical degree is high, the production capacity is high, and the like.

Owner:CENT SOUTH UNIV +1

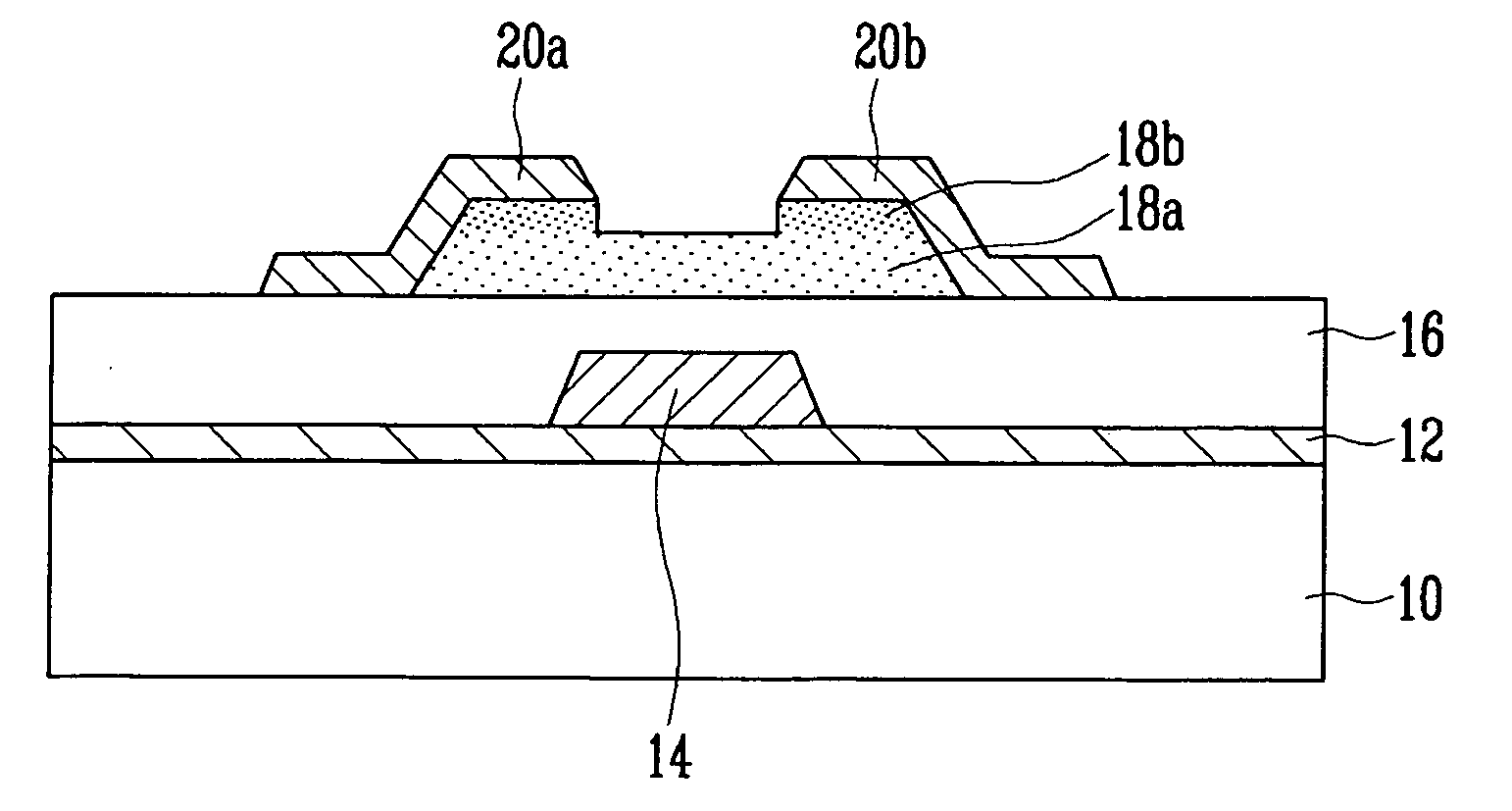

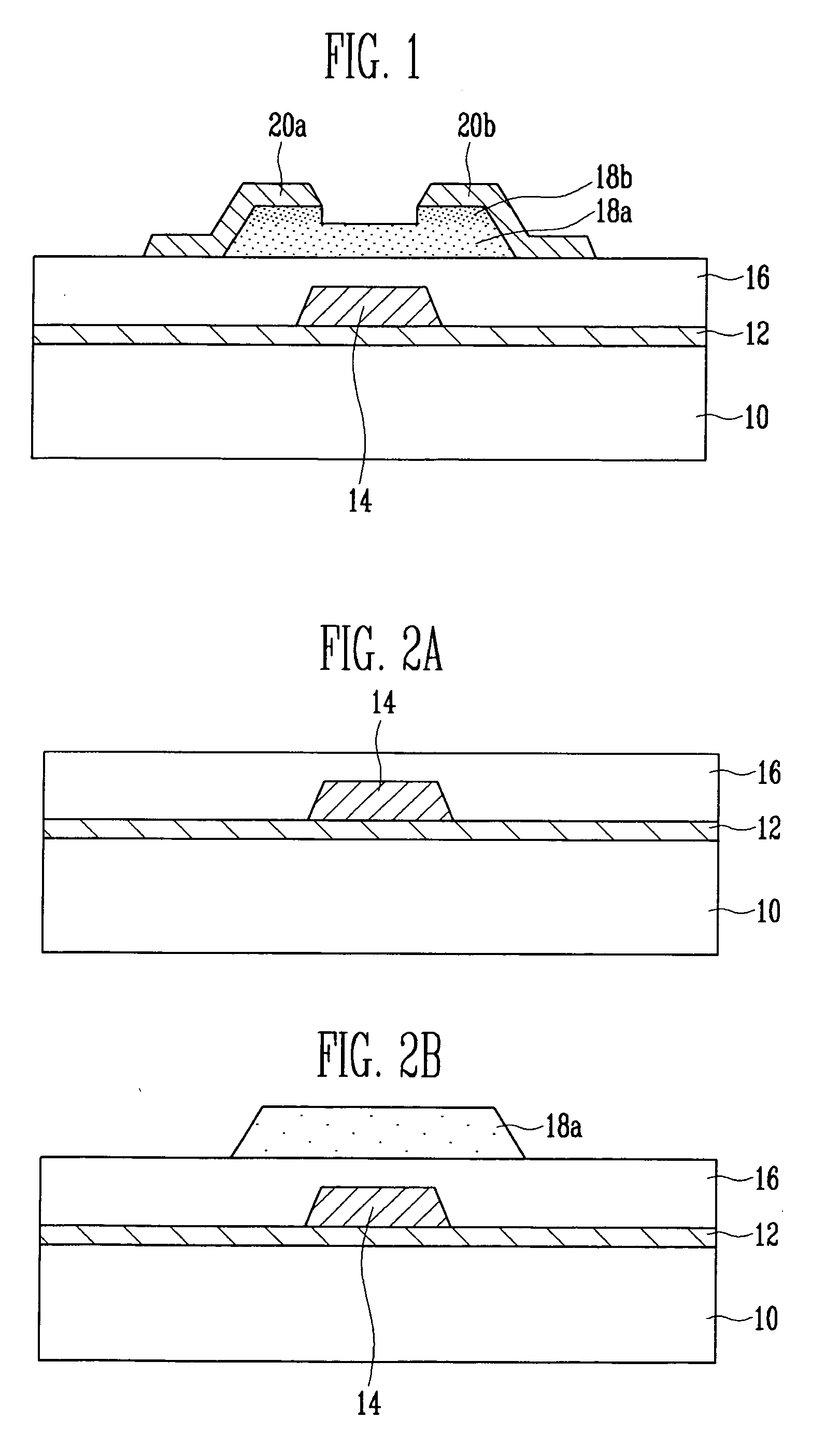

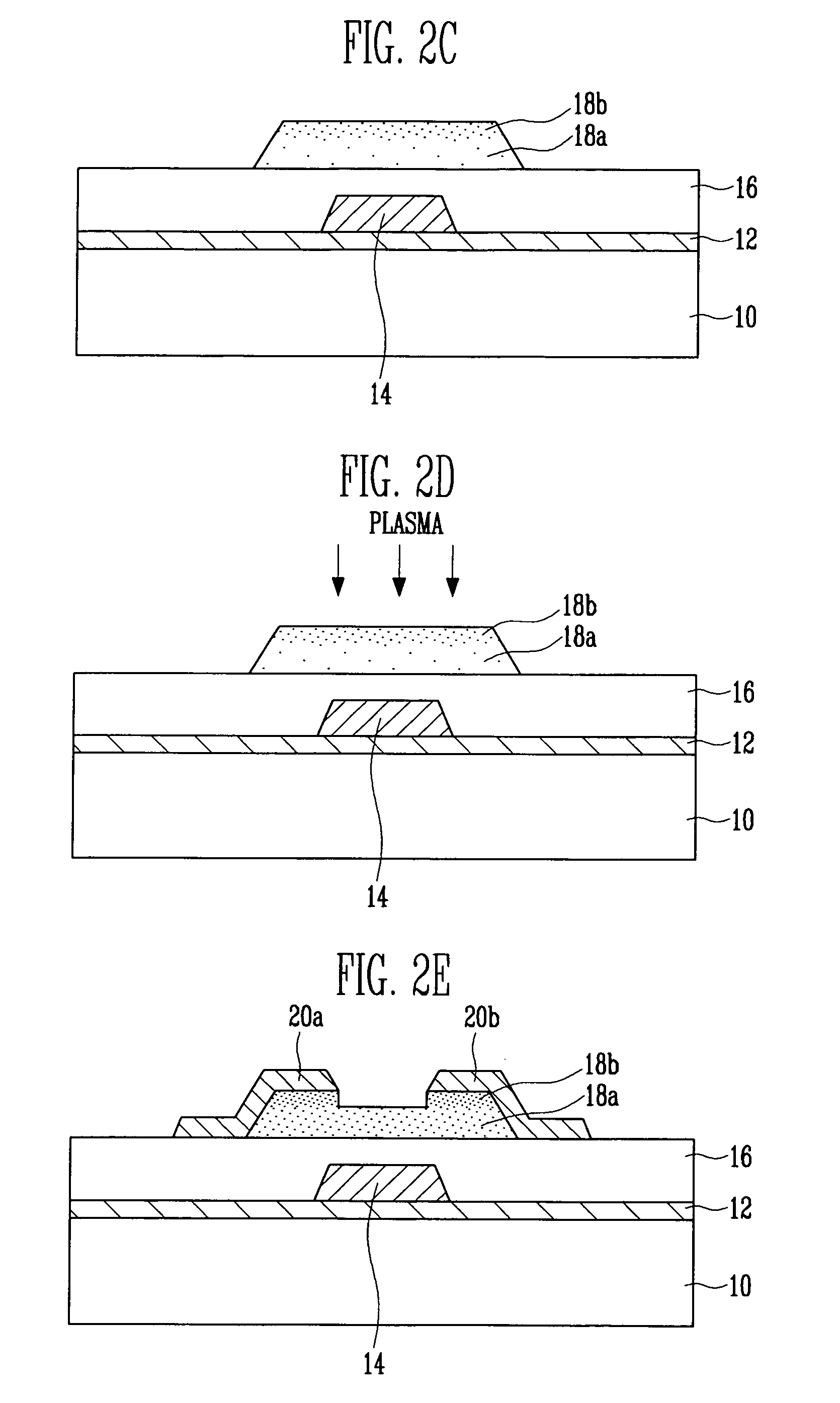

Thin film transistor, method of manufacturing the same and flat panel display device having the same

ActiveUS20090294772A1Easily through energy barrierDepletion width is decreasedDischarge tube luminescnet screensLamp detailsCharge carrierOhmic contact

A thin film transistor is provided having an oxide semiconductor as an active layer, a method of manufacturing the thin film transistor and a flat panel display device having the thin film transistor. The thin film transistor includes: a gate electrode formed on a substrate; an oxide semiconductor layer isolated from the gate electrode by a gate insulating layer and including channel, source and drain regions; source and drain electrodes coupled to the source and drain regions, respectively; and an ohmic contact layer interposed between the source and drain regions and the source and drain electrodes. In the TFT, the ohmic contact layer is formed with the oxide semiconductor layer having a carrier concentration higher than those of the source and drain regions.

Owner:SAMSUNG DISPLAY CO LTD

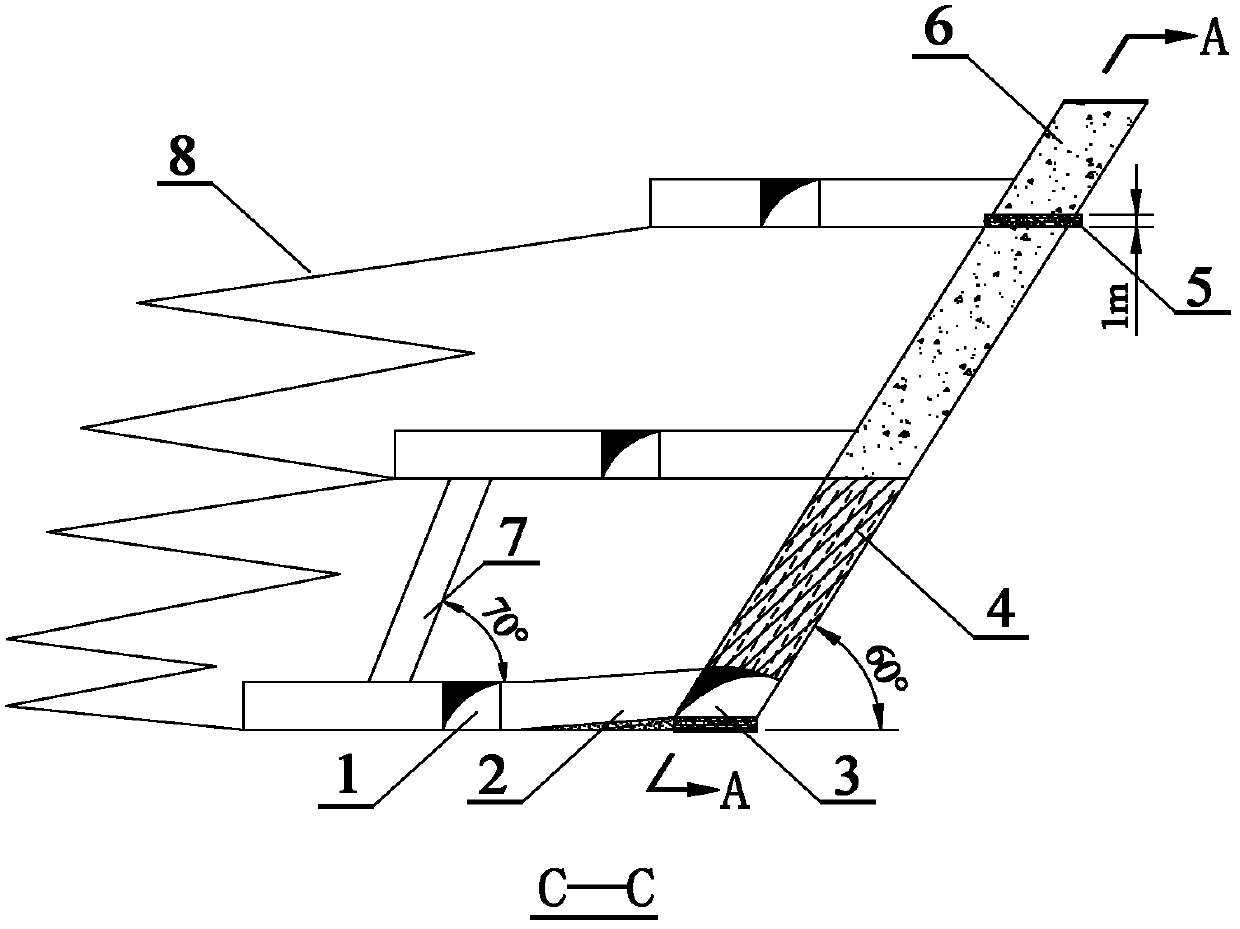

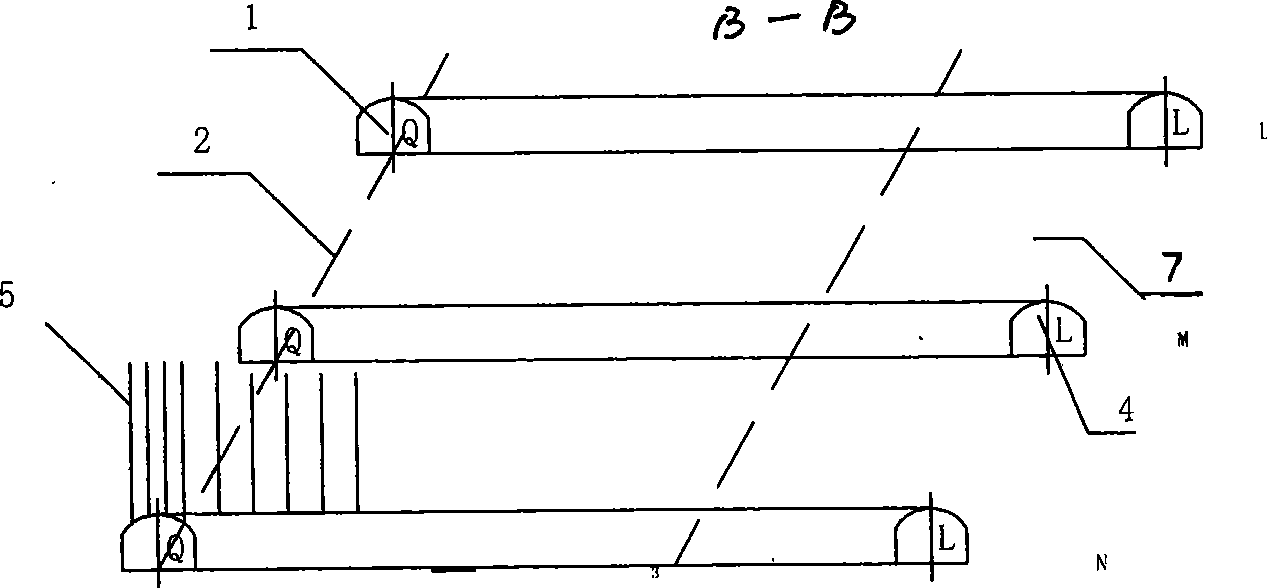

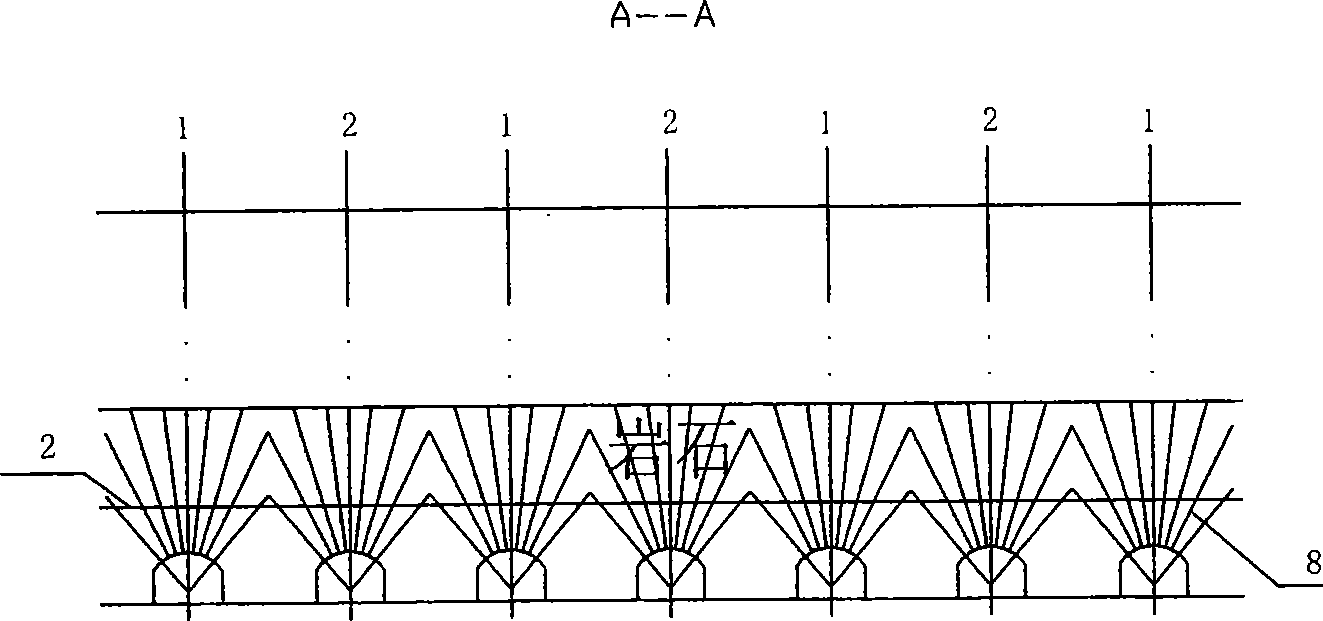

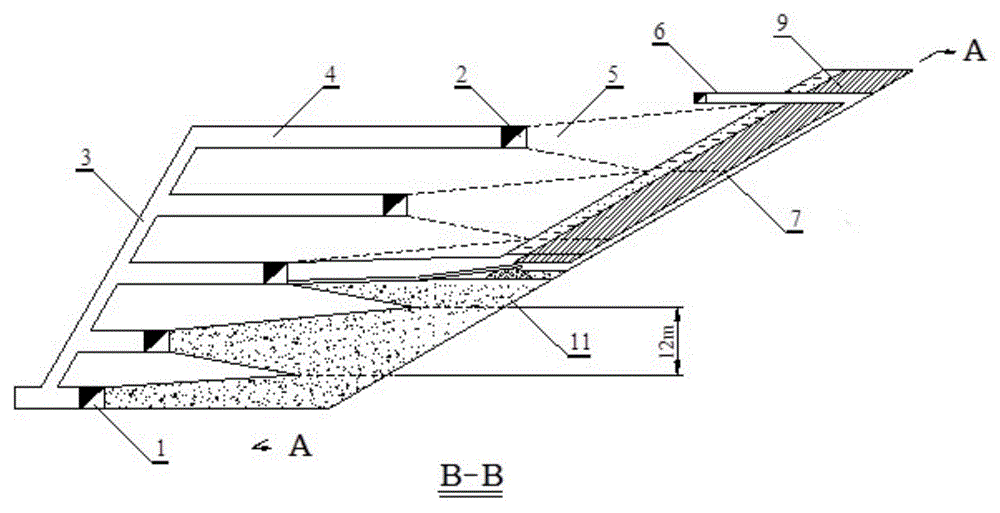

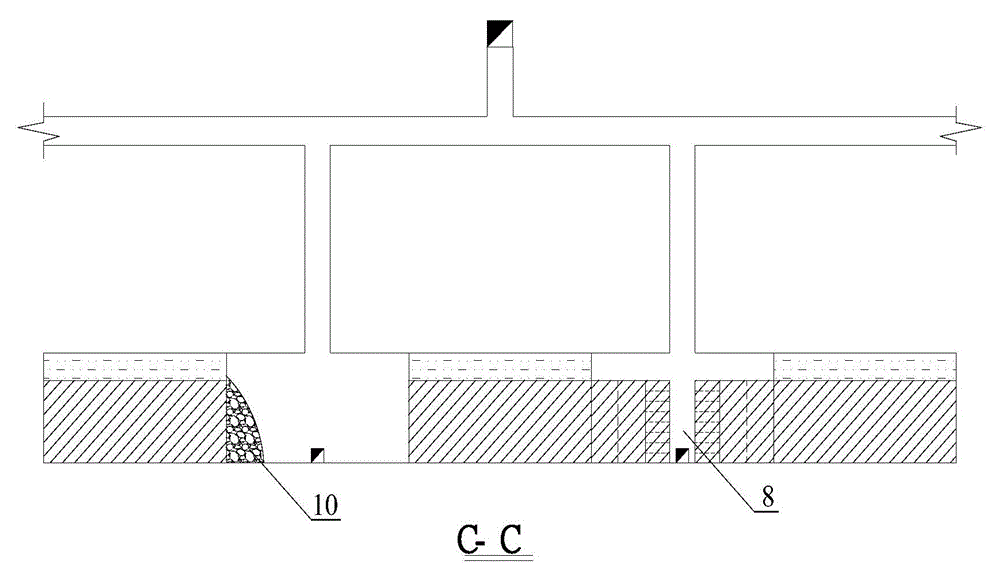

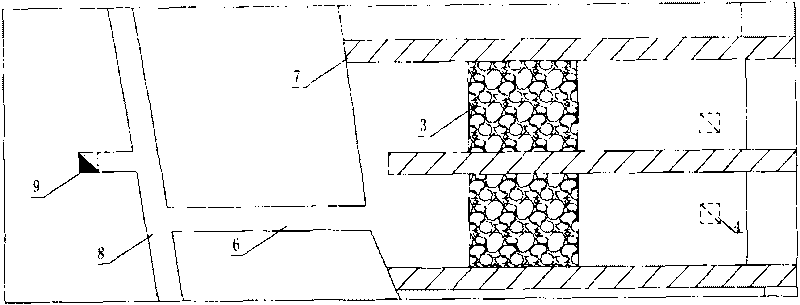

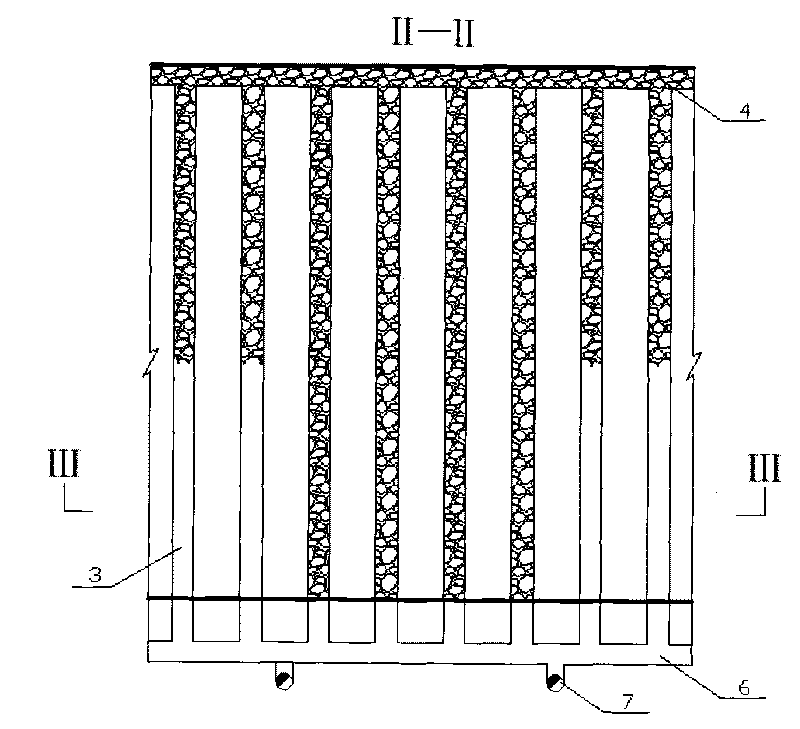

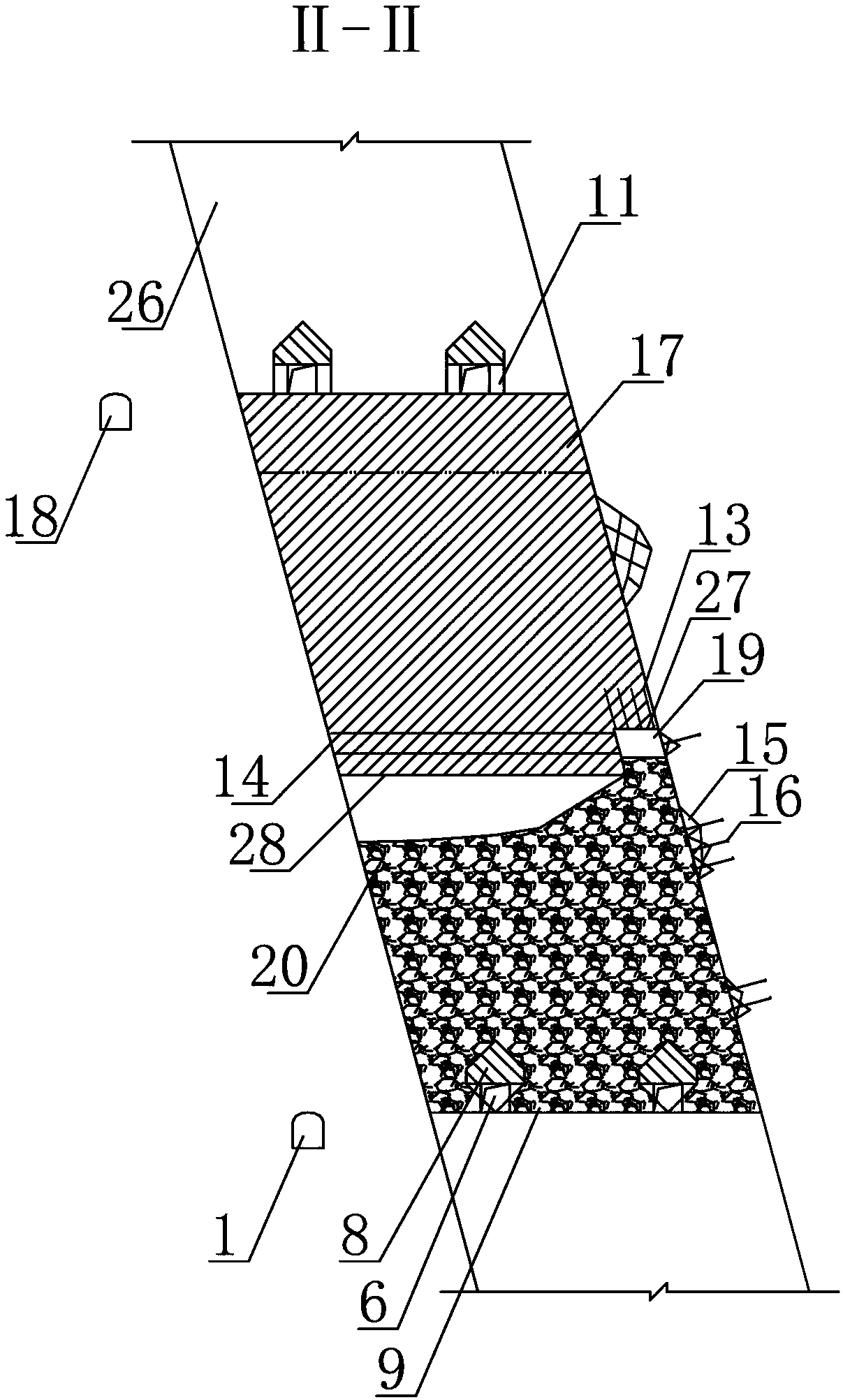

Sublevel fill-mining method

The invention discloses a sublevel fill-mining method. By utilizing the natural angle of repose characteristics of caving ores and dry mine fill and according to medium hole drilling device-adapted height and the ore-permitted exposed area, space and time at present, sublevel mining is carried out from the bottom to the top in the open-field state and the dry mine fill is adopted for filling in time. The sublevel fill-mining method has the advantages of an open-field method and a dry fill and sublevel caving method without sill pillar, thereby forming a novel sublevel dry fill-mining method without sill pillar, and is particularly applied to ore mines with large-scale ore body and high yield requirement. The top filling of a filling body is realized by the self-weight of the filling body; a vibratory roller or a device special for underground tamping is adopted to apply pressure to the filling body through a lane top plate to tamp the filling body in a vibration mode, so that the filling body generates a certain bearing force to the above ore body or the rock mass. The sublevel fill-mining method is a mining method which has the advantages of safety, high efficiency, high mining capacity, low loss and dilution, and low production cost.

