Patents

Literature

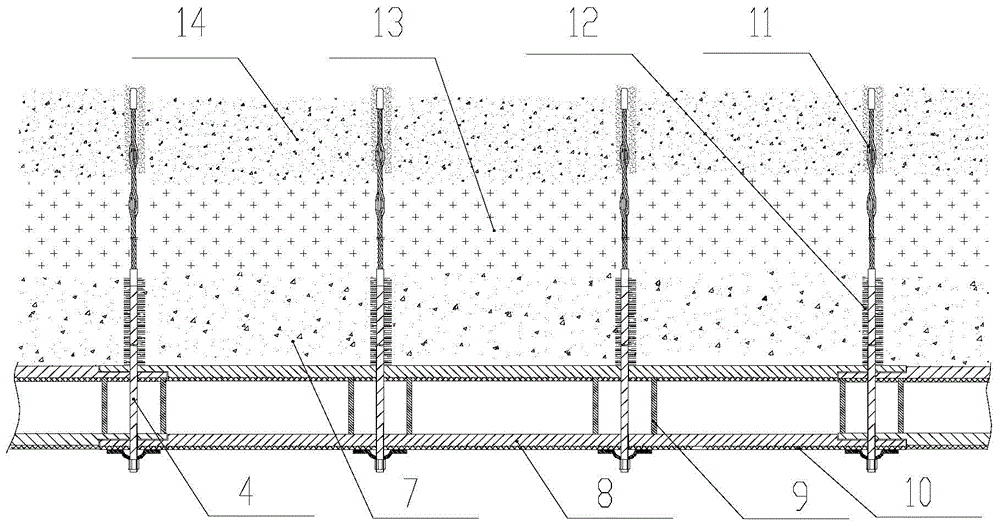

46results about How to "Prevent ground pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure relief and consolidation synergizing prevention and control method for rock burst in deep coal drift

InactiveCN102220866AAvoid blindnessPrevent ground pressureOptical detectionBlastingRock burstDeep mining

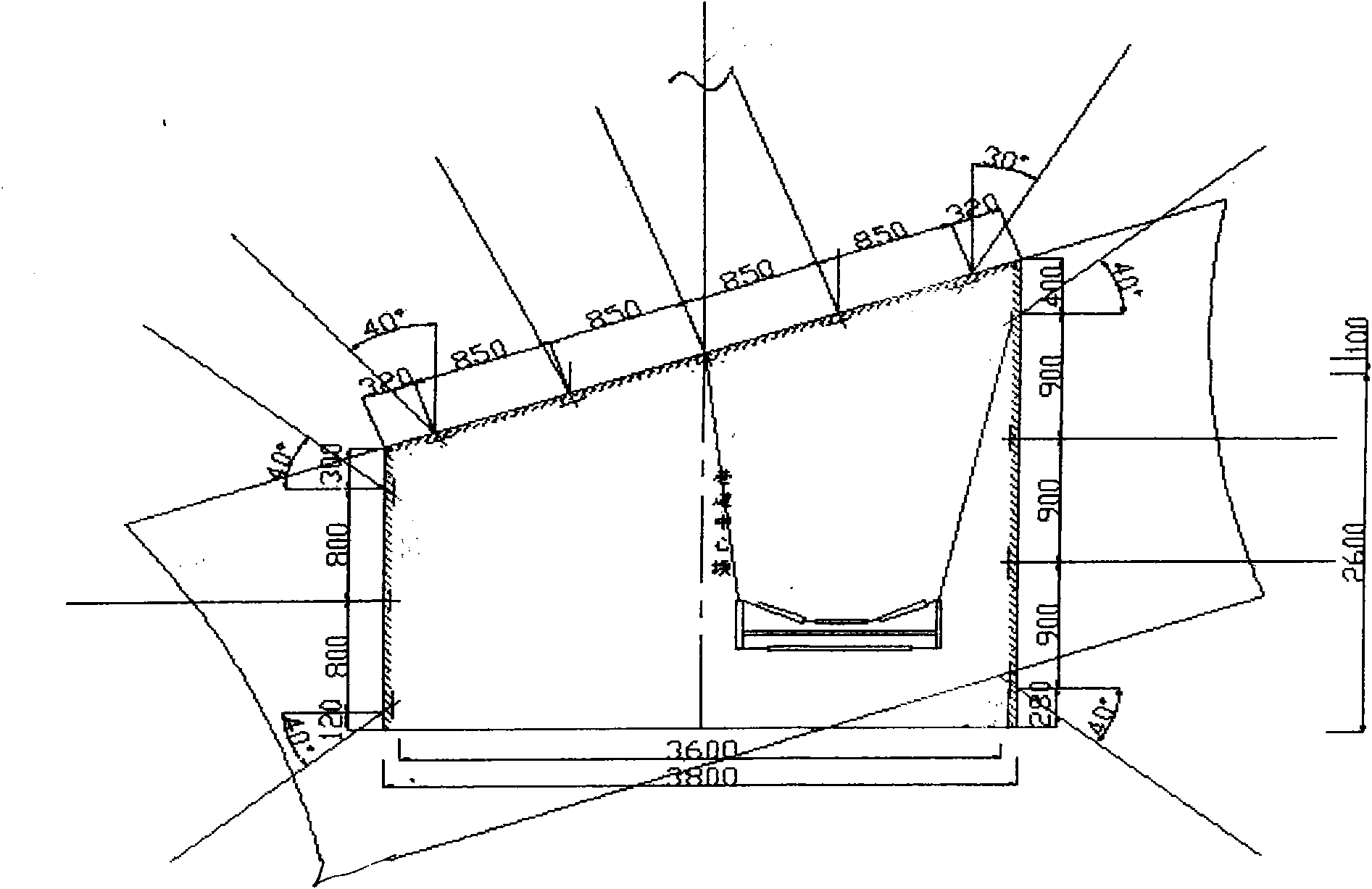

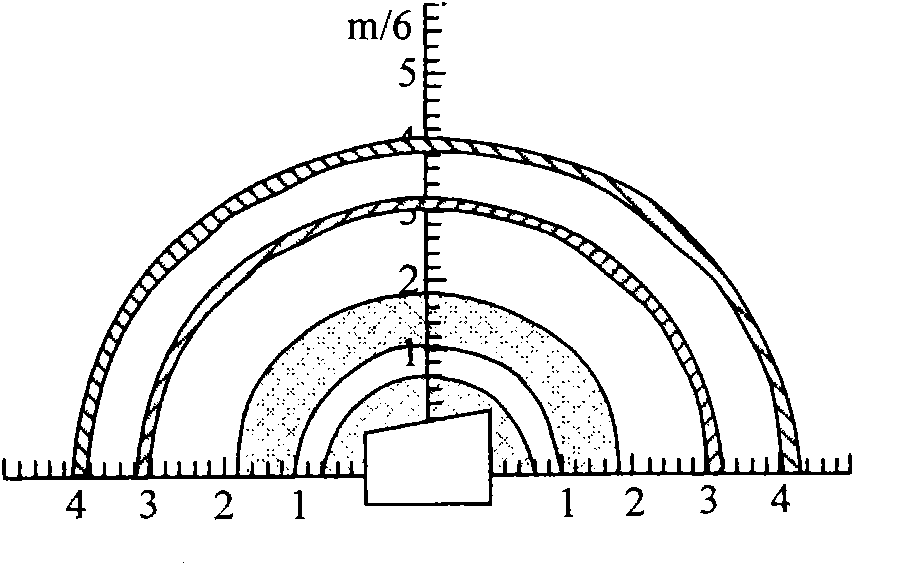

The invention discloses a pressure relief and consolidation synergizing prevention and control method for rock burst in a deep coal drift. According to the method, based on deep hole photographic detection and analytic processing technology, discontinuous rupture distribution of the surrounding rocks in the deep coal drift and the evolution law of abutment pressure with mining are firstly detected, the deep hole blasting depth is determined according to the detection results and the pressure generated by deep blasting is relieved, and the range and consolidation method of barrier layers of the shallow surrounding rocks around the roadway surrounding rocks are finally determined; therefore, optimal synergy of pressure relief and consolidation is realized and and the aim of prevention and control of the rock burst in the deep mining coal drift is achieved.

Owner:SHANDONG UNIV OF SCI & TECH

Method for controlling high mine pressure of open-air roadway by hydraulic fracturing

InactiveCN103758570ARelieve pressureReduce leading bearing pressureMining devicesAbutmentHydraulic fracturing

A method for controlling high mine pressure of an open-air roadway by hydraulic fracturing comprises the following steps of determining a hard rock stratum of a roof according to a geological information bar chart of a coal face; designing a control drilling hole; respectively controlling abutment supporting pressure and lateral supporting pressure; slotting or slitting in the bottom of the hole after hole drilling construction is finished so as to achieve the purpose of directional fracturing; applying a hydraulic fracturing process; and weakening the hard roof or cutting off the hard roof along a directional fracturing slot of the drilling hole so as to transfer stress or weaken surrounding rock and reduce the lateral supporting pressure and the abutment supporting pressure of the open-air roadway. A weakening zone in the surrounding rock can effectively absorb or weaken impact stress waves; a dynamic disaster of rock burst caused by the reason that the hard roof cracks suddenly is avoided; and large deformation of the open-air roadway is controlled. The method for controlling the high mine pressure of the open-air roadway by hydraulic fracturing is not only applicable to controlling the high mine pressure of the open-air roadway with the coal face with the hard roof, but also is applicable to controlling the high mine pressure of the roadway of which a work face is in tunnelling crossing with a work face of an adjacent roadway during mining. Moreover, the method is simple, effective, safe and reliable, and is low in cost.

Owner:CHINA UNIV OF MINING & TECH

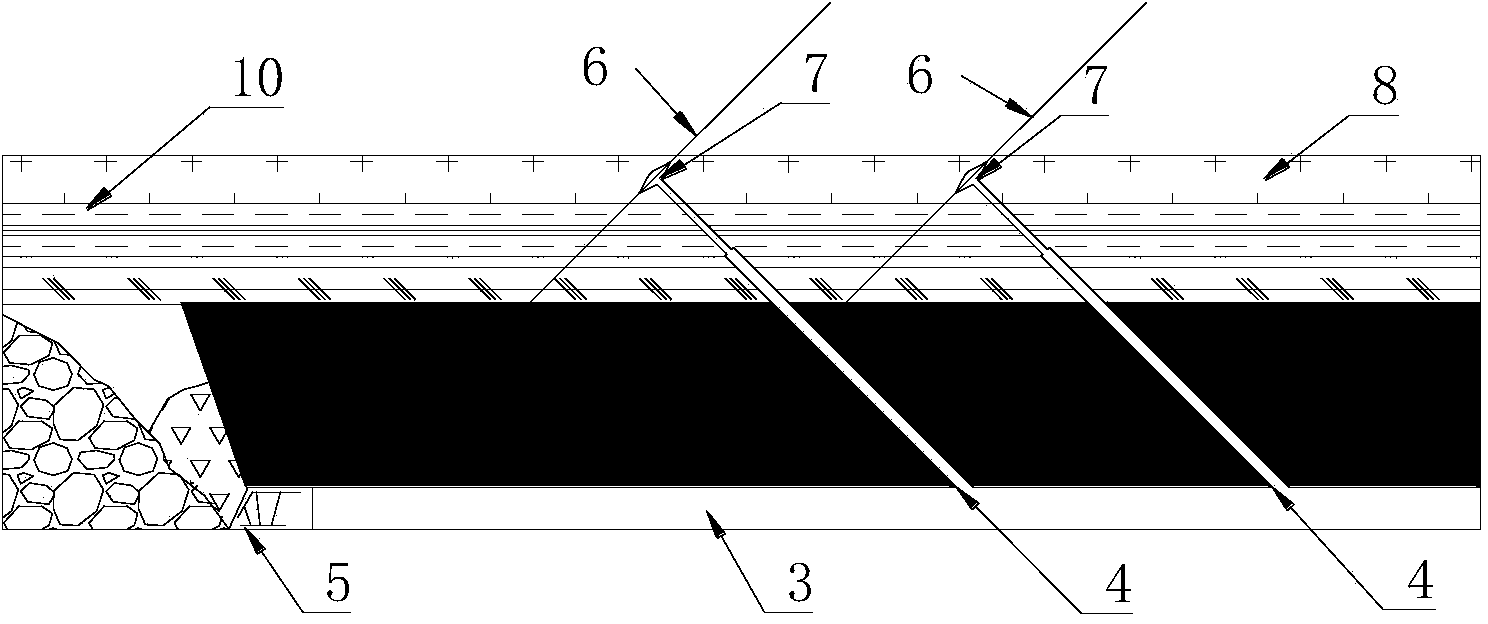

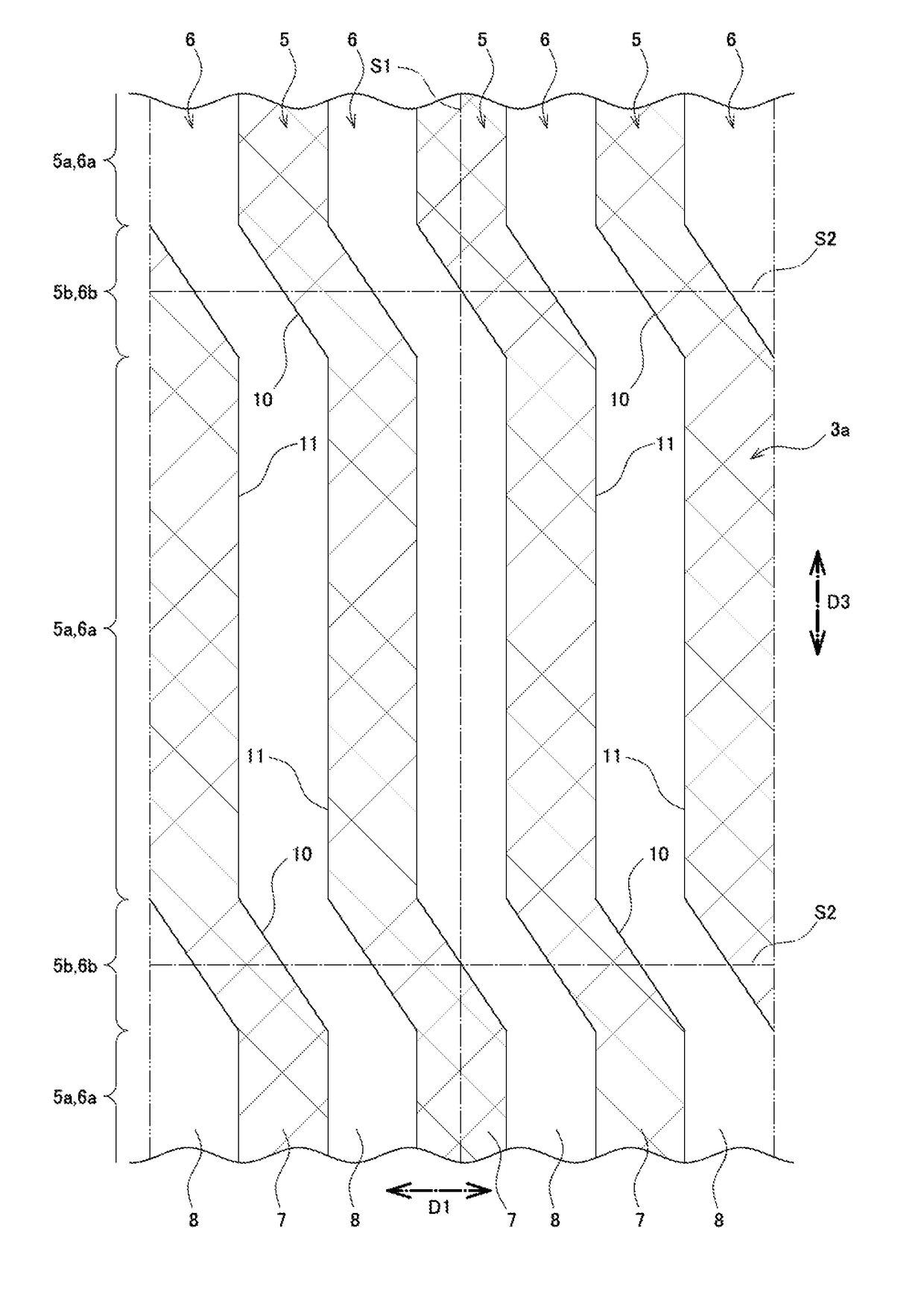

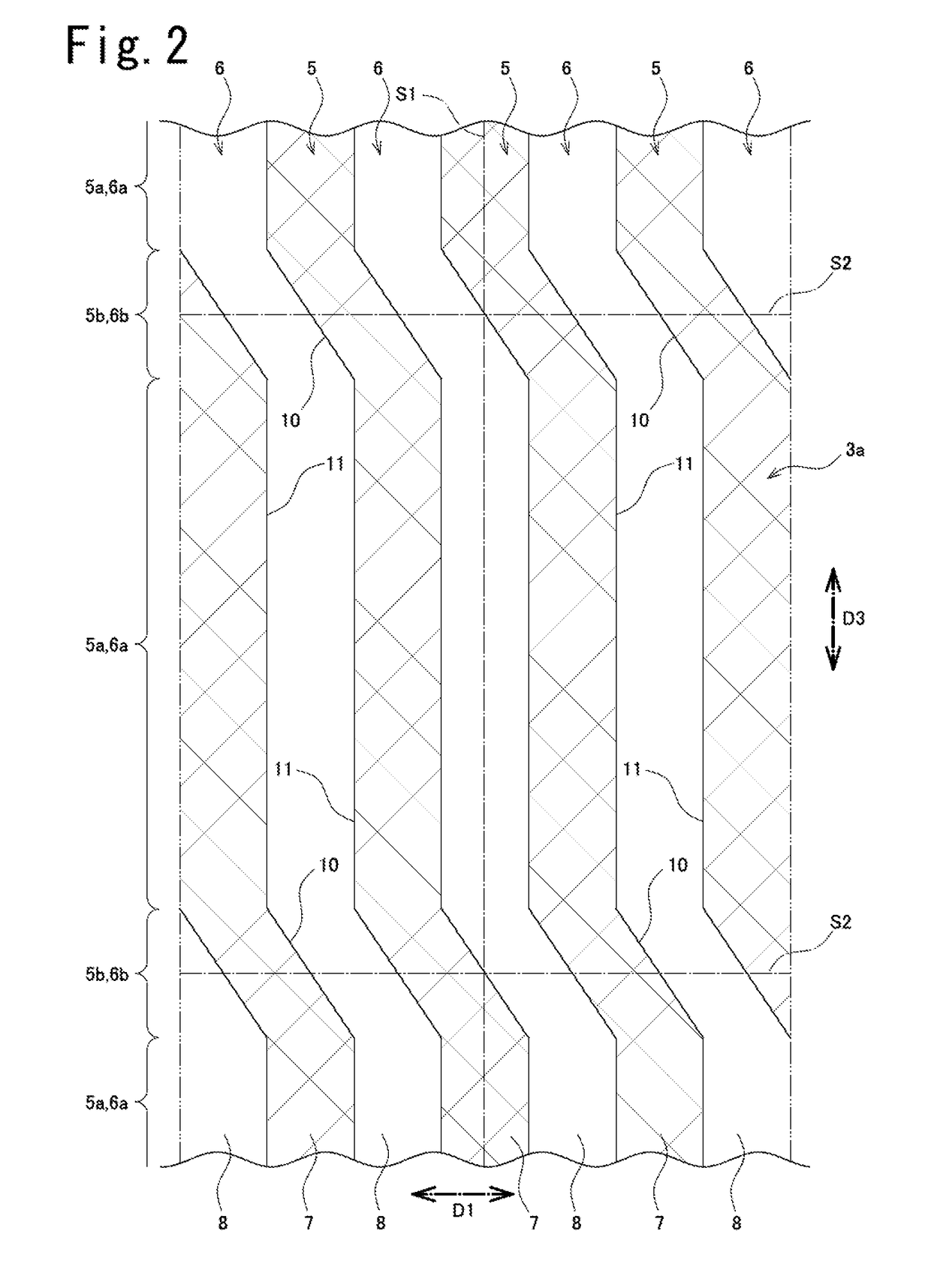

Impact ground pressure preventing method of full seam gateway

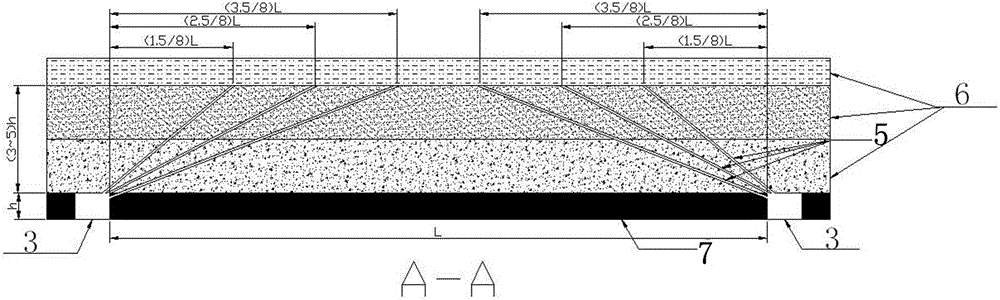

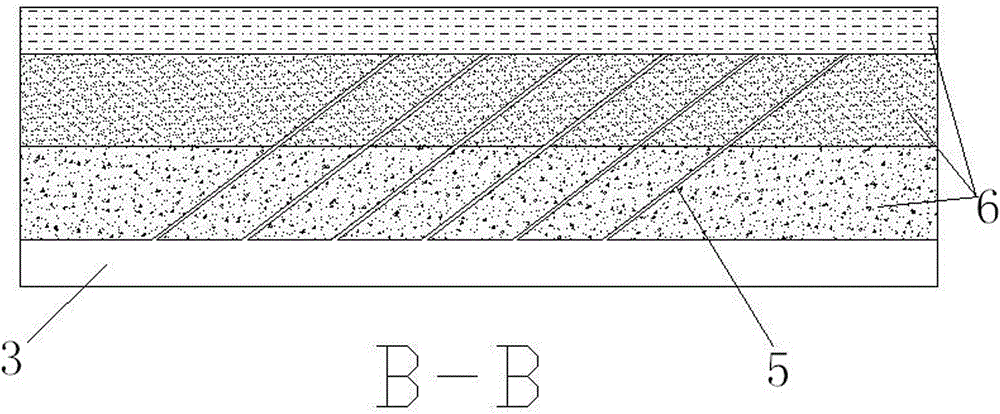

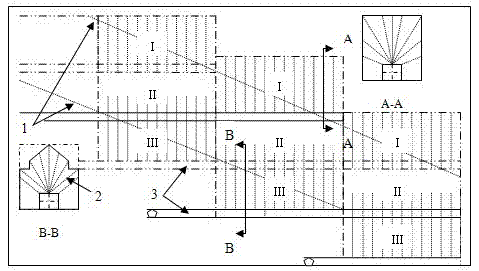

ActiveCN104806265AImproved anti-shock performanceEven by forceUnderground chambersBlastingSupporting systemEngineering

The invention provides an impact ground pressure preventing method of a full seam gateway. The method is that an impact preventing support consisting of energy absorbing steel beams and energy absorbing anchor rod ropes is added on the basis of the general support composed of an iron wire net, a steel belt and an anchor rod, wherein the energy absorbing steel beams are lengthways distributed at intervals along the gateway, comprising two layers of steel plates, and energy absorbing boxes which are fixed at intervals between the two layers of steel plates; gateway surrounded rock in a propping plate and two sides is drilled and grouted, so that the gateway surrounded rock can damp the impact; two bottom corners of the gateway within the advance influence range of a workface are blasted to release pressure. According to the method, the general support, the impact preventing support, the surrounded rock modification and the blasting and pressure release of the bottom corners of the gateway are synchronously carried out to form a point-line-face-body 3D distribution type energy absorbing and impact preventing system; the incident stress wave can be reduced through the support system, and the reflecting stress wave of the gateway surface can be reduced; the modified loose surrounded rock mass can greatly reduce the influence of the impact energy on the support structure; the four measures supplement each other and synergistically interacted, so that the impact ground pressure preventing capacity of the gateway can be greatly improved.

