Patents

Literature

55results about How to "Avoid decompression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

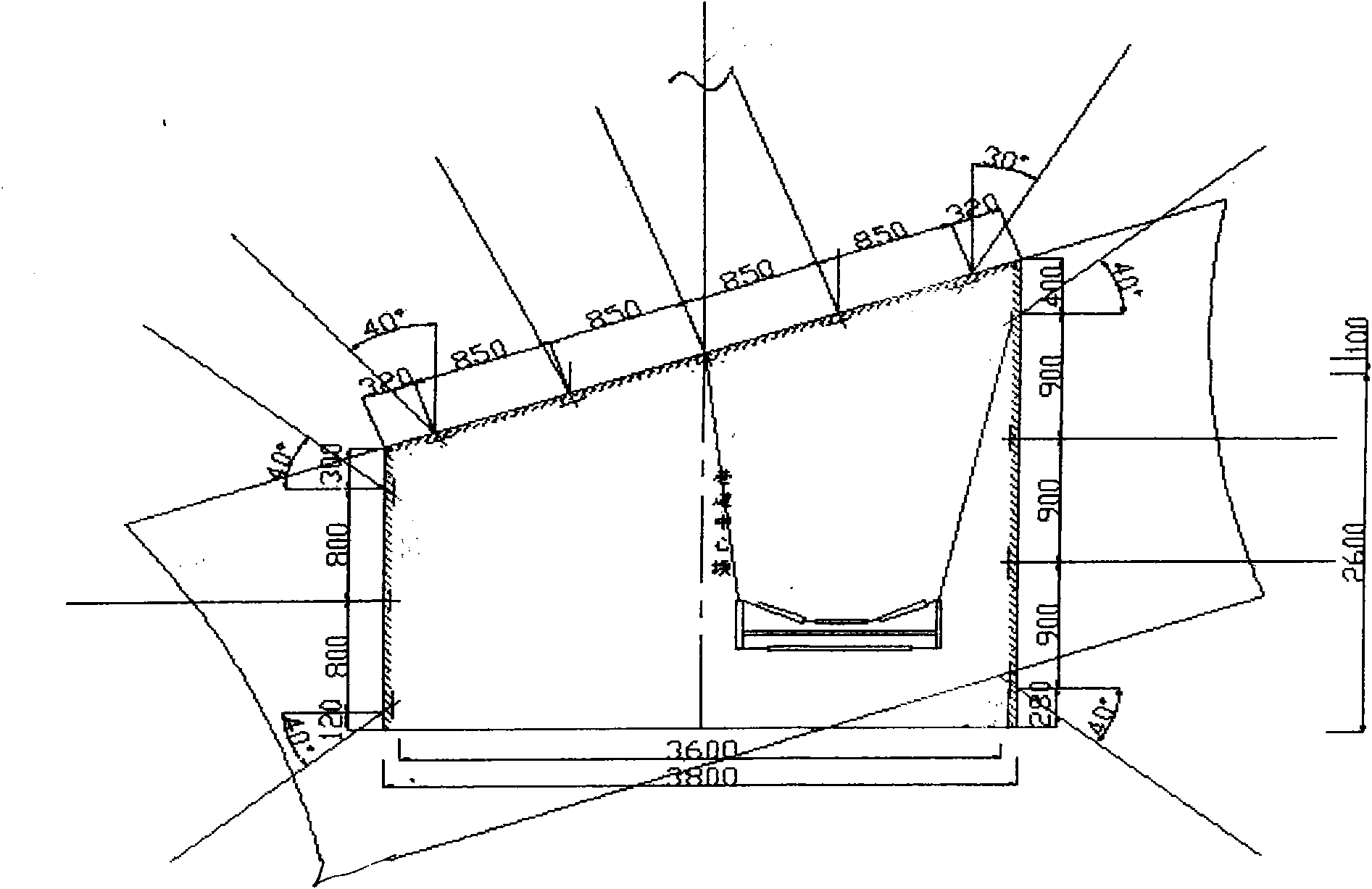

