Filling stope pillar recovery mining method

A mining method and bottom pillar technology, applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of increasing the complexity of ore pillar mining, poor mining conditions, and ore pillar deformation, so as to reduce dilution and loss. , the effect of reducing insecurity and high-efficiency recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

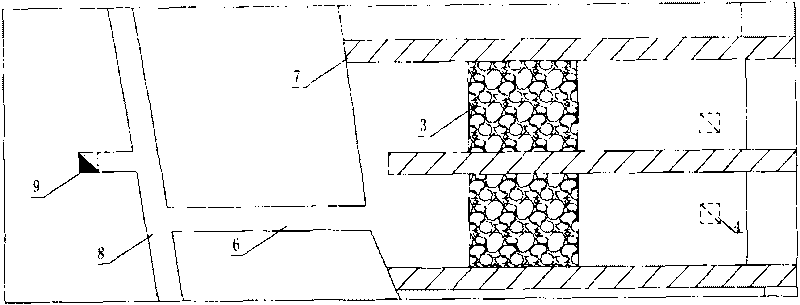

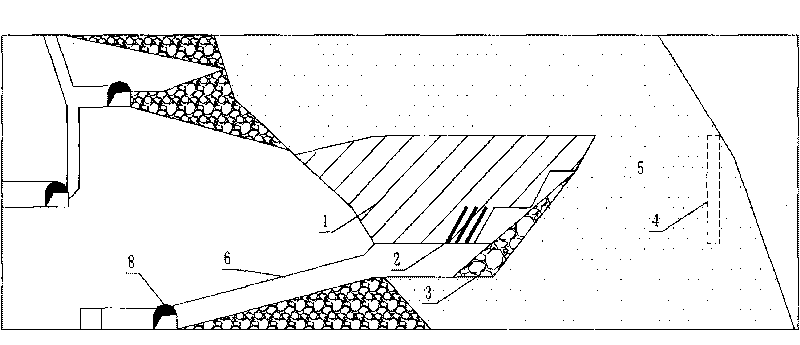

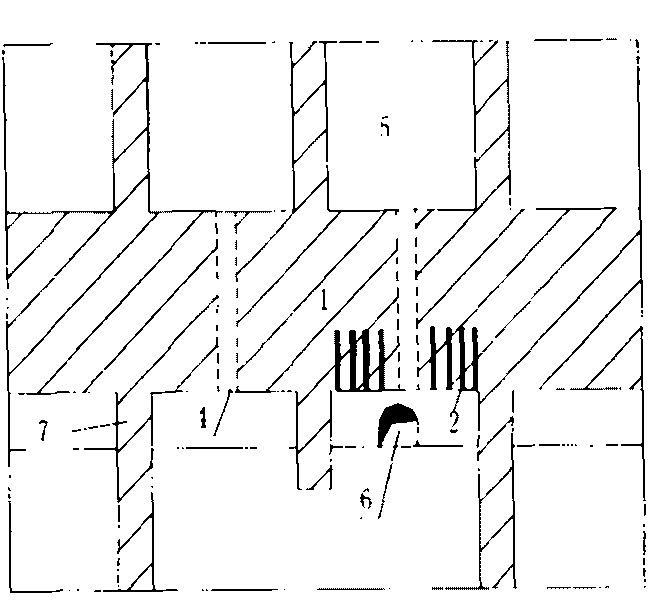

[0022] 1. The height of the ore body is from the roof of the existing stope to the floor of the bottom layer of the upper middle stope, with an average height of 8.0 meters and an average width of 16 meters. Two pillar stopes are arranged perpendicular to the strike of the ore body, each stope is 7 meters wide, and a 2-meter column is reserved in the middle.

[0023] 2. Construct a cutting patio on the top wall of each stope, with a specification of 2.0×2.0 meters and a height of 8 meters to the bottom floor of the upper and middle stope, as the free surface for the initial inclined ore falling.

[0024] 3. Adopt 7655 air-leg rock drill with rated air volume of 60l / s, impact frequency of 35Hz, drill bit of Φ40mm inline, and drill inclined parallel holes with an inclination angle of 60 degrees.

[0025] 4. After the working plane is formed, the distance between the ore-falling blastholes is 1.2 meters, the minimum resistance line is 0.7 meters, and 11 rolls of charges are charg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com