Owner:HEBEI HAN XING INST OF MINE & METALLURGY DESIGN

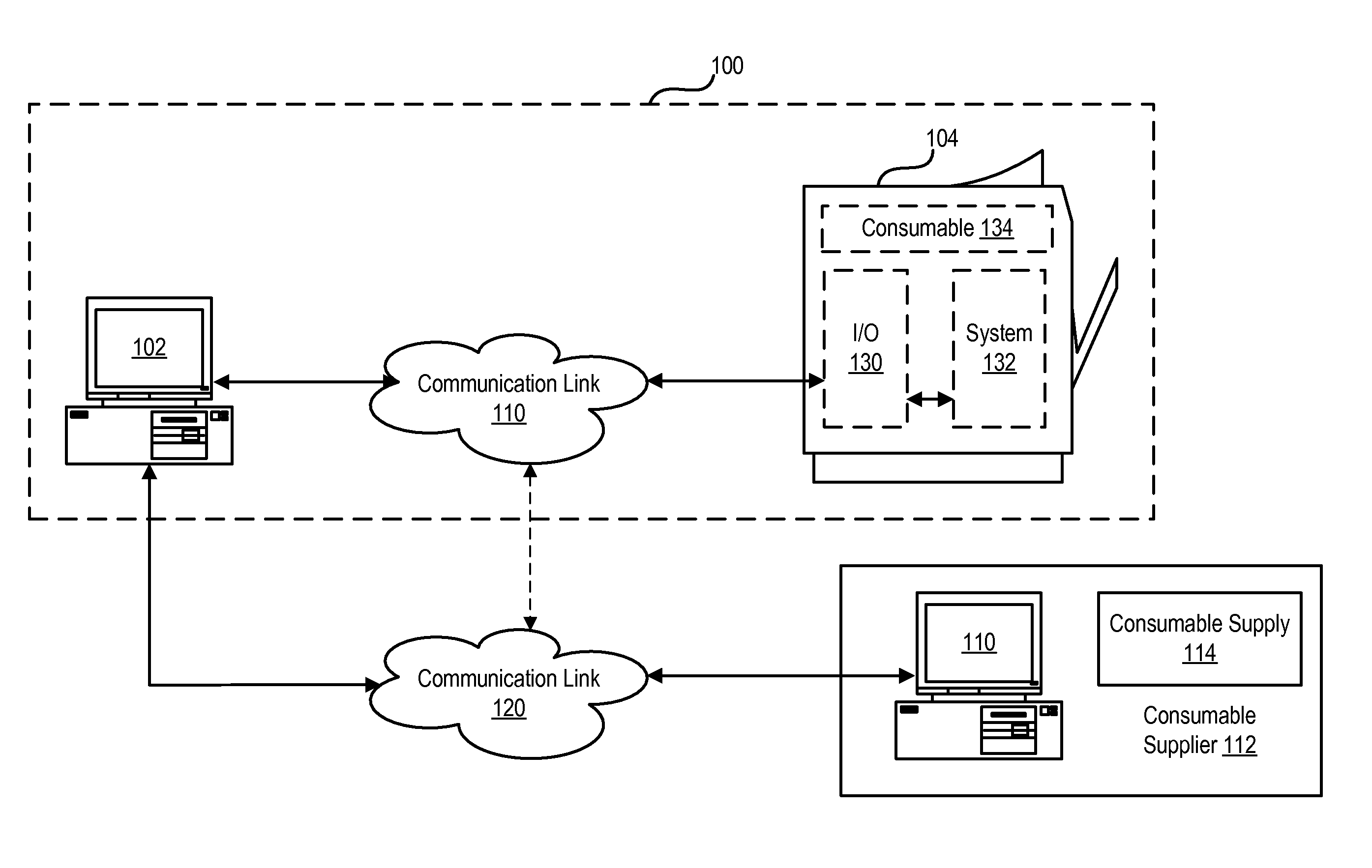

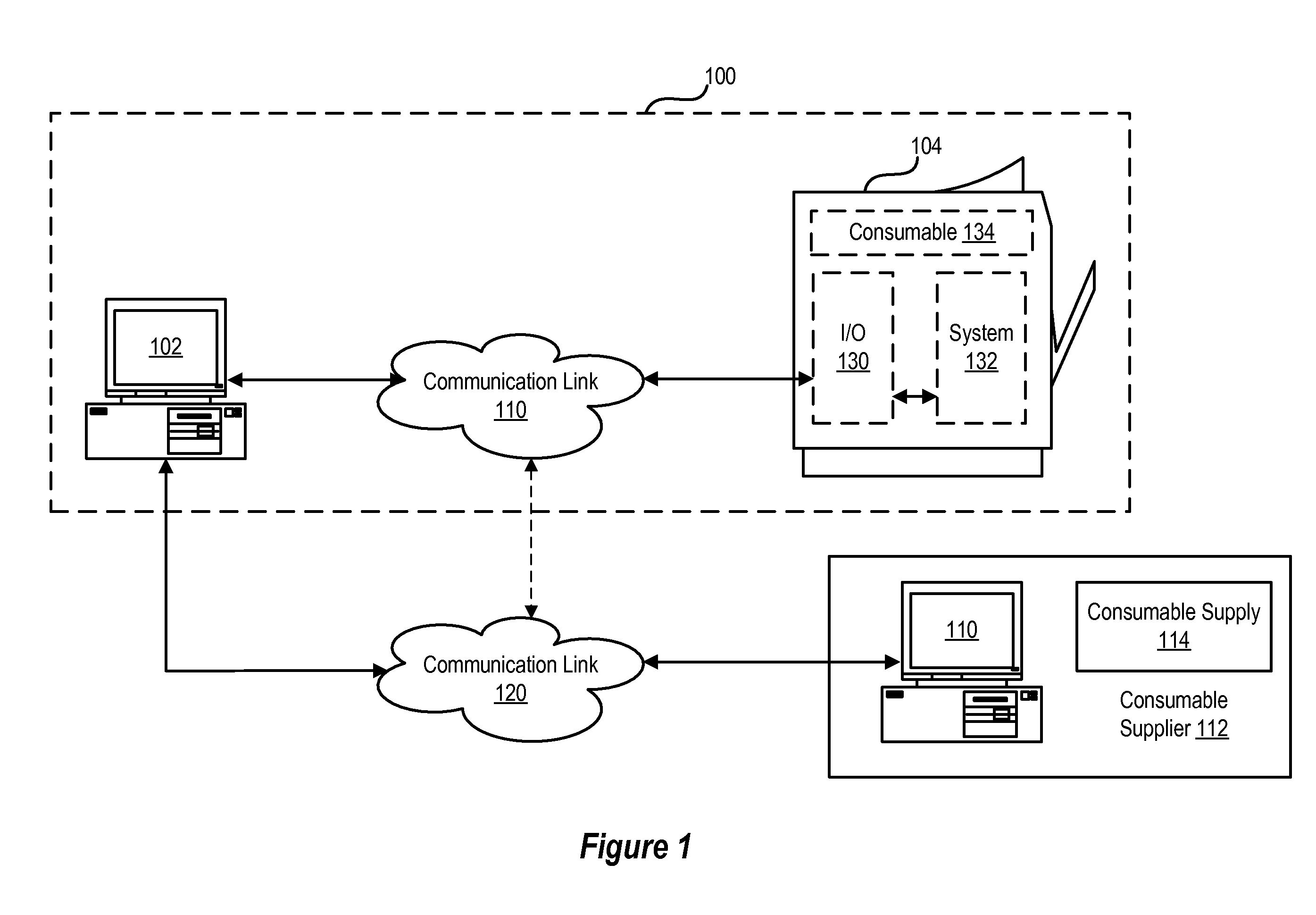

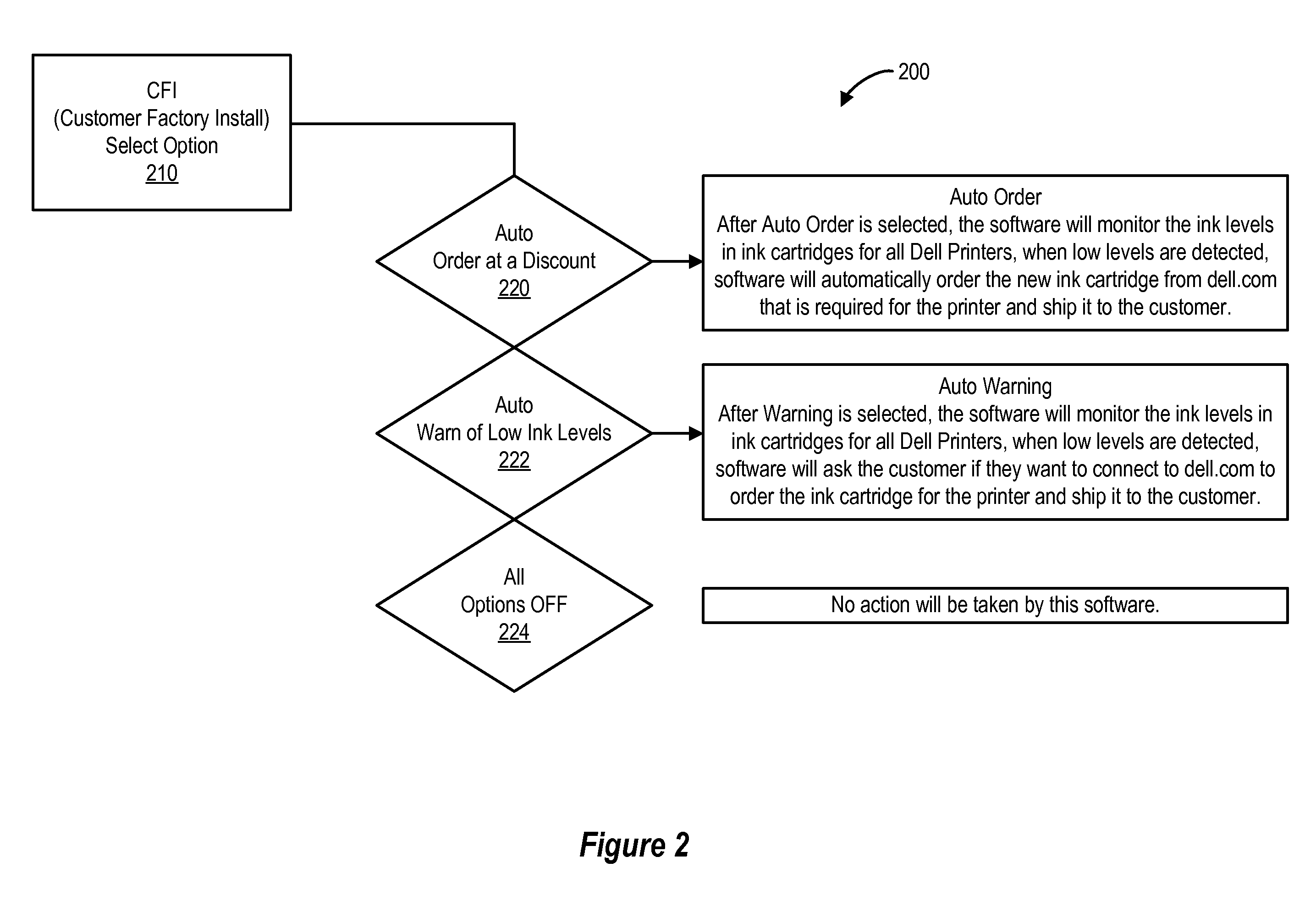

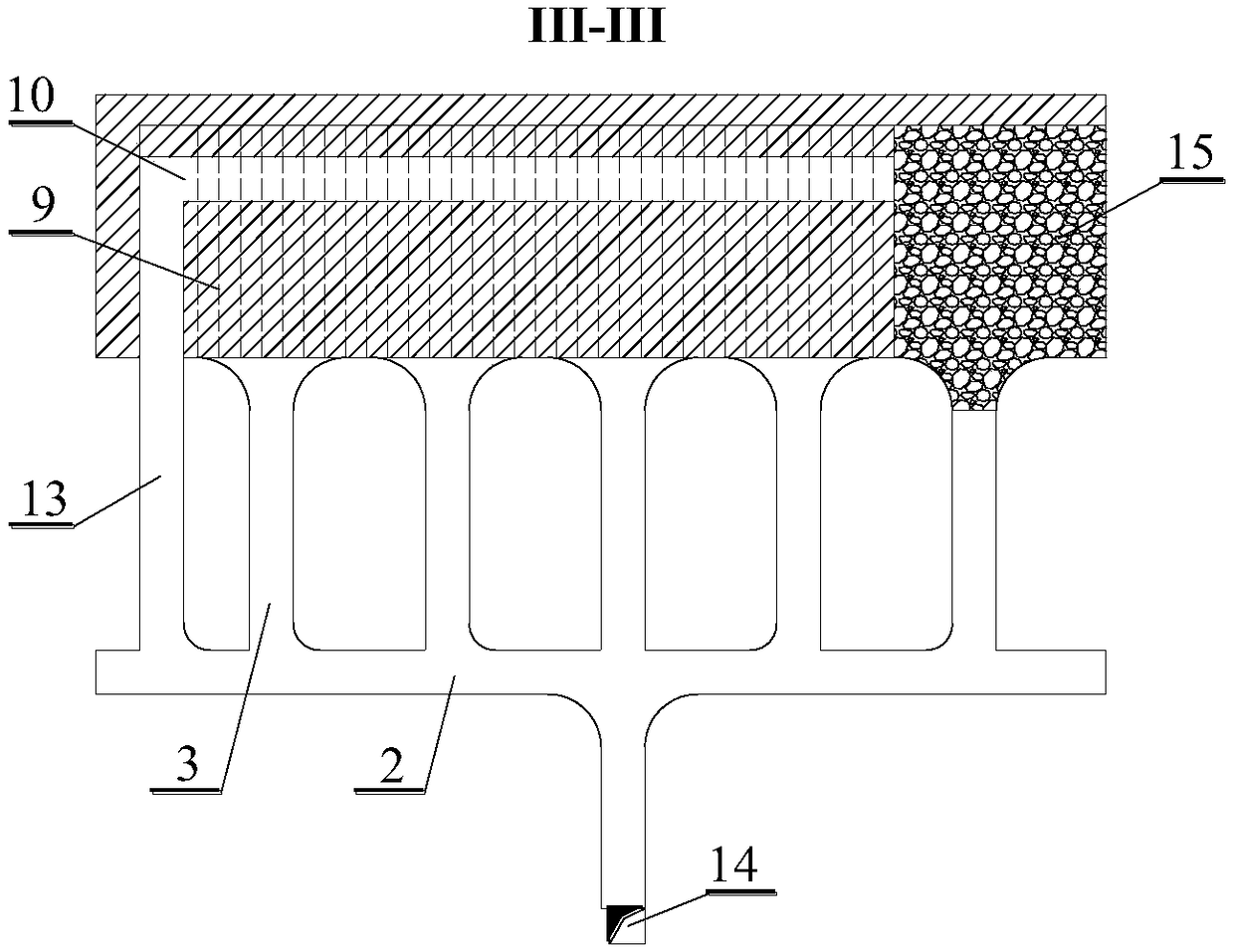

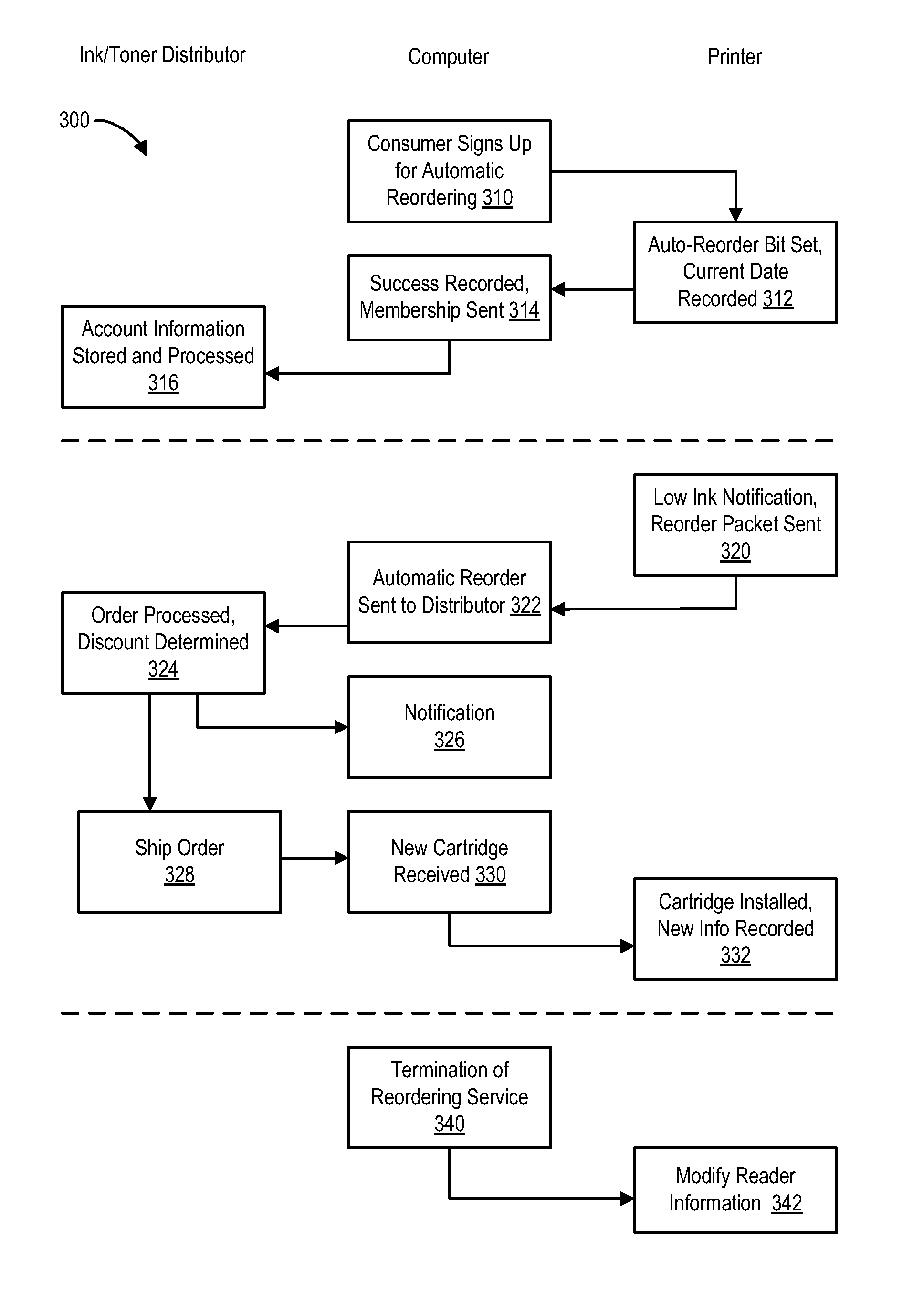

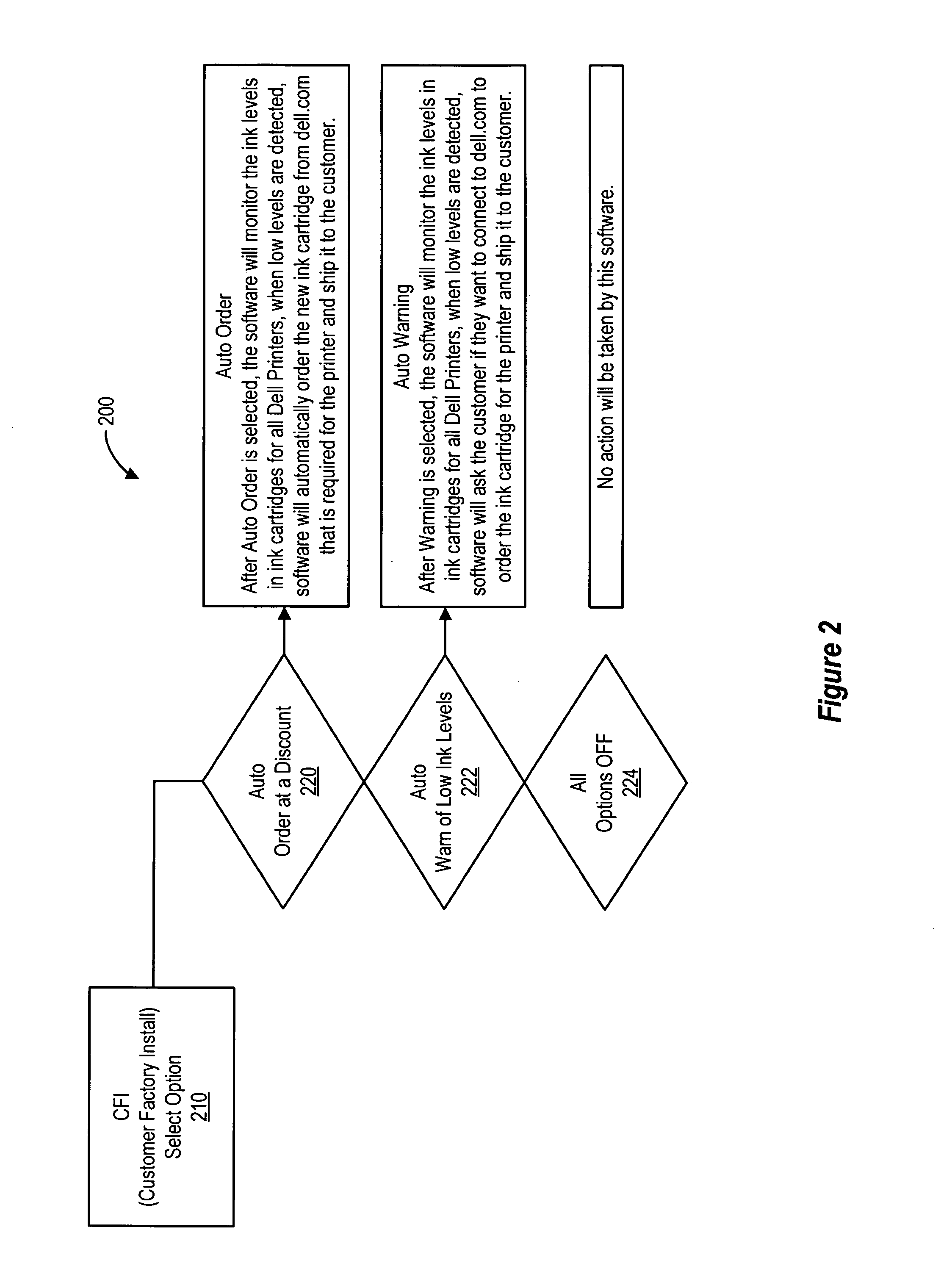

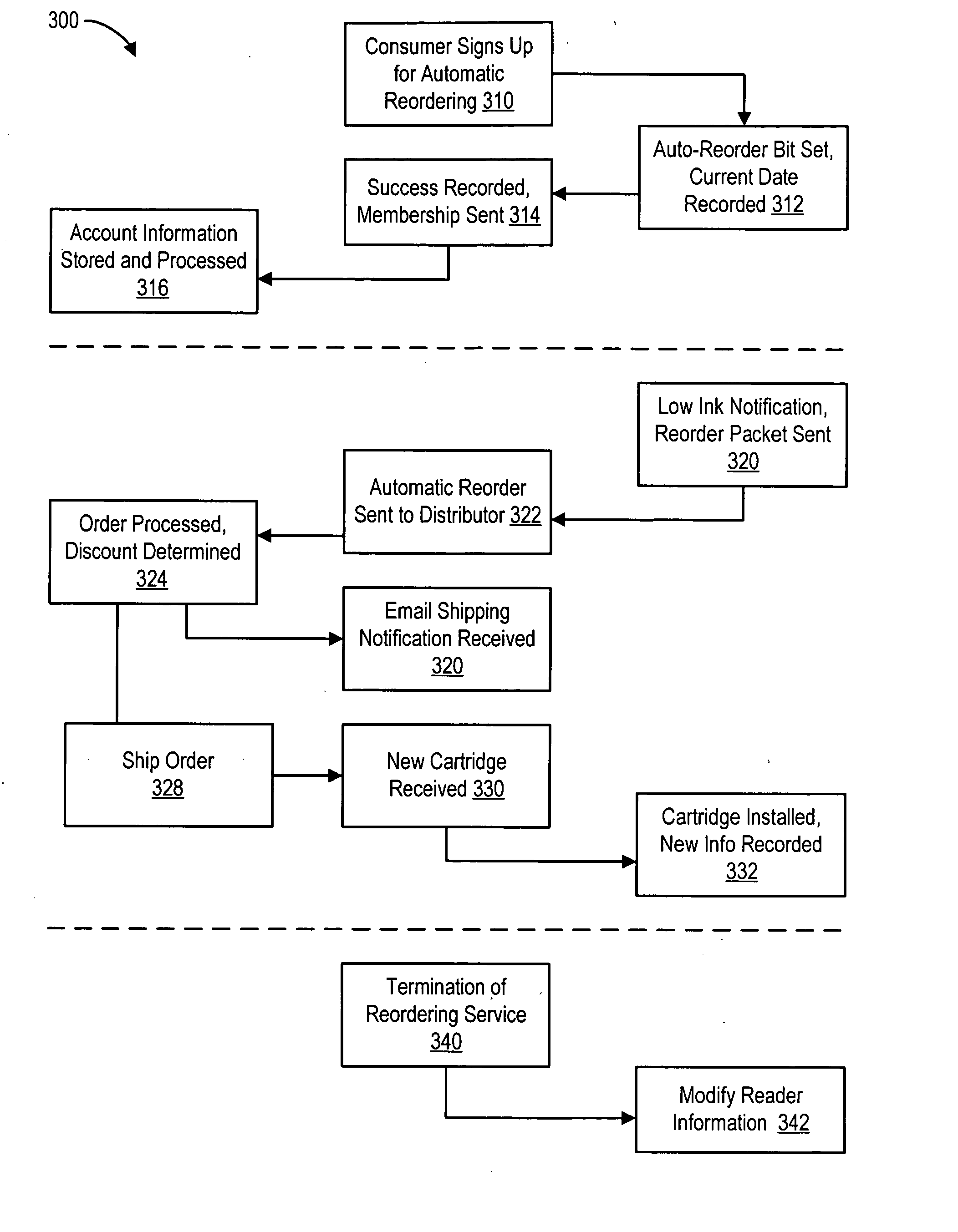

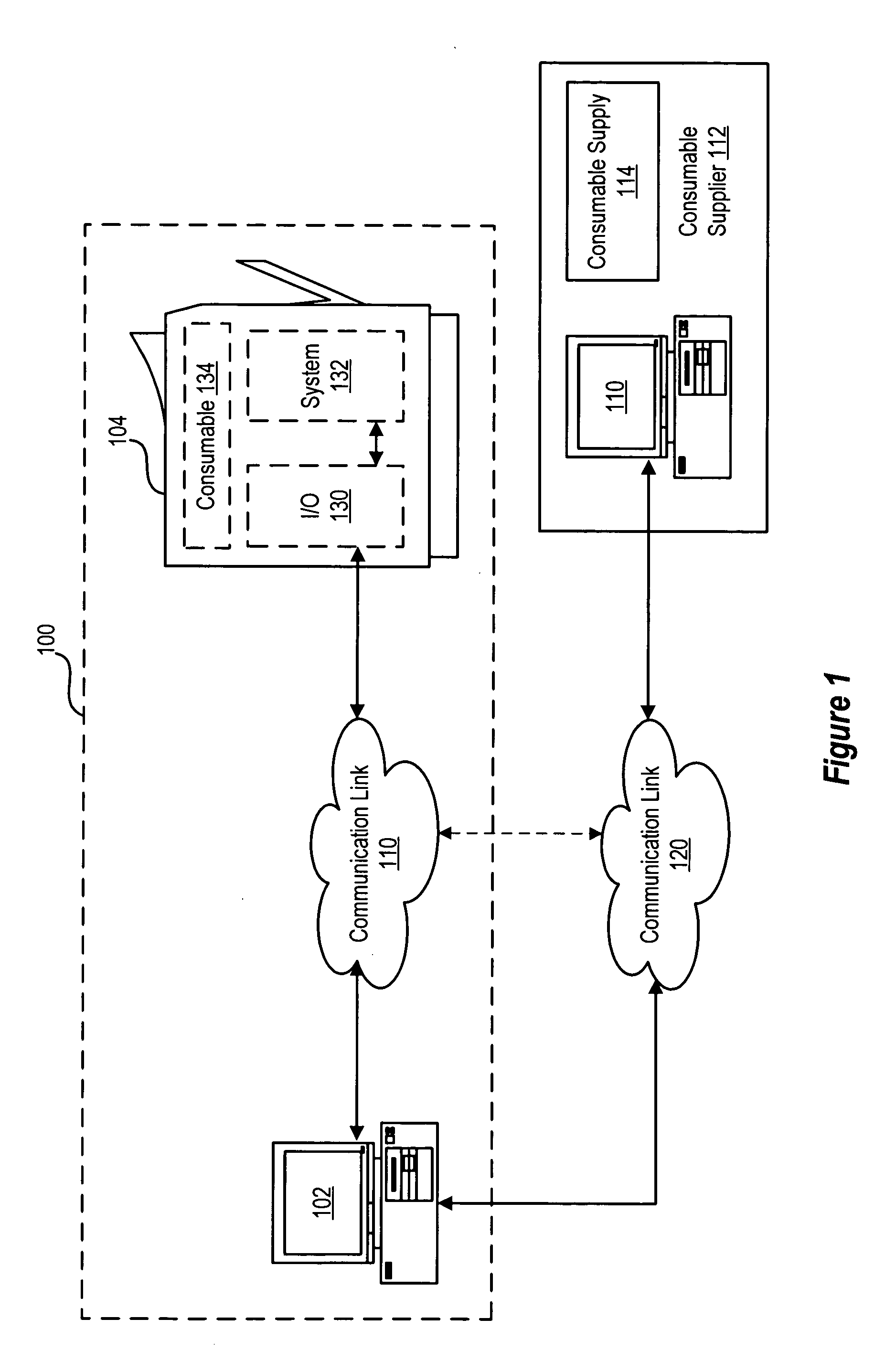

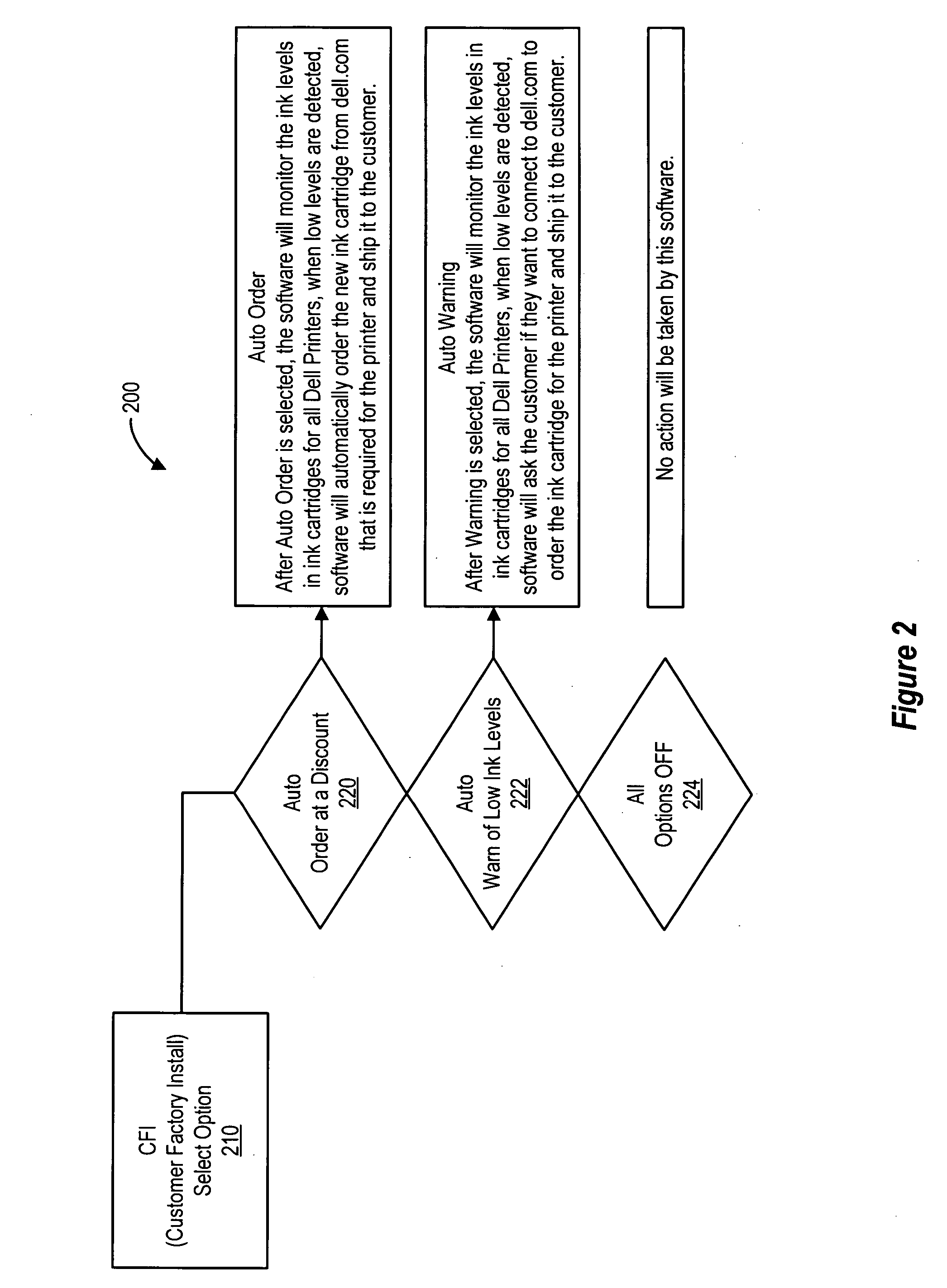

Print Cartridge Ordering System

A method for automatically ordering printer consumables which includes determining when a printer consumable is close to depletion and automatically ordering a replacement to the printer consumable based upon a plurality of criteria. The criteria includes the amount of consecutive time a consumer has been a member of a printer consumable subscription service and the number of printer consumables ordered by a consumer.

Owner:GARRANA HENRY N +5

Mining method for hanging wall surrounding rock broken inclined medium thick orebody

InactiveCN108612530AIncrease job securityImprove working environmentUnderground miningSurface miningDrift miningSecurity Measure

The invention discloses a mining method for a hanging wall surrounding rock broken inclined medium thick orebody. Stope division is carried out on the orebody along the orebody trend, broken ores aretransported in stages, subsections are divided within the stages, sublevel drift mining method is adopted in advance for stoping and filling of the orebody close to the hanging wall, the drift too plates of at one ends of all sublevel mining drifts close to a heading wall are interconnected to form a slope, thus making preparations for trench ore-drawing and enabling trench ore-drawing at all subsections, then a bottom-up stoping sequence is employed for stoping and filling of each subsection orebody, thereby effectively solving the problem of potential safety hazard when a carry scraper enters a stope for a long time. In addition, implementation of downward fan-shaped medium-deep holes improves the rock drilling efficiency and safety, all construction guarantees no destruction to the hanging wall broken surrounding rock, also a rock drilling gallery is employed as the air-return way, and the problem of difficult ventilation is effectively solved. The method provided by the invention generally shows significant security measures in ore drawing, rock drilling and ventilation of middle-low grade hanging wall surrounding rock broken inclined medium thick stable orebodies.

Owner:CENT SOUTH UNIV

Print cartridge ordering system

A method for automatically ordering printer consumables which includes determining when a printer consumable is close to depletion and automatically ordering a replacement to the printer consumable based upon a plurality of criteria. The criteria includes the amount of consecutive time a consumer has been a member of a printer consumable subscription service and the number of printer consumables ordered by a consumer.

Owner:DELL PROD LP

CMOS process with Si gates for nFETs and SiGe gates for pFETs

InactiveUS20070235759A1Reduced poly depletionBig impactSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricProviding material

An integration scheme for providing Si gates for nFET devices and SiGe gates for pFET devices on the same semiconductor substrate is provided. The integration scheme includes first providing a material stack comprising, from bottom to top, a gate dielectric, a Si film, and a hard mask on a surface of a semiconductor substrate that includes at least one nFET device region and at least one pFET device region. Next, the hard mask is selectively removed from the material stack in the at least one pFET device region thereby exposing the Si film. The exposed Si film is then converted into a SiGe film and thereafter at least one nFET device is formed in the least one nFET device region and at least one pFET device is formed in the at least one pFET device region. In accordance with the present invention, the least one nFET device includes a Si gate and the at least one pFET includes a SiGe gate.