Owner:LIAONING TECHNICAL UNIVERSITY

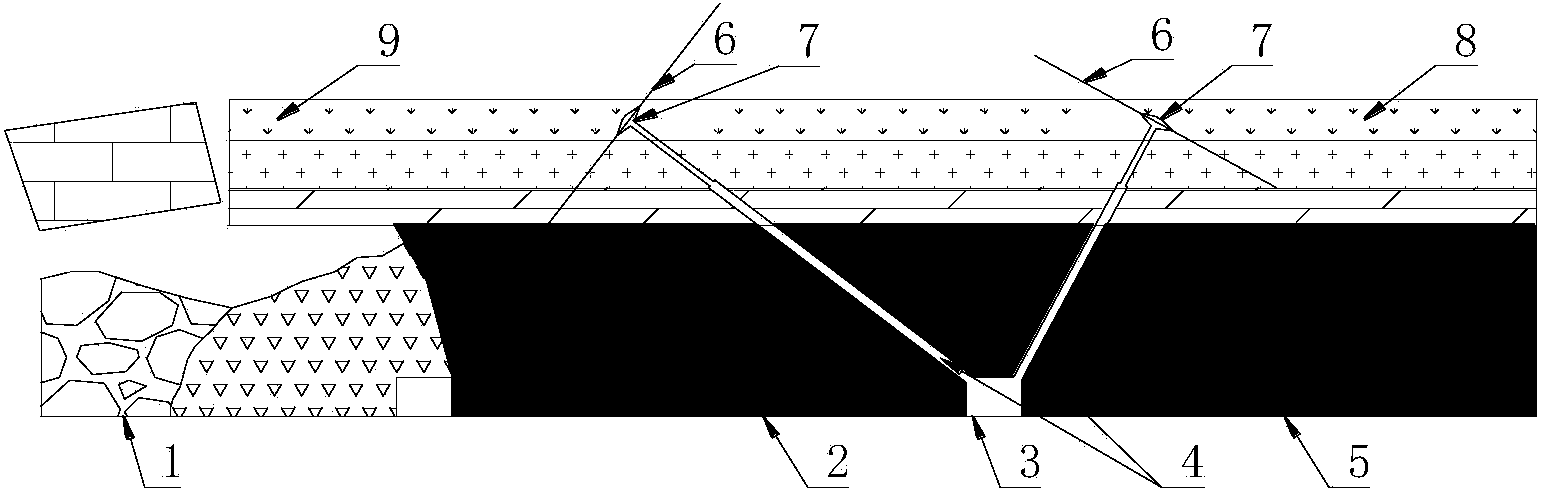

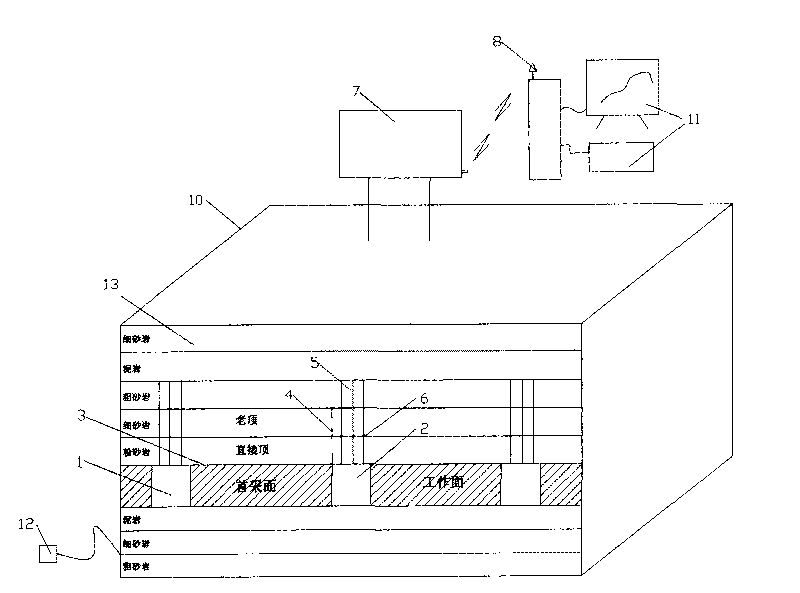

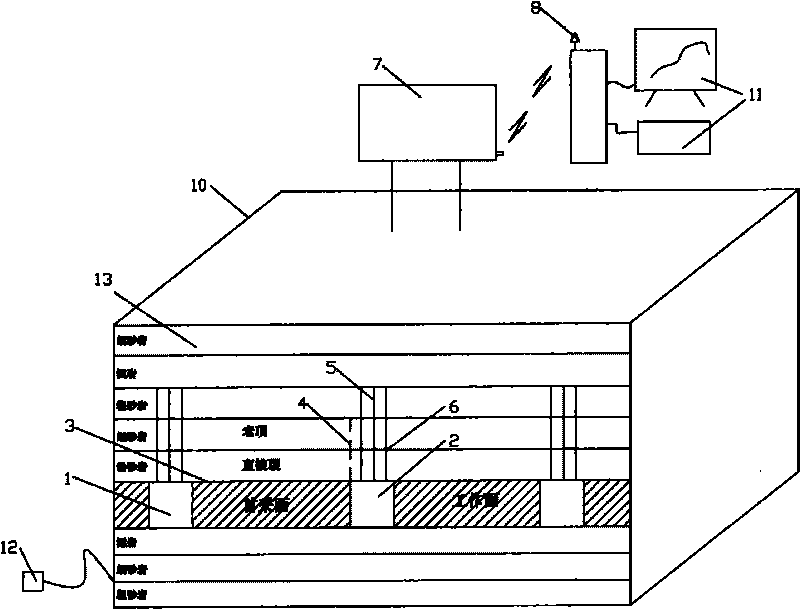

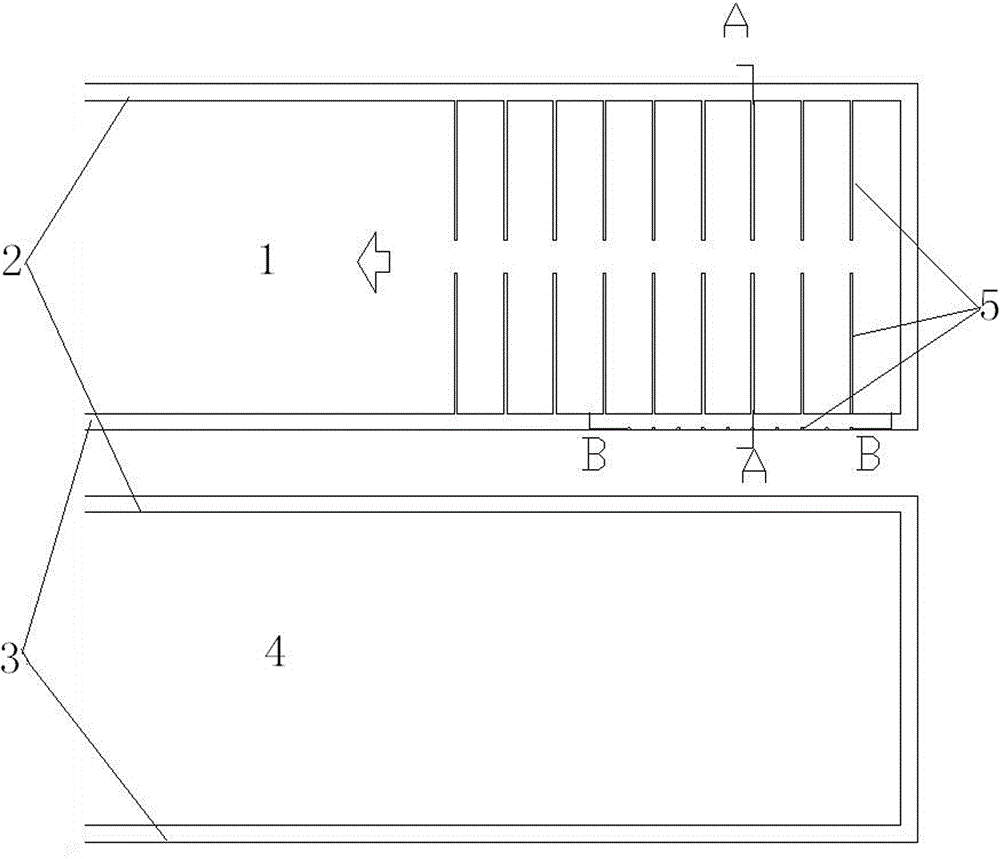

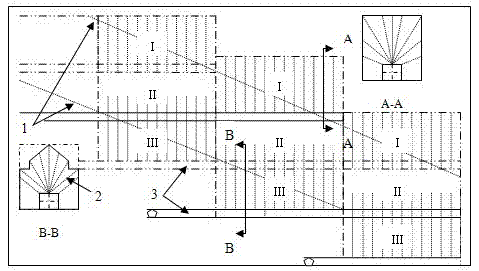

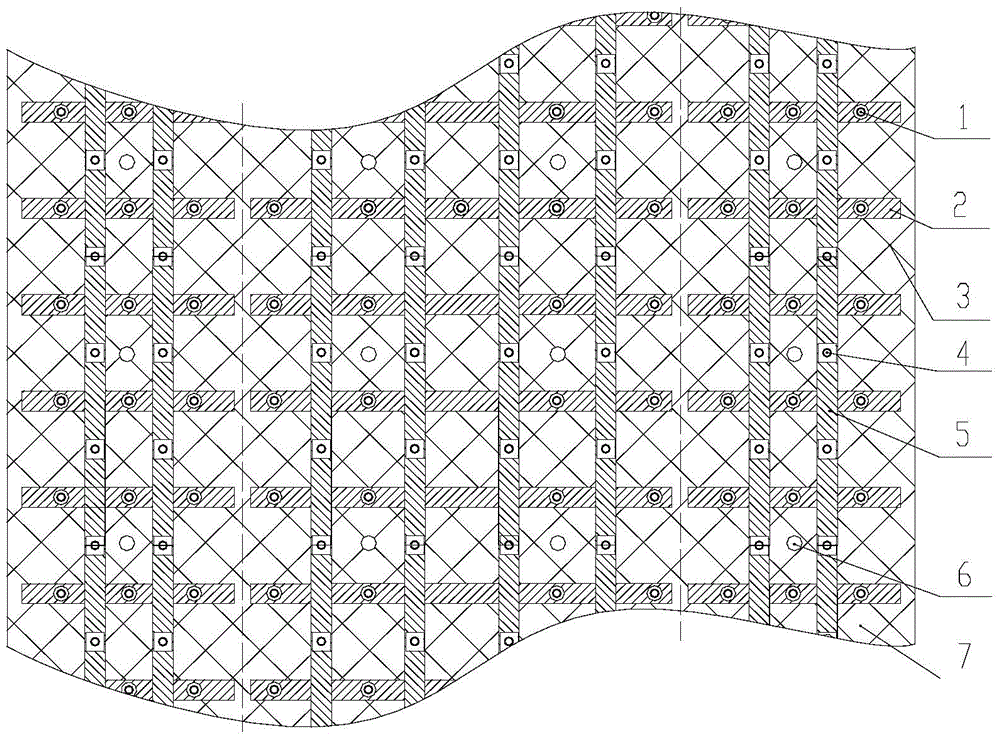

Deep stope automatic lane forming physical simulation test method and device

ActiveCN101737056AReduce stress concentrationReduce wasteForce measurementTunnelsStress concentrationLongwall mining

The invention discloses a novel lane forming method for mining a long wall, namely a deep stope automatic lane forming physical simulation test method which changes the traditional mode of mining the long wall through a single face and double lanes. An oriented pre-cracking top-cutting lane-reserving technique is adopted; and a return mining lane of a gate road under a primary work face is reserved and serves as one of return mining lanes of the next new work face so as to mine through a single face and a single lane. The method has the advantages of removing concentrated stress above the coal on adjacent working faces, reducing the mining ratio, improving the production efficiency and reducing the resource waste, and belongs to a novel, safe, efficient, economic and scientific mining technique. At the same time, the invention designs a deep stope automatic lane forming physical simulation test device based on the principle so as to prove the reliability of the method and ensure the authenticity and the availability of the test process.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for preventing hard top plate type rock burst on basis of carbon dioxide blasting

ActiveCN105735993AAchieve stabilizationTo achieve the effect of pre-crackingDisloding machinesEngineeringPre cracking

The invention belongs to the technical field of mine safety and particularly relates to a method for preventing hard top plate type rock burst on the basis of carbon dioxide blasting.Firstly, a plurality of sets of drilled holes are formed in the portions, close to the top corner of a work face, of a transport roadway and an air return roadway which are located on the two sides of the work face in the direction of a top plate rock stratum on the inner side of the work face, and carbon dioxide fracturing devices are installed in the drilled holes and used for sequential grouping pre-cracking blasting.Meanwhile, a plurality of parallel drilled holes are formed in the top of the air return roadway of the work face close to a replaced work face in the direction of the work face, the drilled holes point to the inside of the top plate rock stratum, certain inclined angles are formed between the drilled holes and the air return roadway, pre-cracking blasting is conducted, and roof-cutting blasting of top plate rock stratums on the front side and the side face of the work face.The method can effectively control rock burst appearance under the hosting conditions of the hard top plate rock stratum, plays an important role in prevention of rock burst caused by the hard top plate, and is simple, good in safety, easy to operate, convenient to use and wide in applicability.

Owner:LIAONING TECHNICAL UNIVERSITY

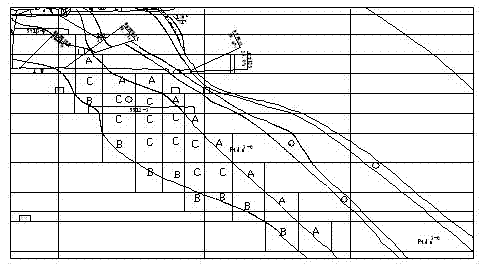

Pillarless sublevel caving method based vertical partitioning and combined ore drawing extraction technology of gently inclined ore bodies

InactiveCN102444403ATop in timeReduce depletionUnderground miningSurface miningMining engineeringMechanical engineering

The invention discloses a pillarless sublevel caving method based extraction technology used under the condition of gently inclined ore bodies. A series of problems of the pillarless sublevel caving method under the condition of gently inclined ore bodies such as efficient extraction of sublevel hanging wall and footwall triangle ore bodies, sublevel transition ore quantity, efficient recovery of footwall residual ores, timely supplementing and caving realization and the like are solved by the technical measures such as vertical partitioning, combined ore drawing, timely supplementing and caving, footwall residue full covering and the like. By designing the new pillarless sublevel caving method based vertical partitioning and combined ore drawing extraction scheme suitable for the condition of gently inclined ore bodies, the loss and dilution indexes when the pillarless sublevel caving method is applied under the condition of gently inclined ore bodies can be substantially reduced and the technical and economic benefits of mining can be increased.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Hard rock roof rock burst segmentation direction control fracturing treatment technology

ActiveCN111322048AIncrease the extension sizeWeakened governanceSurveyFluid removalMechanical engineeringDrill hole

The invention discloses a hard rock roof rock burst segmentation direction control fracturing treatment technology. The technology comprises the following steps of S10, obtaining hard rock roof groundstress parameters; S20, designing an arranging manner of a directional long drill hole and parameters of a direction control fracturing technology; S30, constructing the directional long drill hole;S40, arranging a segmentation direction control fracturing device in the directional long drill hole; S50, carrying out segmentation direction control fracturing construction; S51, forming a manual precast direction control jet crack; S52, forming a fracturing crack net; S53, stopping a pump, draining water, shrinking a packer, and dragging to the next segment of fracturing position; and S54, repeating the steps of S51-53, and finishing whole directional long drill hole fracturing construction. According to the hard rock roof rock burst segmentation direction control fracturing treatment technology, a hard rock roof layer can be precisely controlled, fracturing is carried out segment by segment, a three-dimensional gap communication network is formed, a hard rock roof can be effectively weakened, and the hard rock roof can be promoted to properly collapse.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

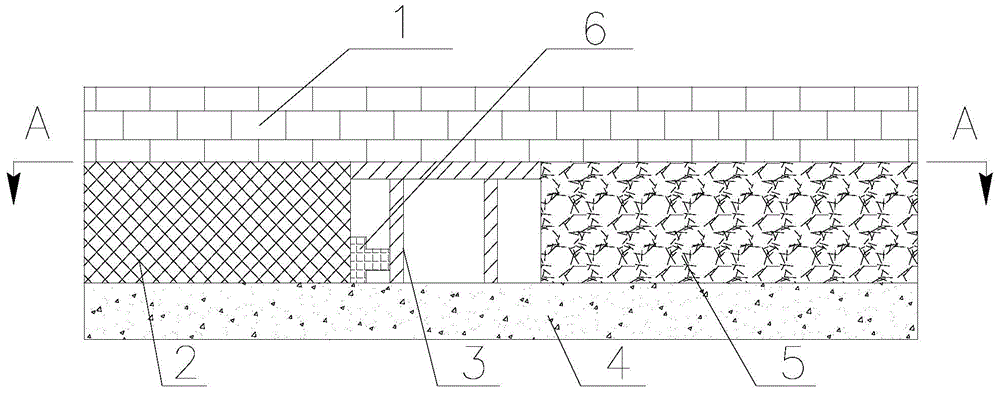

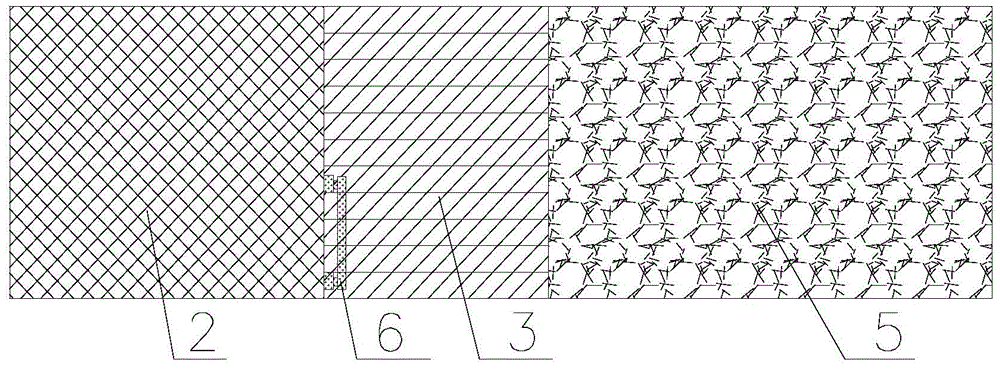

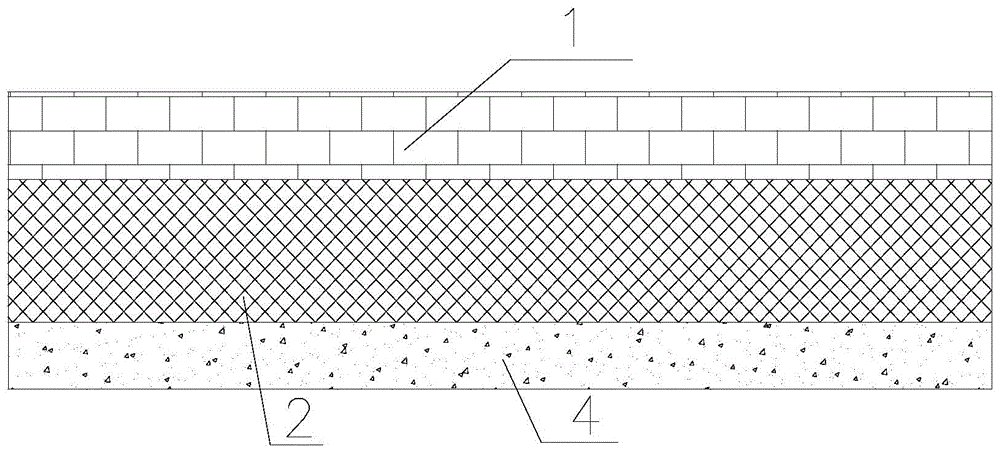

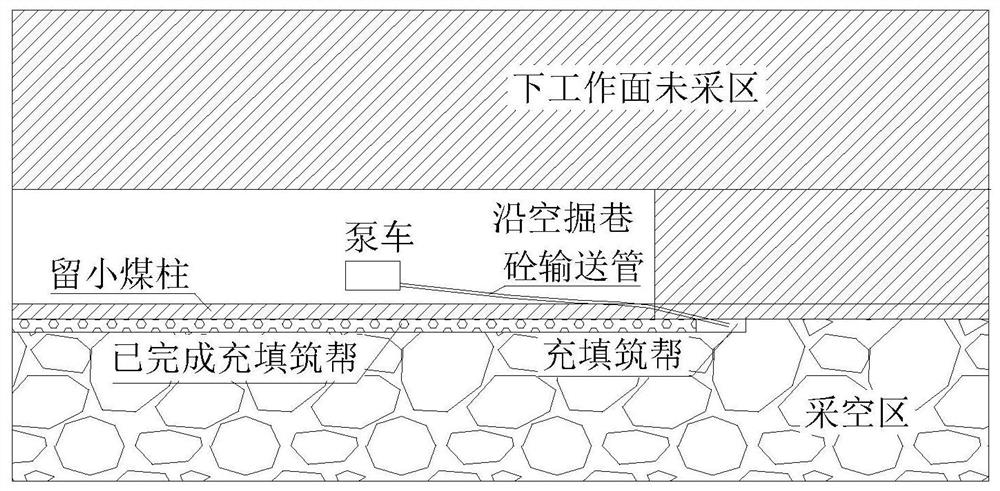

Method for preventing and treating rock burst by using filling mode

InactiveCN104948191AReduce maintenanceStrong active support abilityUnderground miningSurface miningEnergy absorptionActive support

The invention discloses a method for preventing and treating rock burst by using a filling mode and belongs to the technical field of coal mine safety production. The method includes the steps that a coal cutter cuts coal and feeds, a scraper conveyer conveys the coal, and a filling rock burst prevention hydraulic support protects side walls and supports roof; after a work face is advanced for a proper distance, a filling rock burst prevention material is adopted to implement filling and rock burst prevention on a goaf through the filling rock burst prevention hydraulic support; with the continuous advance of the filling operation, the filling rock burst prevention material is accumulated and compacted continuously to form a rock burst prevention body; the front stoping of the filling rock burst prevention hydraulic support and the rear filling of the filling rock burst prevention hydraulic support are conducted synchronously; after the filling operation meets requirements, a cycle of the work face filling coal mining is completed; the scraper conveyer is pushed to move to conduct a next cycle. The method for preventing and treating the rock burst by using the filling mode has the advantages that the active supporting capacity is strong, the integrality is strong, the setting lead is rapidly provided, crush resistance is achieved, tension resistance is achieved, the durable effect is achieved, yielding is achieved, water prevention is achieved, fire prevention is achieved, energy absorption is achieved, the low price is achieved, operation is convenient, the filling operation is rapid, the number of using personnel are less, the filling operation is simple, the road maintenance amount can be reduced, and the expense expenditure is reduced.

