Sublevel fill-mining method

A technology of backfill mining and sub-caving method, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of high cost, unsatisfactory effect and low filling efficiency of cemented filling, and achieves low cost, good ventilation conditions, The effect of low filling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

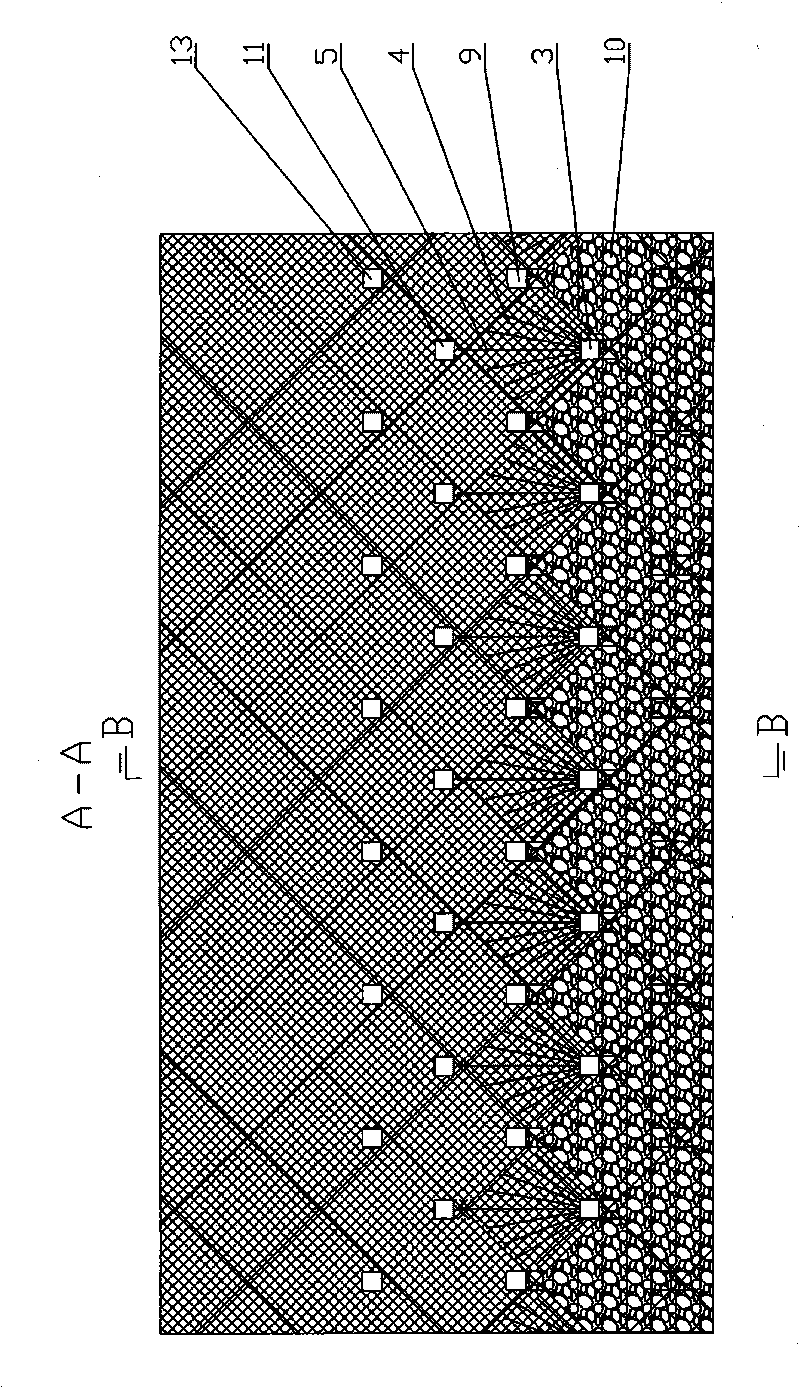

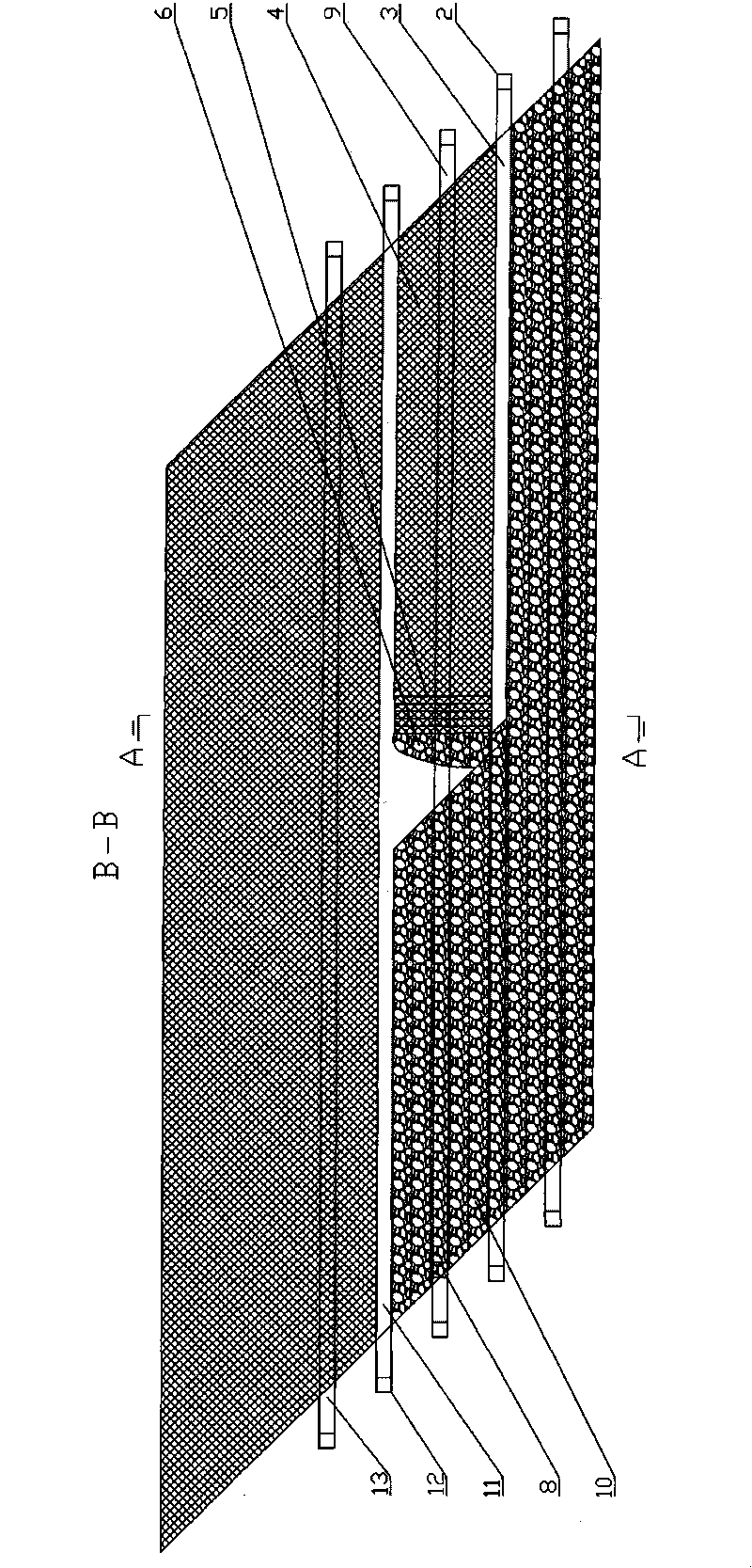

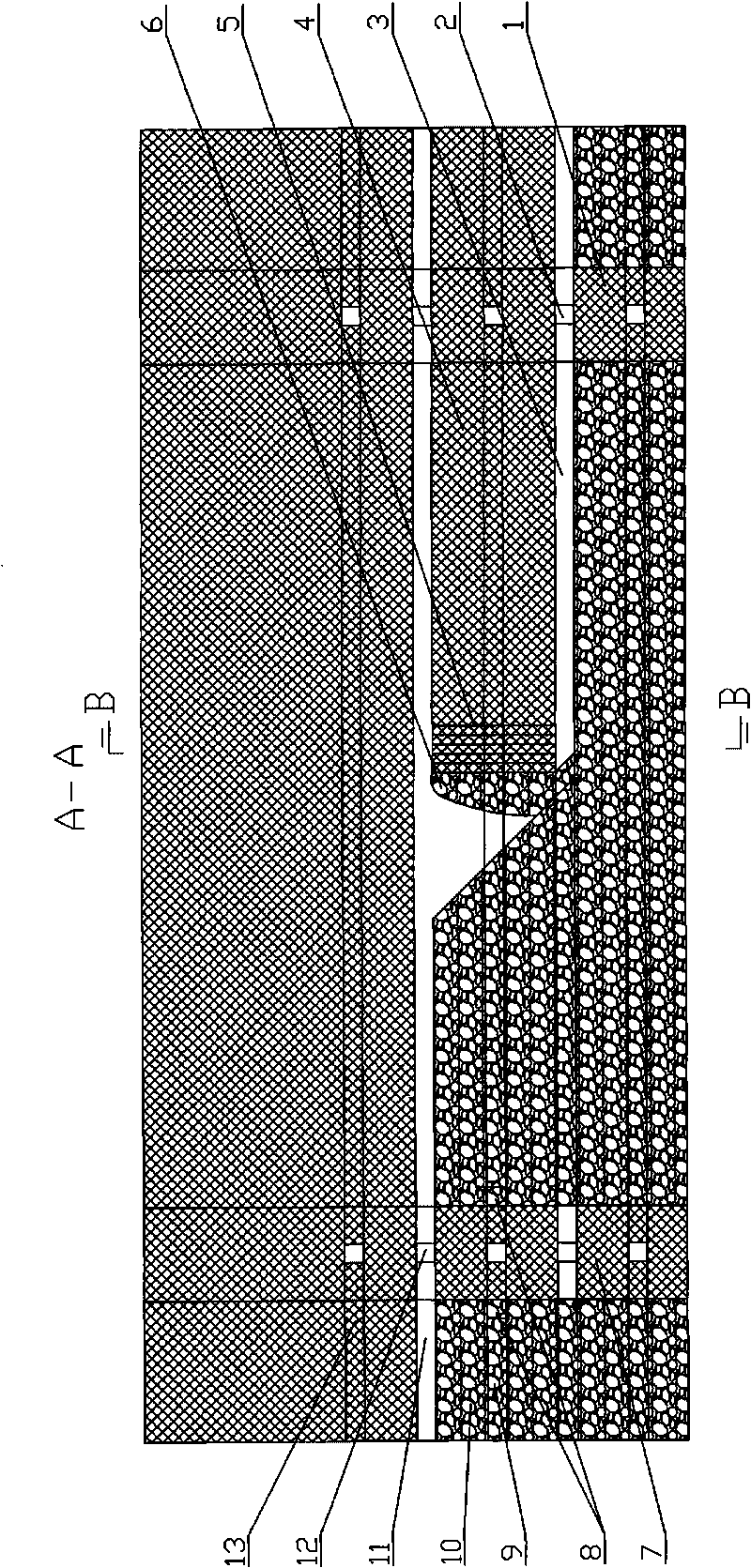

[0035] The present invention will be further described below in conjunction with the accompanying drawings. like Figure 1~5 As shown, a subsection filling mining method includes the following steps:

[0036] A. Ore body division and route layout

[0037]According to the height that the current medium and deep hole rock drilling equipment can adapt to and the exposure area, exposure space and exposure time allowed by the ore rock, refer to the method of dividing the ore body by the segmental caving method without pillars. At the same subsection height as the method, horizontal roadways are arranged along the ore body strike or vertical ore body strike; adjacent subsection roadways are arranged in a staggered manner; the proposed mining body 4 of each roadway is a rhomboid; each proposed mining rhomboid The shaped ore body involves two subsections, three levels, and four approaches; the roadway under the prismatic ore body to be mined is the mining approach 3, and the level a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com