Hard rock roof rock burst segmentation direction control fracturing treatment technology

A hard roof, rock burst technology, applied in directional drilling, fluid production, measurement, etc., can solve the problems of difficult to guarantee the weakening effect, limited development scale of fractures, difficult to control the direction, etc. Energy, the effect of preventing the impact of ground pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

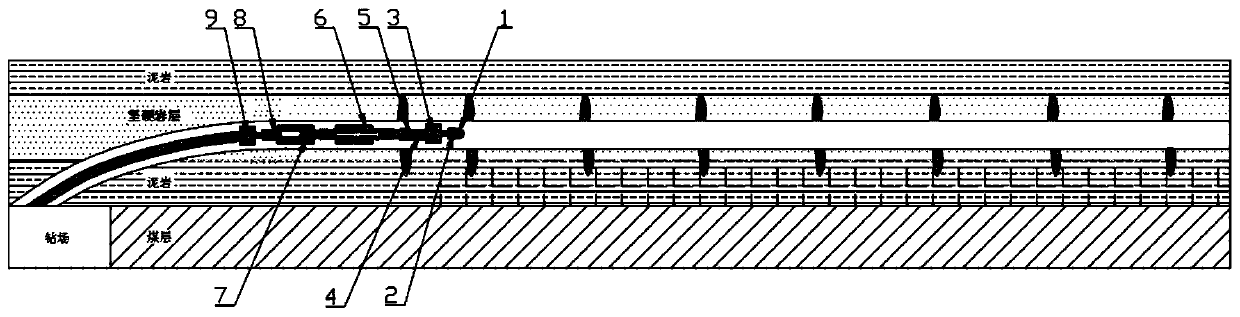

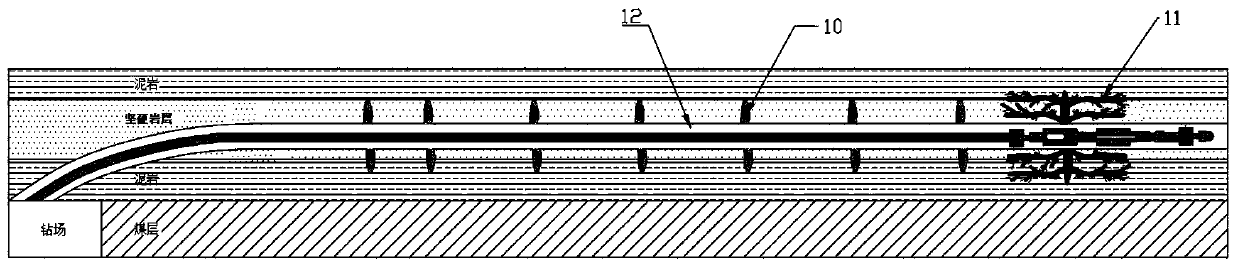

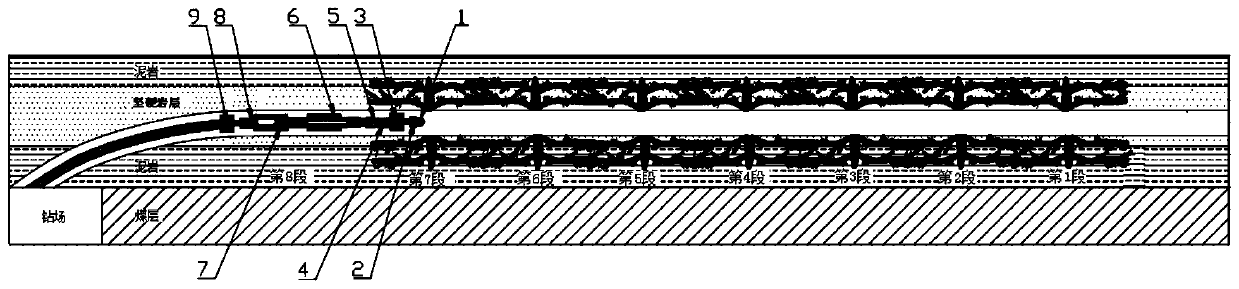

[0038] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0039] Before describing the technical solution of this embodiment, it is necessary to explain the terminology of the hard roof impact rock pressure fracturing control technology by stage control.

[0040] The hard roof rock burst segmental control fracturing treatment technology refers to the feedback and adjustment of the three-dimensional real-time data of the drilling trajectory through the measurement-while-drilling and hole bottom motor adjustment system based on directional drilling equipment, and the real-time ultra-long and accurate High-pressure fracturing fluid and high-pressure injection directional fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com