Owner:LIAONING TECHNICAL UNIVERSITY

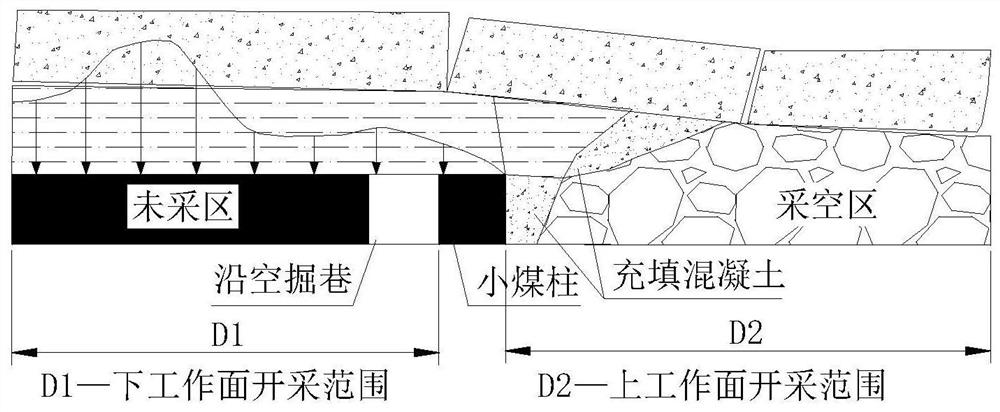

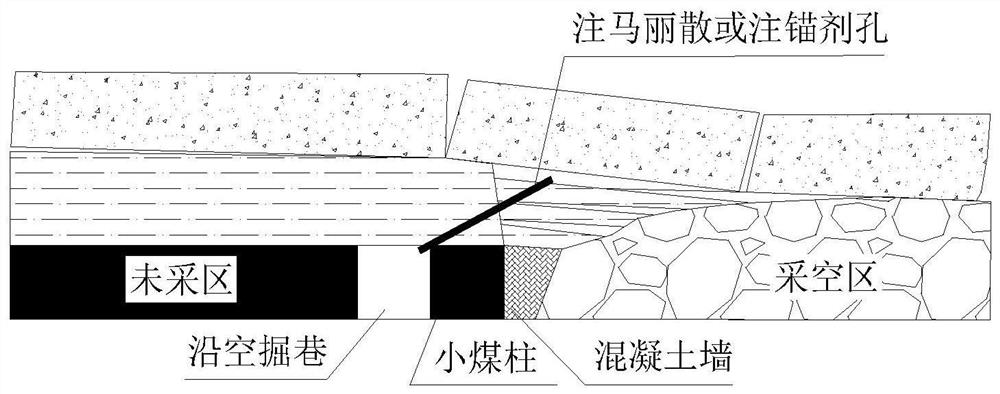

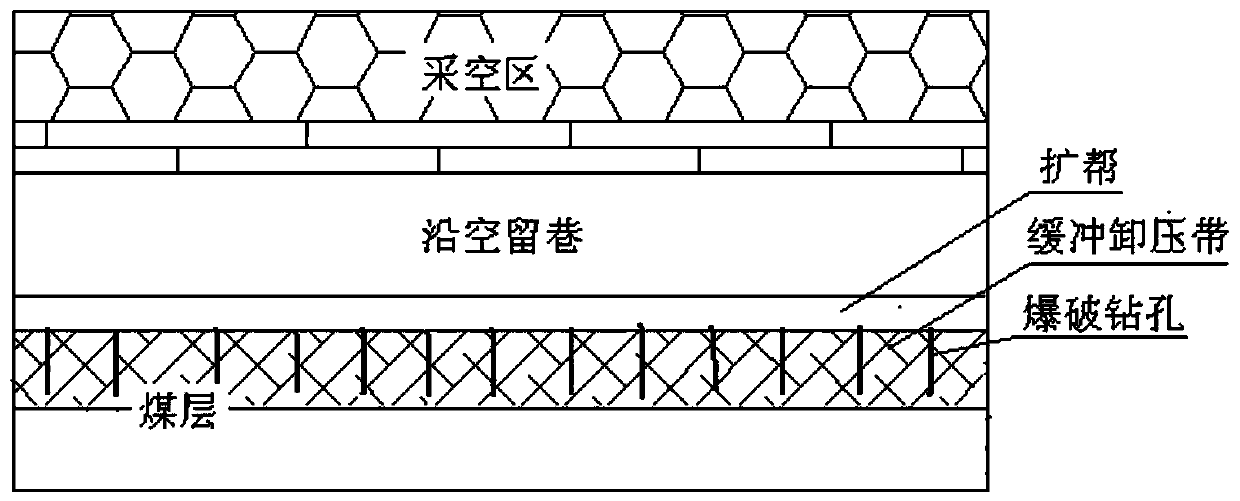

Novel coal mine rock burst treatment method

ActiveCN112031775AReduce distortionAvoid damageUnderground miningFluid removalCoal spontaneous combustionMining engineering

The invention provides a novel coal mine rock burst treatment method which is suitable for being used in a mine. After a working face roof is stable after goaf, a new working face gate roadway is tunneled along a goaf, small coal pillars are reserved, construction drilling is conducted on the boundary area of the adjacent goaf through advancing gate roadway tunneling till the goaf is reached, andconcrete grout is poured into drilled holes to fill the boundary gap of the goaf; and the small coal pillars are reserved to tunnel the gate roadway along the goaf, drilling is conducted on the roadway surrounding rock separation layer fracture area through lagging tunneling, surrounding rock is reinforced through drilling grouting, construction is repeated till construction of the whole gate roadway is completed, the concrete grout forms a filling slope-filling concrete wall along the goaf, then another gate roadway and a cutting hole of a new working face are arranged to conduct mining on the new fully mechanized coal mining face, and after stoping is completed, the steps are repeated to achieve mining of the small coal pillars reserved between the working faces of the whole goaf. According to the novel coal mine rock burst treatment method, stress concentration can be eliminated, generation of rock burst is avoided, the goaf is effectively isolated, deformation and damage of the small coal pillars are significantly reduced, spontaneous combustion of residual coal of the small coal pillars and the goaf is eradicated, and the resource recovery rate is increased.

Owner:陈卫军

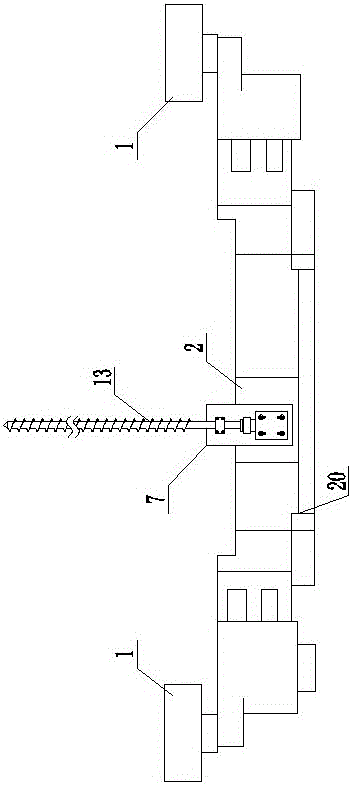

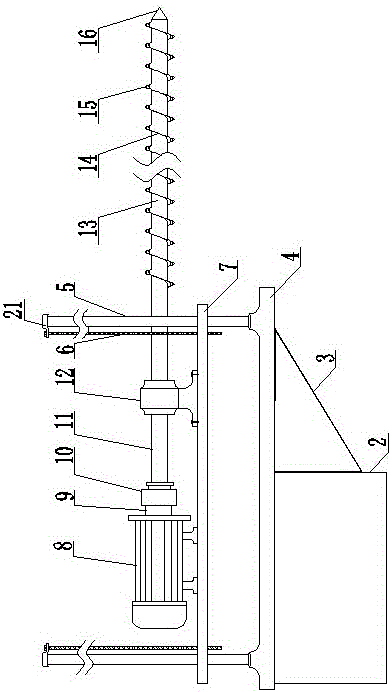

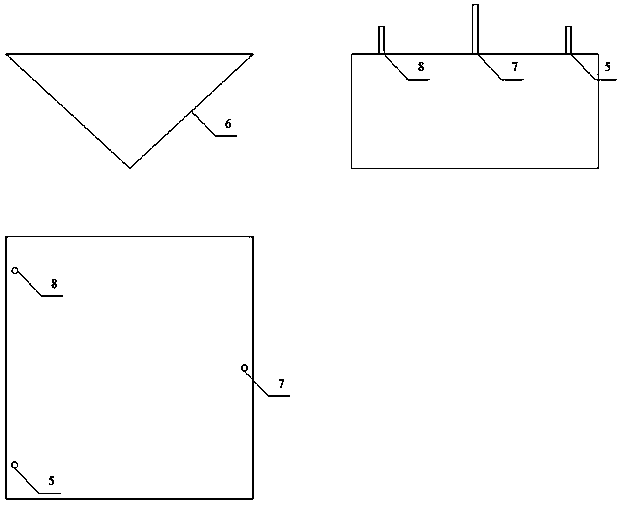

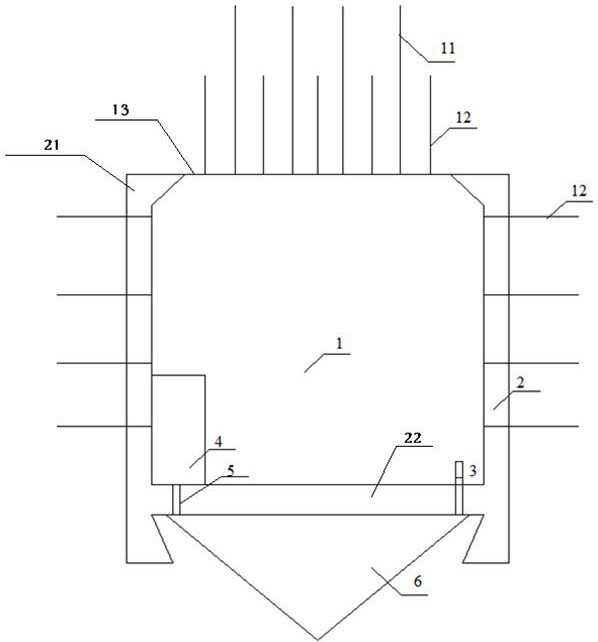

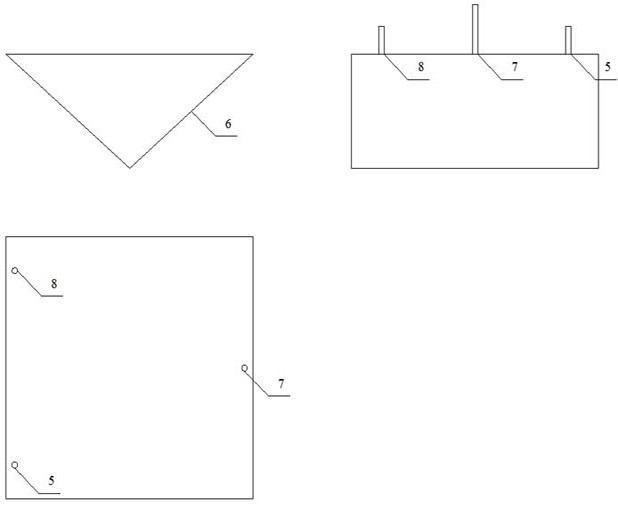

Onboard continuous grooving pressure relief coal mining equipment and onboard continuous grooving pressure relief coal mining method

ActiveCN105064994AEasy dischargeIncrease the exposed areaMining devicesUnderground miningStress concentrationEngineering

The invention discloses onboard continuous grooving pressure relief coal mining equipment and an onboard continuous grooving pressure relief coal mining method. The equipment comprises a coal mining machine, an ascending and descending device and a cutting device, wherein a triangular frame is arranged in front of an electric control box of the coal mining machine; a fixing plate is fixed on the electric control box and the triangular frame; the ascending and descending device is arranged on the fixing plate; an operation table capable of ascending and descending is arranged in the middle of the ascending and descending device; the cutting device is arranged on the operation table; a cutting drill pipe is arranged in the cutting device; in the coal cutting walking process of the coal mining machine, a long groove is cut in front of the coal wall by the cutting drill pipe; the continuity of a coal body is cut by the cut long groove; the exposure area of the coal body is increased, so that the coal body around the long groove realizes the pressure relief; the stress gradient is reduced; the elastic potential energy accumulated in the coal bed is released; and a stress concentration region continuously moves to the deep part of the coal body. After a pressure relief groove is dug, a continuous and stable pressure relief region along the production working face inclination direction (trend) can be formed in front of the working face, so that the occurrence of coal and gas outburst and the rock burst can be effectively prevented; and the continuous and stable operation of the coal mining machine can be ensured.

Owner:HENAN POLYTECHNIC UNIV

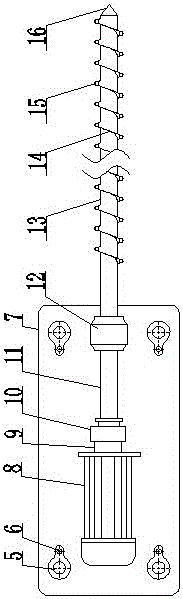

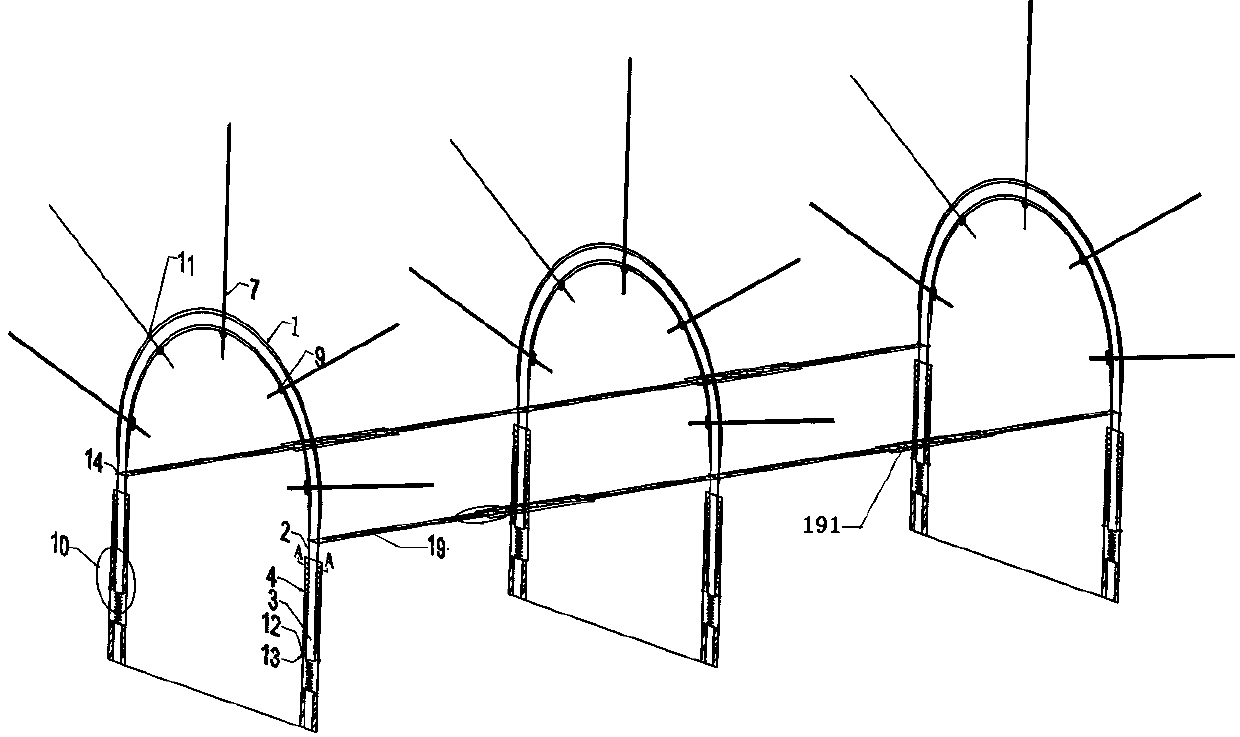

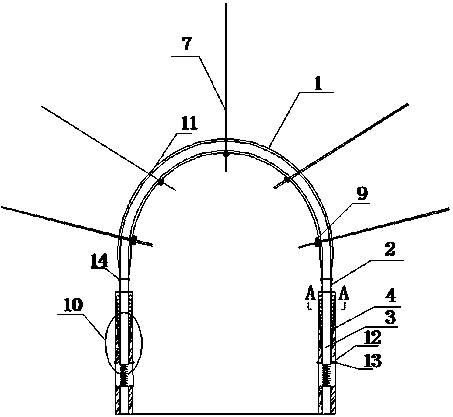

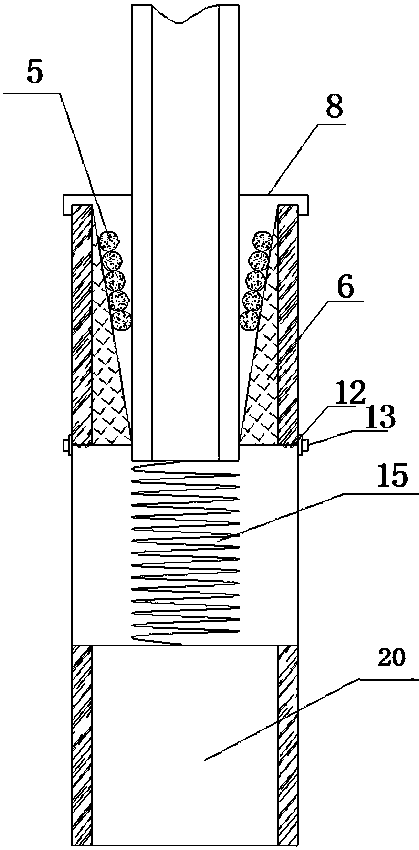

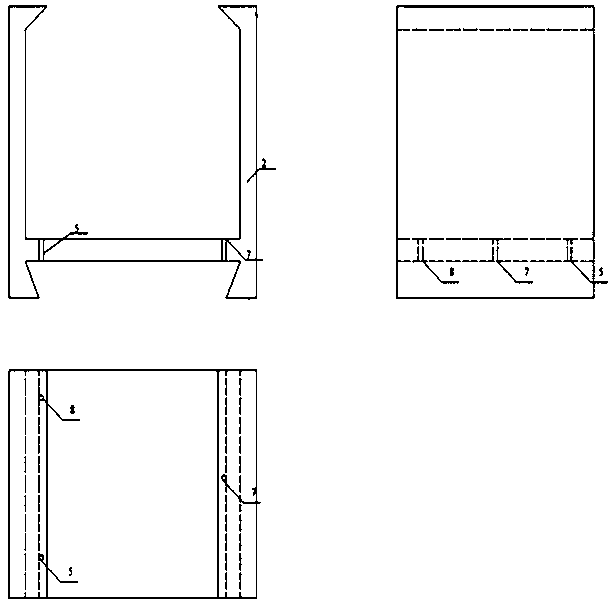

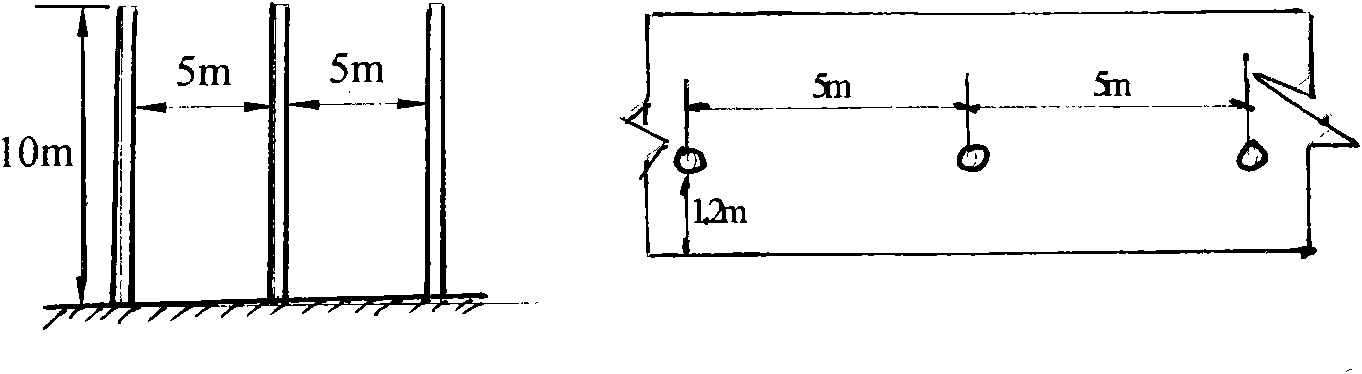

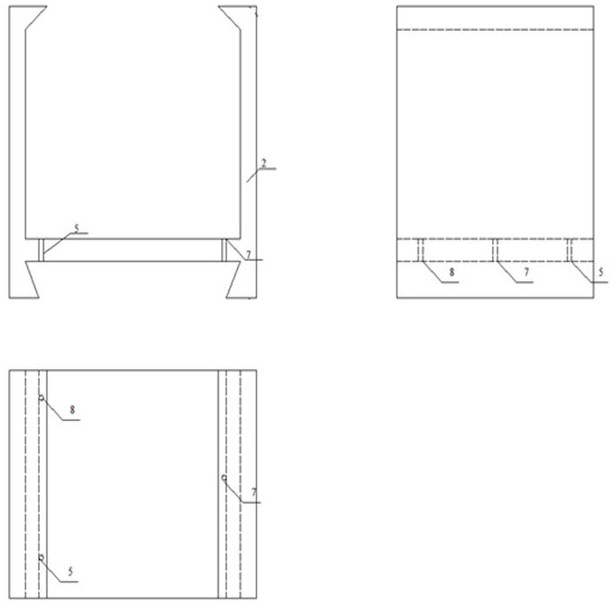

Buffering support capable of implementing three-dimensional yielding and supporting method

PendingCN109653775AEasy to recyclePlay a supporting roleUnderground chambersTunnel liningEnergy absorptionEngineering

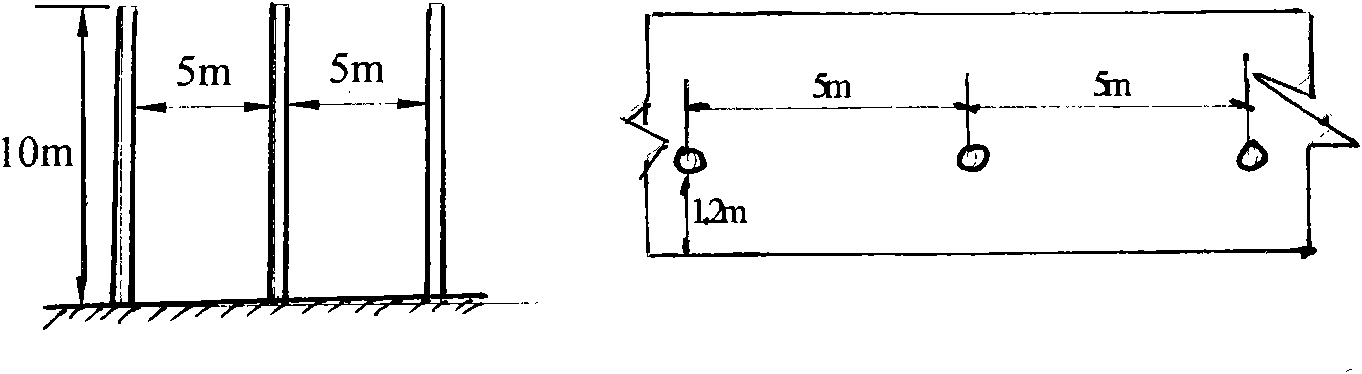

The invention discloses a buffering support capable of implementing three-dimensional yielding and a supporting method. The support comprises a plurality of U-shaped steel supports, wherein the plurality of U-shaped steel supports are arranged in parallel, and support legs on the same sides of two adjacent U-shaped steel supports are connected by virtue of a crossbeam; the U-shaped steel support comprises a semicircular top beam, two support legs and two energy absorption apparatuses, and two ends of the top beam are respectively connected with the upper ends of the two support legs; the energy absorption apparatus comprises an inner pipe, an outer pipe, an energy absorption pipe, a plurality of groups of steel balls and a spring seat; the inner pipe is arranged in the outer pipe; the energy absorption pipe is arranged between the outer pipe and the inner pipe, an inner hole of the energy absorption pipe is a cone with large top and small bottom, the plurality of groups of steel ballsare arranged between the inner hole of the energy absorption pipe and the inner pipe, and each group of steel balls is disposed in a same horizontal plane; the lower end of the inner pipe is connectedwith the spring seat by virtue of a spring; and the lower ends of the two support legs are respectively connected with the upper ends of the inner pipes of the two energy absorption apparatuses. Whenused in a mine environment with impact ground pressure, rock explosion and the like, the buffering support is good in application effect; the harm of the impact ground pressure can be prevented, thesafety of the personnel can be ensured, the supporting cost can be greatly reduced, the overall supporting effect can be improved, the impact ground pressure can be effectively prevented, the long-term stability of the surrounding rock of a roadway can be ensured.

