Method for preventing and treating rock burst by using filling mode

A technology of rock burst and anti-scour, which is applied in the field of rock burst prevention and control by filling methods, and coal mine prevention and control of rock burst, to achieve the effects of reducing expenses, reducing pressure, and slowing down bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

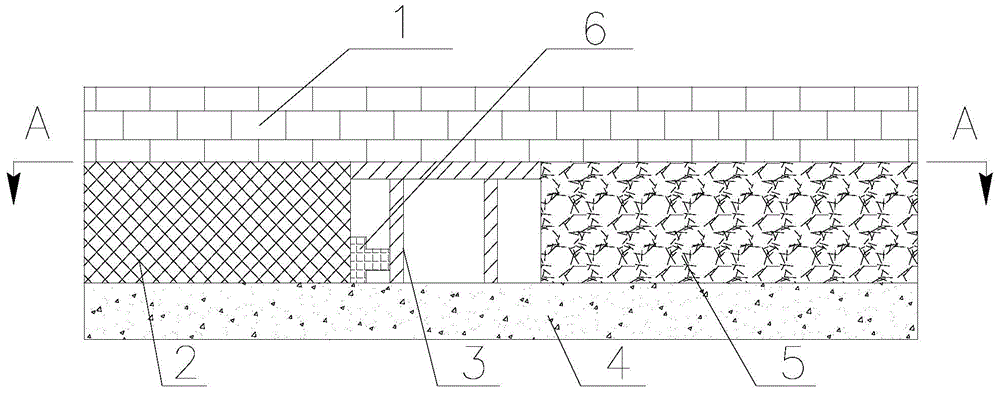

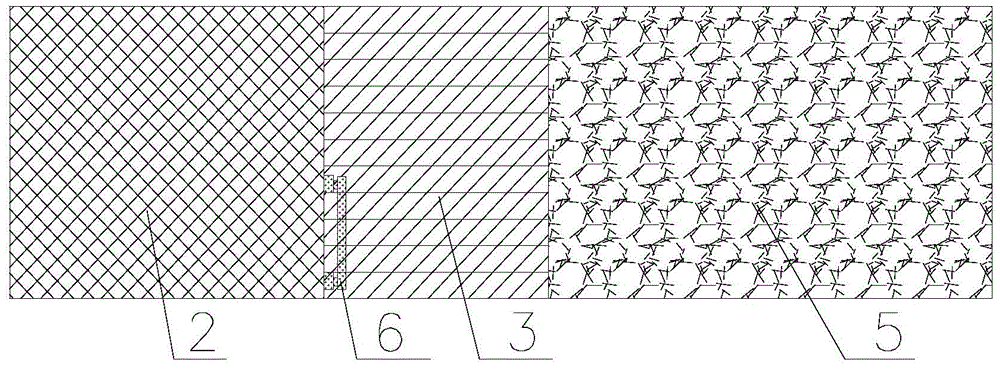

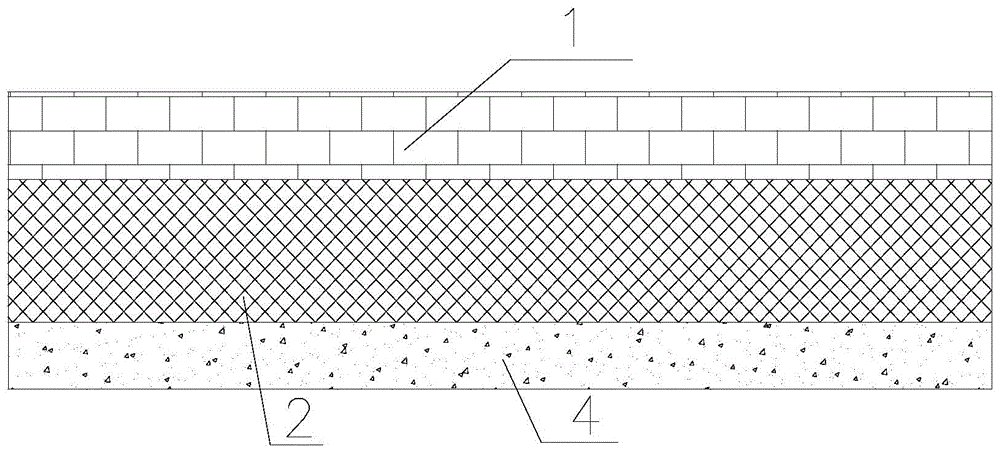

[0040] Such as Figure 1 to Figure 9 As shown, a method of preventing and controlling rockburst by means of filling includes the following steps:

[0041] Step 1: The shearer 6 cuts coal and feeds the knife, the scraper conveyor transports coal, and fills the anti-scouring hydraulic support 3 side guards and roof guards;

[0042] Step 2: After the working face is advanced by an appropriate distance, filling and anti-scouring materials are used to fill and prevent the goaf through the filling anti-scouring hydraulic support 3, and the filling and anti-scouring materials are transported from the ground to the working face and mixed on the working face; With the continuous advancement of the filling operation, the filling and anti-scouring materials are continuously accumulated and compacted to form a filling and anti-scouring cemented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com