Owner:GLOBALFOUNDRIES INC

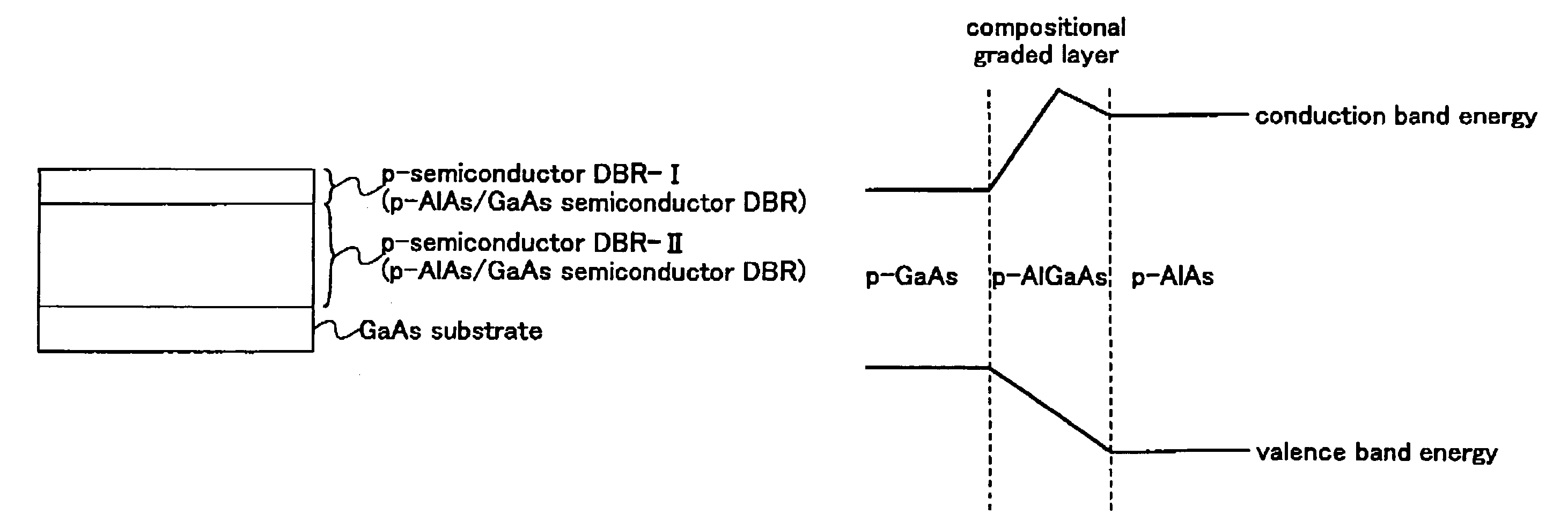

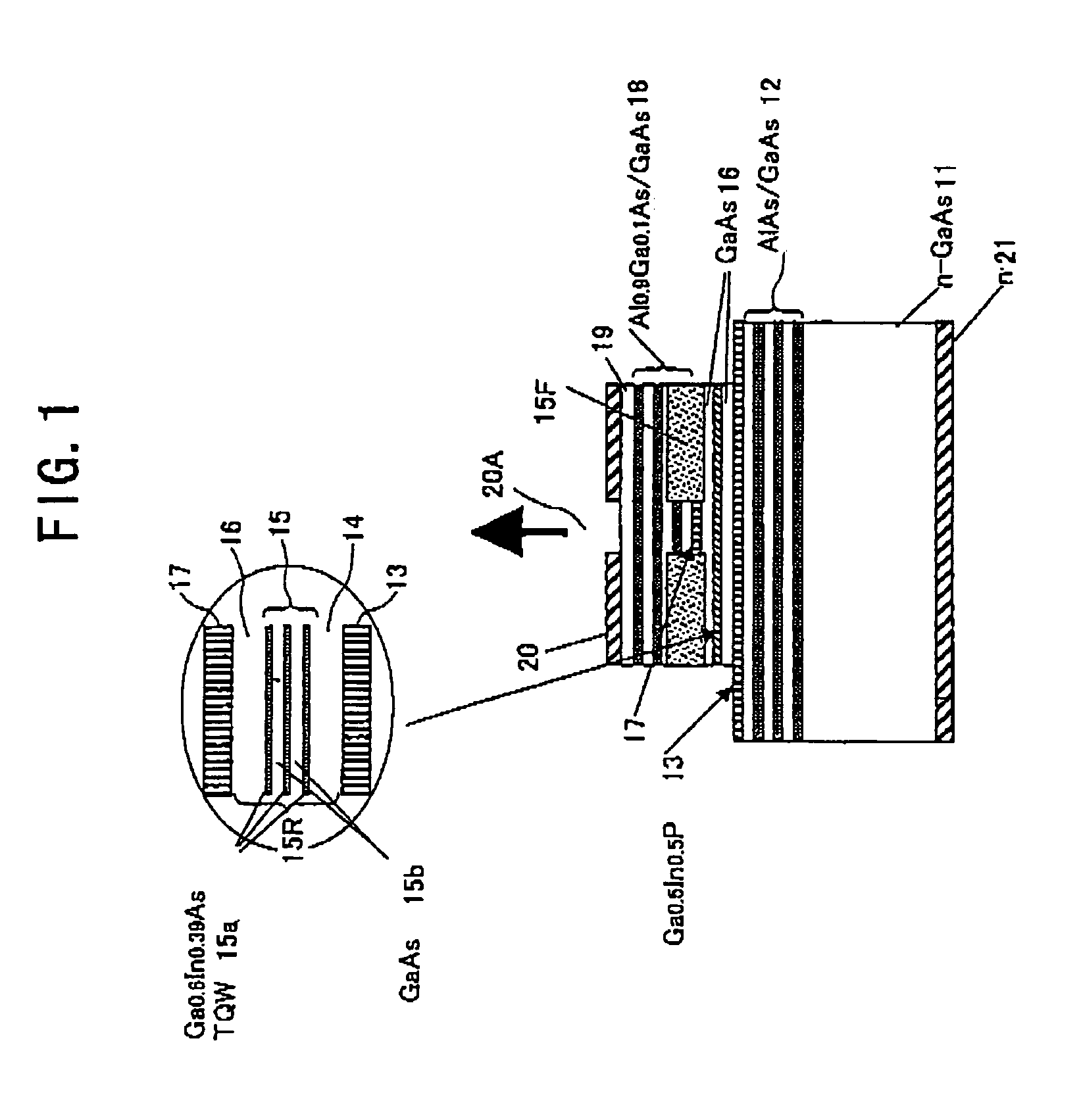

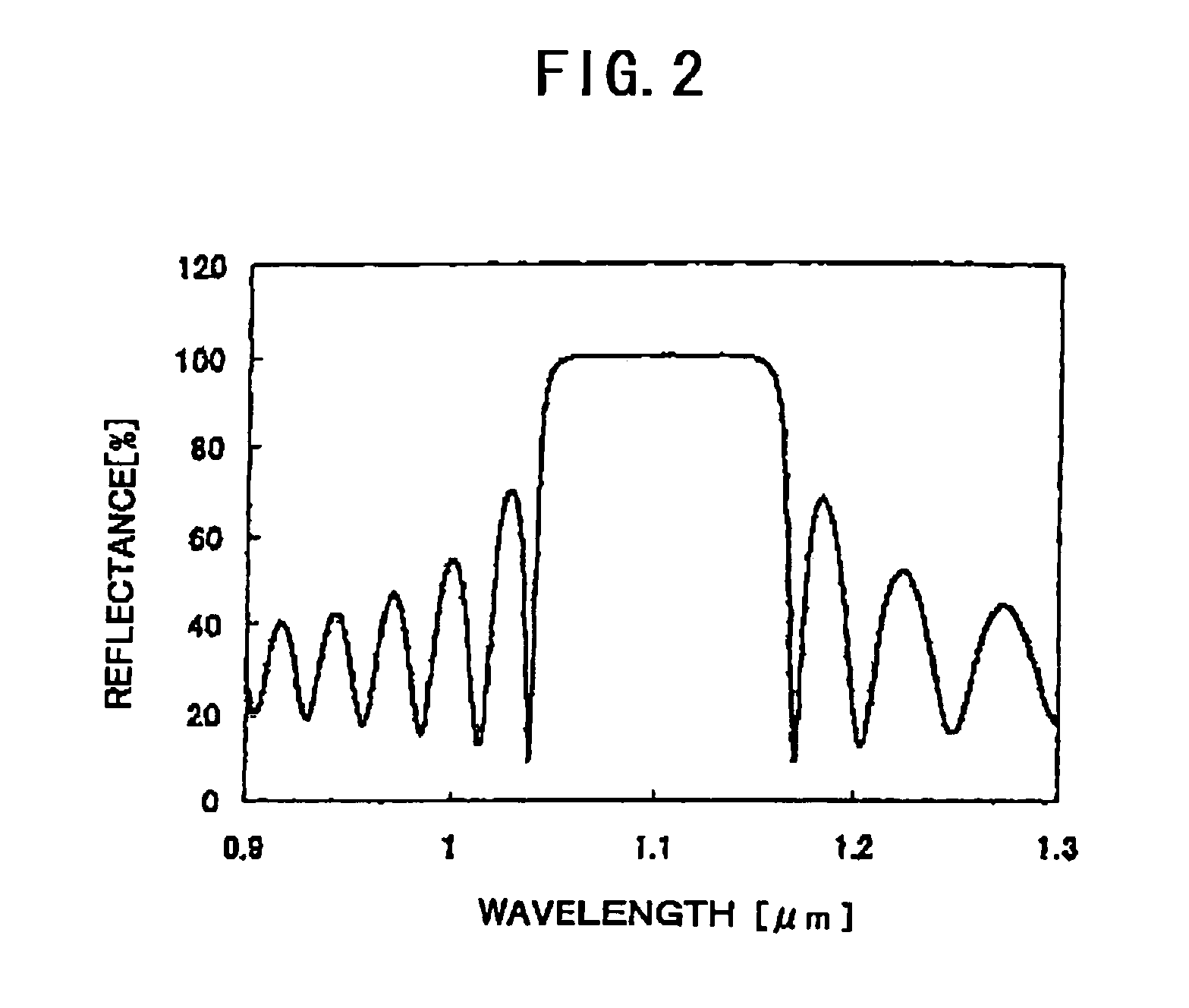

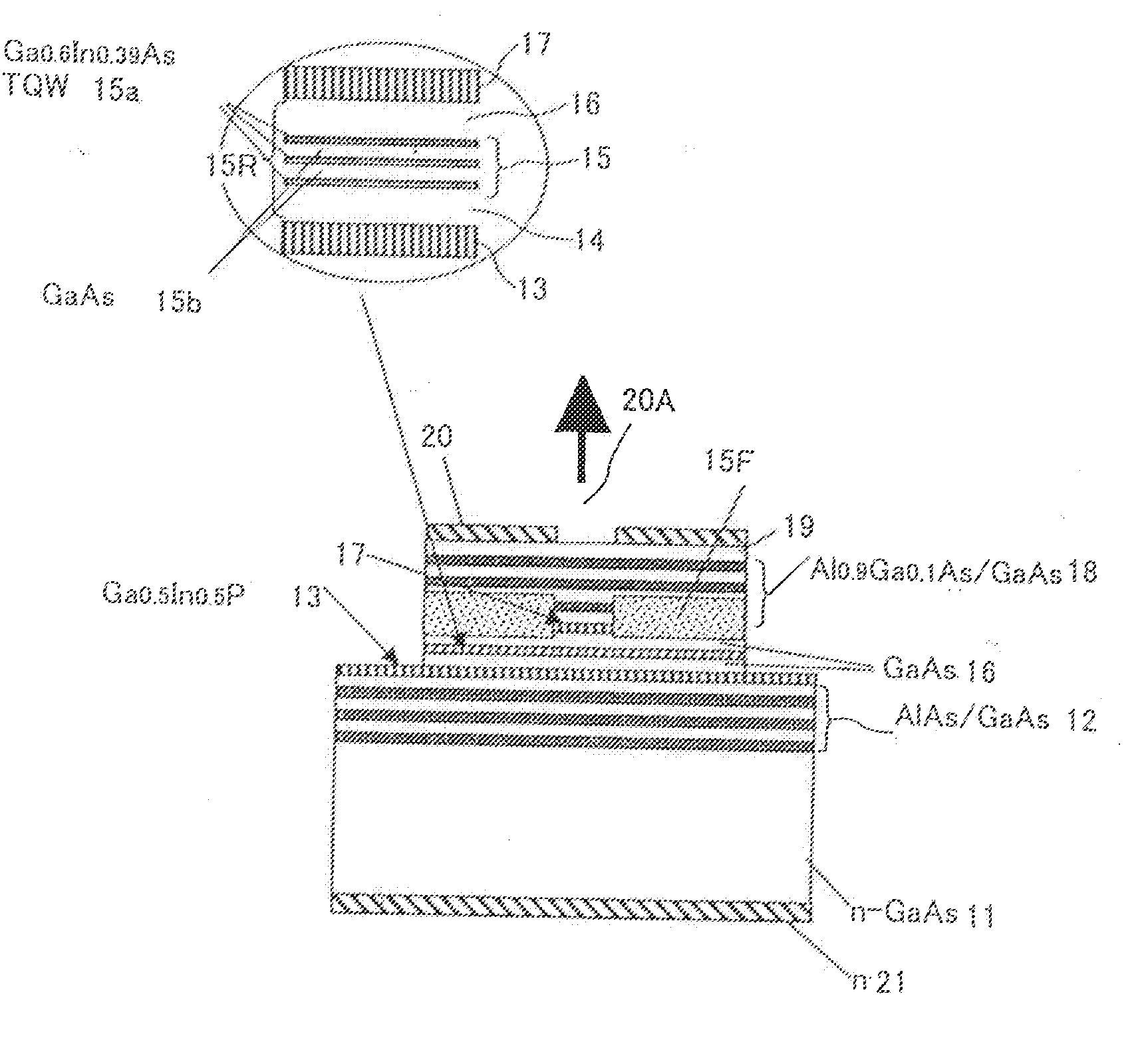

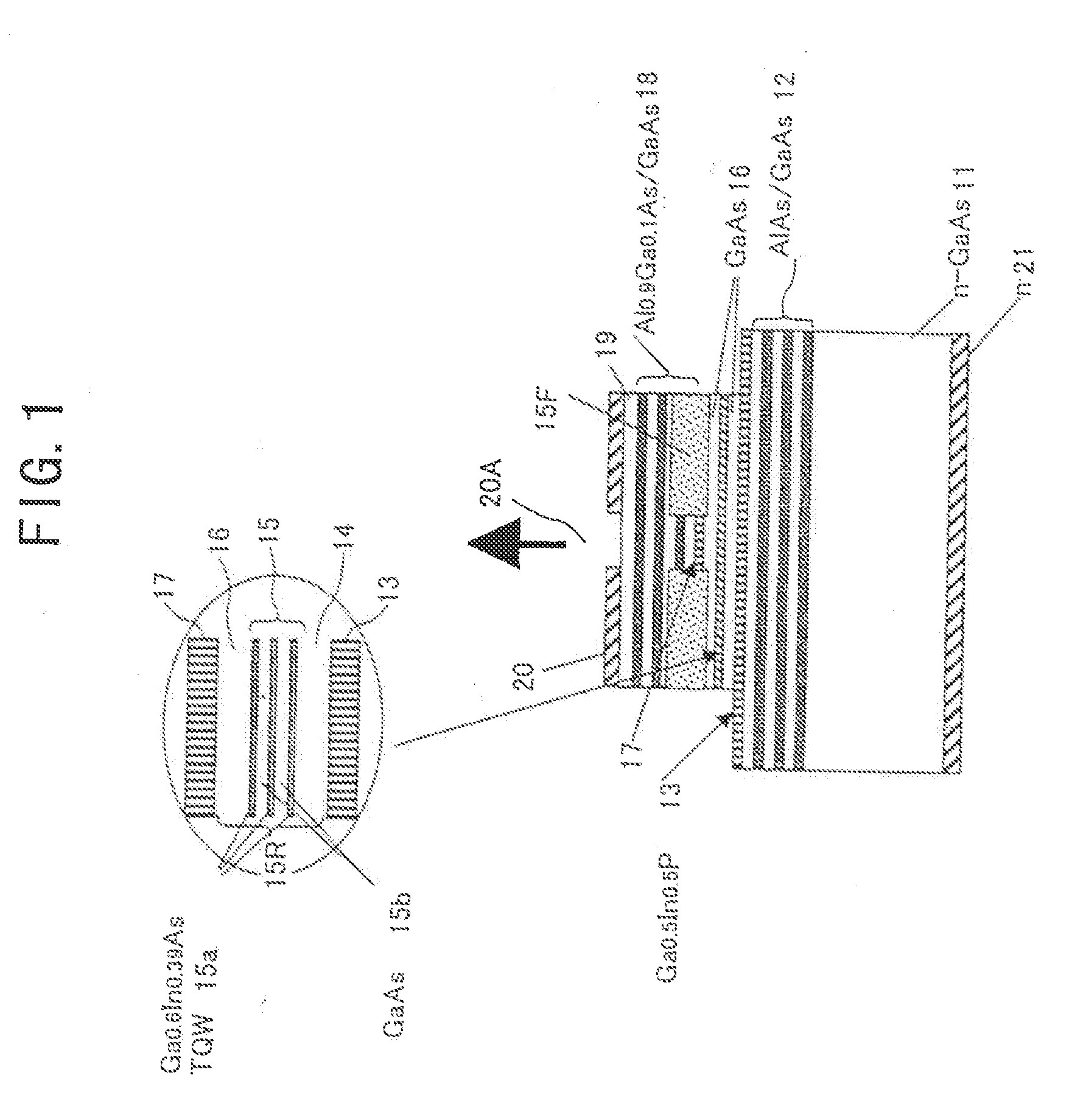

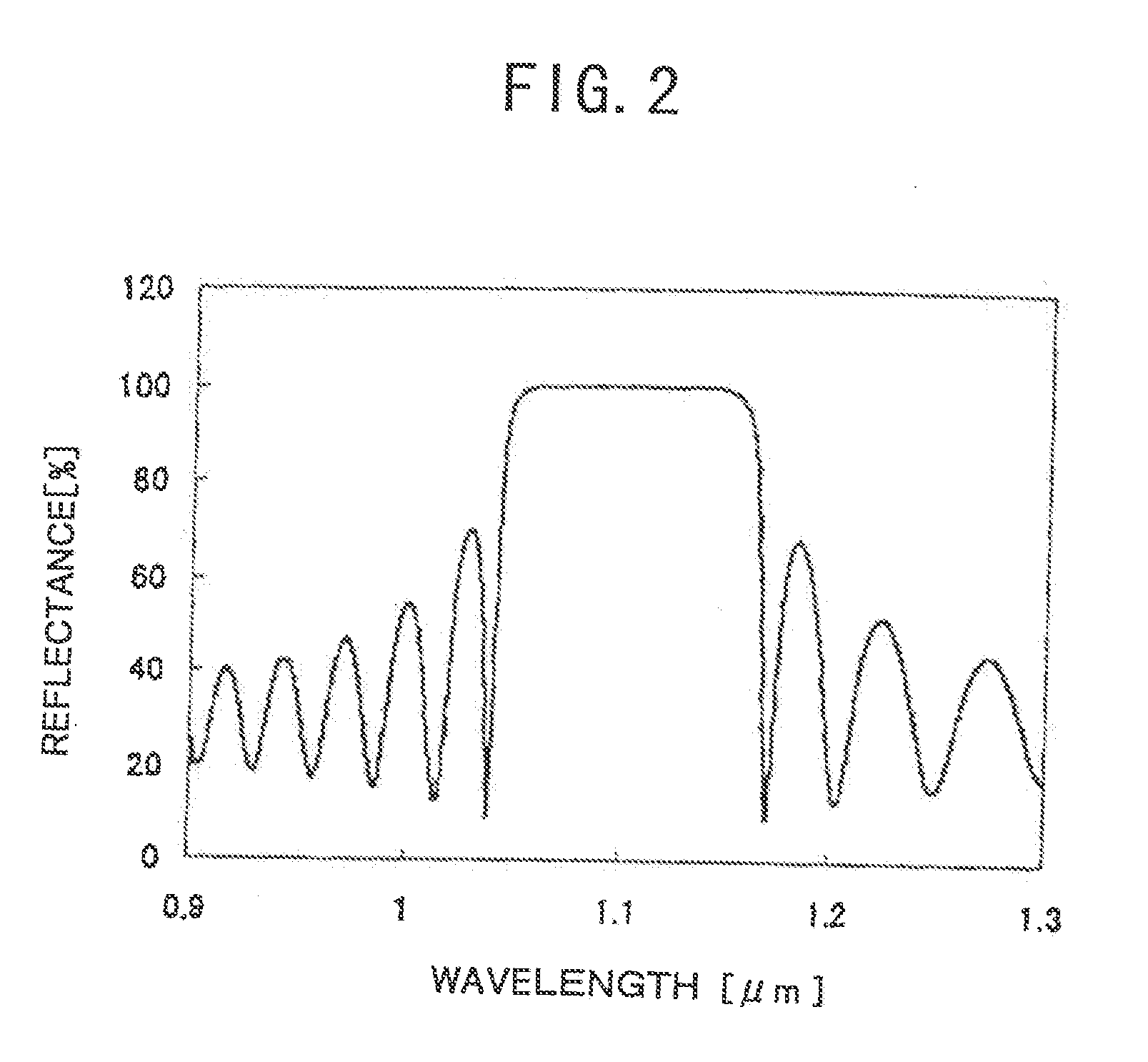

Surface-emission laser diode operable in the wavelength band of 1.1-1.7mum and optical telecommunication system using such a laser diode

InactiveUS7245647B2Reduce areaHigh speed modulationLaser active region structureSolid-state devicesCommunications systemDistributed Bragg reflector

A surface-emission laser diode includes a distributed Bragg reflector tuned to wavelength of 1.1 μm or longer, wherein the distributed Bragg reflector includes an alternate repetition of a low-refractive index layer and a high-refractive index layer, with a heterospike buffer layer having an intermediate refractive index interposed therebetween with a thickness in the range of 5–50 nm.

Owner:RICOH KK

Method for recovering disc ore on incline ore block

InactiveCN101424186ASimple methodFlexible and convenient constructionUnderground miningSurface miningSpelunkingBody height

The invention relates to a method for recovering hanging wall ores of a slant ore body, which mainly solves the technical problems of low ore recovery rate, large mining difficulty, low production efficiency and the like existing in the process of recovering the hanging wall ores of the prior slant ore body. When the slant ore body is exploited, an extracting drift is arranged according to the construction layout of a hanging wall prospecting drift, an ore rock boundary line and a hanging wall cutting tunnel, wherein the prospecting drift is dug out 1.5 to 3 meters from the ore rock boundary line, and the hanging wall cutting tunnel is arranged within the ore rock boundary line; the ore body height above the position of the hanging wall cutting tunnel is taken as a subsection, and a vertical upward cutting blast hole is arranged along the direction of the hanging wall cutting tunnel; and vertical or pitching upward back production fan-pattern holes are arranged according to ore caving step pitch and rock drilling row space in the back production direction. The method is suitable for the prior sublevel caving method without sill pillar and a novel technology of large space mining without the sill pillar.

Owner:宝钢集团上海梅山有限公司

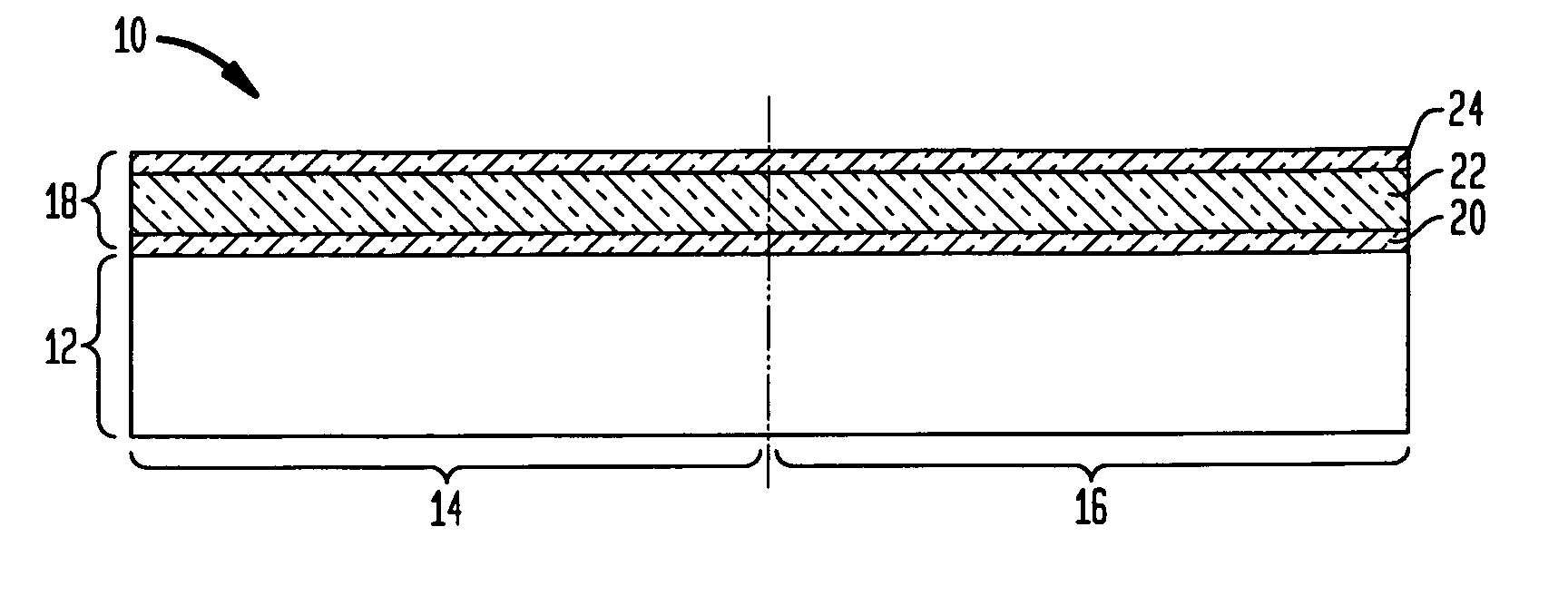

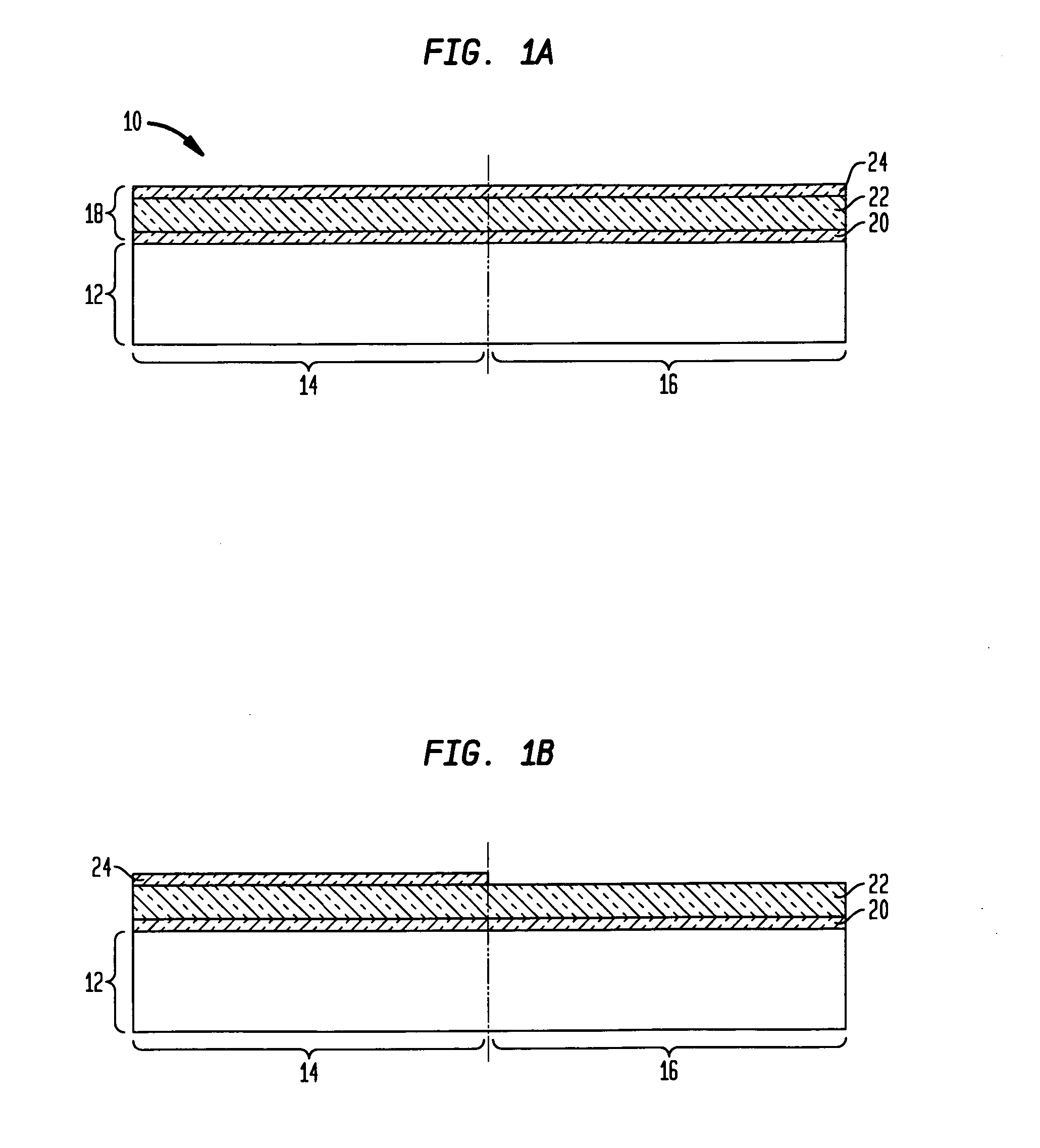

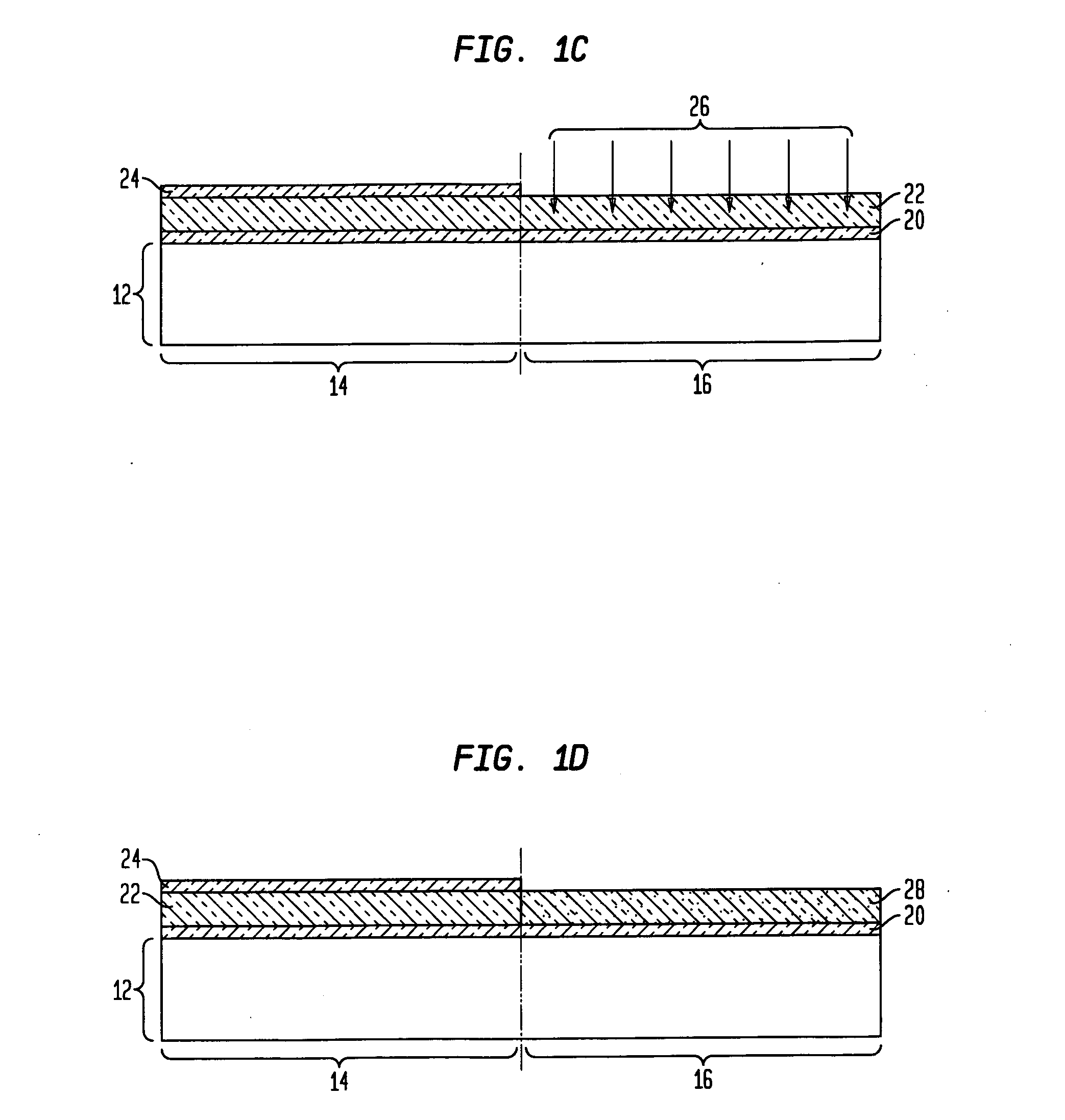

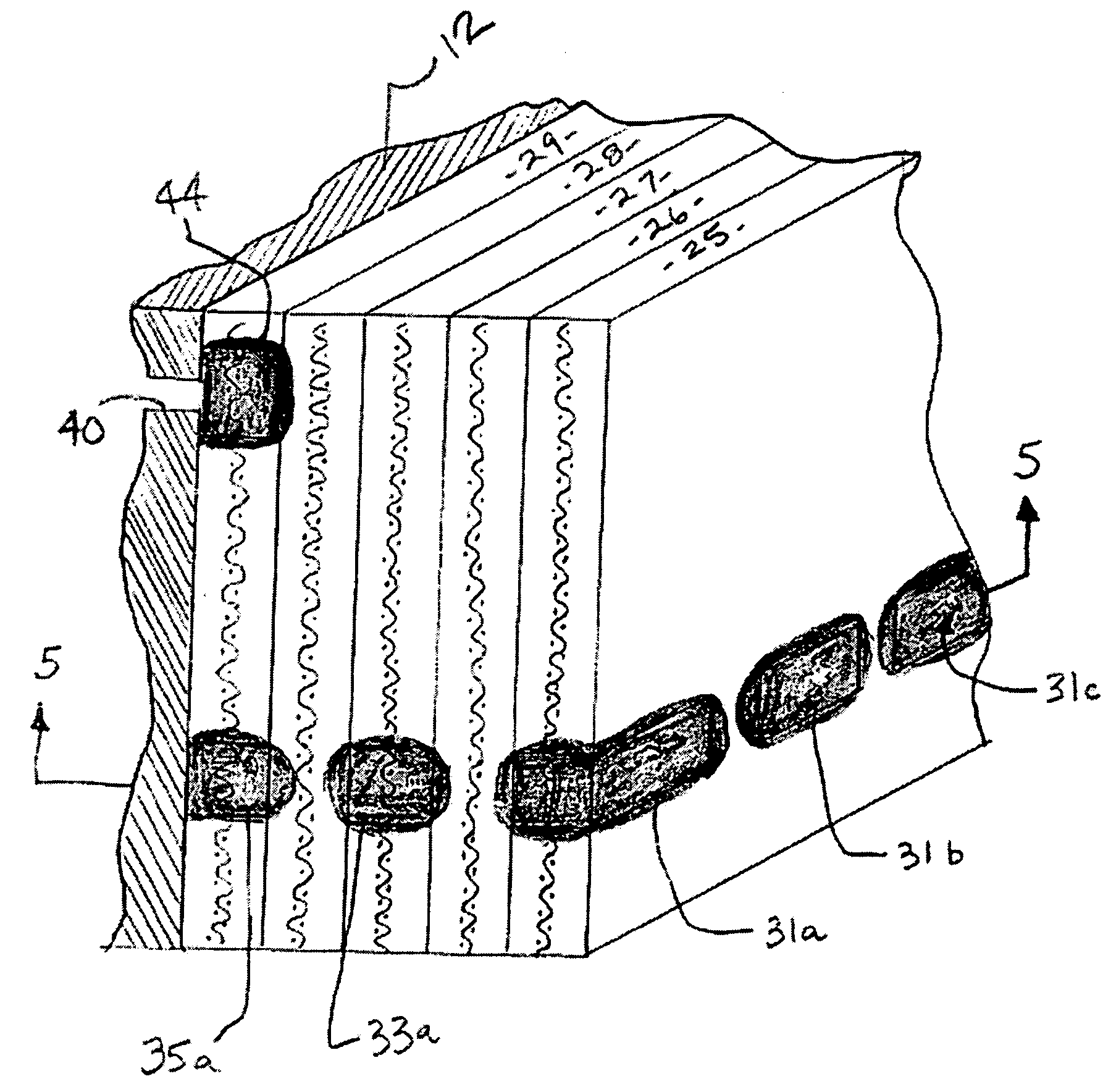

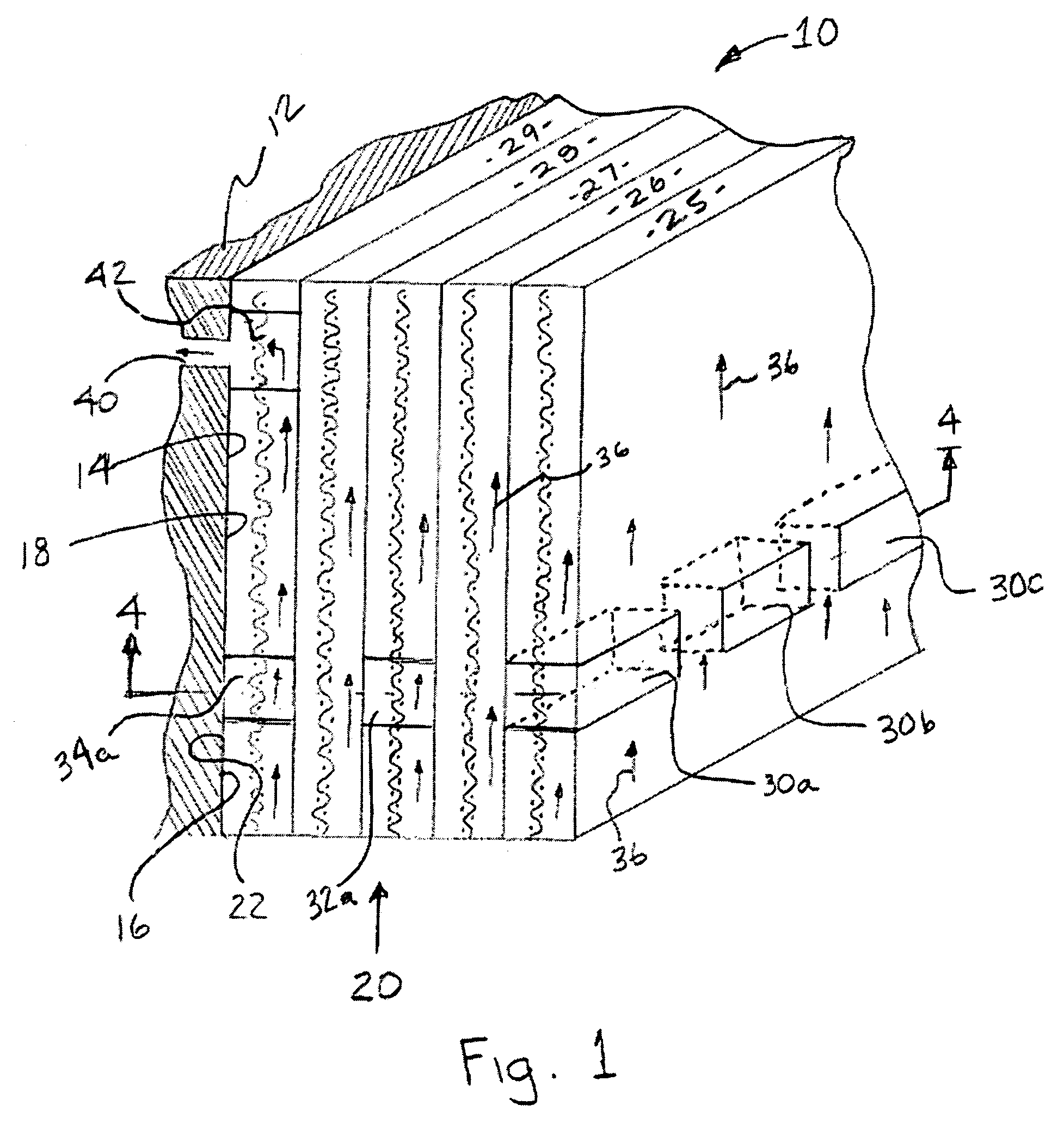

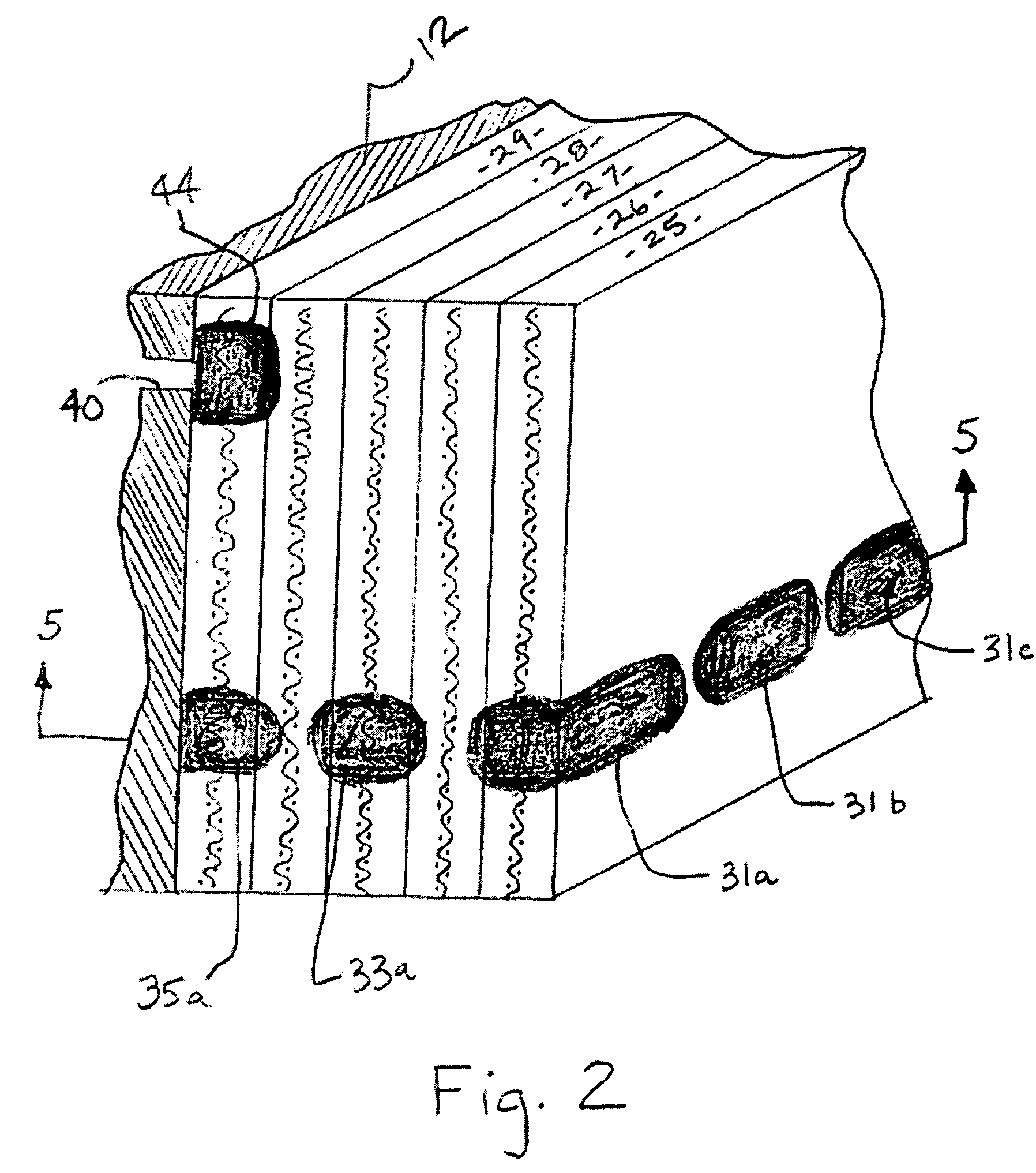

Control of resin flow during molding of composite articles

InactiveUS7255549B2EliminatePrevent from flowConfectioneryWood working apparatusComposite materialFiber

The flow of resin during the molding of composite articles is controlled by forming areas of immobilized resin during the infusion of resin into the fibrous body. The immobilized resin is formed using an immobilization agent that interacts with the infused resin to form a high viscosity resin barrier that is effective in blocking the flow of non-immobilized resin. The barriers of immobilized resin are located within the fibrous body so as to control the flow of non-immobilized resin during the molding process to prevent or least reduce resin depletion and to selectively block resin flow from the mold.