Owner:HUNAN UNIV OF SCI & TECH

Method for recovering coal resources in upper adjacent layer and reducing stress concentration of upper adjacent layer

ActiveCN111927453AIncrease productionImprove productivityUnderground miningLiquid/gas jet drillingStress concentrationMining engineering

The invention discloses a method for recovering coal resources in an upper adjacent layer and reducing stress concentration of the upper adjacent layer, and belongs to the technical field of mining industry. By omnidirectionally recovering the abandoned coal resources in the upper adjacent layer, an immediate roof of the upper adjacent layer is integrally sunken, an overlying key block tends to begentle, the original overlying loads concentrated on the abandoned coal resources are jointly borne by residual coal resources and stereotaxis gangue in goafs on the two sides, the stress concentration phenomenon is greatly reduced, and rock burst is prevented; the large deformation phenomenon of a roadway roof and surrounding rock is completely eradicated, and thus deformation of the surroundingrock of the working face roadway is controlled to be in the safe, reasonable and supportable range; the phenomenon of large-area roof weighting of the working face roof due to the fact of passing thelower part of residual coal pillars in the promoting process of a stope face is prevented; and thus safe mining of a lower coal seam is ensured.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

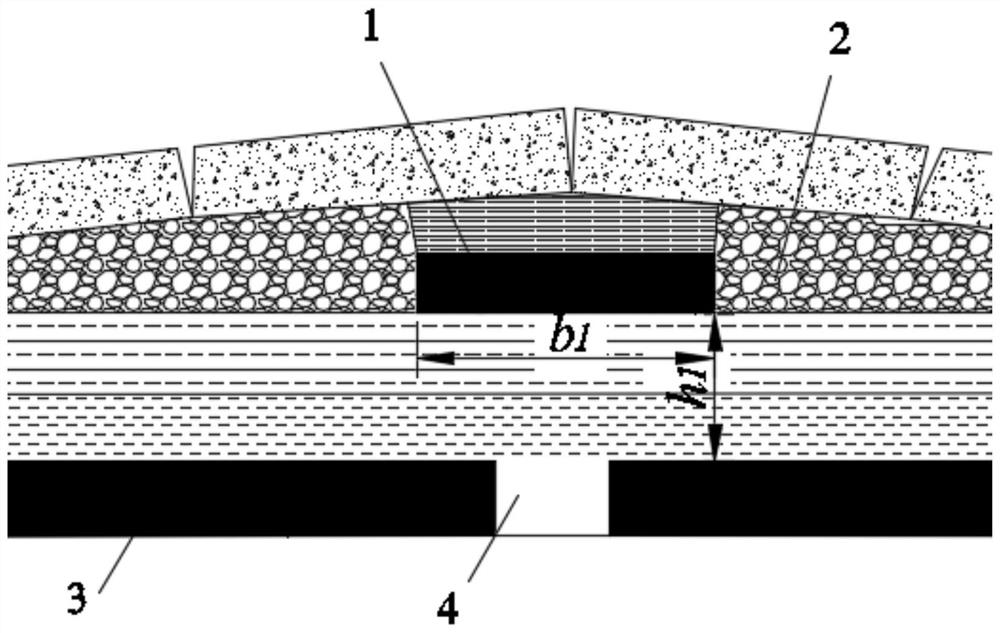

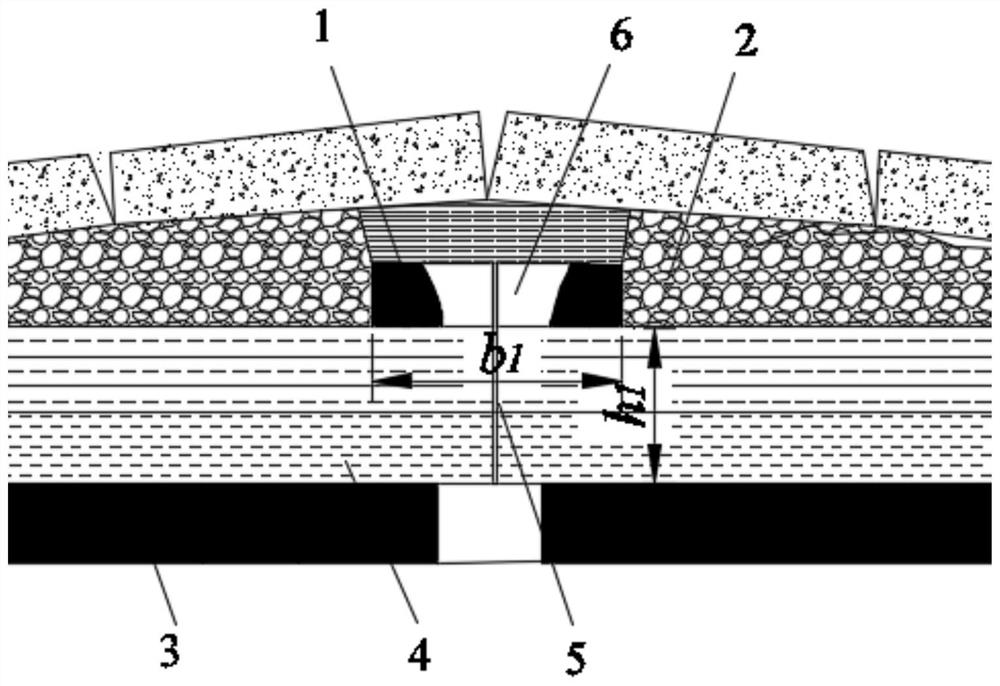

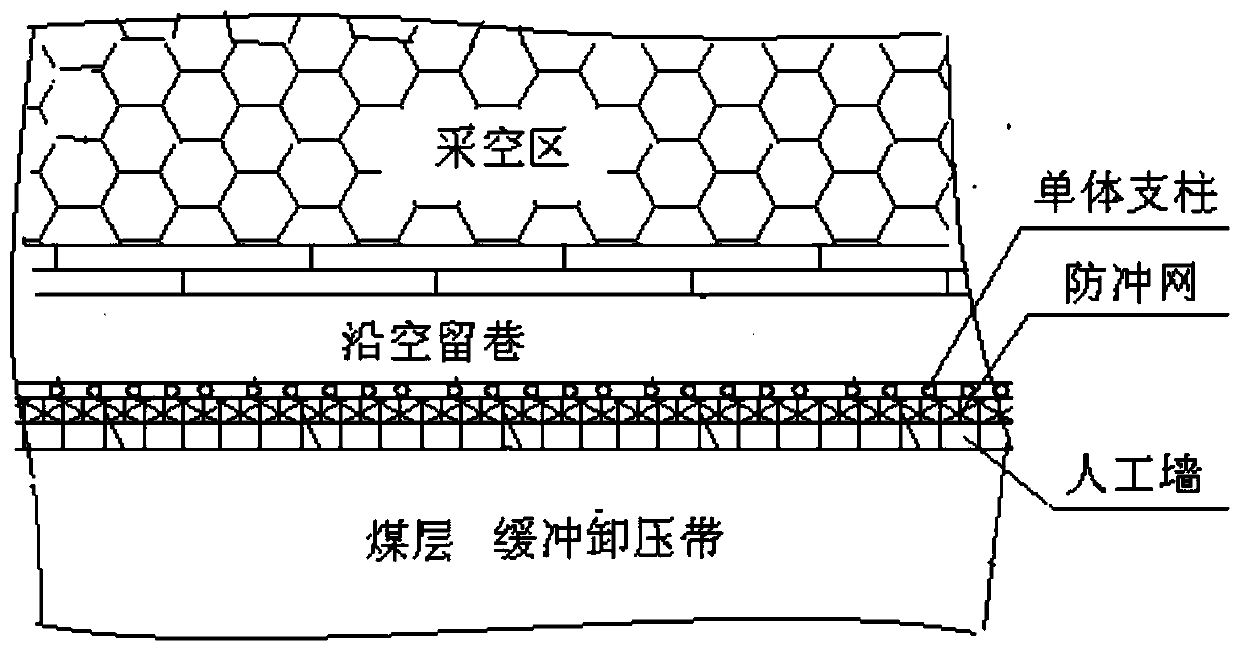

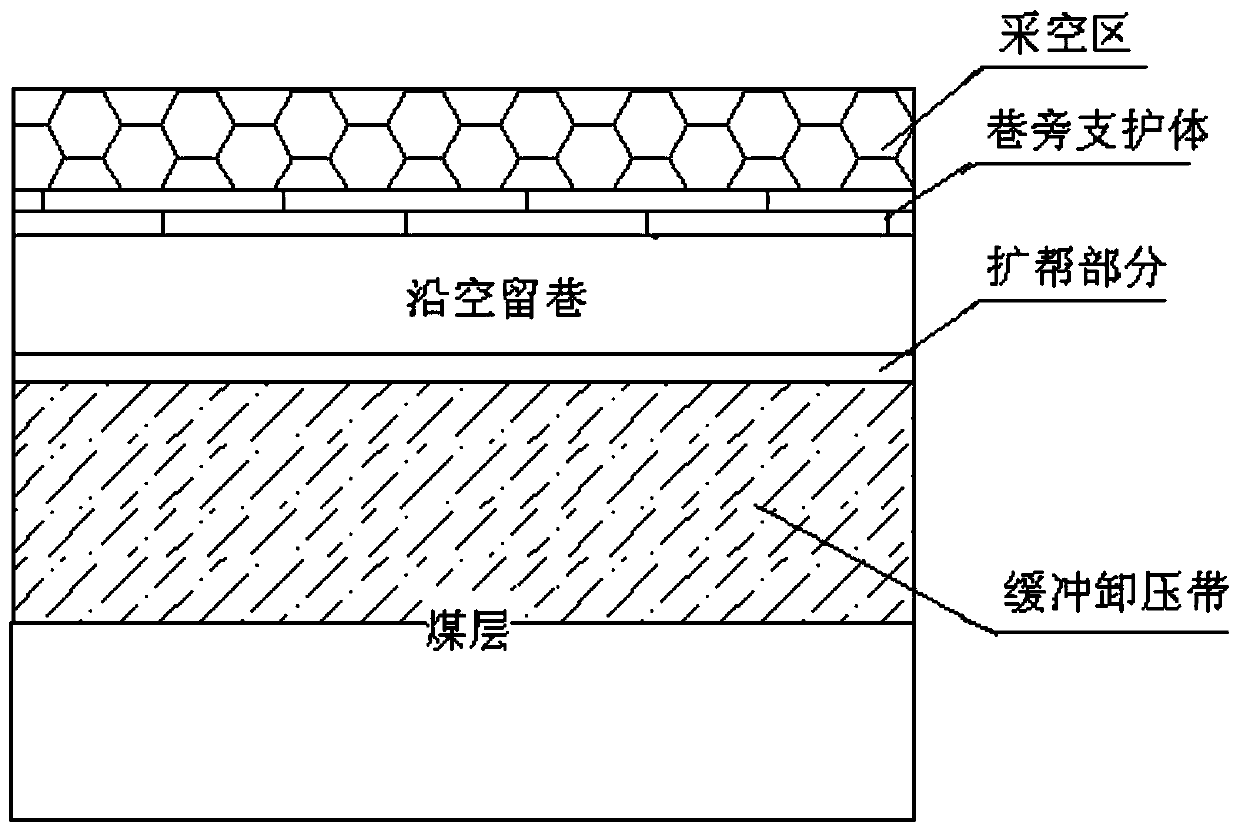

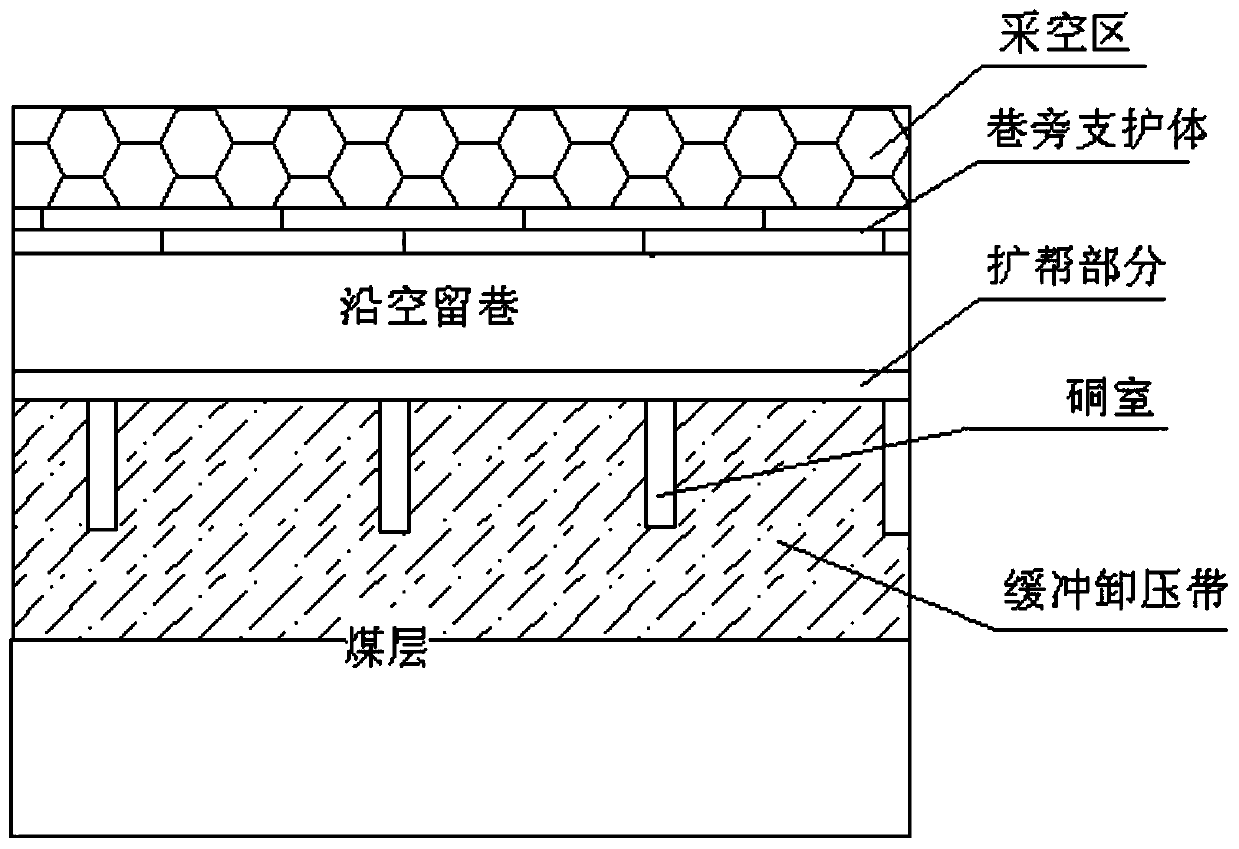

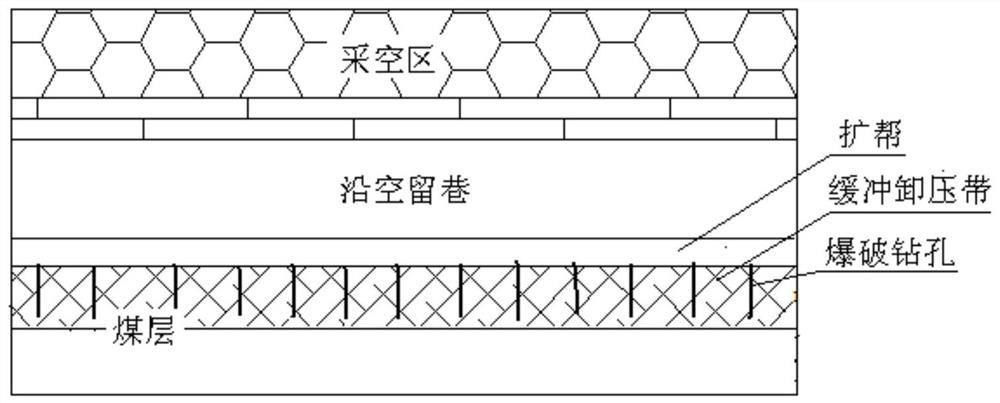

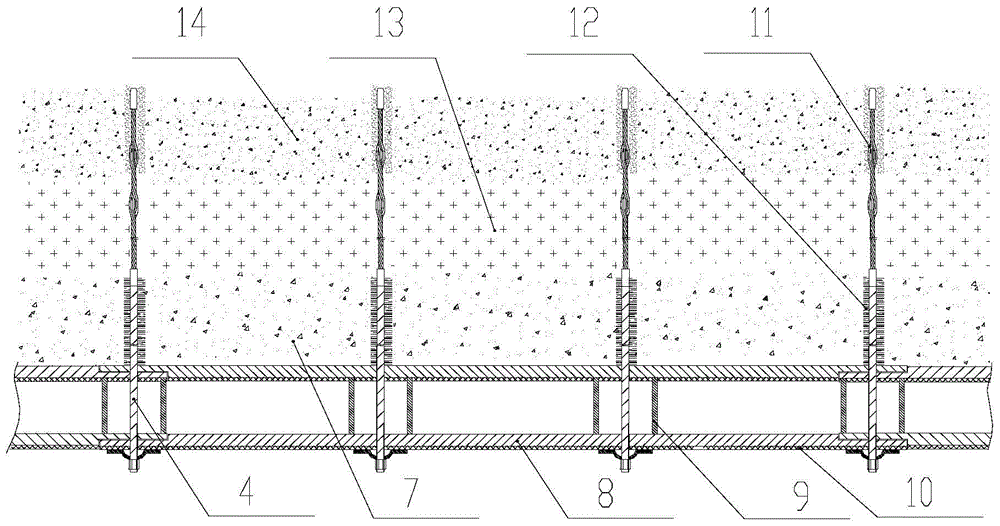

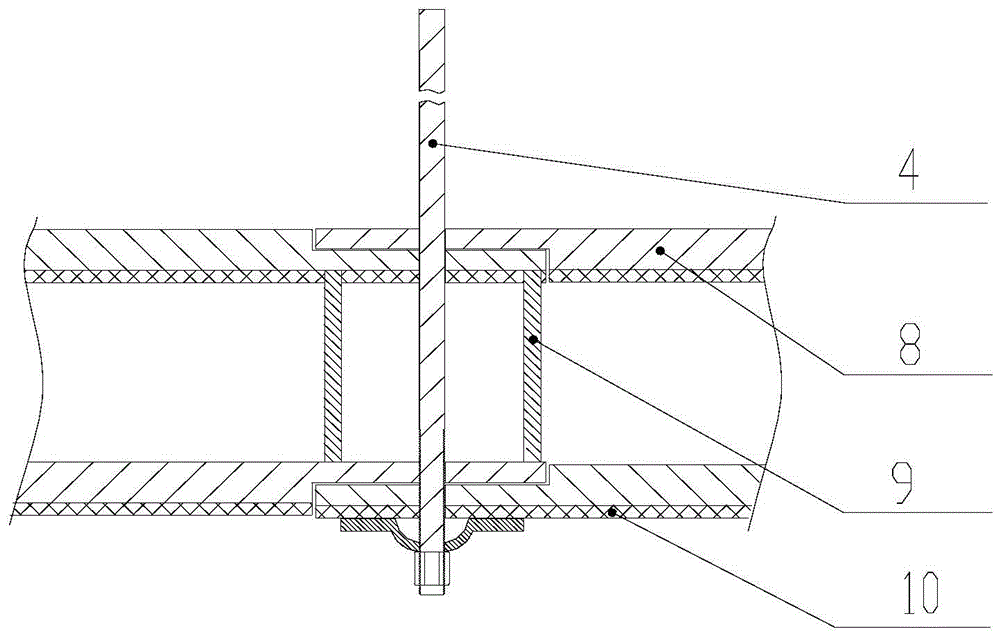

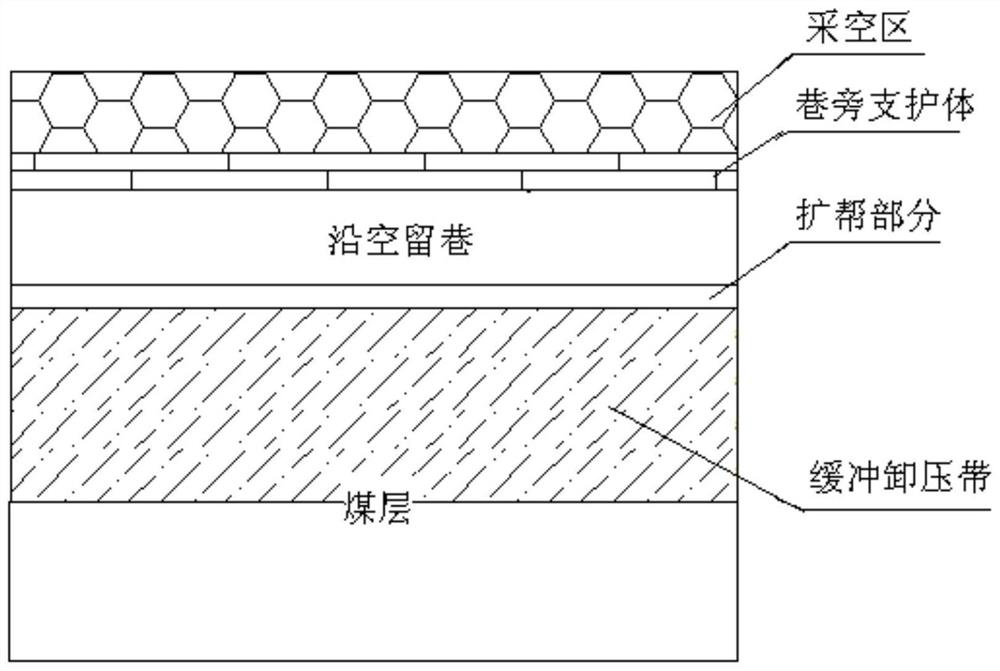

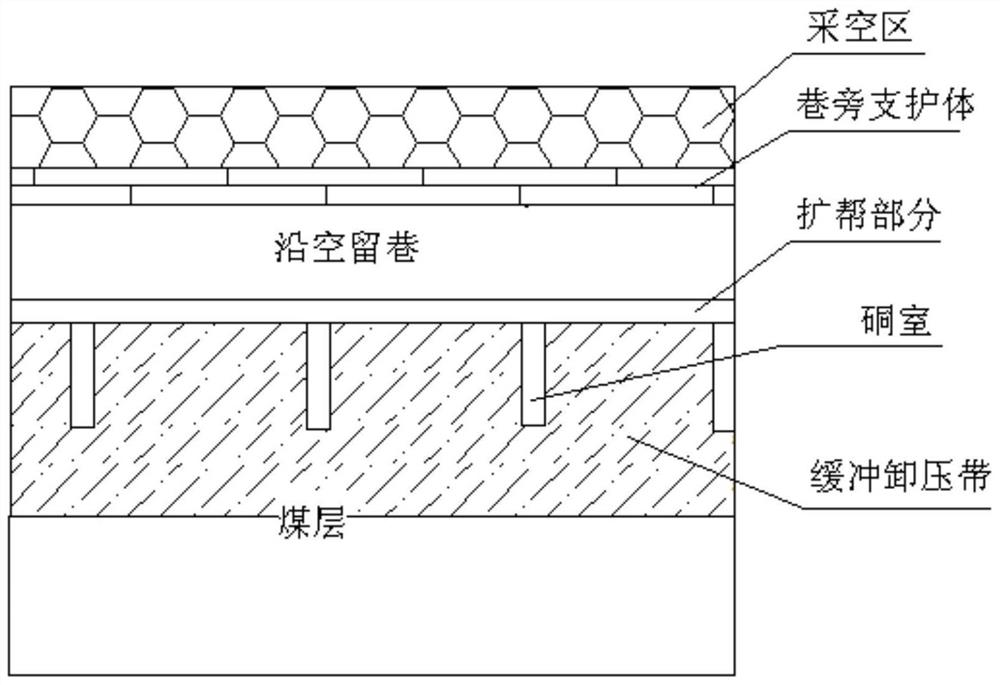

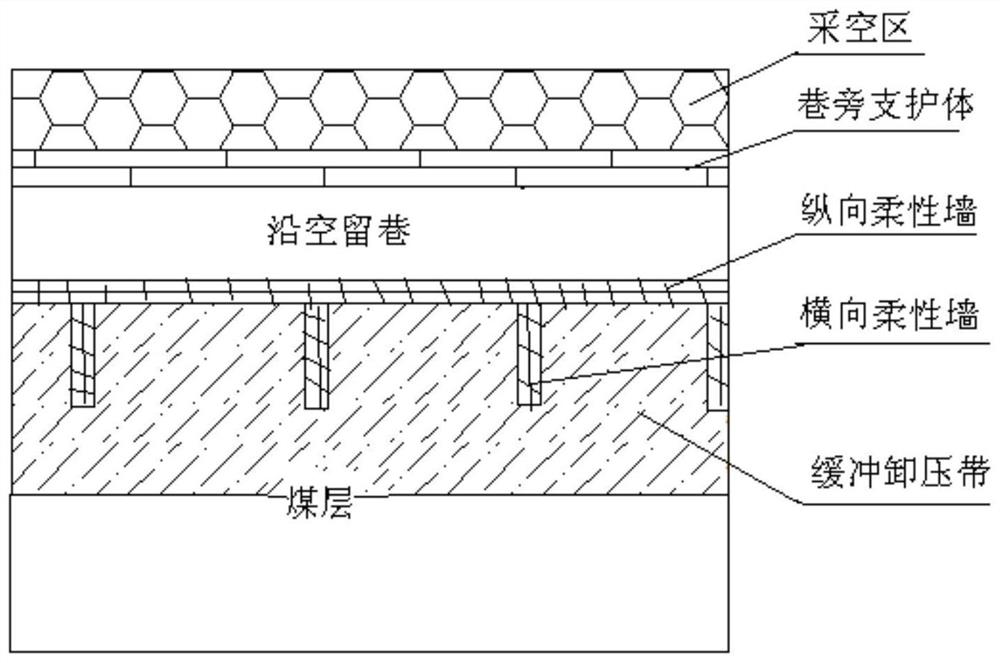

Method for preventing impact ground pressure of hard roof remained roadway by buffer pressure relief belt and wide roadway flexible wall

ActiveCN110219649AChange stress distributionChange the impact propertiesMining devicesUnderground miningCombined techniqueStructural engineering

The invention discloses a method for preventing impact ground pressure of a hard roof remained roadway by a buffer pressure relief belt and a wide roadway flexible wall. The method is characterized bycomprising the steps that firstly, side expanding and bottom excavating are carried out on the coal wall side of an original remained roadway, and coal bodies after side expanding is carried out areloaded into a woven bag for stand-by application; in accordance with a conventional method, holes are punched in the coal wall after side expanding is carried out for blasting, and the buffer pressurerelief belt with the width of 8-12 m is artificially manufactured; the woven bag with loaded materials is used as the wall material, and an artificial wall with the width of 1.5-1.6 m is built alongthe space position after side expanding is carried out; and the flexible wall is reinforced and blocked by a combined technique of a protective net and a single prop. Through the buffer pressure relief, the impact properties of the coal bodies are changed; and the artificial flexible wall and blasting in the roadway side are adopted to form a flexible body so as to realize impact prevention of theremained roadway.

Owner:SHANDONG UNIV OF SCI & TECH

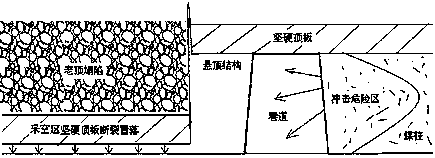

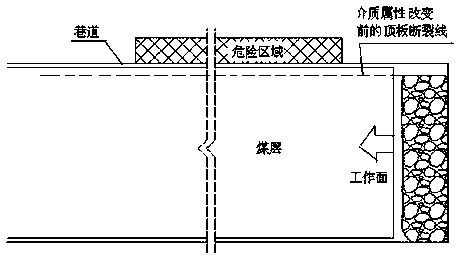

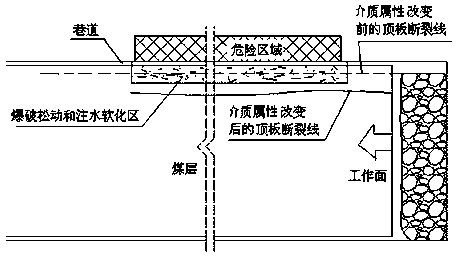

Hard-roof rock burst control method based on medium property change

