Pillarless sublevel caving method based vertical partitioning and combined ore drawing extraction technology of gently inclined ore bodies

A segmented caving method and vertical zoning technology, which is applied in ground mining, earth square drilling, underground mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

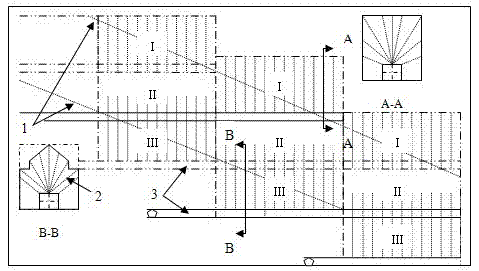

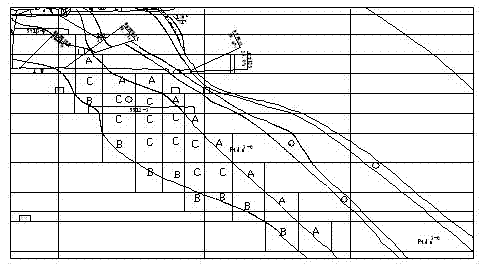

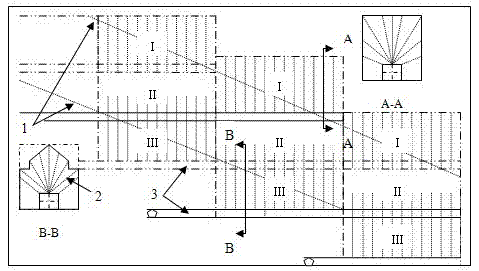

[0012] The mining technology of "vertical partition and combined ore drawing" mining technology of gently inclined ore body without bottom pillar caving method is characterized by "vertical partition and combined ore drawing; timely supplementary caving and full coverage of footwall residue".

[0013] A. Take the vertical line at the junction point of the mining approach and the ore body hanging wall boundary, and the ore body range between the two vertical lines between two adjacent segments is a "vertical partition". For actual ore bodies with irregular shapes, the range of vertical partitions can be appropriately adjusted according to the boundary between the mining approach and the upper and lower walls of the ore body. The principle is to facilitate the layout of mining blast holes and the full recovery of ore.

[0014] B. In the loose ore drawing and pressure relief section (Ⅰ) of the upper wall, fan-shaped blastholes with rectangular rows are arranged ( figure 1 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com