Owner:HEXCEL COMPOSITES LTD (GB)

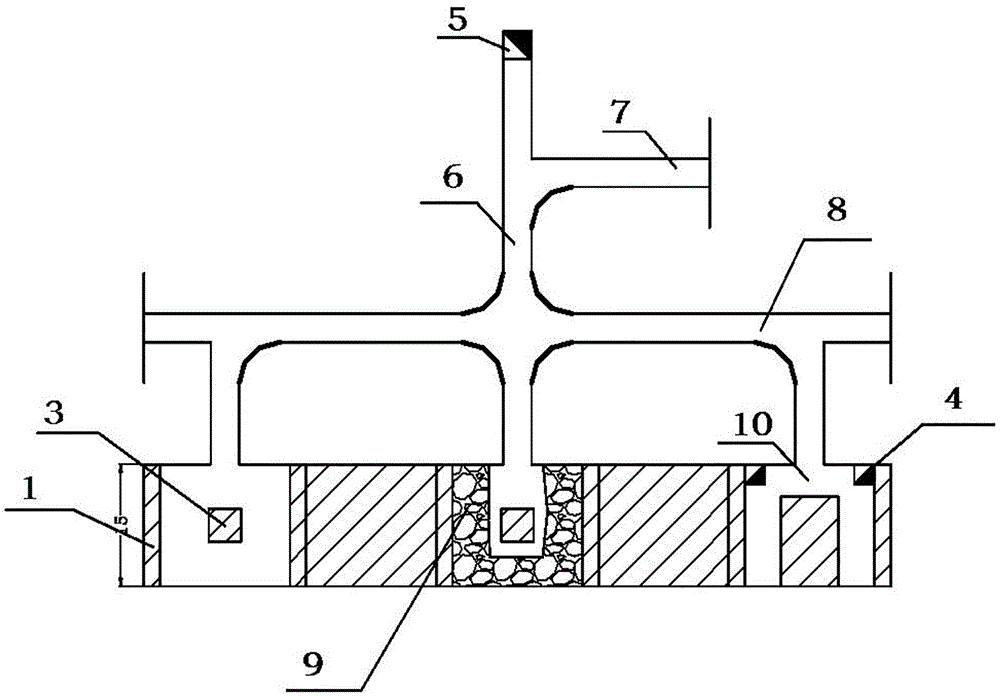

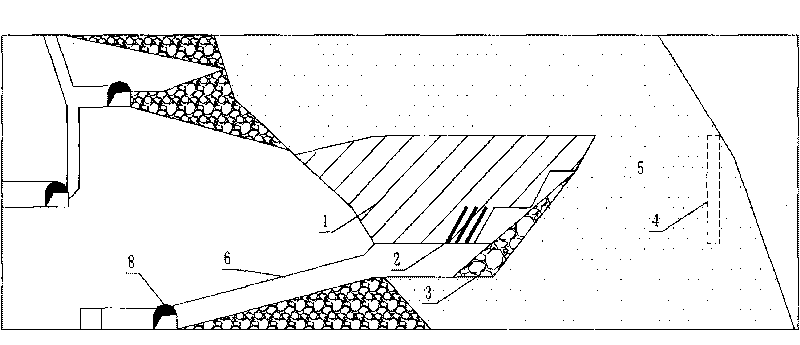

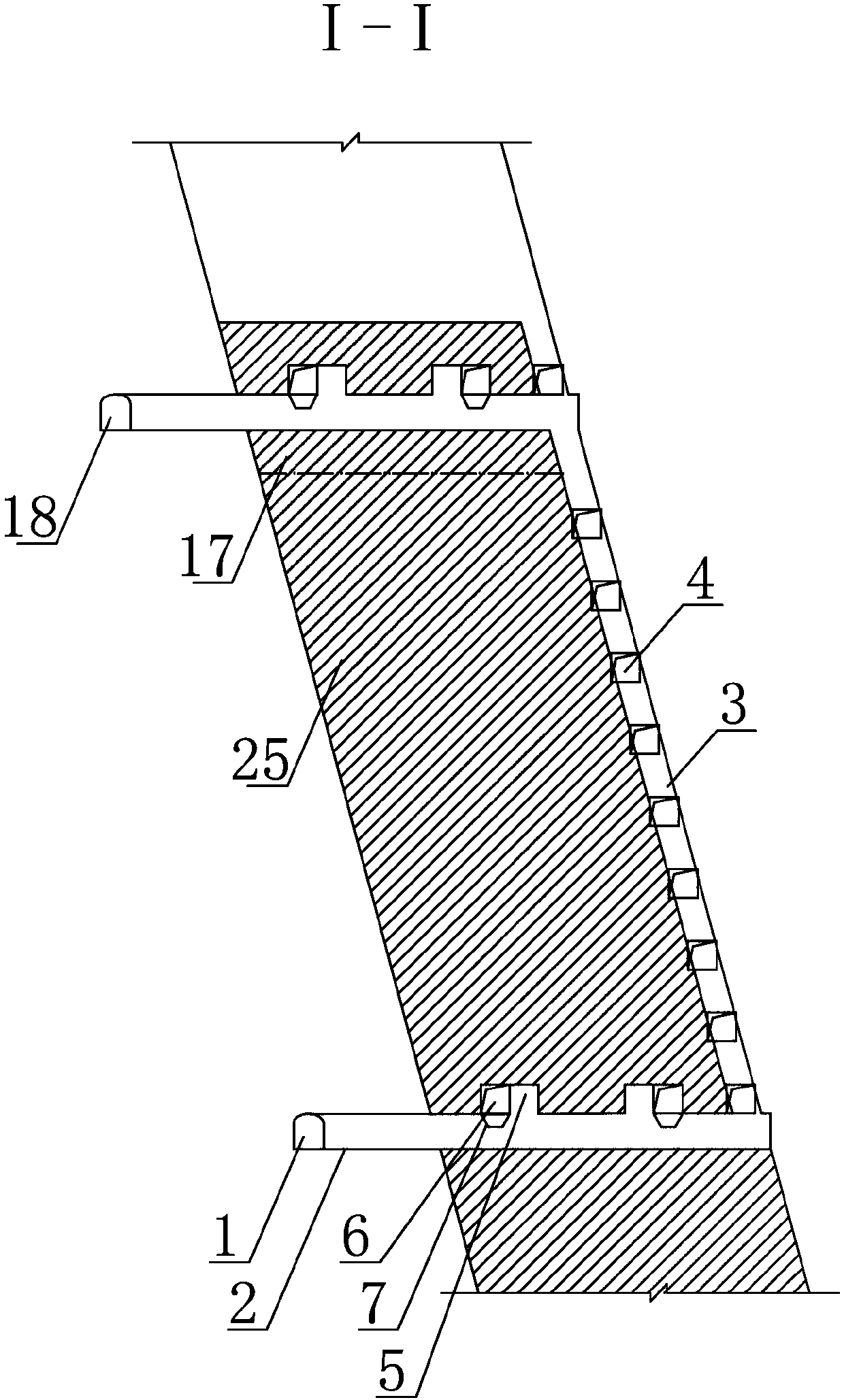

Divided mining method for inclined medium-thick ore body with unstable false roof

ActiveCN104018836AOut of stopeReduce the dilution loss rateUnderground miningSurface miningEngineeringNo removal

The invention discloses a divided mining method for an inclined medium-thick ore body with an unstable false roof. The ore body is divided into panels along the strike, ore pillars of chambers are divided in the panels and a top pillar is reserved during stoping; an outside-vein slice drift, a layered linking roadway and a trackless stope preparation project of a chute mine are distributed on the upper panel of the ore body, and an upward air roadway is filled and is distributed at a position at the center of the ore pillars of the chambers and close to the lower panel; chambers are mined firstly and the ore pillars are mined secondly in the panels, and the chambers and the ore pillars are mined in an up-down layering manner; the stoping is performed from an ore removal crossdrift, the false roof and the ore body are mined in sequence, after ores are conveyed out by a carry-scraper, the false roof at the lower sub-layer is subjected to caving in advance by shallow holes, waste stones of the false roof are reserved in a stoping field, and the ore breaking compensation height is compensated in a layering filling manner, the stoping is performed on the lower sub-layer, and the laying caving is performed on the false roof after layering ore breaking and ore conveyed out, the operation is repeated for multiple times until the stoping field is stoped completely, and the bottom layer of the stoping field is filled to close to the back. By using the method, the operating safety, high mechanical degree, no removal of the waste stones of the false roof, low production cost, and low ore dilution loss can be realized.

Owner:CENT SOUTH UNIV

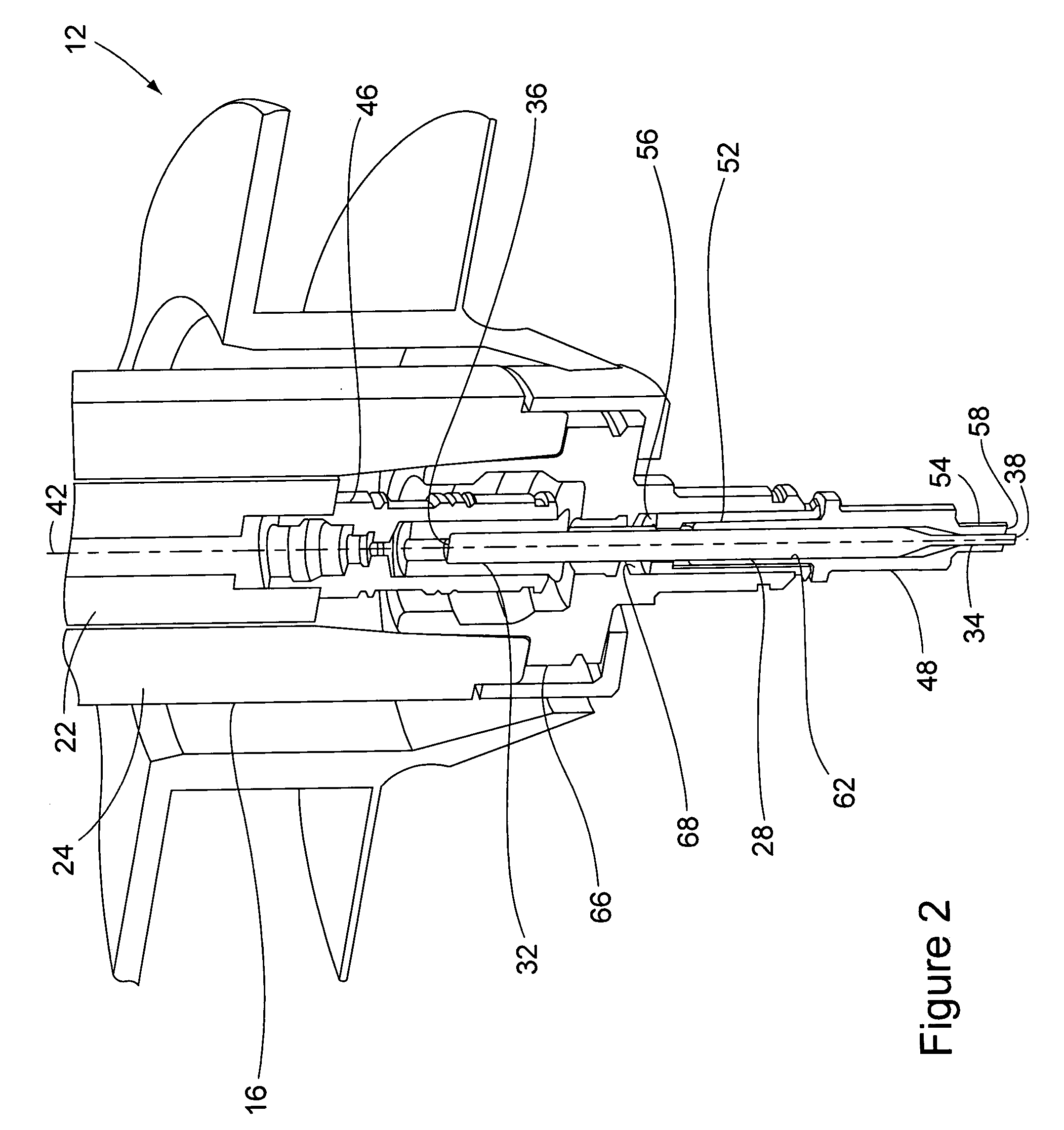

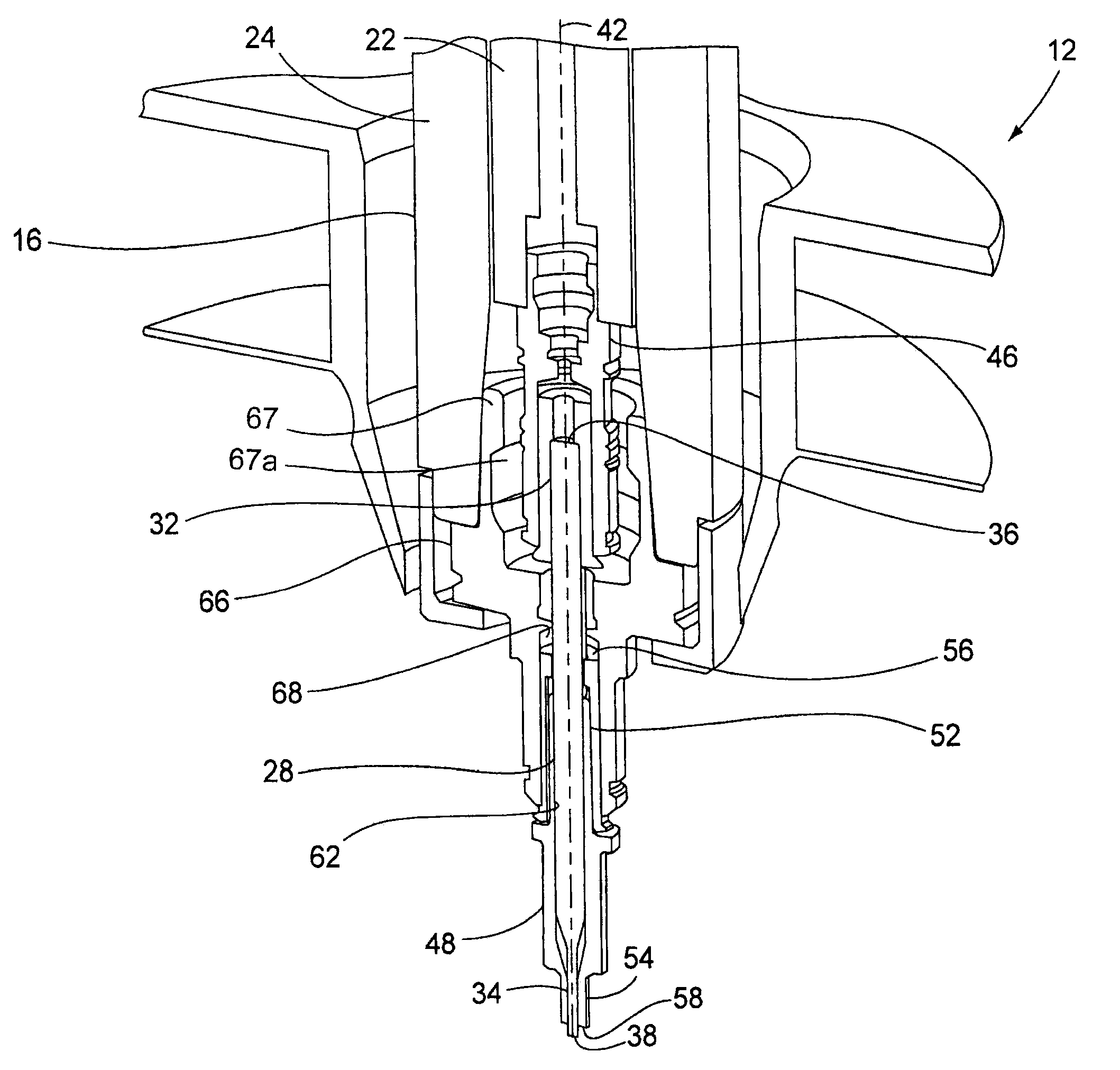

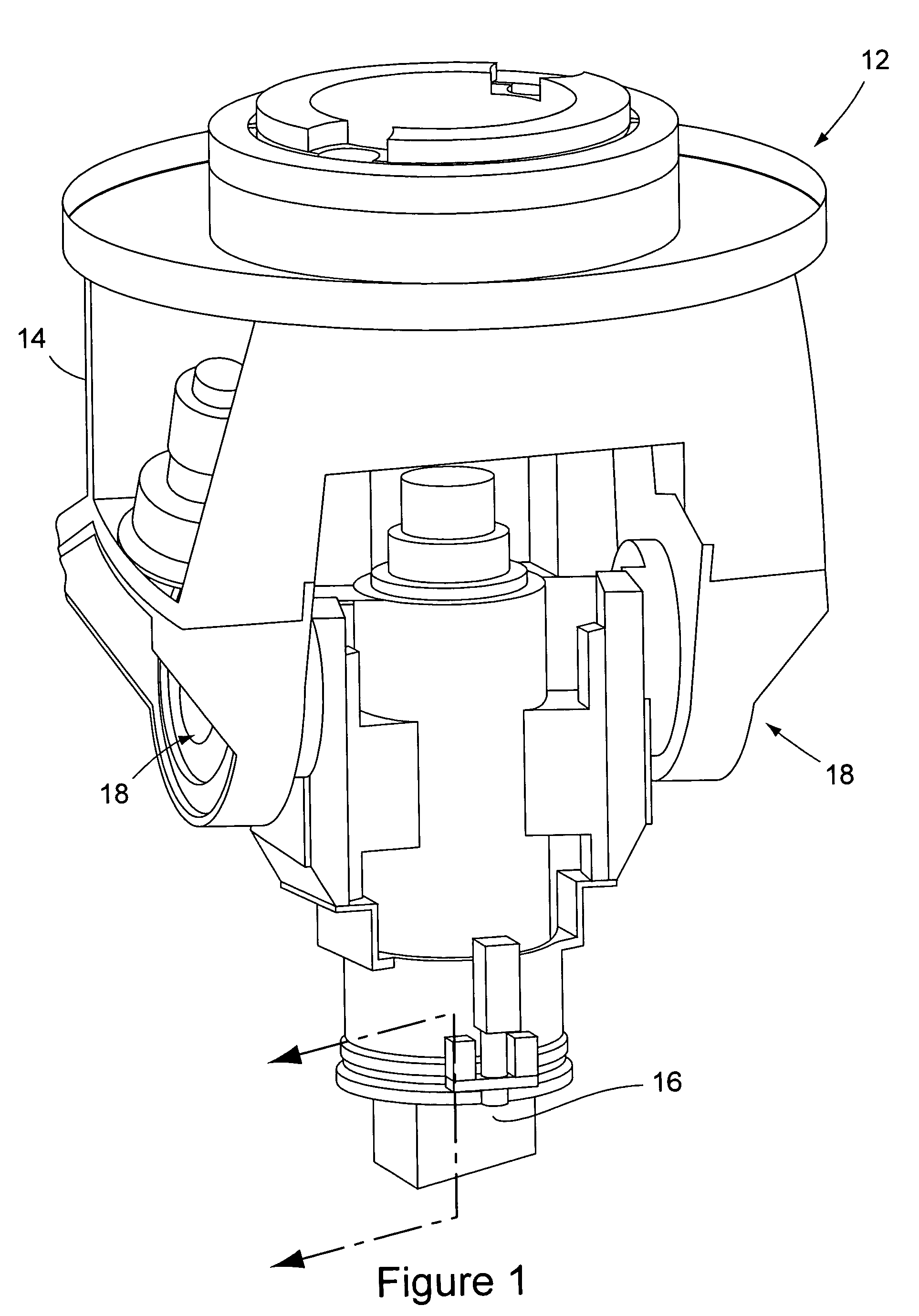

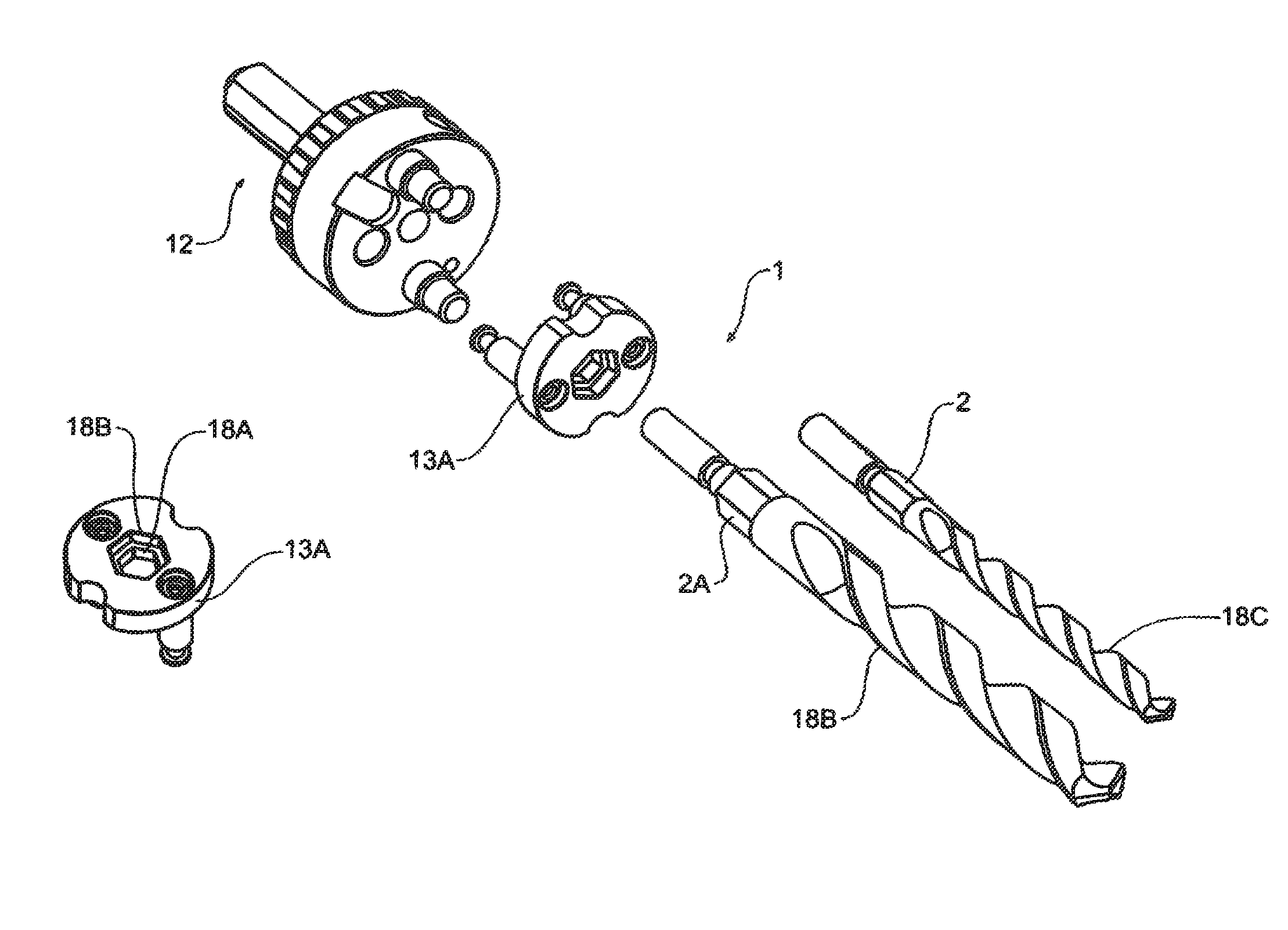

Friction stir welding apparatus

ActiveUS20060163316A1Facilitates installation and removalIncreases available production timeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFriction stir welding

A friction stir welding apparatus has a novel tool-in-tool construction where a friction stir welding pin tool extends through a center bore of a friction stir welding shoulder tool and is moveable axially and rotationally relative to the shoulder tool. The pin tool and shoulder tool both have their own dedicated tool holders and spindles that enable the tools to rotate and move axially relative to each other and enable easy replacement of each of the tools.

Owner:THE BOEING CO

Surface-emission laser diode operable in the wavelength band of 1.1-1.7 micrometers and optical telecommunication system using such a laser diode

InactiveUS20080043796A1Reduce areaHigh speed modulationSolid-state devicesSemiconductor laser optical deviceMicrometerDistributed Bragg reflector

A surface-emission laser diode includes a distributed Bragg reflector tuned to wavelength of 1.1 μm or longer, wherein the distributed Bragg reflector includes an alternate repetition of a low-refractive index layer and a high-refractive index layer, with a heterospike buffer layer having an intermediate refractive index interposed therebetween with a thickness in the range of 5-50 nm.