InactiveCN110905596AChange boundary conditionsChange the law of fracture movementMining devicesBlastingMining engineeringStructural engineering

The invention discloses a hard-roof rock burst control method based on medium property change. The hard-roof rock burst control method based on medium property change comprises the following steps: determining a burst hazard range, and the hazard levels of different sections in the range at first; then starting to blast a coal body step by step from the boundary of the hazard area in the burst hazard range, carrying out pressure relief and loosening on the coal body to modify, enabling the coal body to be exploited in the burst hazard range to form a fluctuation conduction medium with difference, weakening the conduction steep of wave, and reducing the roof pressure impact; and carrying out low-pressure water injection on the interior of a blasting loosening area, and realizing softening with different depths for the coal body, so that displacement change is generated on the fracture line of the original hard roof, irregular fracture occurs, and moreover, the fracture line at a place which is much softened, that is, a place with a higher hazard level, has a farther distance away from a roadway, so that a safer stope is achieved.

Owner:SHANDONG UNIV OF SCI & TECH

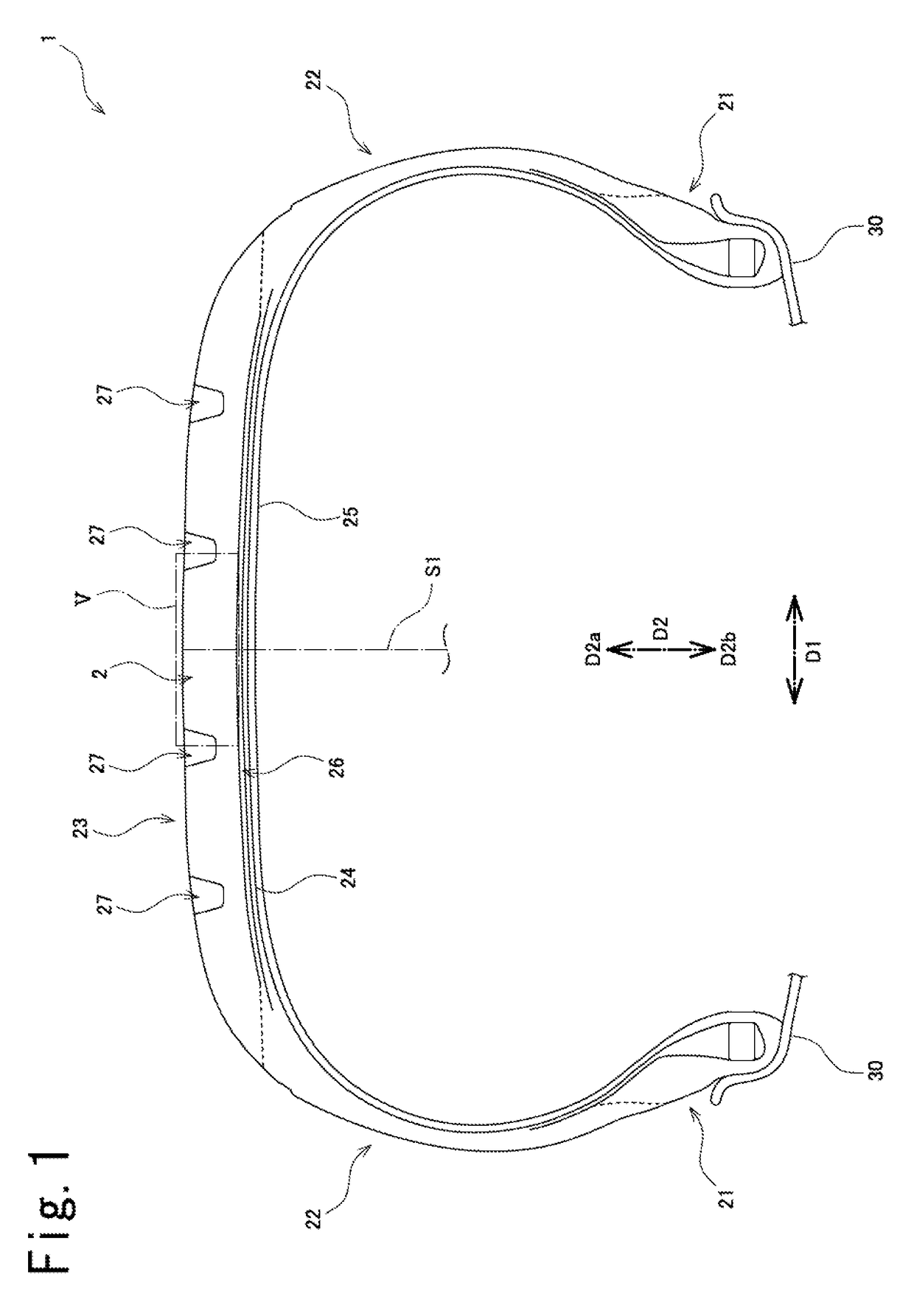

Tire

ActiveUS20180186192A1Obstruction on road surfaceGood effectTyresTyre tread bands/patternsRoad surfaceMechanical engineering

In a tire, a tread rubber includes a first layer which is grounded on a road surface in an outer peripheral surface thereof, and a second layer which is joined to an inner peripheral surface of the first layer in an outer peripheral surface thereof, the first layer includes a joint portion where rubbers having different elastic modulus are joined, and the second layer is formed by a rubber having a greater elastic modulus than an elastic modulus of at least one of the rubbers constructing the first layer.

Owner:TOYO TIRE & RUBBER CO LTD

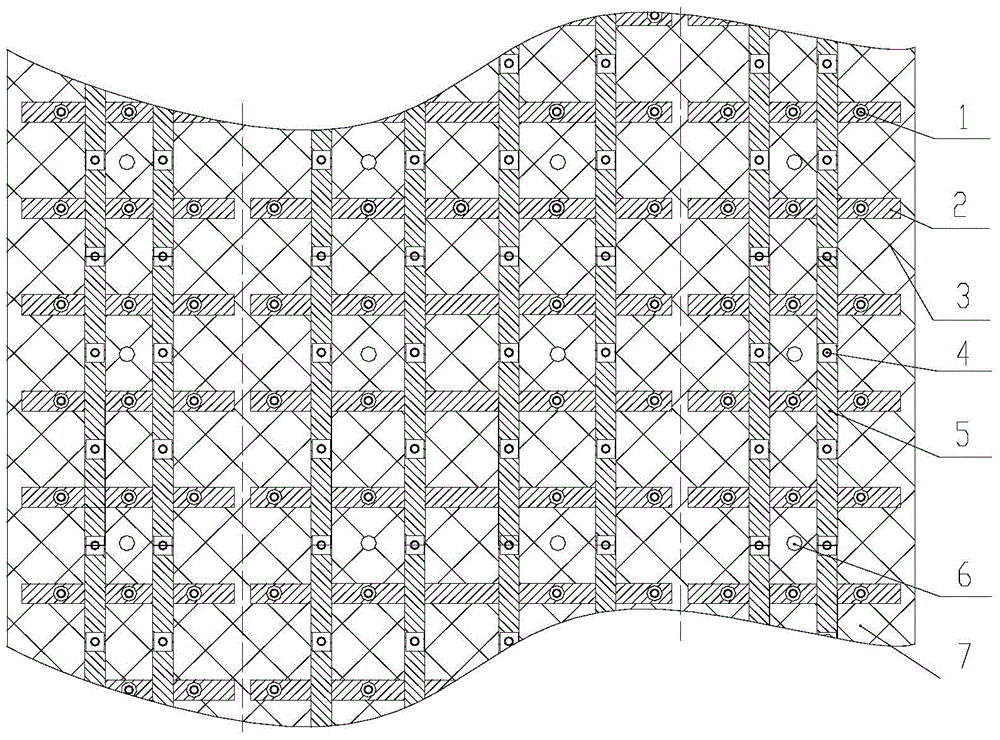

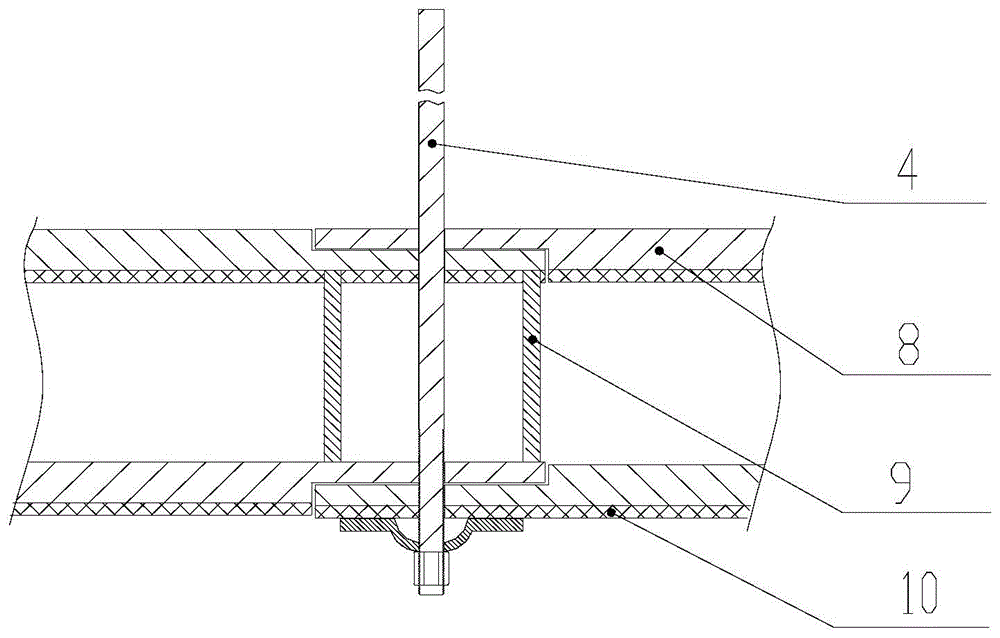

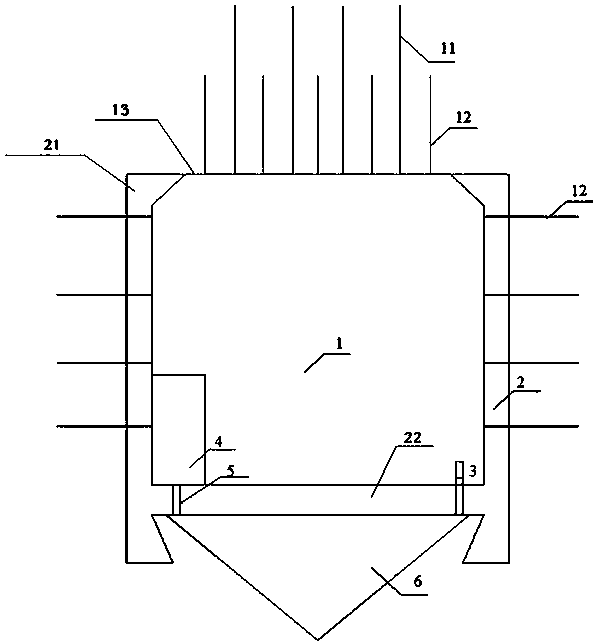

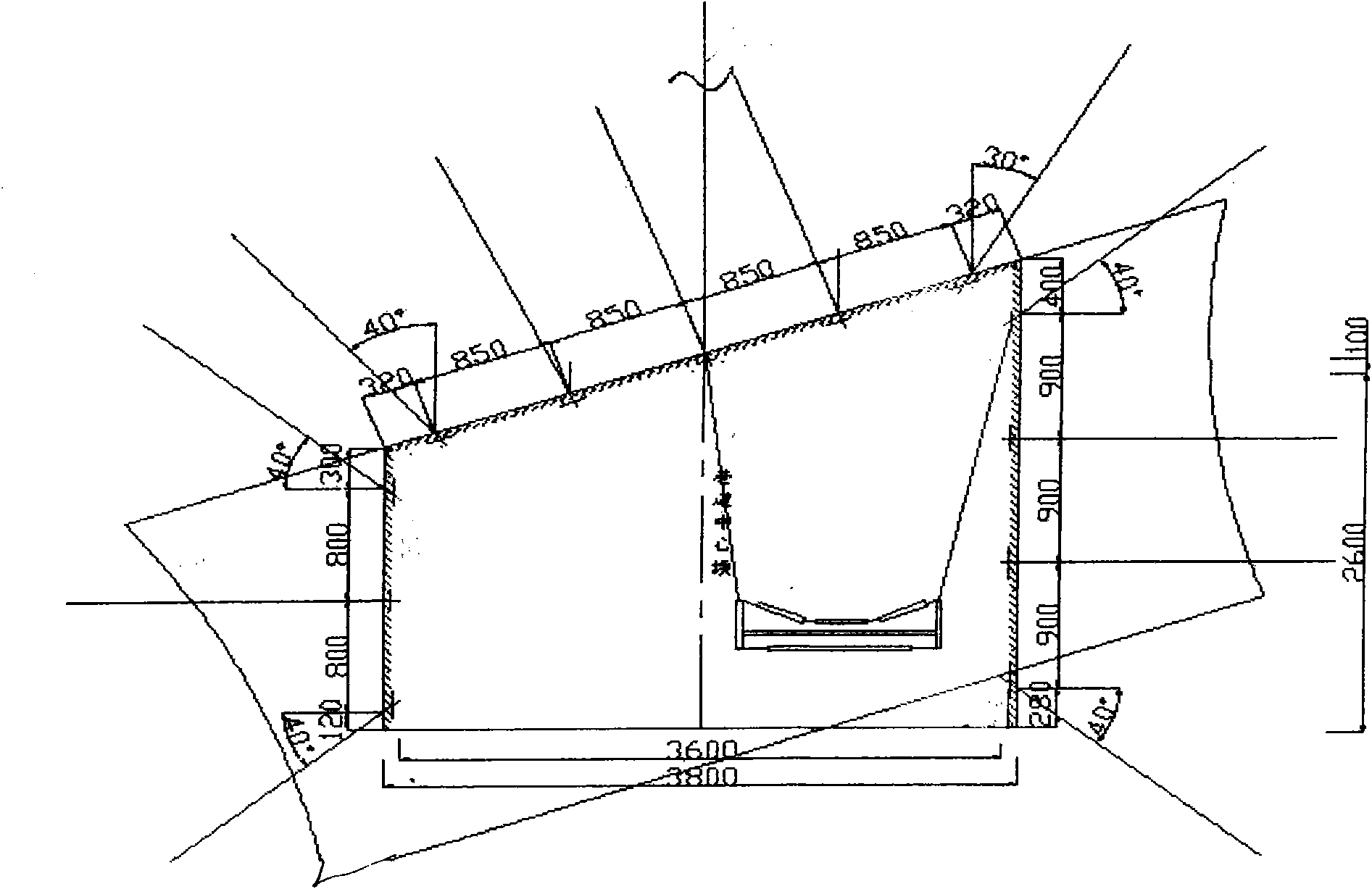

Deep roadway bottom heave control device and method based on intelligent hydraulic bag

ActiveCN110529142APrevent ground pressureEasy to useMining devicesUnderground chambersSupporting systemEmulsion

The invention discloses a deep roadway bottom heave control device and method based on an intelligent hydraulic bag. The device comprises a top plate supporting system, an H-type support and an intelligent hydraulic bag system; the H-type support is poured by C30 reinforced concrete with the length of 2 m; steel ribs with the diameter of 10 mm are adopted as a framework; No.425 cement is poured; meanwhile, a roadway wall anchoring rod hole, a hydraulic bag liquid inlet hole, a hydraulic bag liquid returning hole and a hydraulic bag pressure relief hole are preserved; the intelligent hydraulicbag system comprises a bottom plate hydraulic bag, a pressure relief pipeline, a pressure relief valve and a mineral emulsion pump; the hydraulic bag is poured with stainless steel with the thicknessof 5 mm, and the ultimate strength is 42 MPa; the hydraulic bag is 3 m wide, 2 m long and 1.5 m high; and meanwhile, a liquid inlet pipe, a liquid returning pipe and a pressure relief pipe are poured.The deep roadway bottom heave control device is simple in design, modular in operation, intelligent in supporting and stable and detectable in supporting effect; stress pre-warning can be realized; rock burst can be effectively prevented; and roadway bottom heave and roadway wall caving can be controlled to the greatest extent.

