Method for improving stability of roadway surrounding rock

A technology for the stability and stability of surrounding rock, which is used in tunnels, tunnel lining, earthwork drilling, etc. problems such as the amount of roadway excavation, to achieve the effects of low cost, prevention of ground pressure impact, and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0018] For the high vertical stress field produced by the supporting stress caused by self-weight stress or excavation, the implementation process of the method for improving the stability of the surrounding rock of the roadway under the high stress field condition by the injection cushion belt of the present invention is as follows:

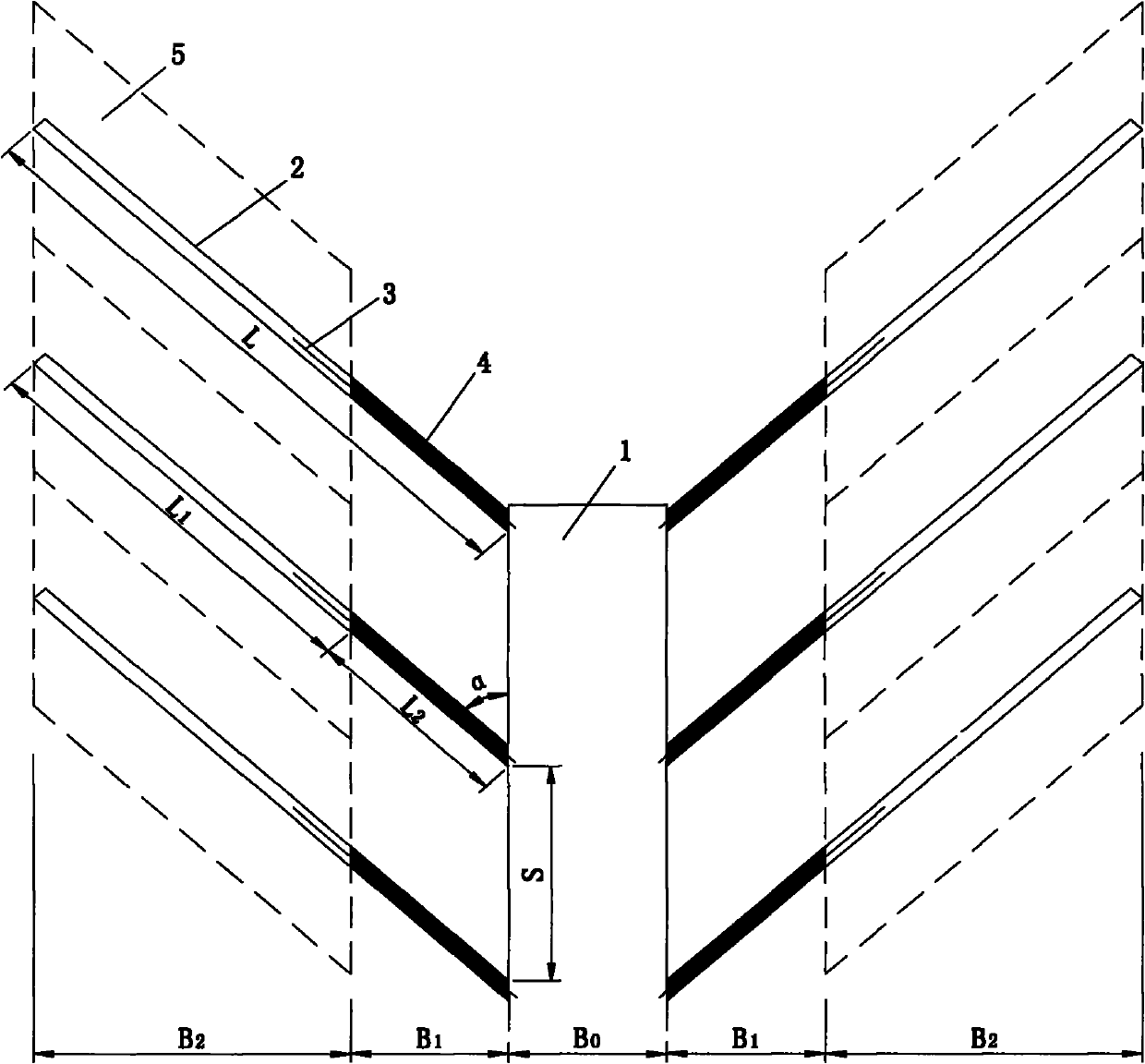

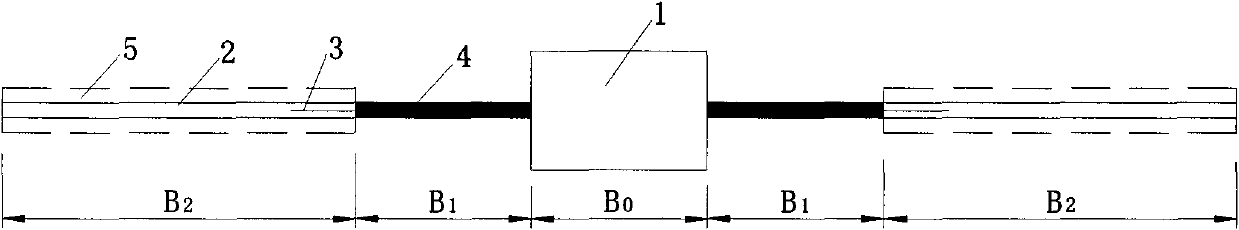

[0019] 1, at the two sides of the roadway 1 in certain mine burial depth H=800m rock formation, set up the pressure injection load-bearing cushion system to the deep part of surrounding rock, according to figure 1 The system shown in the figure injects load-bearing cushion material deep into the surrounding rock of the two sides of the roadway to form a load-bearing cushion belt, with the purpose of improving the integrity and stability of the superficial surrounding rock of the two sides of the roadway. The width of roadway 1 is 5m and the height is 4m. The position of drill hole 2 is 2m away from the bottom plate of the roadway. It forms an ang...

Embodiment approach 2

[0024] The length of borehole 2 is L=22.5m, the diameter of the borehole is φ=80mm, and the width of the designed pressure injection cushion is B 2 =11m, sealing length L 1 = 8m, the spacing S of borehole 2 = 7.5m, the mass ratio of the slurry material is: water: cement: gangue powder = 1: 0.4: 0.9, when the pressure in the injection borehole reaches 50Mpa, stop pouring into the borehole Cushion materials are injected under this condition. After the bearing cushion material is injected into the deep rock mass of the surrounding rock to form a bearing cushion belt, the supporting stress caused by the self-weight stress in the surrounding rock at the superficial part of the roadway is reduced by 40%. Same as Embodiment 1.

Embodiment approach 3

[0026] The length of the borehole 2 is L=24m, the diameter of the borehole is φ=90mm, and the width of the designed pressure injection cushion is B 2 =12m, sealing length L 1 = 9m, the spacing S of borehole 2 = 10m, the mass ratio of the slurry material is: water: cement: gangue powder = 1: 0.5: 0.8, when the pressure in the injection borehole reaches 60Mpa, stop pressing into the borehole Cushion material is injected. Under this condition, the load-bearing cushion material is injected into the deep rock mass of the surrounding rock to form a load-bearing cushion belt, which can reduce the bearing stress caused by the self-weight stress in the superficial surrounding rock of the roadway by 50%. Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com