Owner:RICOH KK

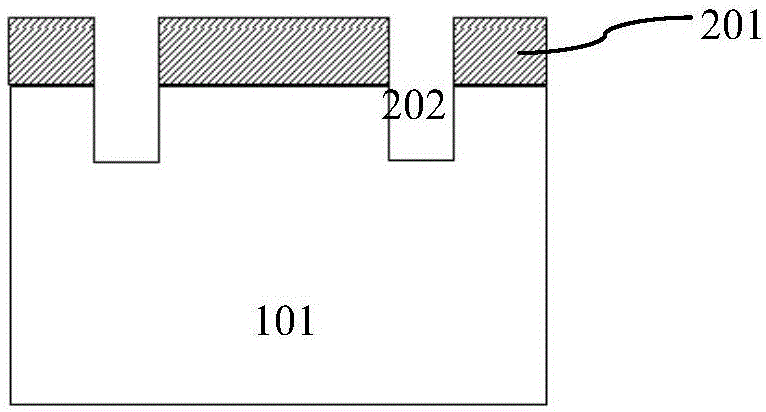

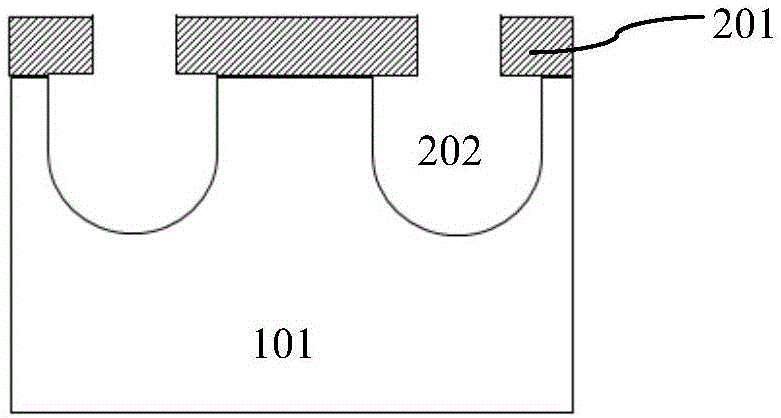

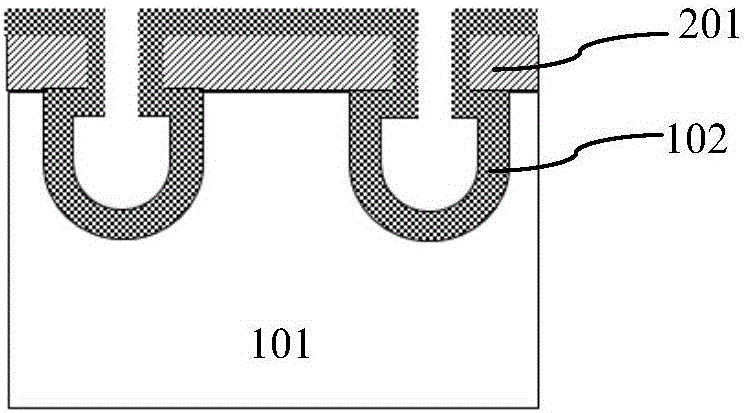

Shield gate trench MOSFET and manufacture method

ActiveCN107527948AReduce gate-to-drain capacitanceFast switching speedSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceTrench mosfet

The invention discloses a shield gate trench MOSFET. The gate trench includes a top trench and a bottom trench. A polysilicon gate is formed on both sides of the top trench. Source polysilicon is located in the middle of the gate trench and extends longitudinally through the entire gate trench. Channel regions are formed on semiconductor substrate surfaces between gate structures and source regions are formed on the surfaces of the channel regions. A polysilicon gate on one side of the top trench is connected to a gate formed by a front metal layer. A polysilicon gate on the other side of the top trench and the source regions are connected to a source through a second contact hole to form a structure for reducing the gate-drain capacitance of a device. The second contact hole reduces the distance between the gate trenches and reduces the on-resistance of the device and form an on-resistance compensation structure. The invention also discloses a method for manufacturing the shield gate trench MOSFET. The shield gate trench MOSFET can reduce the gate-drain capacitance, can increase the switching speed of the device, and can reduce the size of a unit device and improve an integration level.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

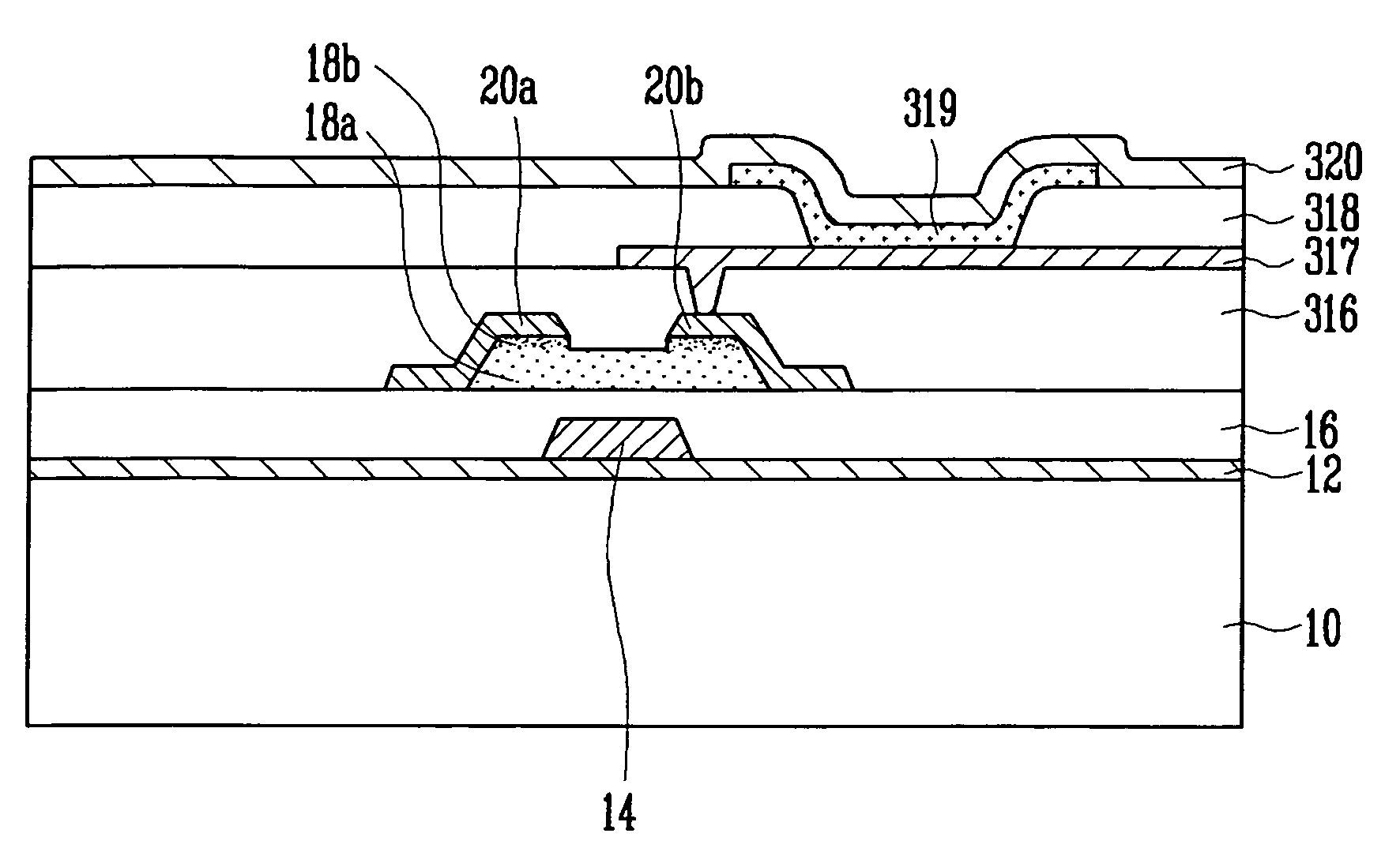

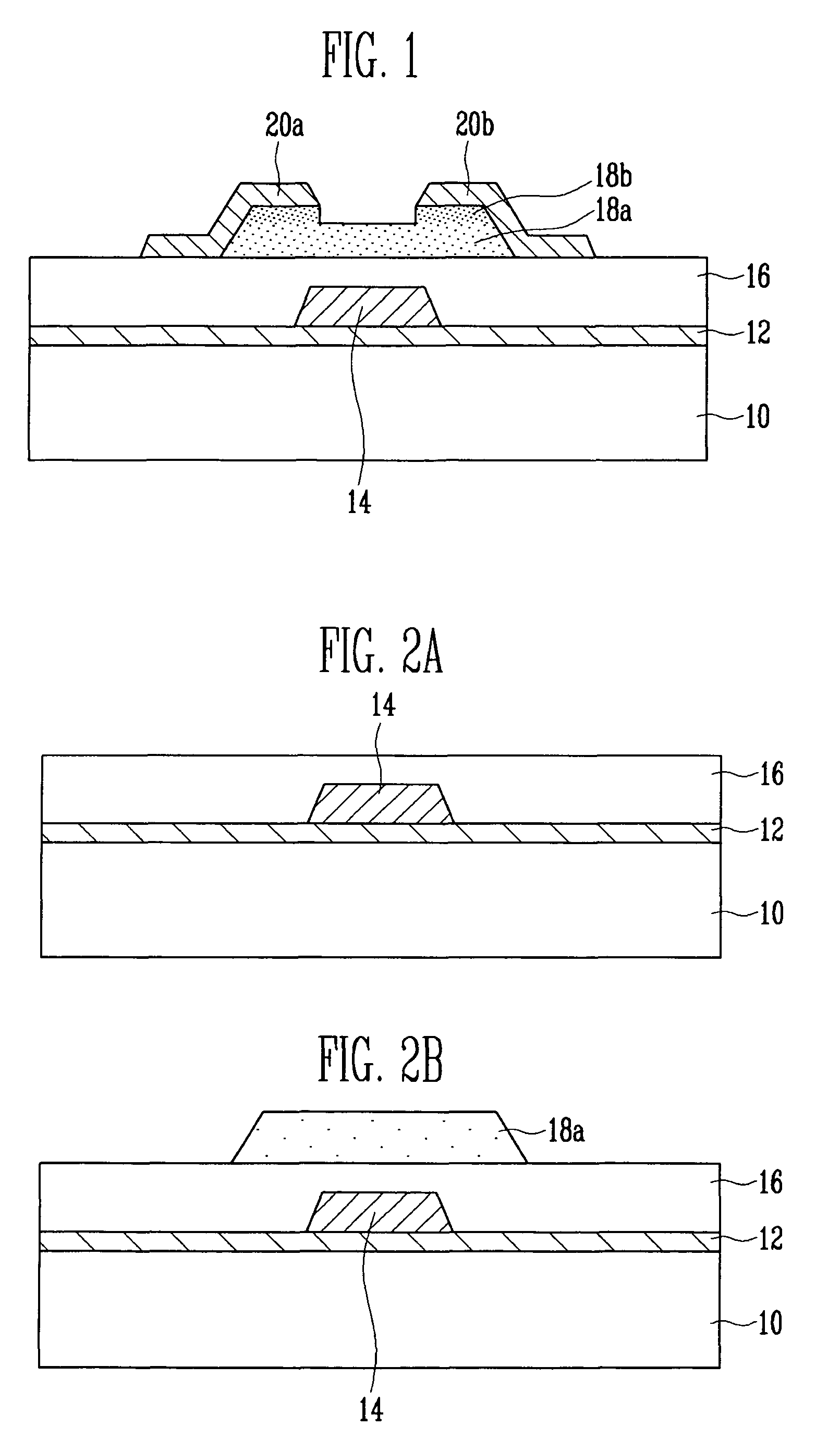

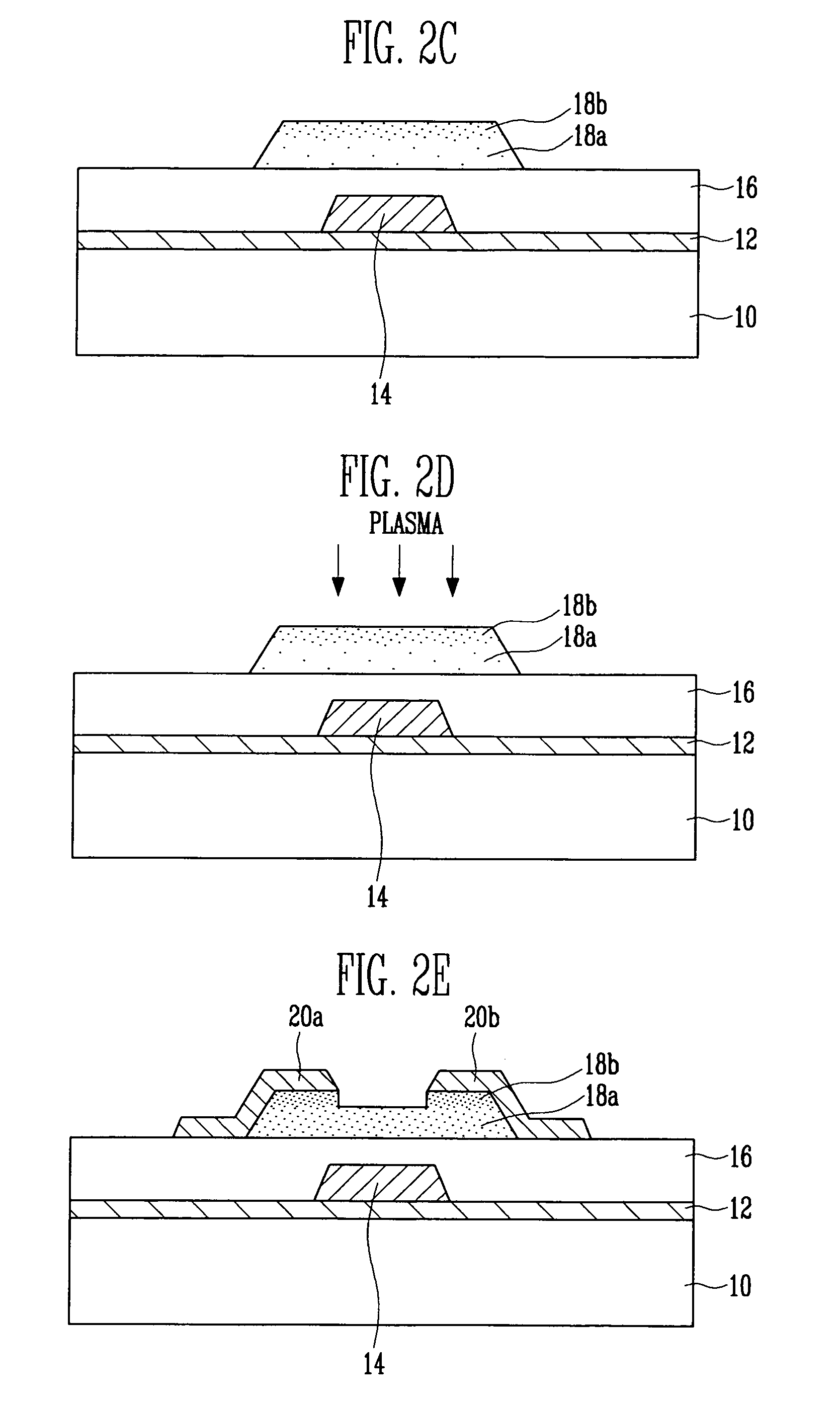

Thin film transistor, method of manufacturing the same and flat panel display device having the same

ActiveUS7994510B2Easily through energy barrierReduce depletionSolid-state devicesSemiconductor/solid-state device manufacturingOhmic contactCharge carrier

A thin film transistor is provided having an oxide semiconductor as an active layer, a method of manufacturing the thin film transistor and a flat panel display device having the thin film transistor. The thin film transistor includes: a gate electrode formed on a substrate; an oxide semiconductor layer isolated from the gate electrode by a gate insulating layer and including channel, source and drain regions; source and drain electrodes coupled to the source and drain regions, respectively; and an ohmic contact layer interposed between the source and drain regions and the source and drain electrodes. In the TFT, the ohmic contact layer is formed with the oxide semiconductor layer having a carrier concentration higher than those of the source and drain regions.