Owner:TAIYUAN UNIV OF TECH

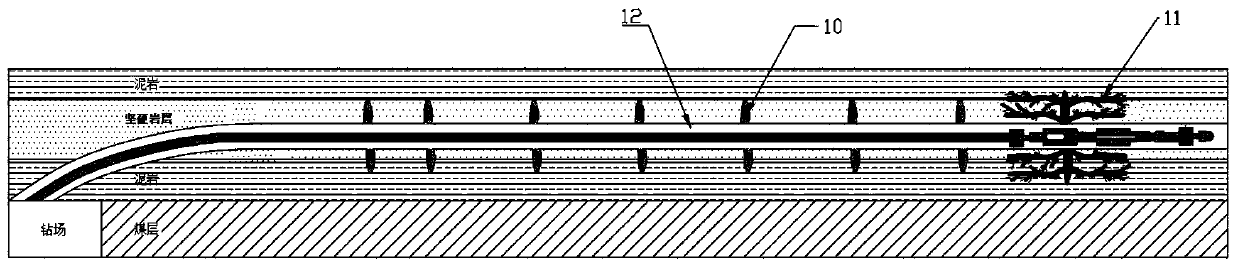

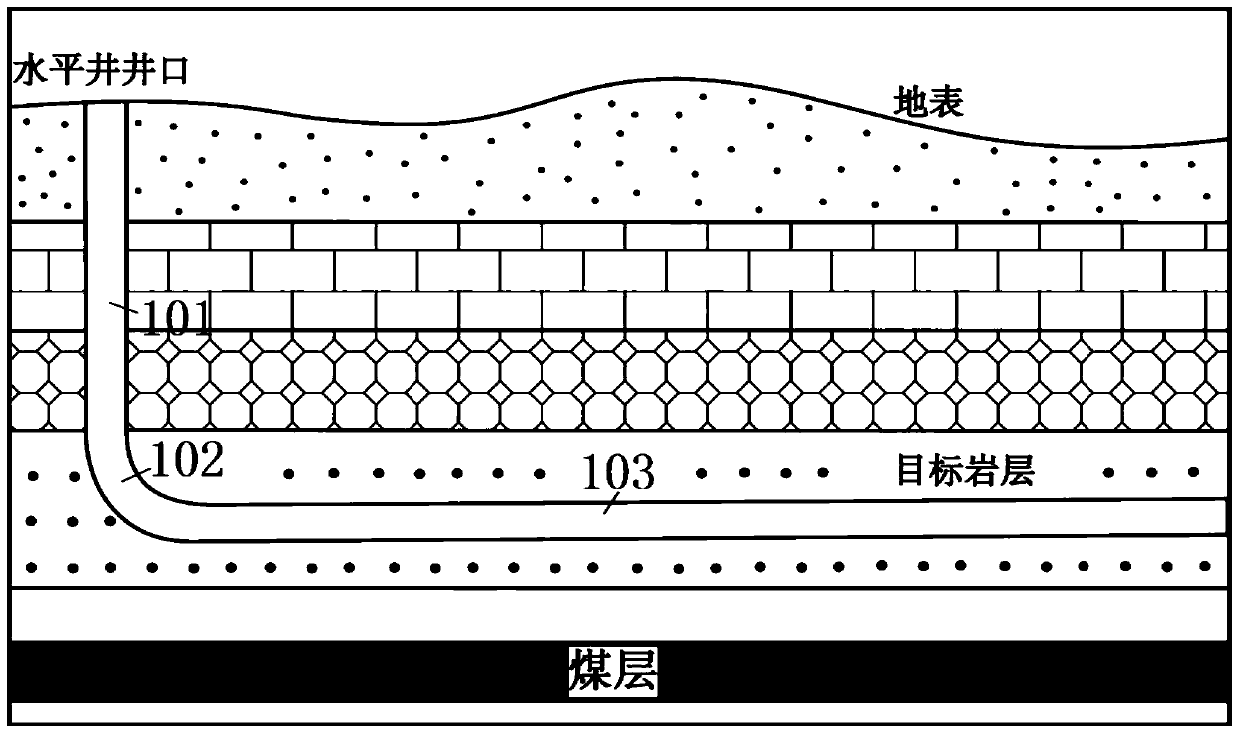

Coal mine impact ground pressure and harmful gas comprehensive prevention and treatment system and method

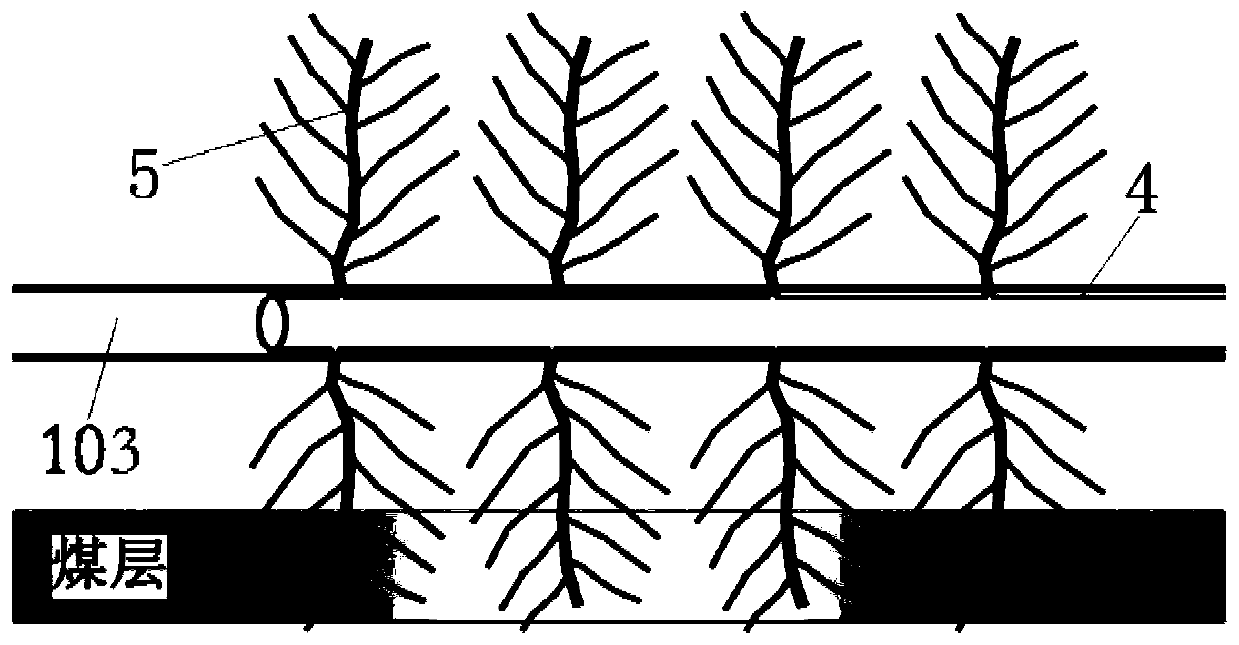

PendingCN111520184AReduce drilling difficultyRealize extractionFluid removalDirectional drillingLithologyMining engineering

The invention discloses a coal mine impact ground pressure and harmful gas comprehensive prevention and treatment system and method. Firstly, according to roof lithology and pressure characteristics of a coal mining work face, a target rock layer of horizontal well staged fracturing is determined, according to the target rock stratum and coal seam work face characteristics, a well spacing manner of a horizontal well is determined, the horizontal well is drilled, in the horizontal well, a target rock stratum and a coal seam are subjected to fracturing, through fracturing, the target rock stratum and the coal seam form an inter-communication net-shaped fracture, a ground pump drainage system is built, harmful gas in the coal seam is subjected to pump drainage, the horizontal well is mountedin the target rock stratum, in the horizontal well, the target rock stratum and the coal seam are subjected to fracturing, the inter-communication net-shaped fracture is formed in the target rock stratum and the coal seam, fracturing pressure relief of the target rock stratum is achieved, the stress state of a coal seam roof is changed, happening of an impact ground pressure accident is avoided, and meanwhile, release and pump drainage of harmful gas in the coal seam can be achieved.

Owner:陕西省煤层气开发利用有限公司

Pressure relief and consolidation synergizing prevention and control method for rock burst in deep coal drift

InactiveCN102220866BAccurately determine the distributionAvoid blindnessOptical detectionBlastingCoalDeep hole

Owner:SHANDONG UNIV OF SCI & TECH

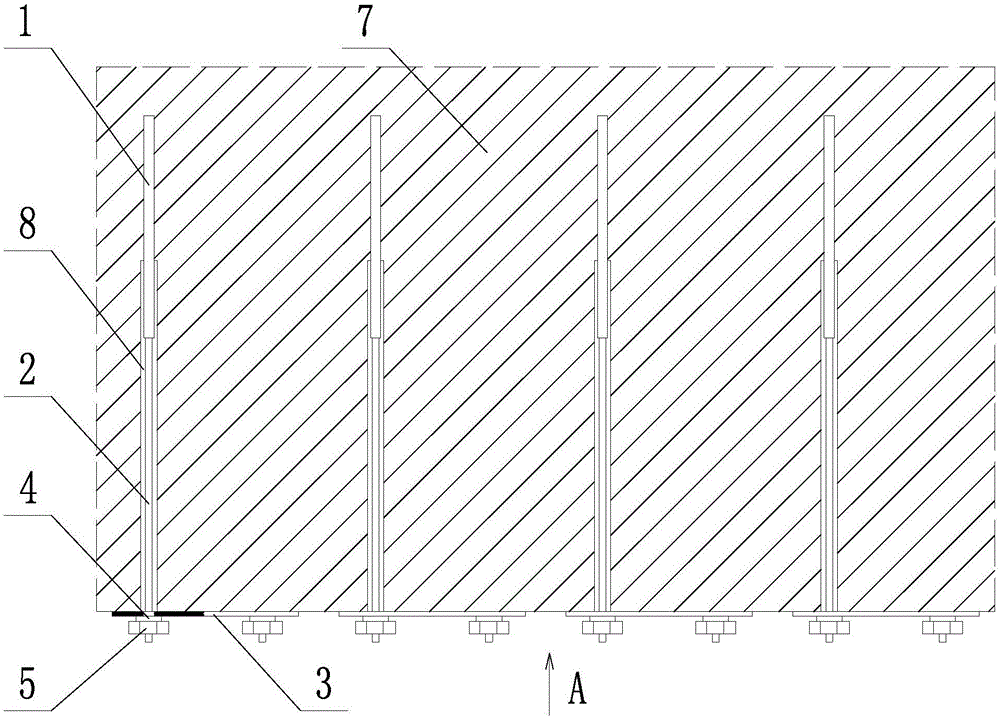

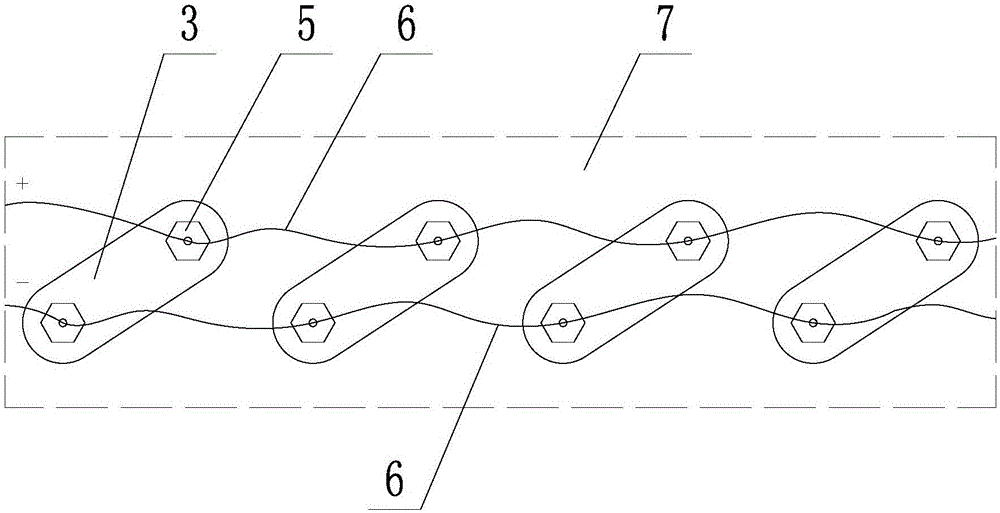

Device and method for preventing rock burst of coal mining working face

InactiveCN106837415APrevent ground pressureIntercept and dampen shock vibrationsMining devicesUnderground miningFracture zoneEngineering

The invention discloses a device and a method for preventing rock burst of a coal mining working face. The device comprises metal tubes, tungsten electrode bars, vibration output pressure plates, ceramic insulation bushings and locking nuts, wherein outer threads are arranged on the outer surfaces of the metal tubes. The method comprises the following steps: drilling two rows of drilling holes on rock wall, and screwing the metal tubes into the bottom parts of the drilling holes; fixedly connecting the tungsten electrode bars with the metal tubes; connecting a row of tungsten electrode bars with an anode of an external power supply, and connecting the other row of tungsten electrode bars with a cathode of the external power supply; outputting vibration through the vibration output pressure plates; transmitting the vibration to the metal tubes for amplifying through the tungsten electrode bars; spreading the amplified vibration to a rock body; peeling a loosened coal rock body in advance; forming an annular vibration zone on the mining working face; intercepting and weakening extraction impact vibration when transmitting the extraction impact vibration to the metal tubes; starting the external power supply while outputting the vibration, generating an electric field between the two rows of tungsten electrode bars, forming an annular electric field at the outer circle of the mining working face, carrying out assisted weakening on the strength of the extraction impact vibration, and realizing prevention of the rock burst in a fault fracture zone.

Owner:LIAONING TECHNICAL UNIVERSITY

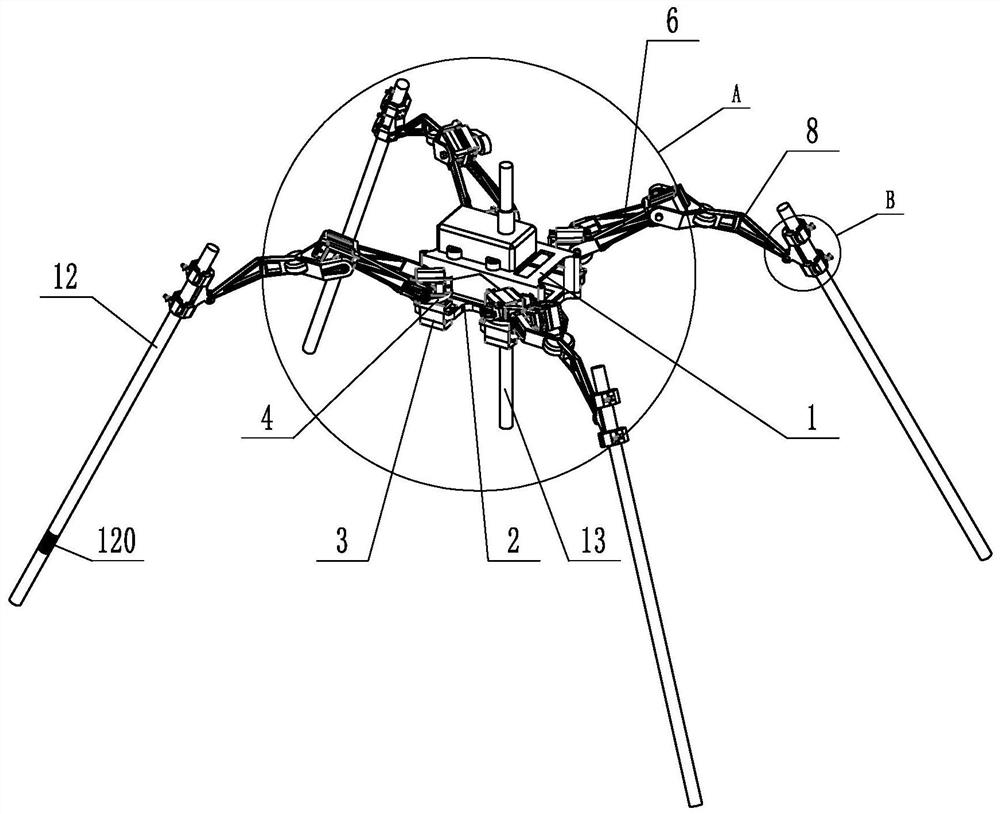

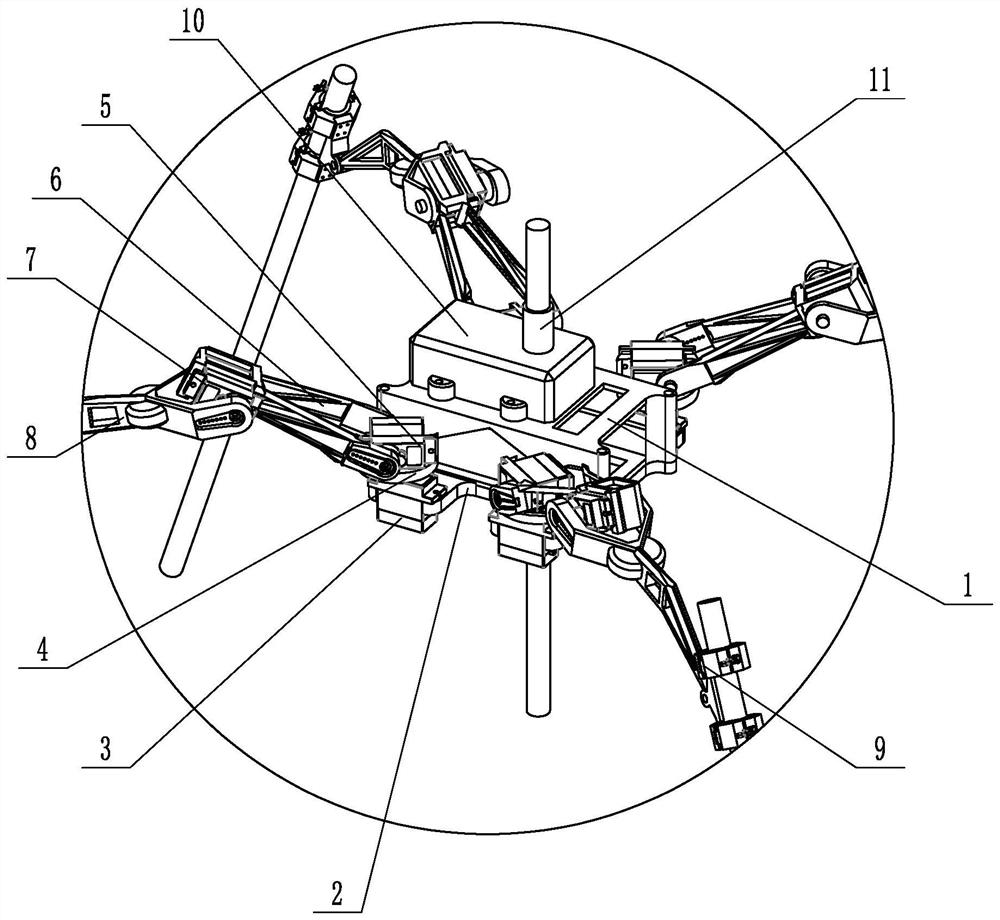

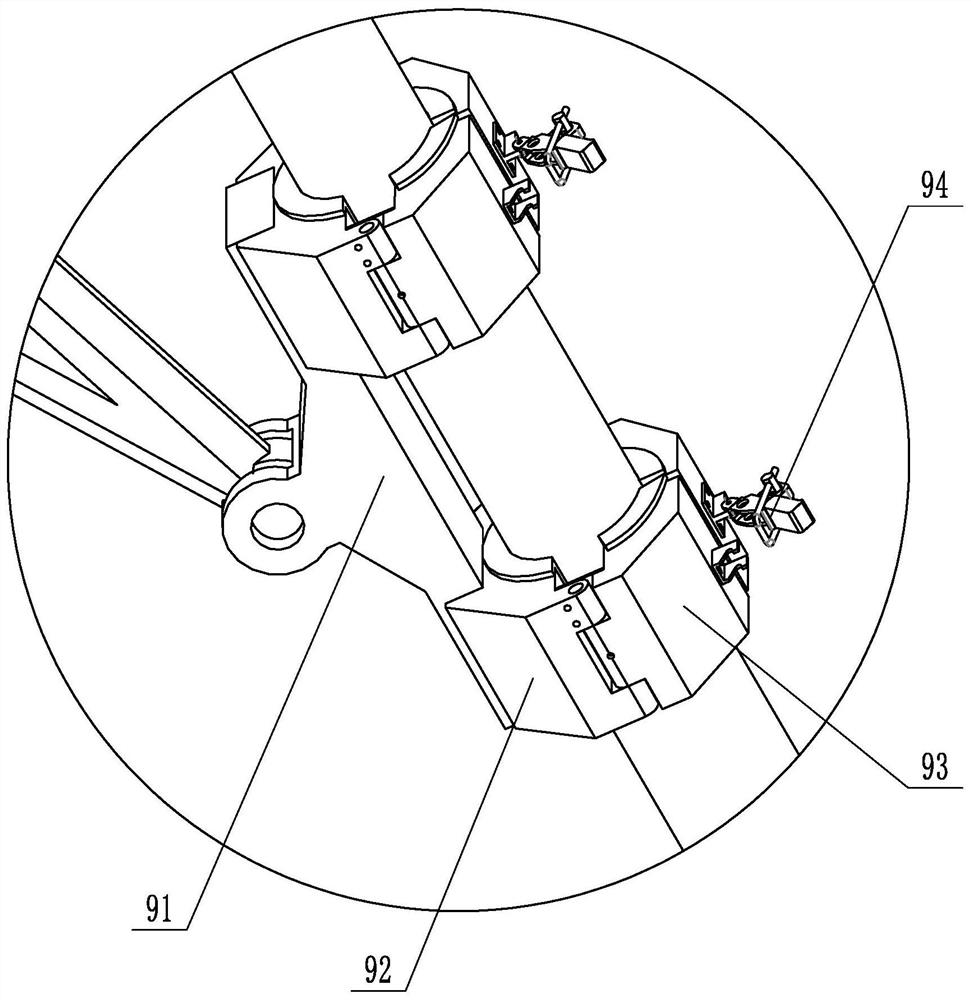

Rock burst prevention and curing device with energy guiding function

PendingCN113818927APrevent ground pressureEnsure construction safetyMining devicesStress concentrationClassical mechanics

The invention provides a rock burst prevention and curing device with an energy guiding function, and mainly relates to the field of coal field geological exploration. The rock burst prevention and curing device with the energy guiding function comprises a middle support, bottom plates are fixedly installed on the two sides of the middle support through bolts respectively, two supporting seats are fixedly installed on each bottom plate, sensor bases are rotatably installed on the supporting seats, first corner sensors are fixedly installed on the sensor bases. A front rocker arm is rotationally installed on a first corner sensor, and a second corner sensor is arranged at the front end of the front rocker arm. The rock burst prevention and curing device with the energy guiding function has the beneficial effects that the rock burst prevention and curing device with the energy guiding function can monitor the stress of a coal seam or a rock stratum in a high-risk-level area of rock burst in real time, and when the stress concentration change exceeds a preset value, early warning information can be sent out; according to the early warning information, a worker can timely conduct energy guiding and releasing on a stress concentration area in a blasting pressure relief mode, a drilling pressure relief mode, an induced blasting mode and the like, and therefore the rock burst is effectively avoided.

Owner:SHANDONG PROVINCIAL COAL GEOLOGICAL PLANNING EXPLORATION & RES INST

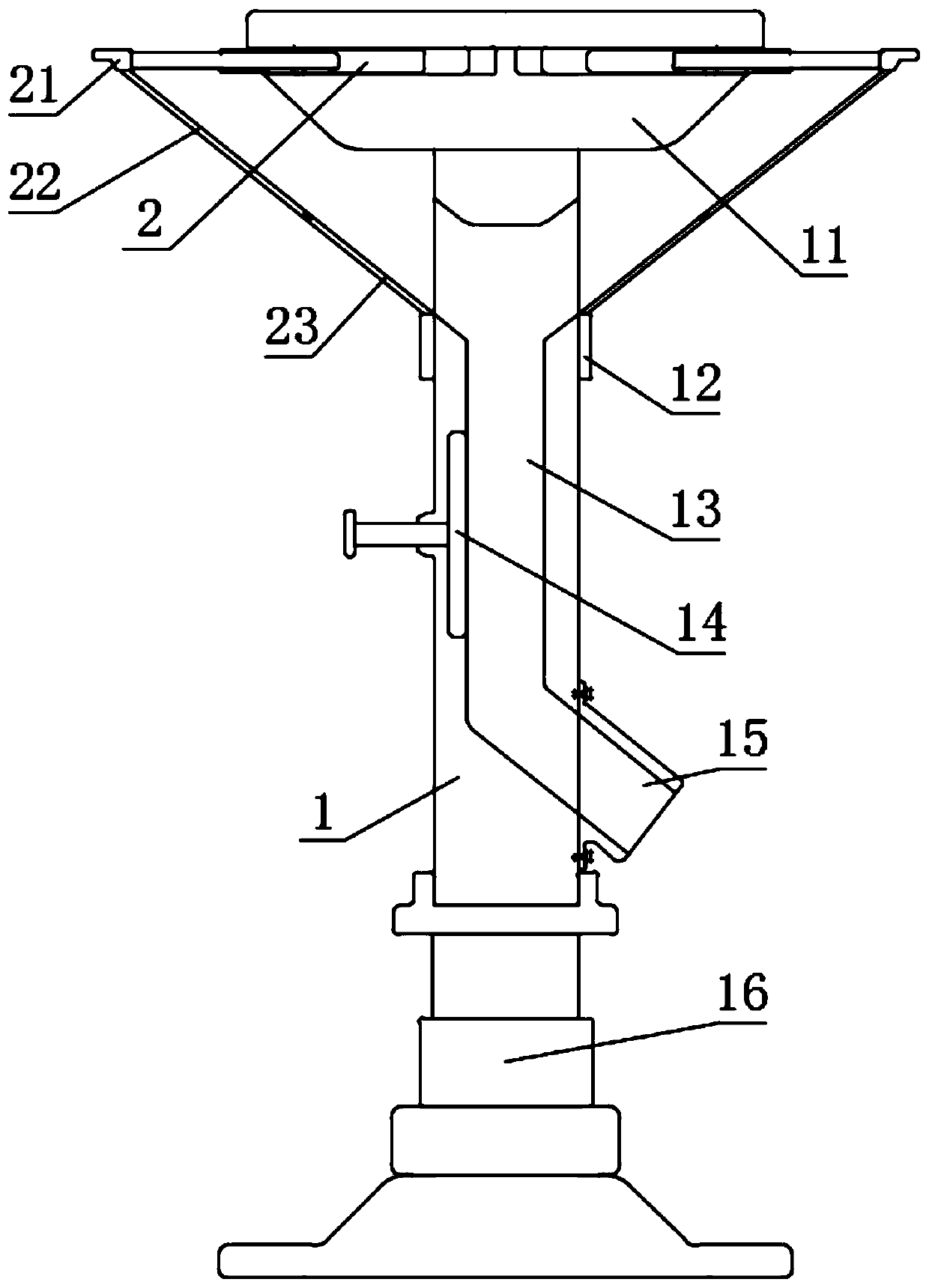

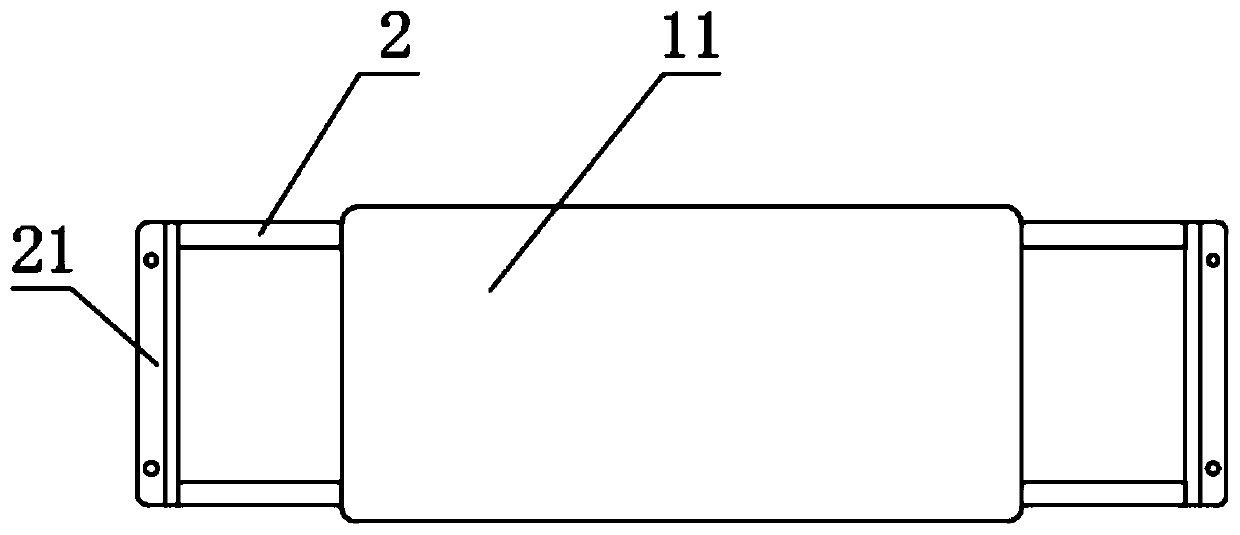

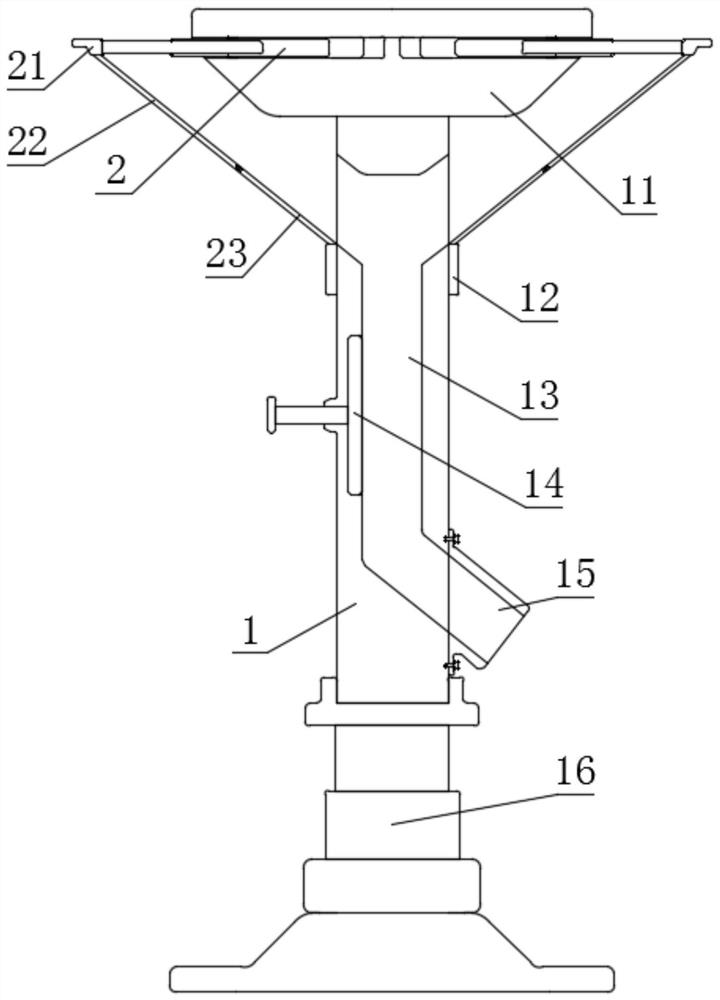

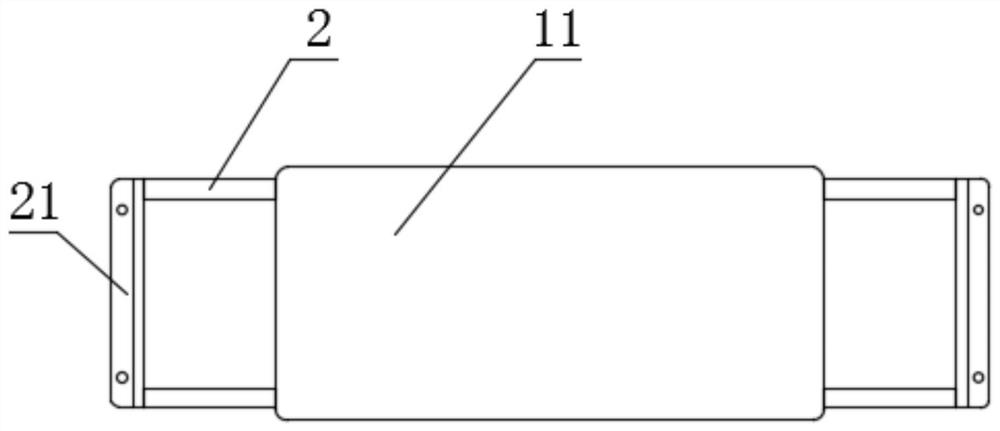

Deep extra thick coal seam impact ground pressure prevention and control equipment

ActiveCN109882218ADoes not increase load capacityPrevent ground pressureProps/chocksHydraulic cylinderCoal briquette

The invention discloses deep extra thick coal seam impact ground pressure prevention and control equipment. The deep extra thick coal seam impact ground pressure prevention and control equipment comprises a prevention and control column body, a hydraulic cylinder fixedly sleeves the bottom end of the prevention and control column body, the hydraulic cylinder is fixed to the ground in a coal mine through bolts, a top plate is fixedly connected to the top end of the prevention and control column body, the top plate is in contact with the top of a coal seam in a coal mine, and the prevention andcontrol column body is used for supporting coal mine internal space to prevent an extra thick coal seam from occurring impacting ground pressure; telescopic rods are movably inserted into four cornersof the top plate, fixed steel plates are fixedly connected to one ends of the two telescopic rods, double-faced rubber hanging rain cloth is fixed to the bottom ends of the fixed steel plates in a threaded mode, and elastic cloth is arranged at one end of the double-faced rubber hanging rain cloth in a sewing mode. According to the deep extra thick coal seam impact ground pressure prevention andcontrol equipment, a movable anti-blocking plate is arranged in a channel, the anti-blocking plate crushes coal briquettes when the fallen coal briquettes are blocked, so that the moving smoothness isimproved, and the coal briquettes are conveniently collected.

Owner:NORTHEASTERN UNIV

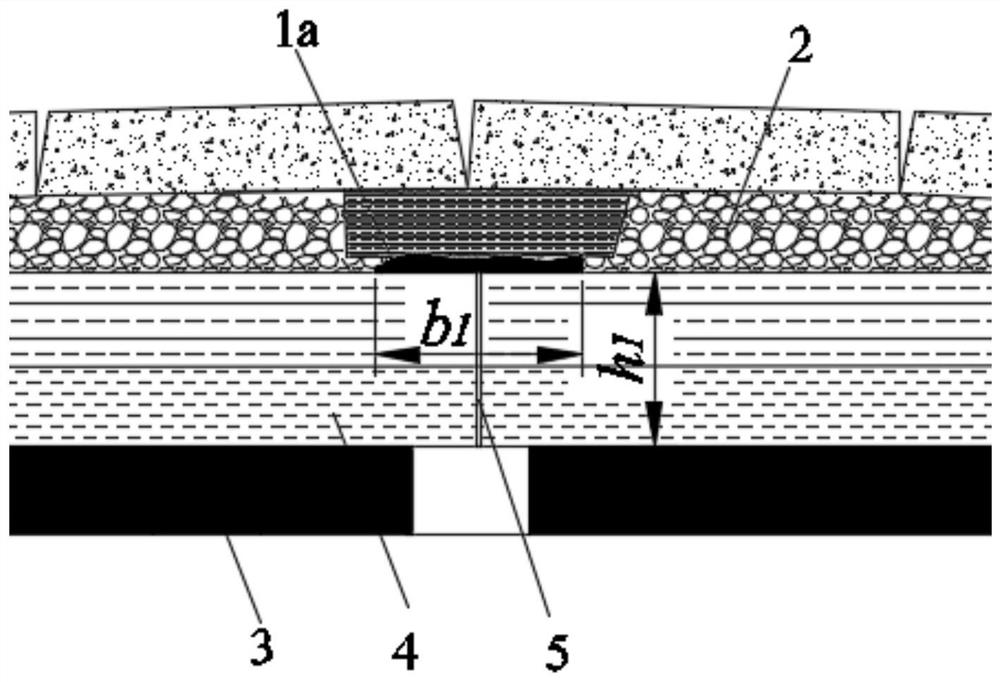

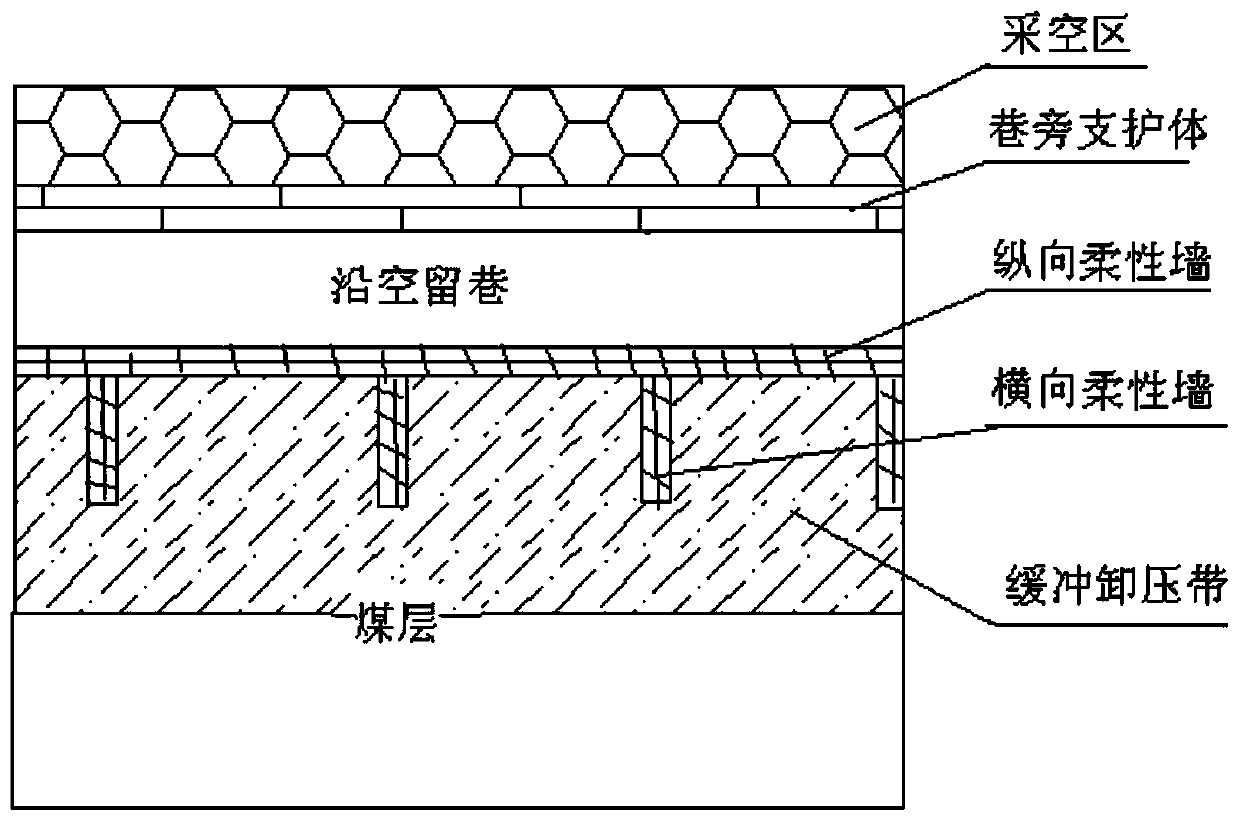

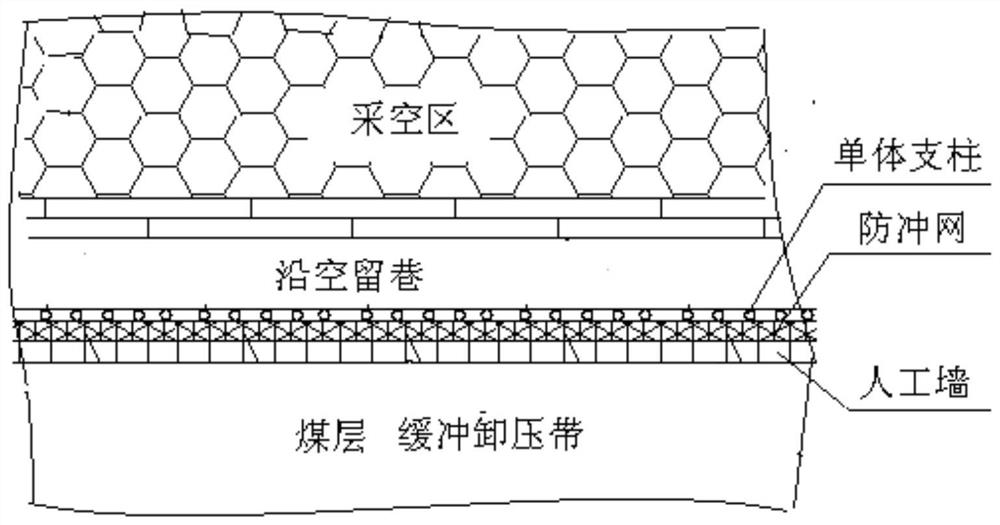

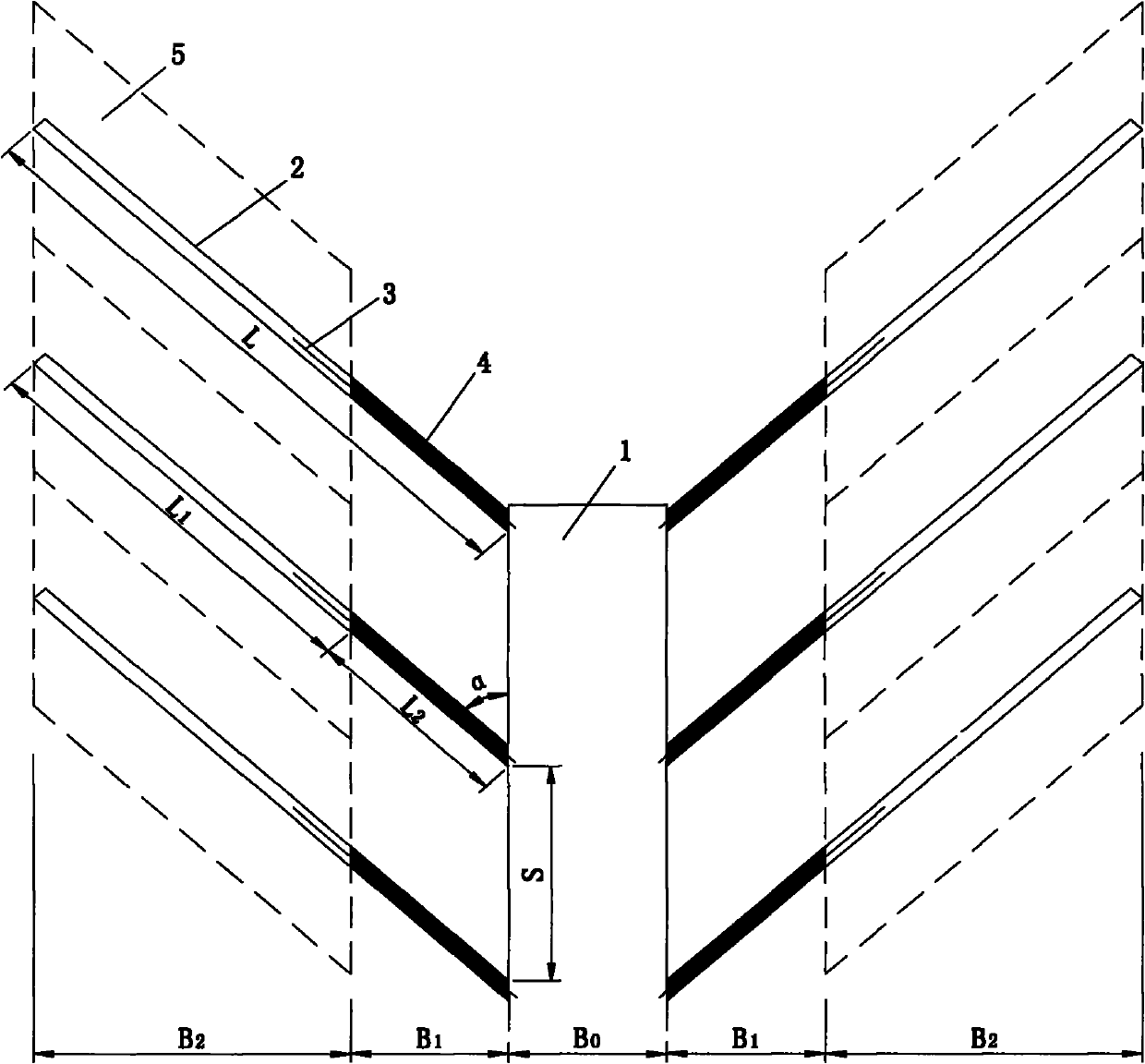

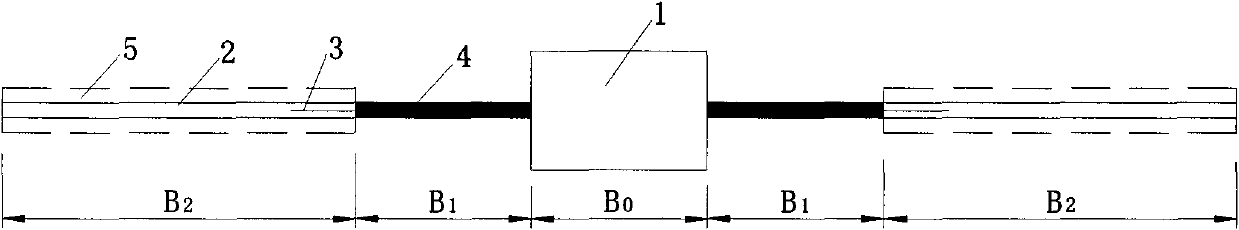

Wide lane and flexible chamber wall hard roof gob-side entry rock burst prevention method

ActiveCN110145307AChange stress distributionChange the impact propertiesUnderground miningBlastingStress distributionRock bolt

The invention discloses a wide lane and flexible chamber wall hard roof gob-side entry rock burst prevention method. The method is characterized in that firstly, rib expanding and bottom cutting are performed on the coal wall side of an original gob-side entry, a coal body which is generated after rib expanding is put in a woven bag, and a buffering pressure relief zone is made manually on the rib-expanded coal wall along the gob-side entry; a chamber is excavated in a coal side of one side of a working surface, conventional anchor bolt supporting is performed on a chamber roof, and transverseflexible walls are formed after backfilling is finished; the woven bag filled with materials is used as a wall material, longitudinal flexible walls are built along the rib-expanded space position; the stress distribution of a coal bed is changed by manually making the buffering pressure relief zone, and occurrence of rock burst is prevented; and a flexible combined body is formed by the transverse flexible walls and the longitudinal flexible walls, and the functions of partition, dynamic load relief and impact strength reduction are achieved.