Owner:SAMSUNG DISPLAY CO LTD

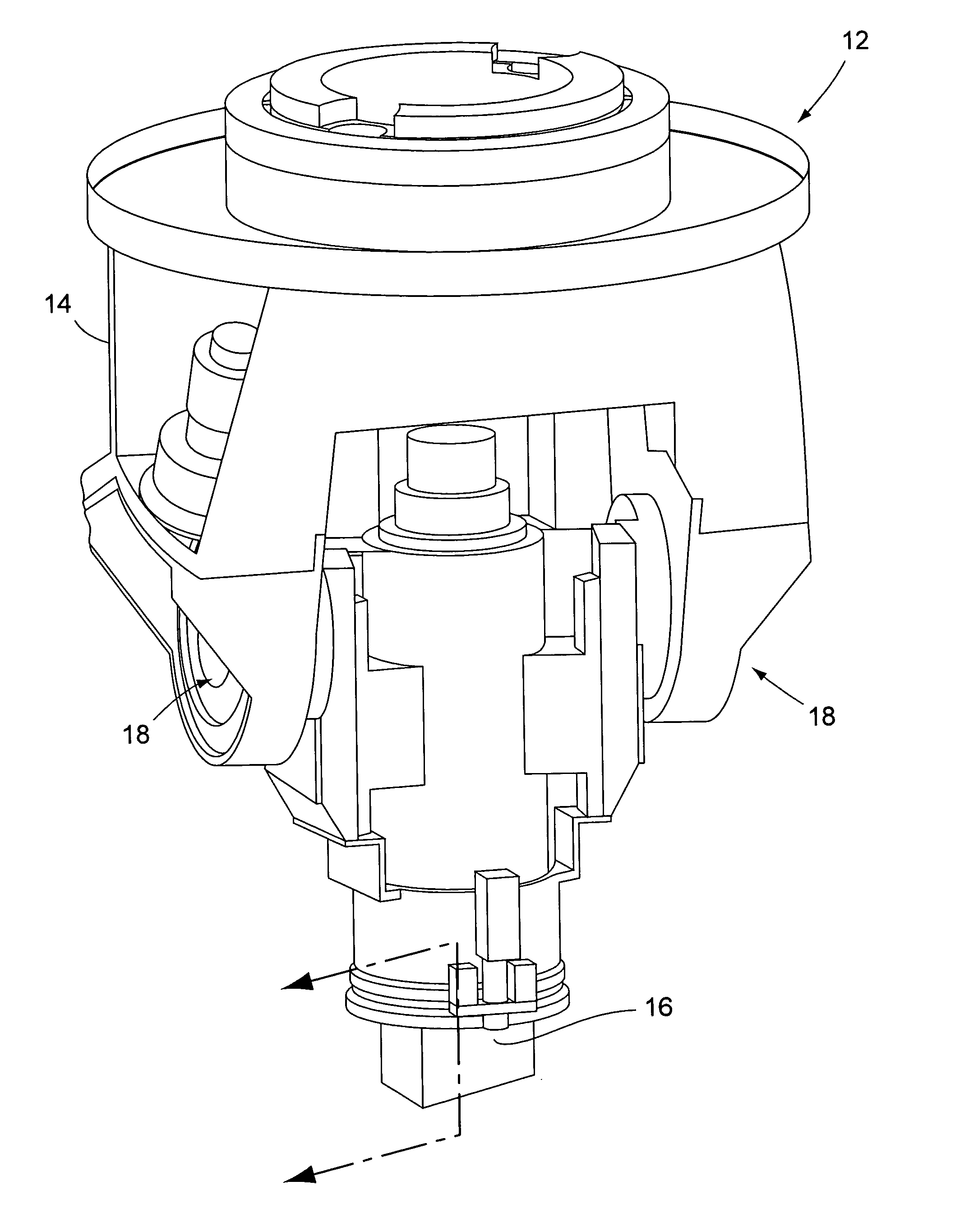

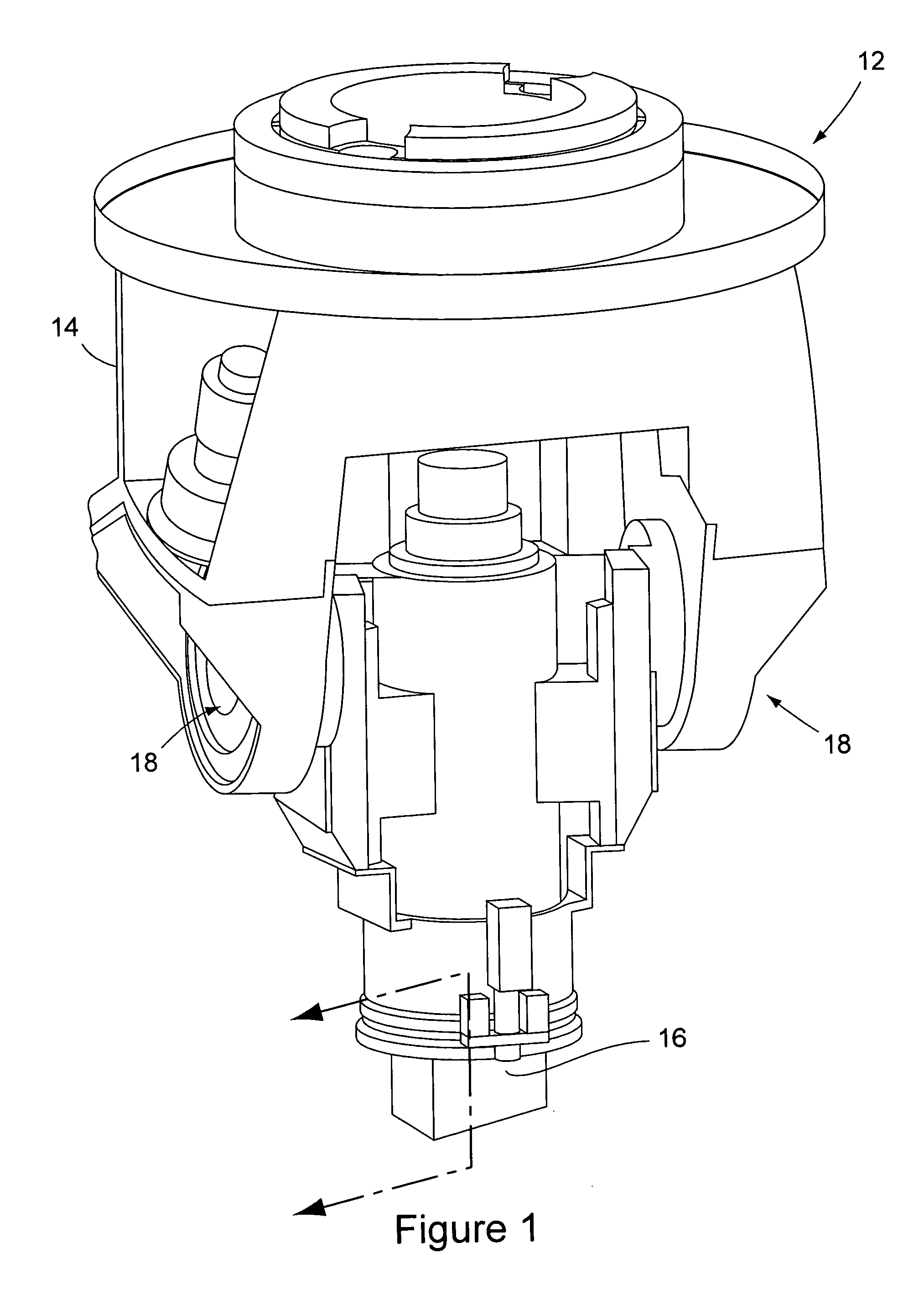

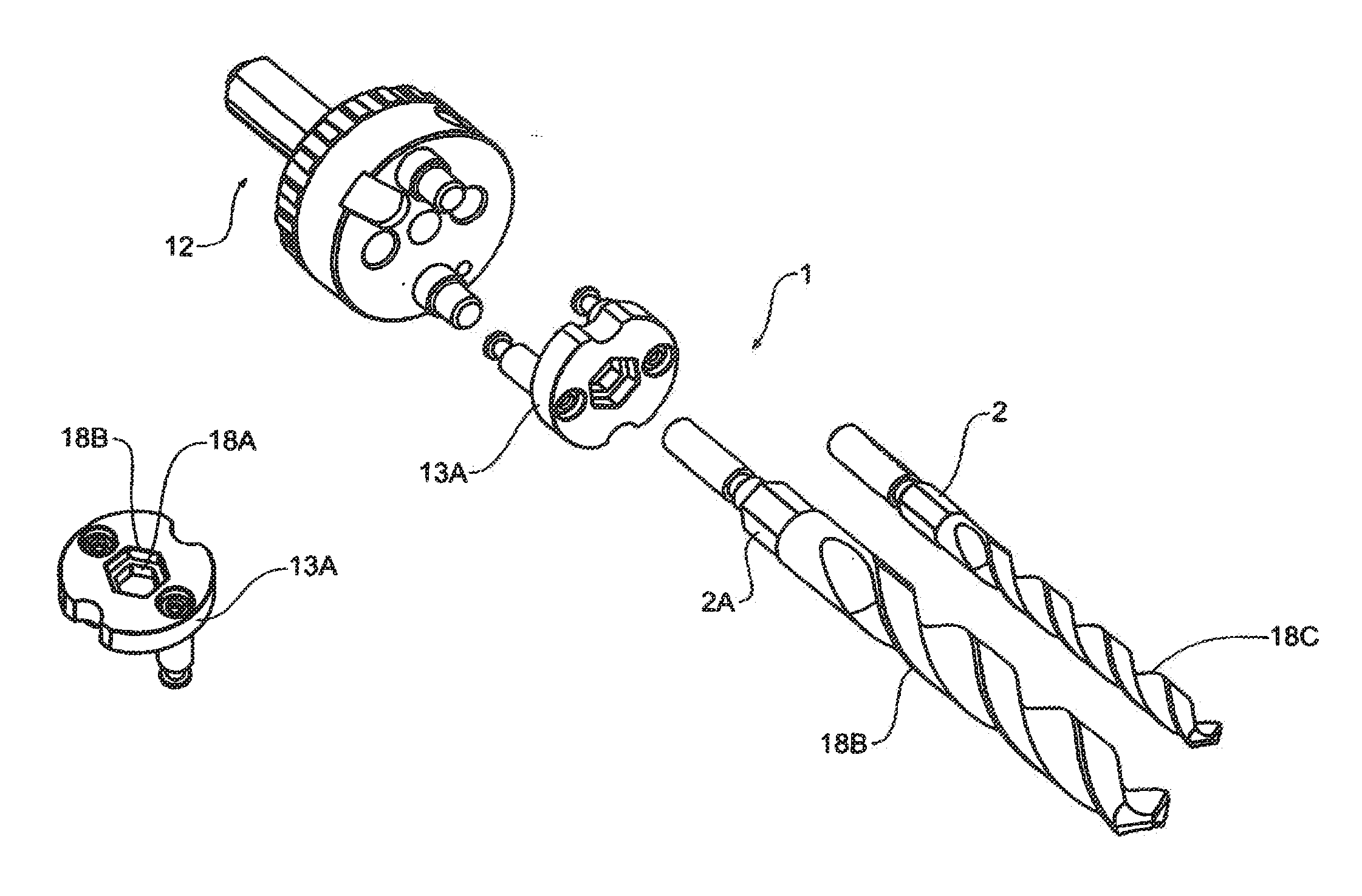

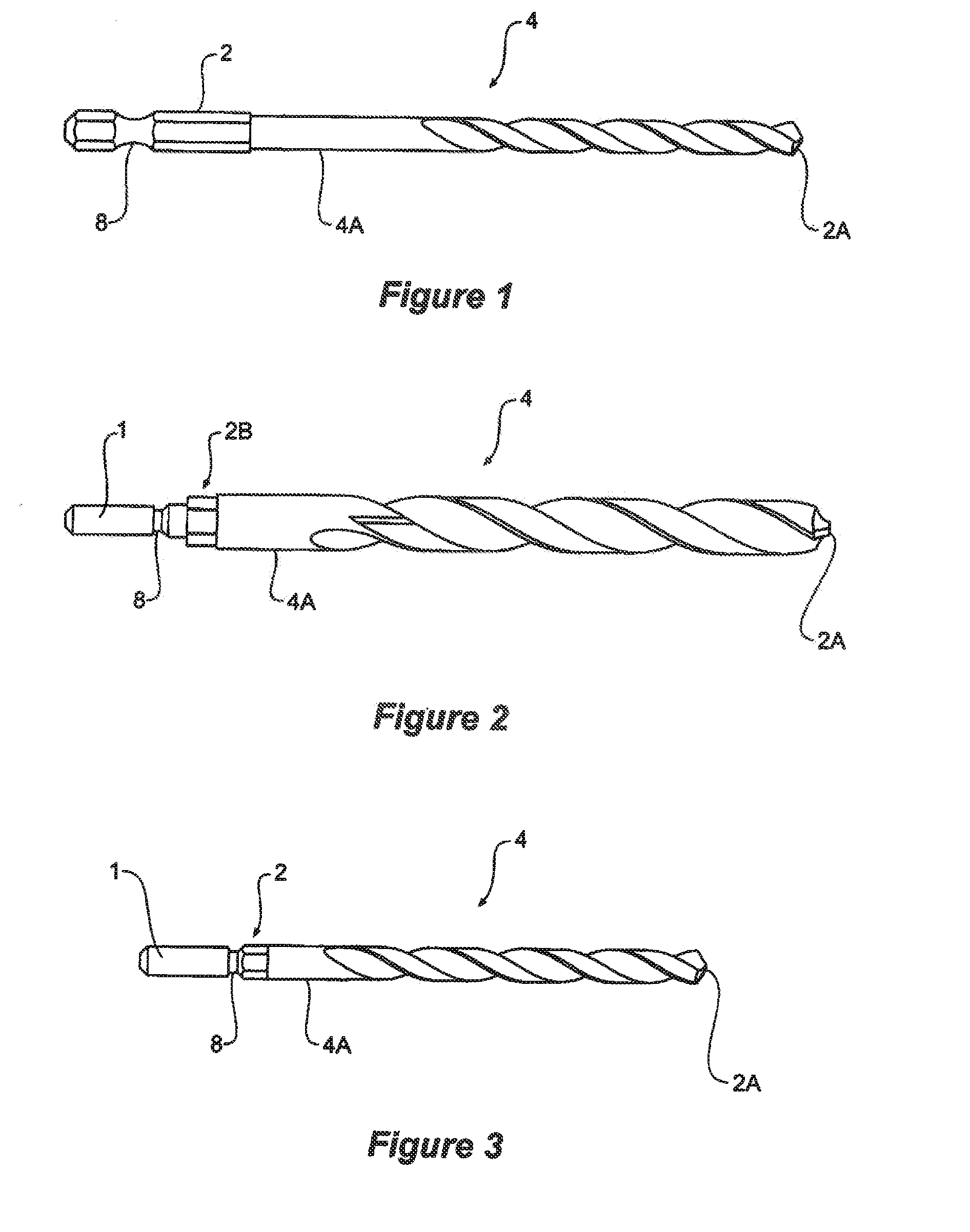

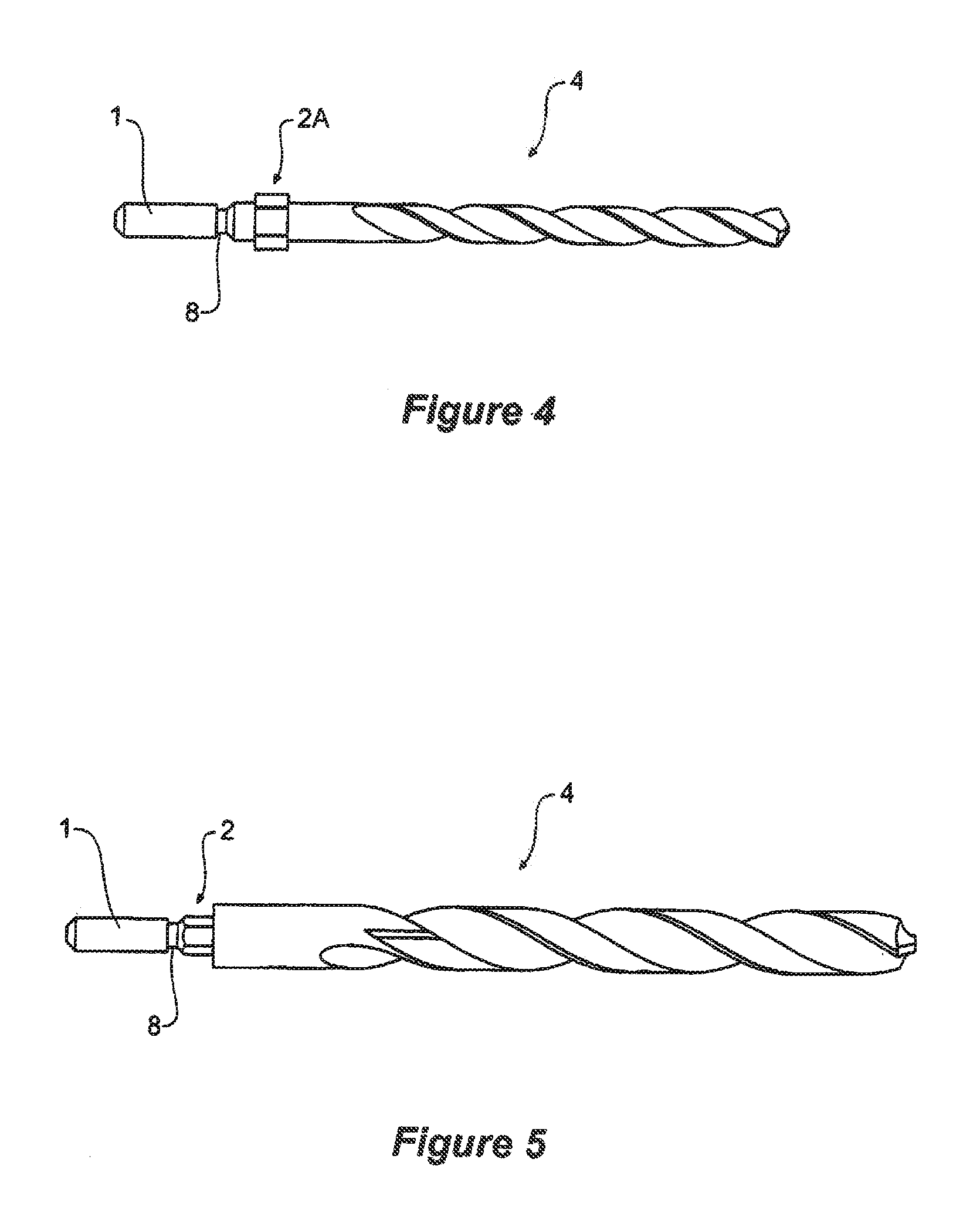

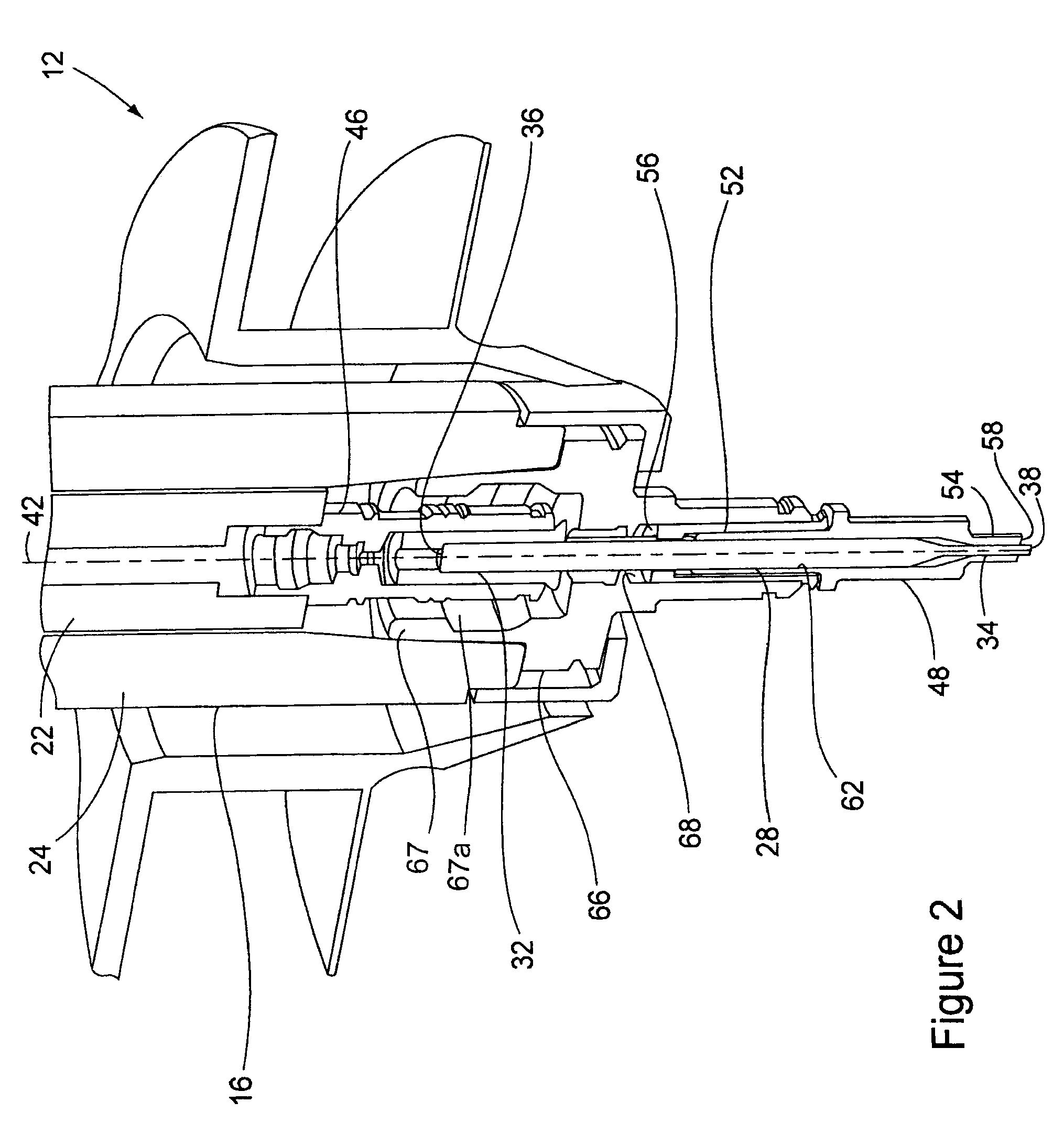

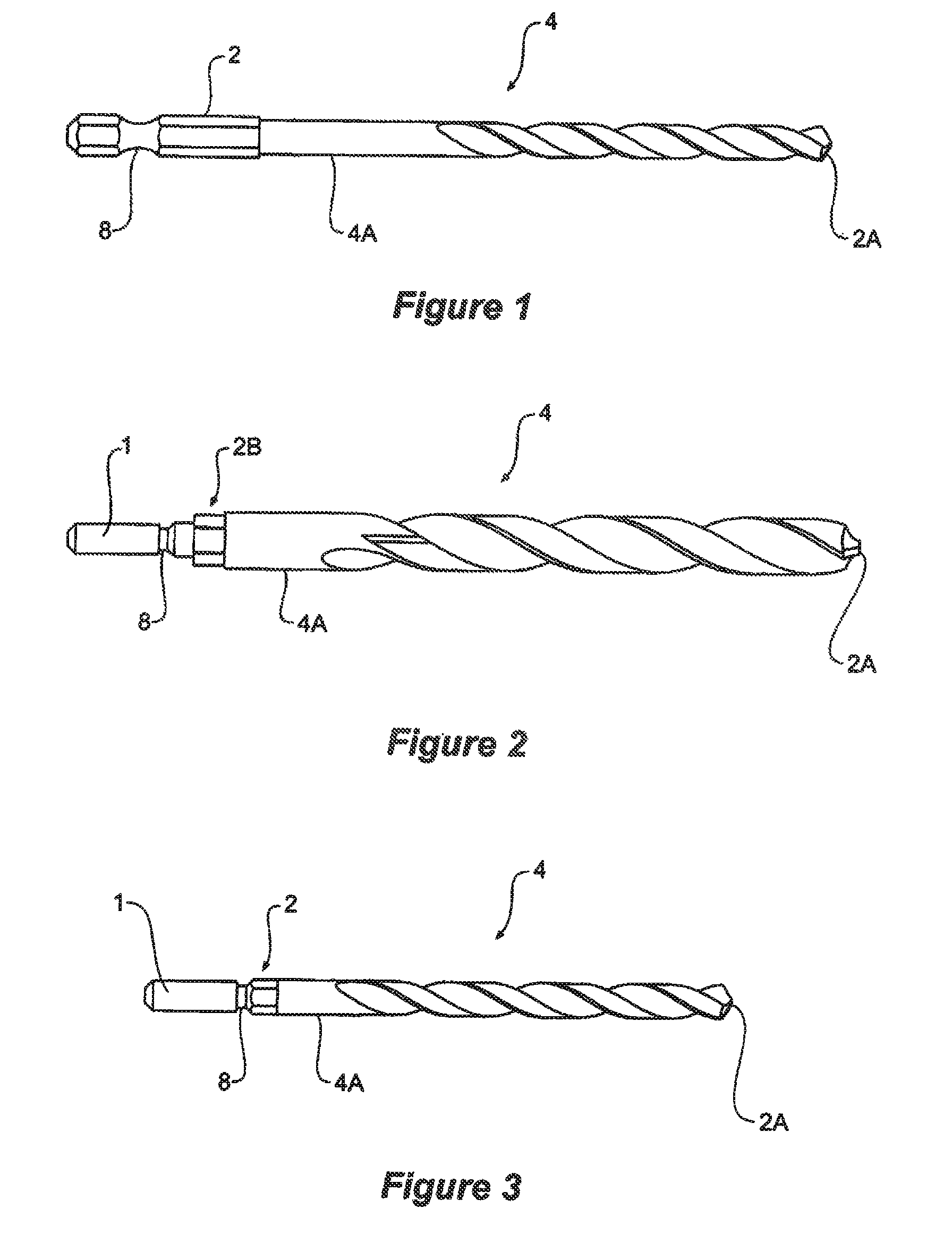

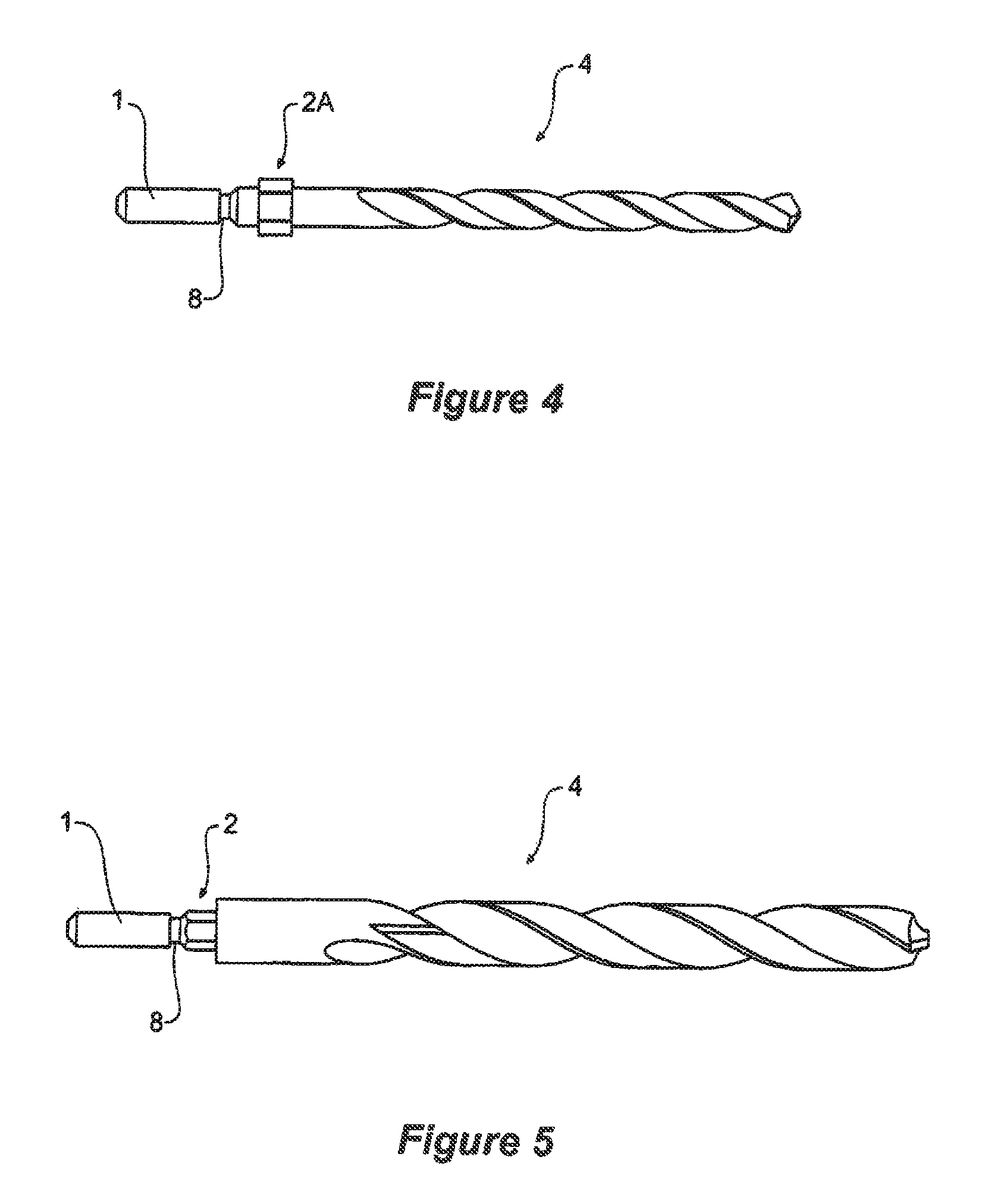

Chuck tool and bits

A tool arrangement and chuck apparatus for quick change of a range of tools; particularly, a quick change chuck adapted to engage various diameter drill bits, tools and tool holders. The tools are rotatable in a chuck or adaptor and have at one end a centering shaft portion having a constant diameter for multiple tool end diameters and shapes, a drive shoulder portion and a lock portion. The chucks have a tool centering arrangement for accommodating the constant diameter centering shaft. The chucks are also described as having tool bit release mechanism operable to disengage the tool from a retention mechanism when a force is applied inwards of the body of the chuck by the user to allow the tool bit to be removed longitudinally from the chuck but also arrange to allow the tool bit to be inserted longitudinally into the chuck without requiring any other user operation.

Owner:KEIGHTLEY KYM JOHN

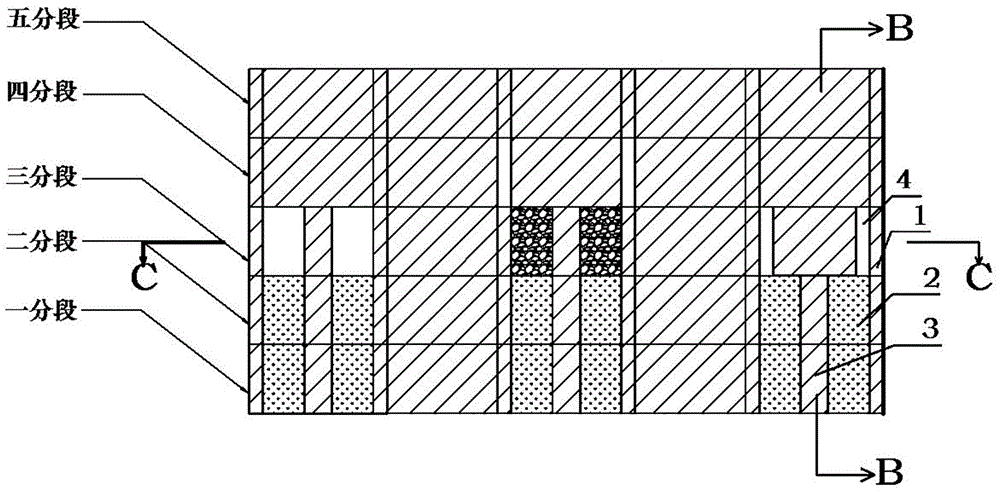

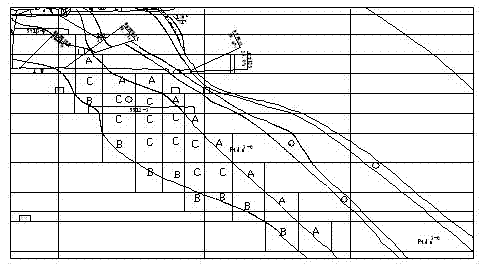

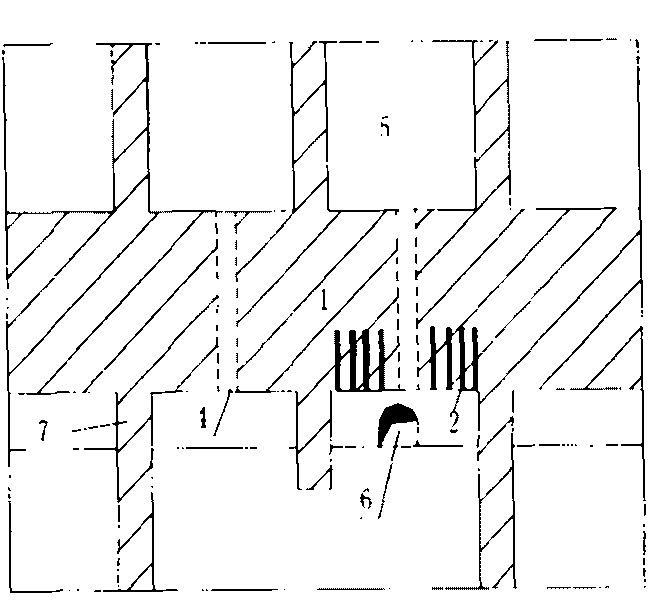

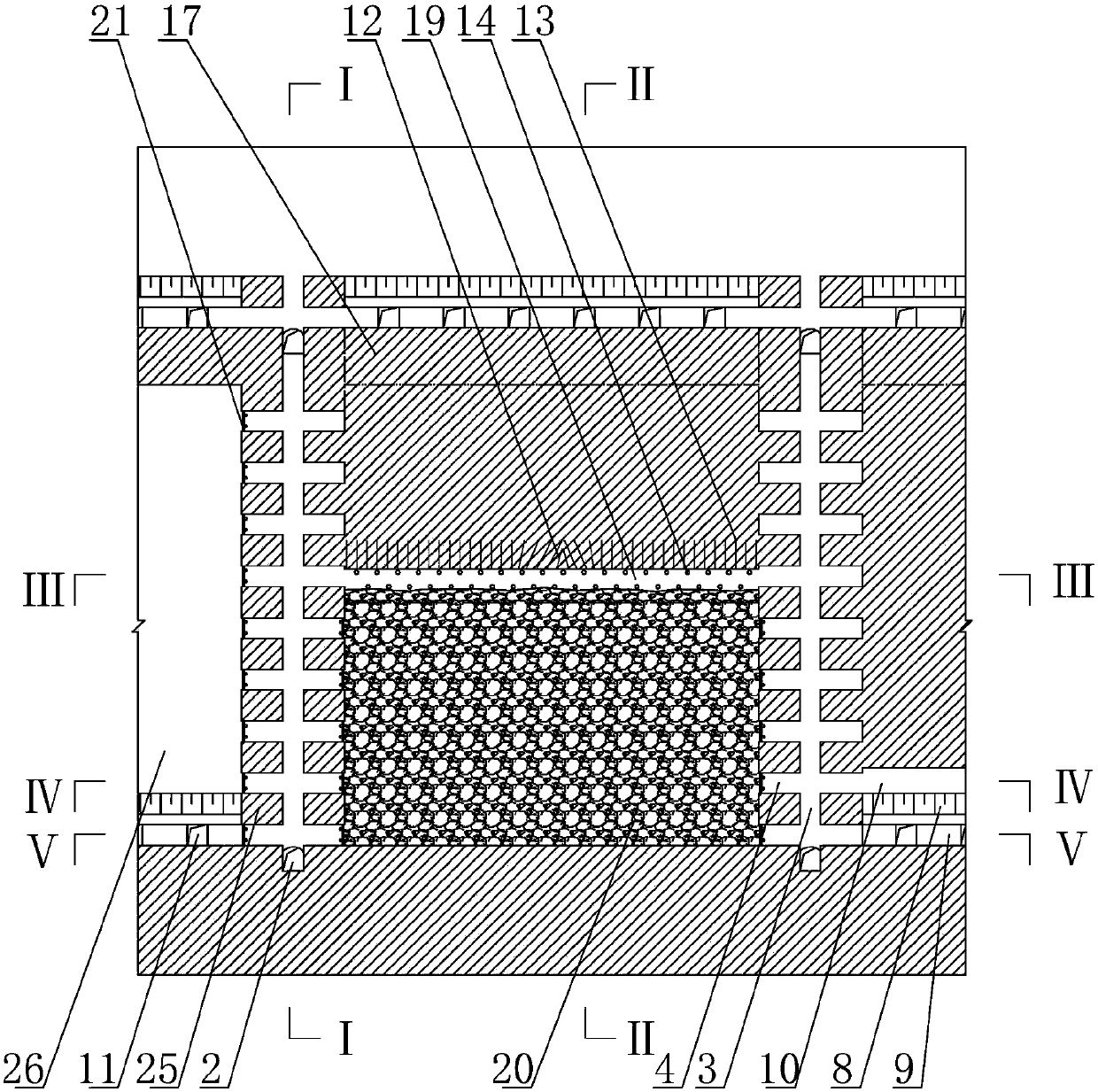

Medium-thickness gentle-dip broken ore body and chamber column type upward horizontal layering filling mining method

The invention belongs to the technical field of metallic mineral deposit underground mining methods, and particularly relates to a medium-thickness gentle-dip broken ore body upward horizontal layering filling mining method. The method includes the steps that firstly, an ore block is divided into multiple mining panels, each panel is further internally divided into multiple stopes, and stoping of each whole panel is conducted in two steps; in the first step, the stoping stopes are arranged at intervals, and studs are reserved on the two sides of each stope; in each stope, a segment is divided every 10 m, after being completely stoped, the next segment is bonded and filled with cement tailings, and the previous segment is stoped; accurate mining engineering in each panel is conducted on an ore body hanging side, and in order to protect the safety of chamber stoping, a pointed column supporting goaf is reserved in the middle of each stope; shallow hole ore falling is adopted, and ores are discharged through a carry-scraper; and after chamber stoping and filling in the first step are finished, the stopes used in the second step are stoped, and the method for stoping the stopes used in the second step is the same as the method for stoping the stopes used in the first step. The method is suitable for mining a medium-thickness gentle-dip broken ore body and has the beneficial effects of being safe in stoping, low in ore dilution and the like.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Forging technology of aviation engine blade based on nickel base superalloy

ActiveCN107598068AReduce depletionReduce chilling effectEngine componentsHeating/cooling devicesAviationMechanical property

The invention discloses a forging technology of an aviation engine blade based on nickel base superalloy and belongs to the technical field of aviation forging. The forging technology comprises the following steps:feeding, coating a bar with a lubricating agent, upsetting and heating, upsetting, cleaning a forging stock, coating the forging stock with the lubricating agent, carrying out finish forging and heating, carrying out finish forging, carrying out side cutting, correcting heating, correcting, cleaning a forge piece, and carrying out thermal treatment and final inspection. The aviationengine blade forged through the forging technology disclosed by the invention is fine and uniform in crystalline grain, and the grain size is grade 9-10; the phenomena that nickel base superalloy is likely to have coarse grain and / or mixed crystal during the forging process are overcome, and the tensile strength can reach 200KSI or above; the forge piece of the blade is complete in outline and isfree of defects including crack, fold and the like, and the machining allowance, mechanical property and the metallographic structure meet the design requirements.A novel selection approach is provided for producing the nickel base superalloy based engine blade with fine and uniform crystalline grain and high tensile strength; and the blade forge piece product can meet the using requirements of the shape and the size of the aviation engine blade.

Owner:AECC AERO SCI & TECH CO LTD

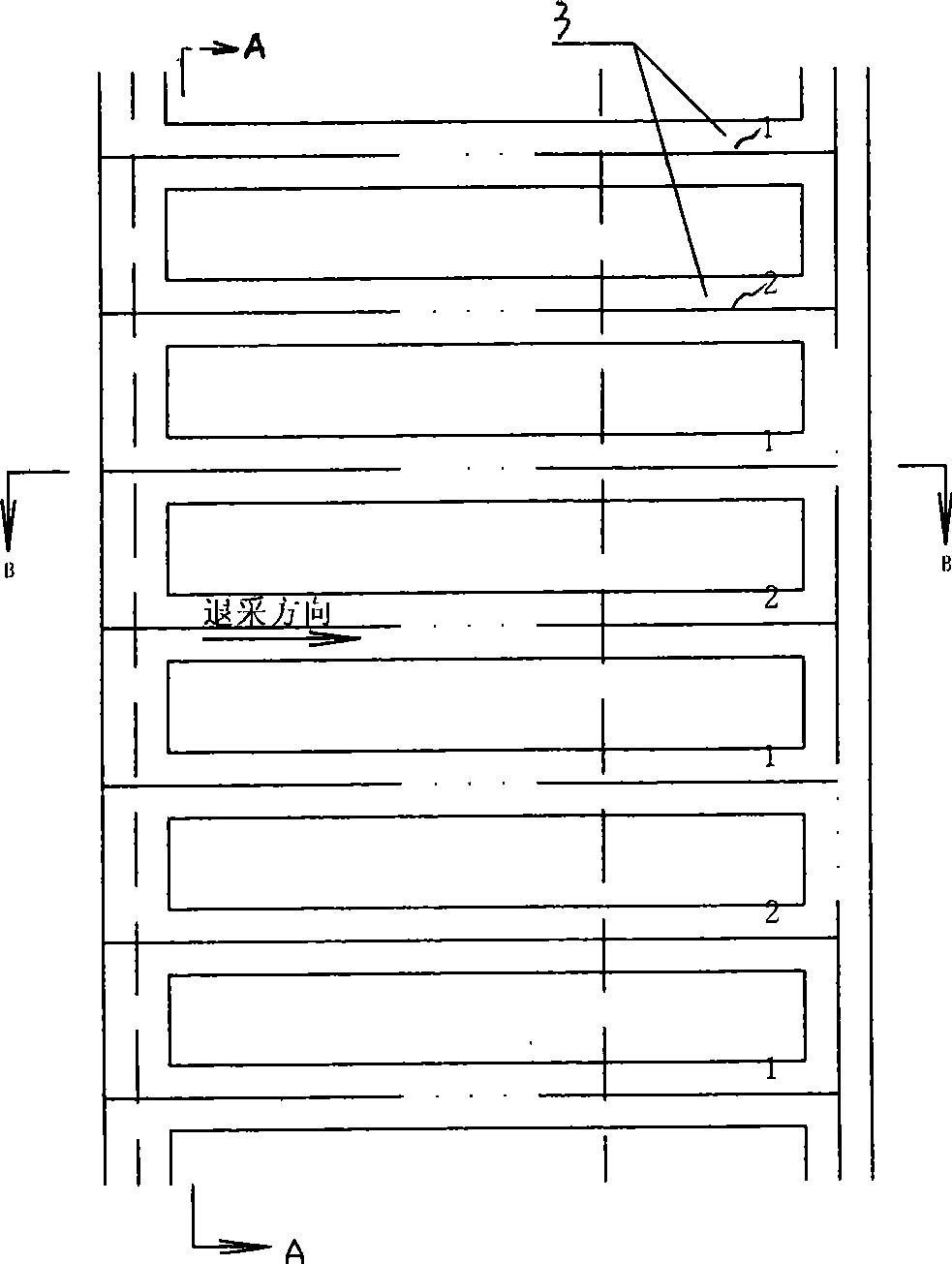

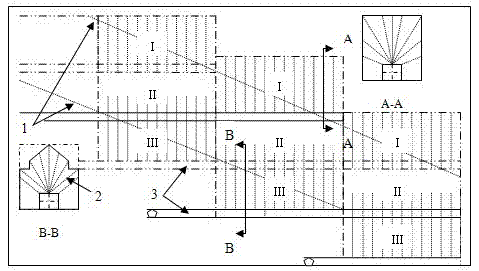

Pillarless sublevel caving method based vertical partitioning and combined ore drawing extraction technology of gently inclined ore bodies

InactiveCN102444403ATop in timeReduce depletionUnderground miningSurface miningMining engineeringMechanical engineering

The invention discloses a pillarless sublevel caving method based extraction technology used under the condition of gently inclined ore bodies. A series of problems of the pillarless sublevel caving method under the condition of gently inclined ore bodies such as efficient extraction of sublevel hanging wall and footwall triangle ore bodies, sublevel transition ore quantity, efficient recovery of footwall residual ores, timely supplementing and caving realization and the like are solved by the technical measures such as vertical partitioning, combined ore drawing, timely supplementing and caving, footwall residue full covering and the like. By designing the new pillarless sublevel caving method based vertical partitioning and combined ore drawing extraction scheme suitable for the condition of gently inclined ore bodies, the loss and dilution indexes when the pillarless sublevel caving method is applied under the condition of gently inclined ore bodies can be substantially reduced and the technical and economic benefits of mining can be increased.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Filling stope pillar recovery mining method

InactiveCN101725351AHigh recovery rateReduce depletion and lossesUnderground miningSurface miningInstabilityMineralogy

The invention relates to a filling stope pillar recovery mining method. Because drilling is carried out below an inclined plane of a safer ore-breaking upper layer, recovery of inbreak of obturation lagging behind part of ore body is ensured, the obturation is avoided to be mixed into ore body heap, the ore recovery rate is improved and the dilution and the loss of the ore are reduced. Meanwhile, because the construction of other development engineering is not carried out, the ore removal efficiency and the stripping ratio are far higher than those of other pillar recovery methods. Finally, the obturation inbreak naturally piles up and extrudes the stope inclined plane to form an active pressure so as to play a role of a certain support on the stope top plate and provide a subsequent drilling operation platform for effectively and safely recovering pillars. The obturation gravity is converted into the support force of the stope top plate so as to reduce the instability of the pillar recovery process and ensure the safety of the equipment and the personnel in the subsequent works of drilling, ore removal and the like. The invention is suitable for stope recovery of a filling mining method, wherein the rock mass is firm, the protodyakonov scale of hardness is 7-12, and the pillar thickness is 5-9 m.