Owner:SHANDONG UNIV OF SCI & TECH

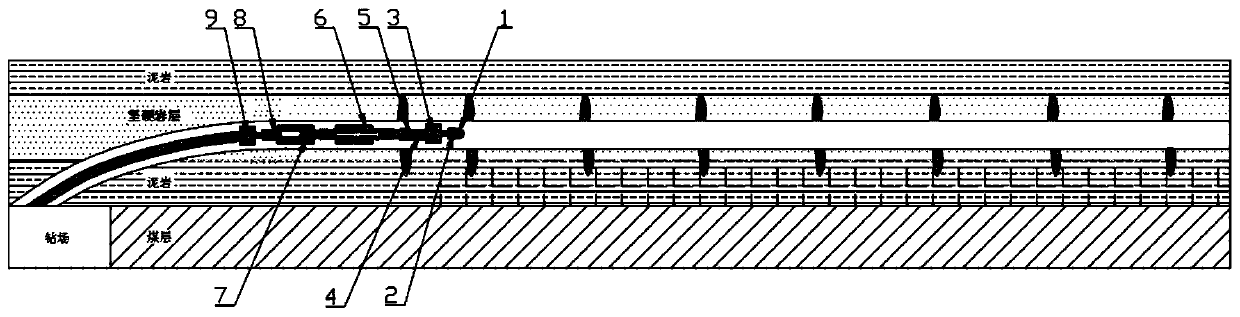

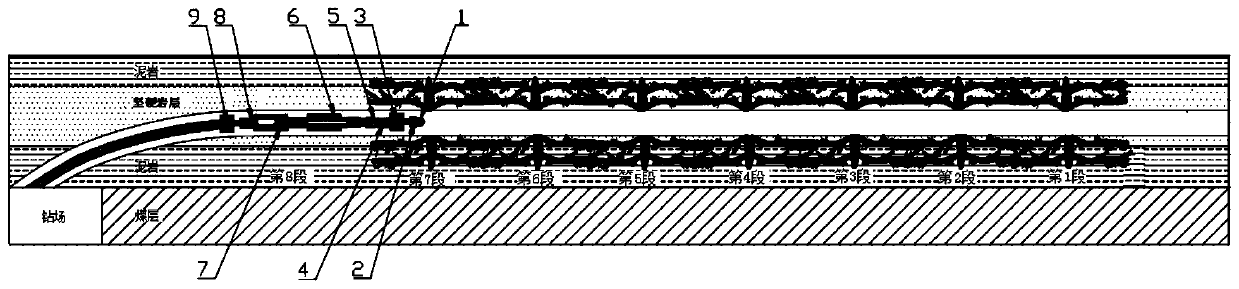

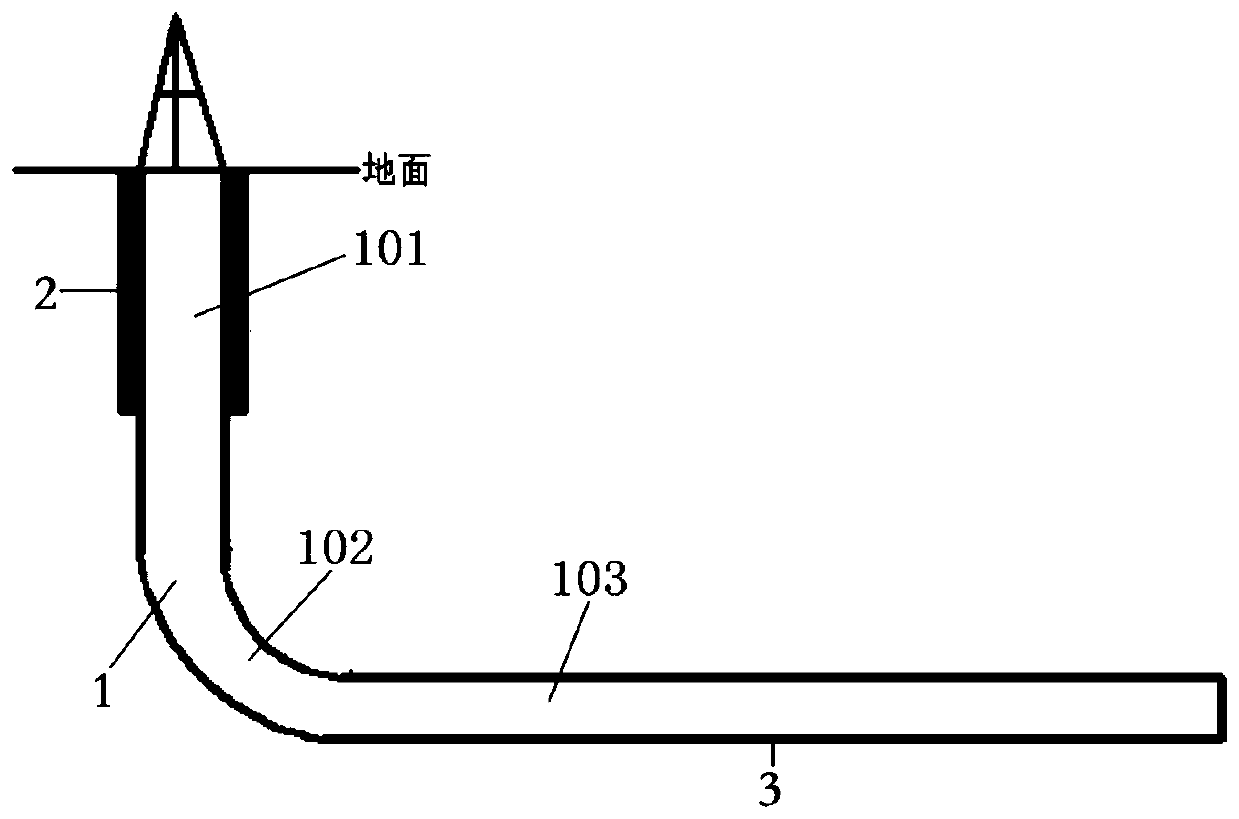

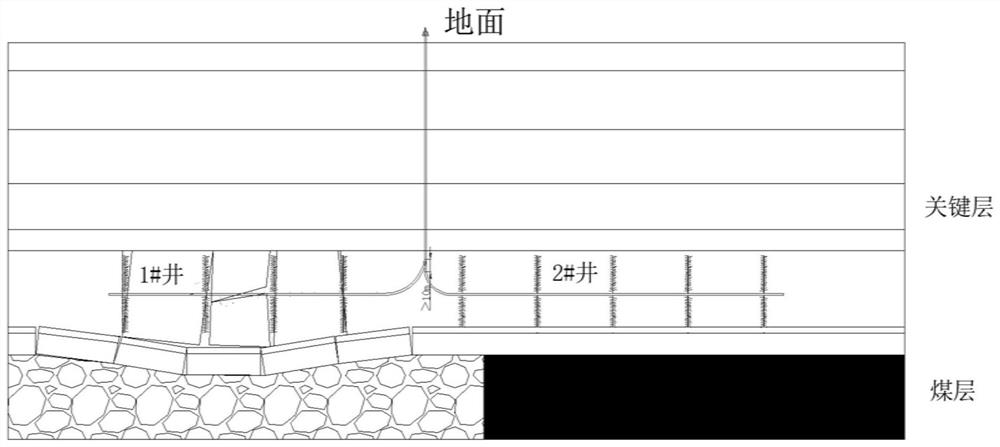

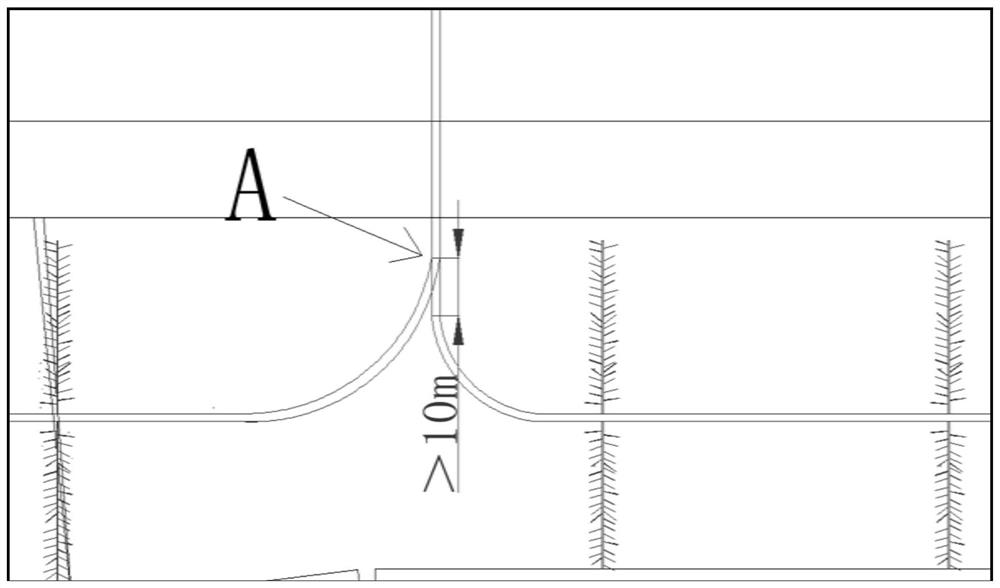

Method for preventing rock burst through staged fracturing of L-shaped ground horizontal well

ActiveCN113404534ASafe and Efficient MiningPrevent ground pressureMining devicesUnderground miningRock burstCoal

The invention discloses a method for preventing rock burst through staged fracturing of an L-shaped ground horizontal well. The method comprises the following steps that the fracturing layer position and the fracturing interval are determined. An L-shaped horizontal well vertical shaft section is constructed on the ground, and a sleeve is embedded to fix the well wall. Deflecting is started at the design point A, the design point A extends to the fracturing layer position, and when drilling is conducted to the horizontal direction, the horizontal section of the 1 # well is started to be constructed; the horizontal section of the 1 # well is fractured in a retreating mode; the deflecting section of the 1 # well is blocked, then the vertical shaft is extended, deflecting in the reverse direction is started at the position not smaller than 10 m below the design point A and extends to the fracturing layer position, and when drilling is conducted to the horizontal direction, the horizontal section of the 2 # well is started to be constructed; and the horizontal section of the well 2 # is fractured in a retreating mode. According to the method, high-pressure hydraulic staged fracturing is carried out on the hard and difficult-to-collapse rock stratum covered on the coal face, so that the rock stratum collapses regularly, rock burst of the coal face caused by large-area suspended roof sudden striding and falling of the rock stratum is avoided, and safe and efficient mining of a mine is achieved.

Owner:陕西彬长孟村矿业有限公司

A device for preventing and controlling rock burst in deep and extra-thick coal seams

ActiveCN109882218BDoes not increase load capacityPrevent ground pressureProps/chocksCoal briquetteHydraulic cylinder

The invention discloses a device for preventing and controlling deep and extra-thick coal seam rockbursts, which includes a prevention column main body. The bottom end of the prevention column main body is fixedly covered with a hydraulic cylinder. The hydraulic cylinder is fixed on the ground in the coal mine through bolts, and The top of the main body of the prevention column is fixedly connected with a roof plate, and the roof plate is in contact with the top of the coal seam in the coal mine. The main body of the prevention column is used to support the internal space of the coal mine to prevent the occurrence of impact ground pressure in the extra-thick coal seam; the four corners of the roof plate are movable. A telescopic rod is inserted, one end of the two telescopic rods is fixedly connected to a fixed steel plate, the bottom end of the fixed steel plate is threaded with a double-sided glued raincoat, and one end of the double-sided glued raincoat is sewn with an elastic cloth. ; The inner channel of the present invention is provided with a movable anti-blocking plate, which crushes the coal when the falling coal is blocked, thereby improving the smoothness of its movement and facilitating the collection of the coal.

Owner:NORTHEASTERN UNIV LIAONING

Deep roadway floor drum control device and method based on intelligent hydraulic bladder

ActiveCN110529142BPrevent ground pressureEasy to useMining devicesUnderground chambersSupporting systemReinforced concrete

The invention discloses a deep roadway bottom heave control device and method based on an intelligent hydraulic bag. The device comprises a top plate supporting system, an H-type support and an intelligent hydraulic bag system; the H-type support is poured by C30 reinforced concrete with the length of 2 m; steel ribs with the diameter of 10 mm are adopted as a framework; No.425 cement is poured; meanwhile, a roadway wall anchoring rod hole, a hydraulic bag liquid inlet hole, a hydraulic bag liquid returning hole and a hydraulic bag pressure relief hole are preserved; the intelligent hydraulicbag system comprises a bottom plate hydraulic bag, a pressure relief pipeline, a pressure relief valve and a mineral emulsion pump; the hydraulic bag is poured with stainless steel with the thicknessof 5 mm, and the ultimate strength is 42 MPa; the hydraulic bag is 3 m wide, 2 m long and 1.5 m high; and meanwhile, a liquid inlet pipe, a liquid returning pipe and a pressure relief pipe are poured.The deep roadway bottom heave control device is simple in design, modular in operation, intelligent in supporting and stable and detectable in supporting effect; stress pre-warning can be realized; rock burst can be effectively prevented; and roadway bottom heave and roadway wall caving can be controlled to the greatest extent.

Owner:TAIYUAN UNIV OF TECH

Method of preventing rockburst in roadway retained by hard roof with buffer pressure relief belt and flexible wall in wide roadway

ActiveCN110219649BChange stress distributionChange the impact propertiesMining devicesUnderground miningArchitectural engineeringStructural engineering

The invention discloses a method for preventing impact ground pressure of a hard roof remained roadway by a buffer pressure relief belt and a wide roadway flexible wall. The method is characterized bycomprising the steps that firstly, side expanding and bottom excavating are carried out on the coal wall side of an original remained roadway, and coal bodies after side expanding is carried out areloaded into a woven bag for stand-by application; in accordance with a conventional method, holes are punched in the coal wall after side expanding is carried out for blasting, and the buffer pressurerelief belt with the width of 8-12 m is artificially manufactured; the woven bag with loaded materials is used as the wall material, and an artificial wall with the width of 1.5-1.6 m is built alongthe space position after side expanding is carried out; and the flexible wall is reinforced and blocked by a combined technique of a protective net and a single prop. Through the buffer pressure relief, the impact properties of the coal bodies are changed; and the artificial flexible wall and blasting in the roadway side are adopted to form a flexible body so as to realize impact prevention of theremained roadway.

Owner:SHANDONG UNIV OF SCI & TECH

A method for anti-shock ground pressure of all-coal roadway

ActiveCN104806265BImproved anti-shock performanceEven by forceUnderground chambersBlastingEngineeringCoal

Owner:LIAONING TECHNICAL UNIVERSITY

Prevention method of rockburst in roadway retained by hard roof with wide roadway and flexible chamber wall

ActiveCN110145307BChange stress distributionChange the impact propertiesUnderground miningBlastingArchitectural engineeringRock bolt

Owner:SHANDONG UNIV OF SCI & TECH

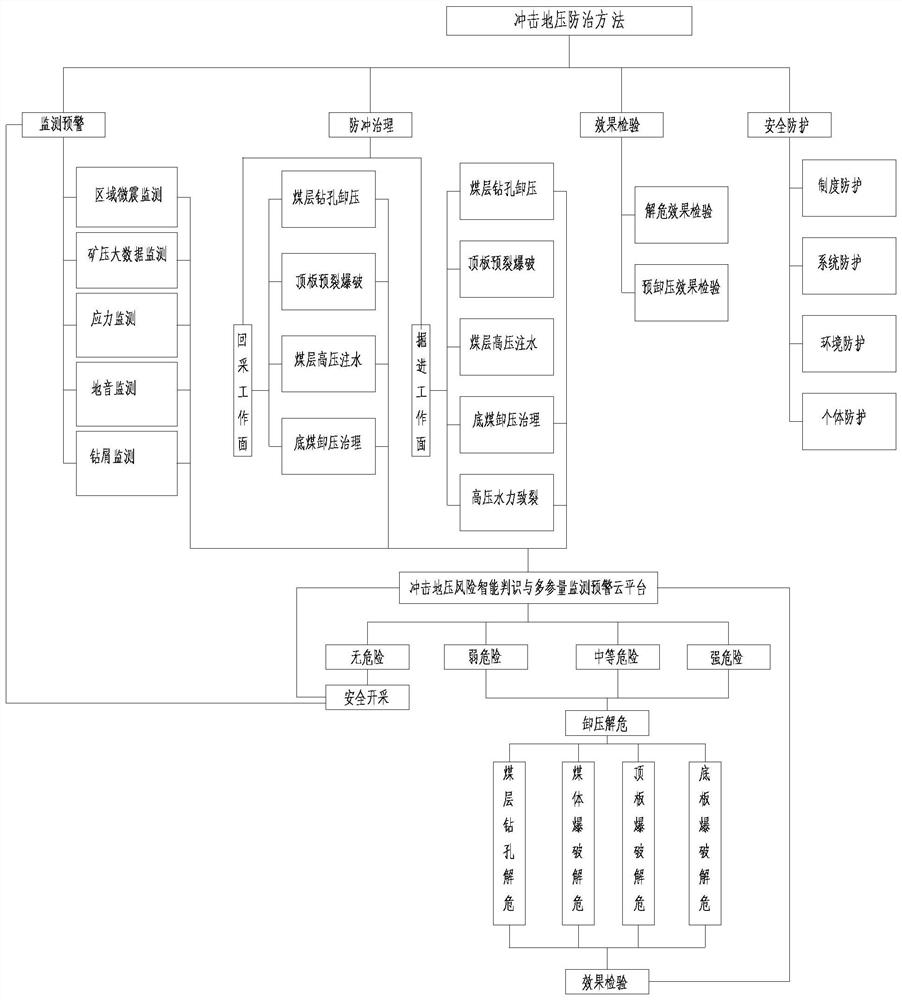

Rock burst prevention and curing method

PendingCN113847093APrevent ground pressureRockburst dropMining devicesGas removalMining engineeringPetroleum engineering

The invention discloses a rock burst prevention and curing method. The rock burst prevention and curing method comprises the following steps that rock burst monitoring and early warning is achieved: rock burst data monitoring is performed on a coal mining area, and if the monitored rock burst data is within a safe range, safe mining is implemented on a coal mine; anti-impact treatment is achieved: if the rock burst data monitored in a rock burst monitoring and early warning step is not in the safe range, anti-impact treatment is carried out on the coal mining area, and the anti-impact treatment comprises an anti-impact measure for a stope face and the anti-impact measure for a driving face; treatment effect detection is achieved: effect detection is carried out on the anti-impact treatment to detect whether the coal mining requirement is met after the anti-impact treatment, if a detection result is within the safe range, safe mining is carried out on the coal mine, and if the detection result is not within the safe range, the anti-impact treatment is carried out continuously; and safety protection is conducted, specifically, safety protection measures are established before mining and in the mining process.

Owner:江苏徐矿能源股份有限公司张双楼煤矿

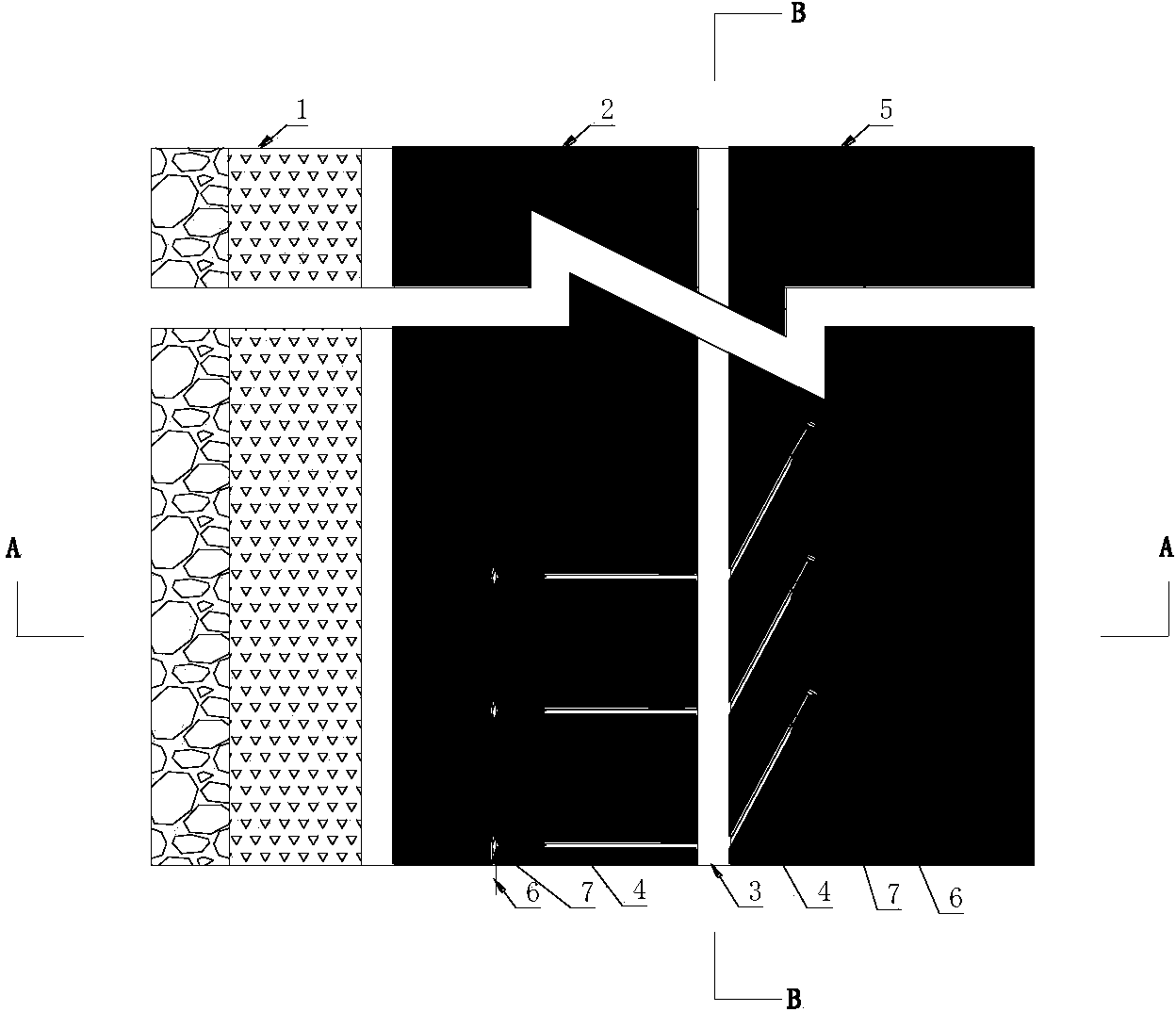

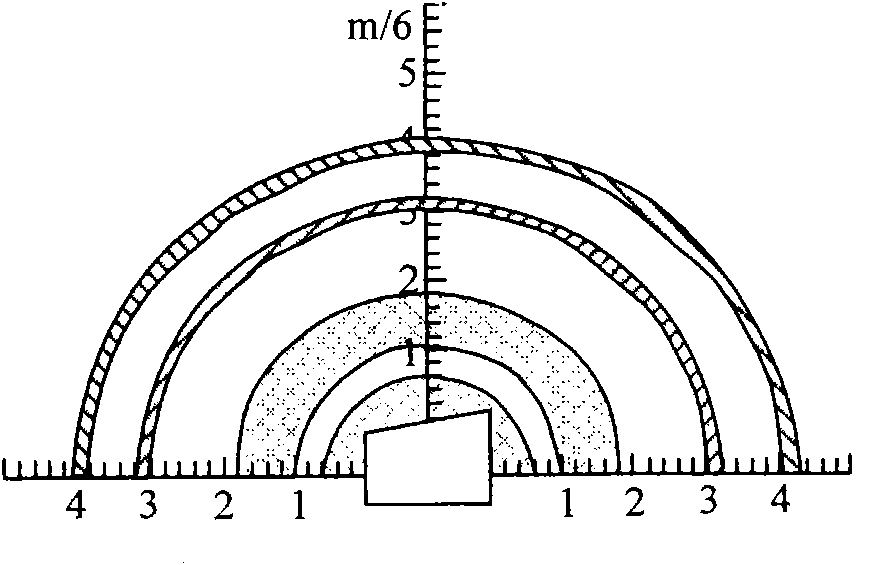

Method for improving stability of roadway surrounding rock

InactiveCN102287205BImprove stabilityIntegrity guaranteedUnderground chambersTunnel liningStress distributionActive support

The invention relates to a method for improving the stability of a roadway surrounding rock, which belongs to the technical field of underground engineering surrounding rack stability under the high-stress condition and is characterized in that the method belongs to a method for forming a bearing pad layer belt and changing the stress distribution of the roadway surrounding rock through pressing and filling bearing pad layer materials into a deep part rock body of the roadway surrounding rock so that the deep part rock body of the roadway surrounding rock has an active support effect, and thestress of the surrounding rock in the superficial position on the periphery of a roadway is reduced, and the method aims at improving the stability of the roadway surrounding rock under the conditionof maintaining the completeness of the surrounding rock in the superficial position on the periphery of the roadway. Compared with the existing method for improving the stability of the high-stress roadway surrounding rock, the method has the substantial characteristics and obvious effects that the implementation is easy, the effect for controlling the stability of the surrounding rock is obvious, the cost is low, safety and reliability are realized, and the like.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com