Owner:招金矿业股份有限公司大尹格庄金矿

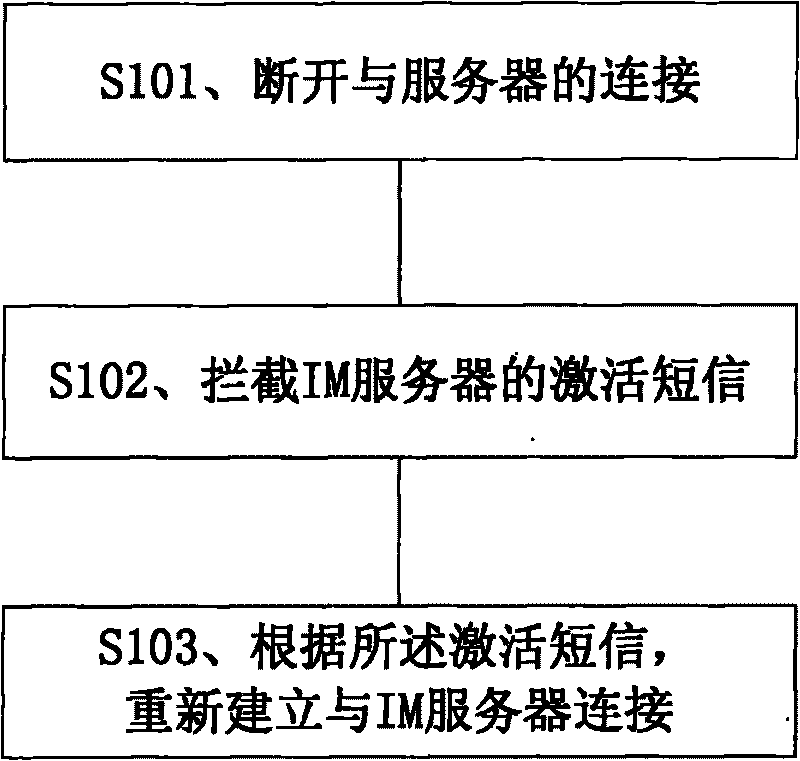

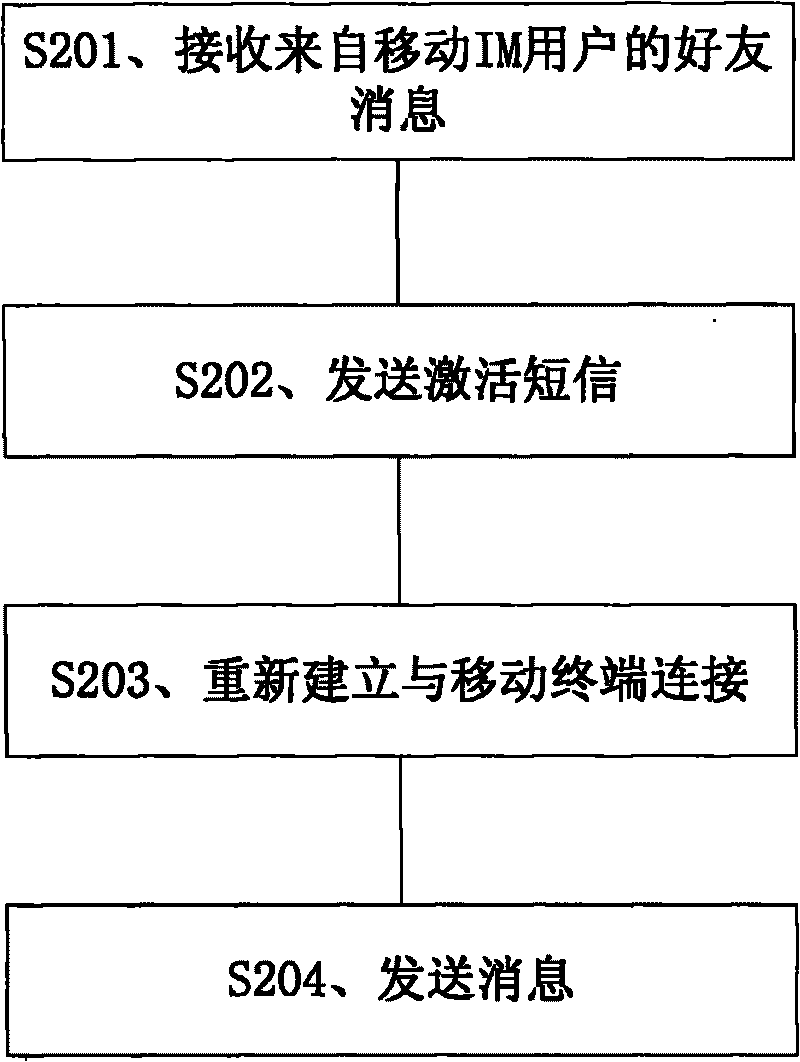

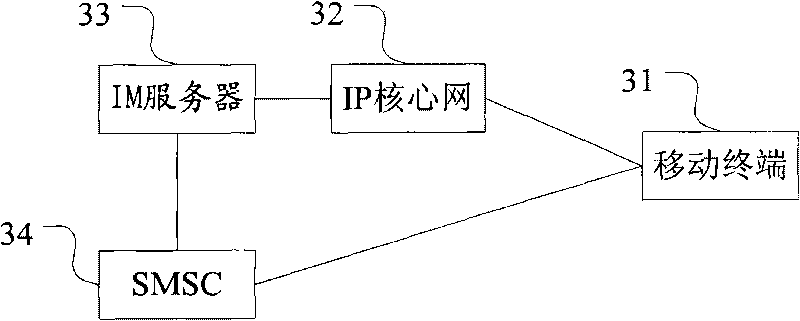

Method and device of mobile instant messaging

InactiveCN101742422AMeet the needs of instant messagingReduce power consumptionMessaging/mailboxes/announcementsData switching networksAir interfaceBiological activation

The invention provides a method of mobile instant messaging, comprising the following steps: disconnecting the connection with an instant messaging (IM) server; intercepting an activation message of the IM server; sending information for establishing a connection request to the IM server according to the activation message and reestablishing connection with the IM server. The invention also discloses a terminal, comprising a communication module and an intercepting module, wherein the communication module is used for disconnecting the connection with the IM server and reestablishing connection with the IM server according to the activation message; and the intercepting module is used for intercepting the activation message of the IM server. The invention realizes that the mobile IM user actively disconnects the connection with the server under certain conditions, and reestablishes connection with the IM server as required, thus not only reducing waste of network resources and air interface resources, reducing device cost and management cost of operators, but also meeting the requirement for instant messaging of mobile users.

Owner:HUAWEI TECH CO LTD

High-temperature anti-oxidation coating for steel billet of plain carbon steel and preparation method of high-temperature anti-oxidation coating

InactiveCN104497653APlay a protective effectHigh applicable temperatureCoatingsCellulosePolyvinyl alcohol

The invention relates to a high-temperature anti-oxidation coating for a steel billet of plain carbon steel and a preparation method of the high-temperature anti-oxidation coating. The technical scheme is as follows: a component A and a component B which are sub-packaged are mixed according to the mass ratio of (0.8-2):1 and are mechanically stirred when the high-temperature anti-oxidation coating is used, wherein the component A is prepared from the chemical components in percentage by mass: 20-35% of alumina powder, 20-30% of silicon dioxide powder, 15-25% of magnesia powder, 5-15% of calcium oxide powder, 5-10% of zirconium dioxide powder, 2-5% of sodium carbonate powder, 2-5% of potassium carbonate powder, 2-5% of iron oxide powder and 1-5% of aluminum powder; and the component B is prepared from the chemical components in percentage by mass: 1-5% of (CH2O)n, 4-10% of (C12H22O11)n, 5-15% of (C6H10O5)n, 0.5-2% of polyvinyl alcohol, 0.1-1% of sodium carboxymethylcellulose, 0.1-0.8% of hydroxyethyl cellulose and the balance of water. The high-temperature anti-oxidation coating has the characteristics of good anti-oxidation effect, high applicable temperature, self-falling capacity, safety, environment friendliness and low cost.

Owner:苏州赛格瑞新材料有限公司

Print cartridge ordering system

A method for automatically ordering printer consumables which includes determining when a printer consumable is close to depletion and automatically ordering a replacement to the printer consumable based upon a plurality of criteria. The criteria includes the amount of consecutive time a consumer has been a member of a printer consumable subscription service and the number of printer consumables ordered by a consumer.

Owner:DELL PROD LP

Thin and extremely thin ore body mining method

InactiveCN109653748AEliminate destructionReduce lossesUnderground miningBlastingSpontaneous combustionReinforced concrete

The invention discloses a (thin and extremely thin ore body mining method) which is mainly used for mining a steep ore body. Hanging wall surrounding rocks of the steep ore body are unstable to moderately-stable and had better naturally collapse to form blocks, heading wall surrounding rocks of the steep ore body are moderately-stable, the ore body is extremely unstable or moderately-stable, a drilling drift is not supported, and a blast hole does not deform. The method is applicable to mining of an ore with regular morphology of the ore body, small thickness change, fewer horse-stones or no interlayer, no spontaneous combustion, no adhesion, collapsible grounds and surrounding rocks, obvious ore-rock boundary lines and complicated conditions. By the aid of a subsection caving method, mid-deep borehole drilling, pre-splitting blasting and reinforced concrete false roof laying is introduced, and actual mining is performed under a false roof (only by laying in a first sub-layer and generally in a middle roadway). The method has the advantages that safety of operators is good, ore block production capacity is high, mining equipment is simple, convenient to use and maintain and low inmining cost, and the mining method is used for mining a steep narrow vein with proper conditions with the development of a mining technology.

Owner:刘宏刚 +2

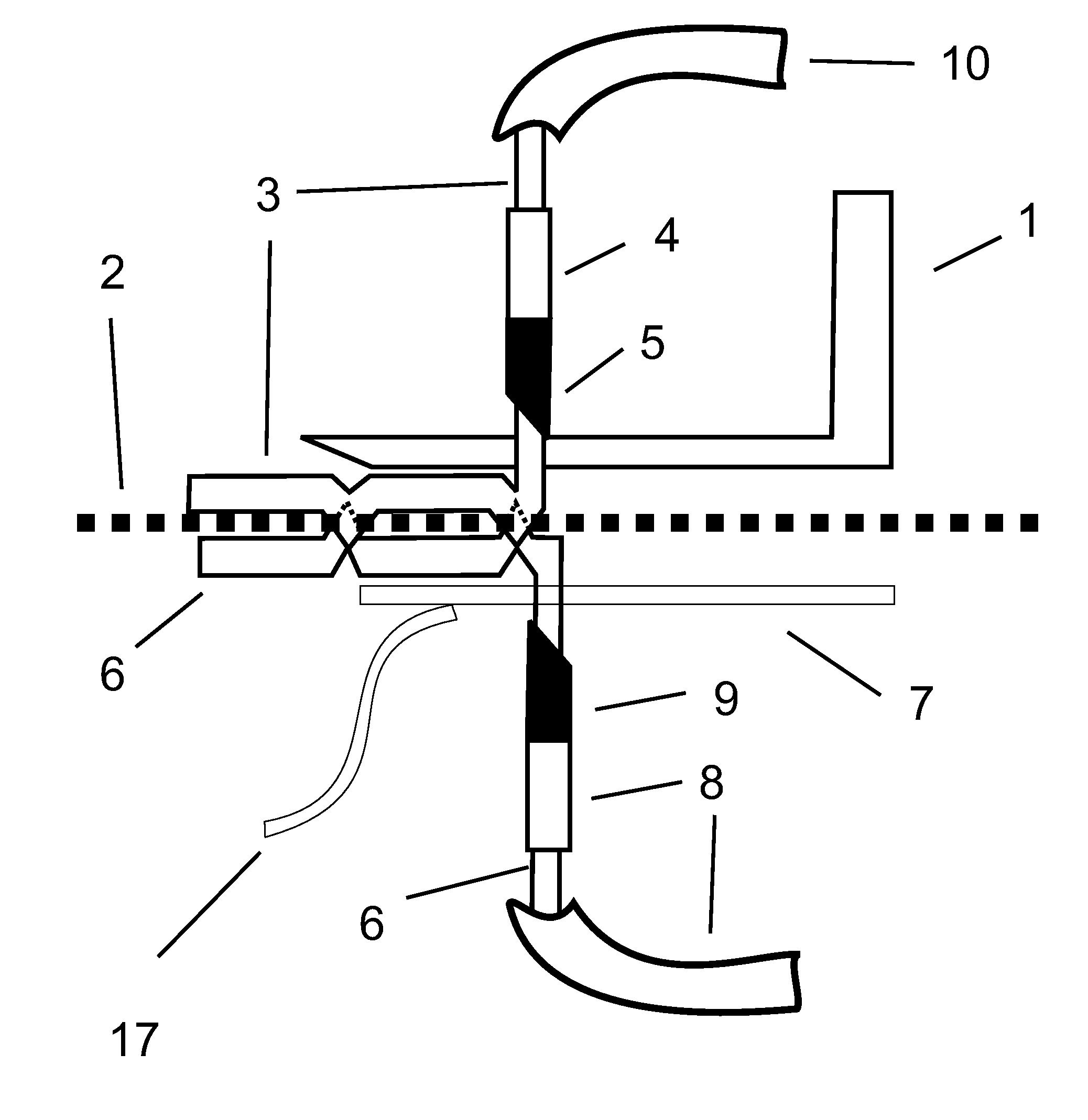

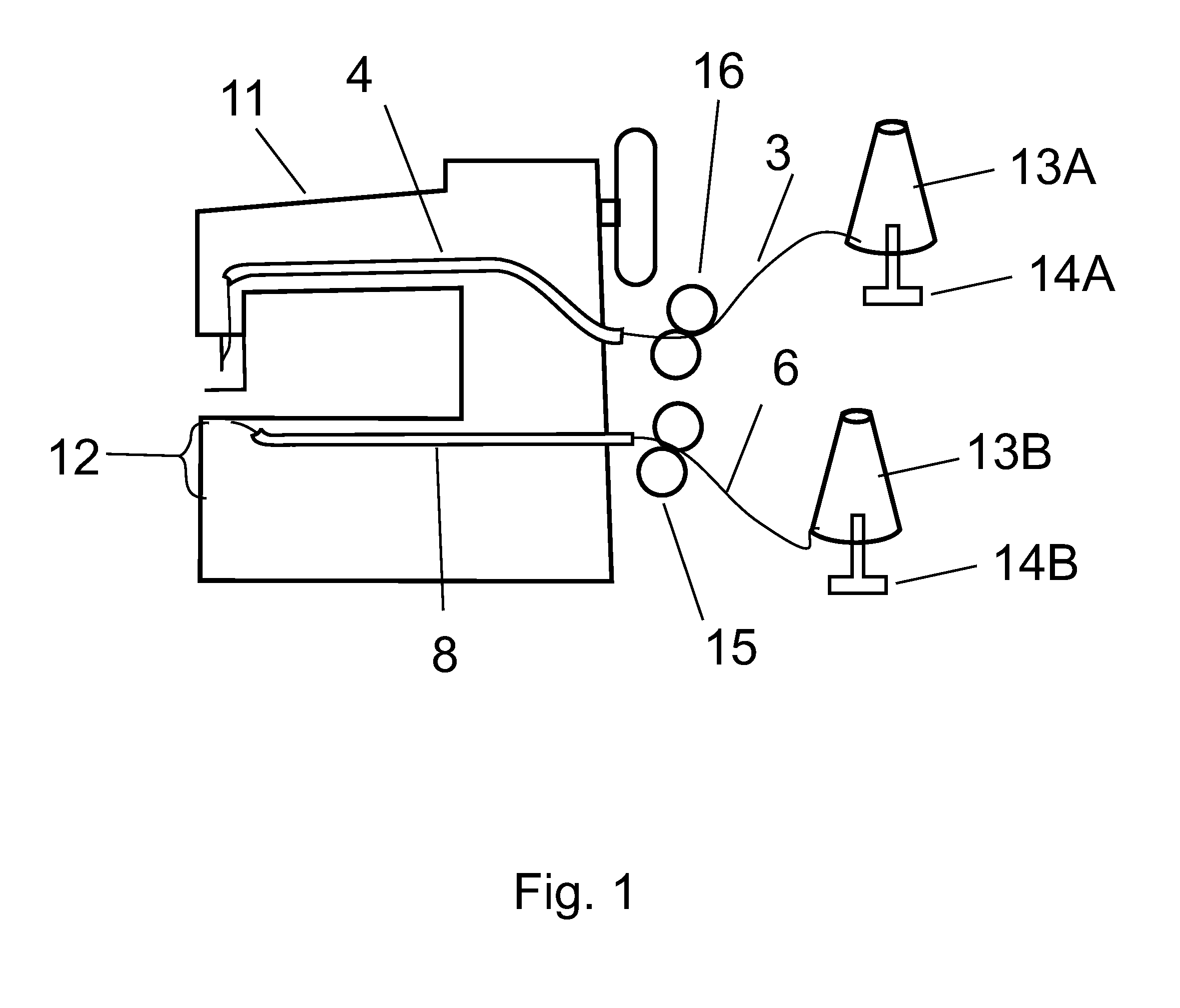

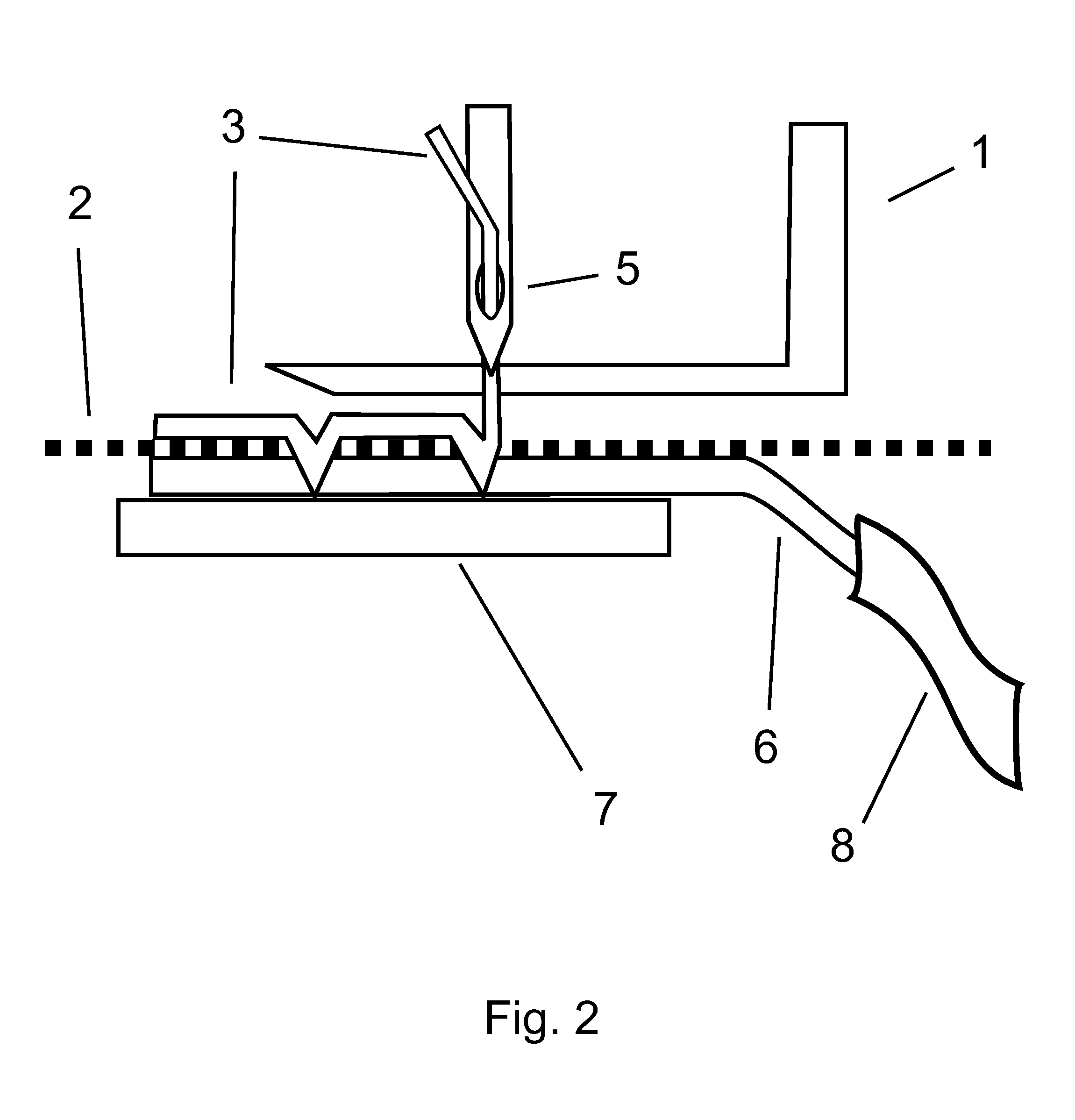

Stitching apparatus and method of use

InactiveUS20140216633A1Reduce complexityReduce breakageLayered productsSewing apparatusBiological activationMechanical engineering

The present invention is a stitching apparatus and method of use wherein large spools of material can be used and driven into position in a sewing, embroidery or other stitching machine, thereby decreasing the complexity of the stitching process and reducing breakage and thread depletion. The apparatus generally comprises an upper thread feeding assembly, a lower thread feeding assembly, a stitching surface area and an activation assembly, wherein the activation assembly bonds the upper thread to the lower thread at the stitching surface area.

Owner:MCCUE FAMILY TRUST

Covering layer forming method of blind ore bodies

The invention discloses a covering layer forming method of blind ore bodies with stable and massive roof surrounding rocks applying a bottom pillar-free subsection collapse method. The method can obviously reduce the work quantity of caving, has low caving cost and a little ore dilution, and improves the production efficiency and economic benefit of mines. The key points of the technical scheme are as follows: a first subsection mining tunnel is distributed in an ore body, and continuous gobs provided after the first subsection mining are used for inducing the roof rocks to collapse; and with the performing of the mining work, the areas of the gobs are expanded continuously, when the areas of the gobs reach the critical exposed area, the roof rocks at the gobs are unstable gradually and collapsed under the effects of stress and gravity so as to form a covering layer. When the first subsection mining tunnel distributes blast holes, the ore bodies among the access roads are required to be thoroughly collapse so as to cut off the support of the roof surrounding rocks completely and form continuous gobs with exposed area. The forming method is applicable to forming the covering layer of more stable and massive blind ore bodies of the roof surrounding rocks.

Owner:KUNMING UNIV OF SCI & TECH

Friction stir welding apparatus

ActiveUS7641096B2Facilitates installation and removalIncreases available production timeWelding/cutting auxillary devicesAuxillary welding devicesFriction stir weldingKnife handles

A friction stir welding apparatus has a novel tool-in-tool construction where a friction stir welding pin tool extends through a center bore of a friction stir welding shoulder tool and is moveable axially and rotationally relative to the shoulder tool. The pin tool and shoulder tool both have their own dedicated tool holders and spindles that enable the tools to rotate and move axially relative to each other and enable easy replacement of each of the tools.

Owner:THE BOEING CO

Ming method for stoping high-dipping thick orebody with medium and above stability in ore mass

ActiveCN107939402AAvoid collapsing intoReduce mix rateUnderground miningSurface miningMineralogyDeep hole

The invention discloses a mining method for stoping a high-dipping thick orebody with the medium and above stability in an ore mass. The method comprises the steps that an inverted-stepped mining faceis arranged in the thickness direction of the orebody in an ore room, mining is advanced from bottom to top, the mining face part close to a hanging wall is ahead of the mining face part close to a lying wall by a certain height, the advanced mining height of the mining face part close to the hanging wall is utilized to provide an operation space, a shallow hole is drilled upwards in the operation space, and a horizontally parallel medium-length hole is drilled in the direction of the lying wall to blast and break ores; and an anchor rod is used for anchoring partial unstable rocks on the hanging wall in the operation space, a part of the mined ores is temporarily left in the ore room to serve as a protective bottom column and a buffer layer of the hanging wall and provide a standing platform for upward operation and temporarily bearing hanging wall rocks, and a large quantity of ores are removed after ore room exploration is completed. The mining method is beneficial for reducing mixing of waste rocks in the mining process of the high-dipping thick orebody and improving the recycling ratio of resources, the blackness of the ores is even, the stope preparation work amount is less,and rock drilling and blast working are easy to organize.

Owner:KUNMING METALLURGY COLLEGE

Chuck tool and bits

ActiveUS9550237B2Reduce depletionSleeve/socket jointsTransportation and packagingTool bitEngineering

A tool arrangement and chuck apparatus for quick change of a range of tools; particularly, a quick change chuck adapted to engage various diameter drill bits, tools and tool holders. The tools are rotatable in a chuck or adaptor and have at one end a centering shaft portion having a constant diameter for multiple tool end diameters and shapes, a drive shoulder portion and a lock portion. The chucks have a tool centering arrangement for accommodating the constant diameter centering shaft. The chucks are also described as having tool bit release mechanism operable to disengage the tool from a retention mechanism when a force is applied inwards of the body of the chuck by the user to allow the tool bit to be removed longitudinally from the chuck but also arrange to allow the tool bit to be inserted longitudinally into the chuck without requiring any other user operation.

Owner:KEIGHTLEY KYM JOHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com