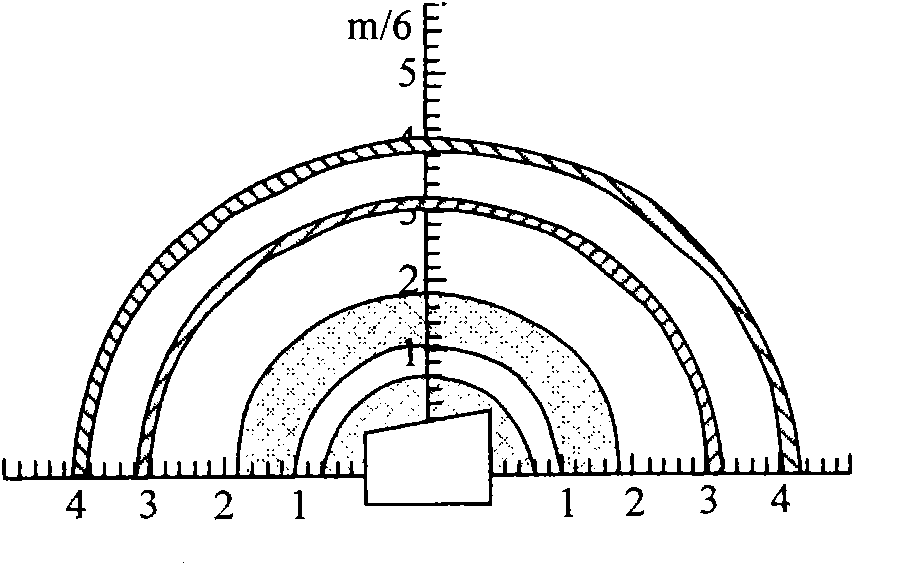

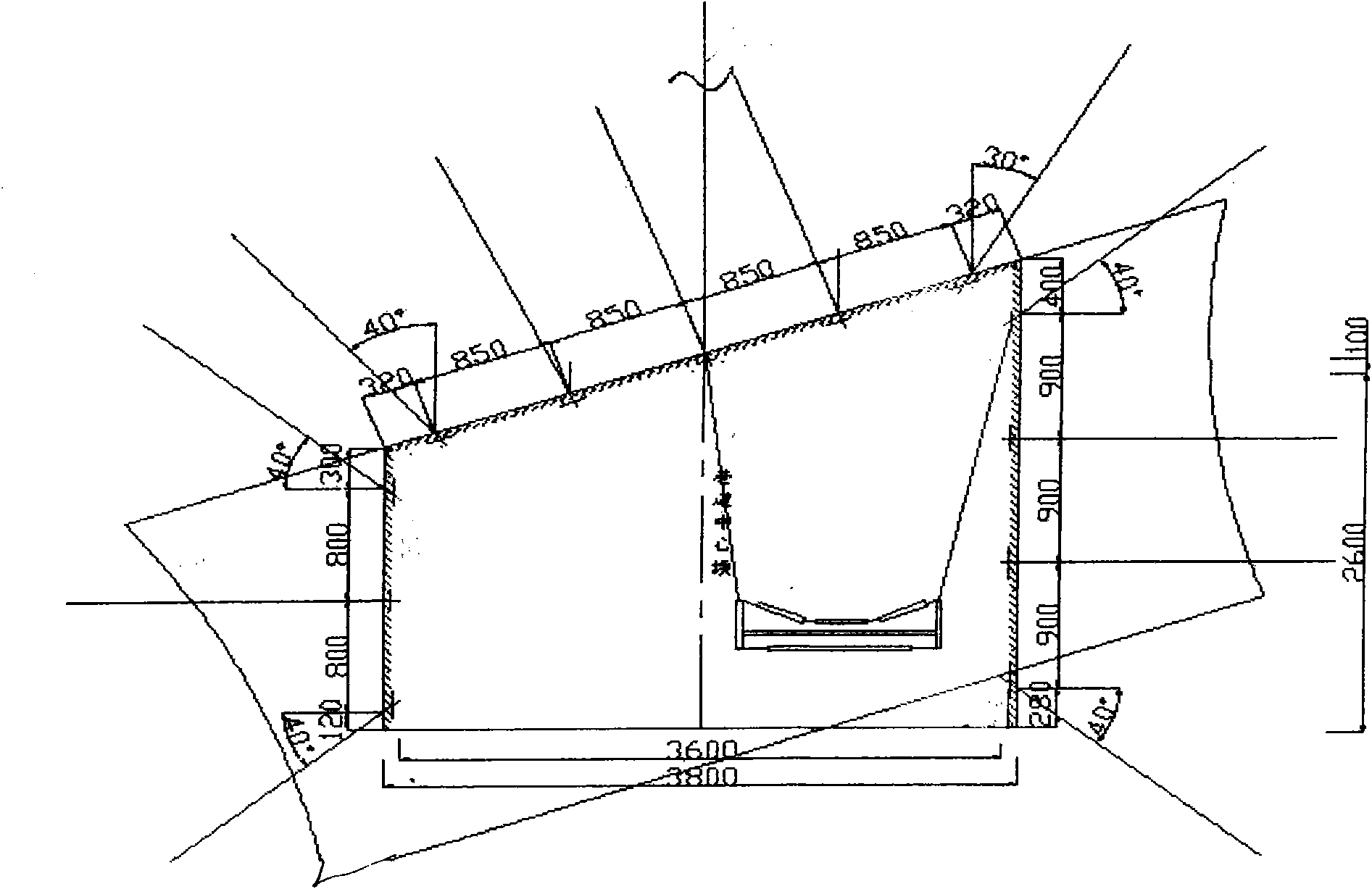

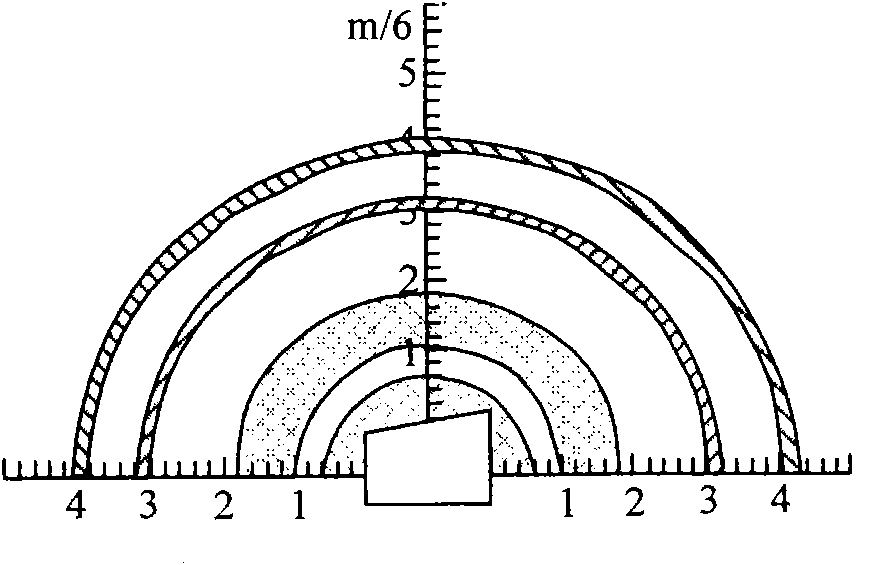

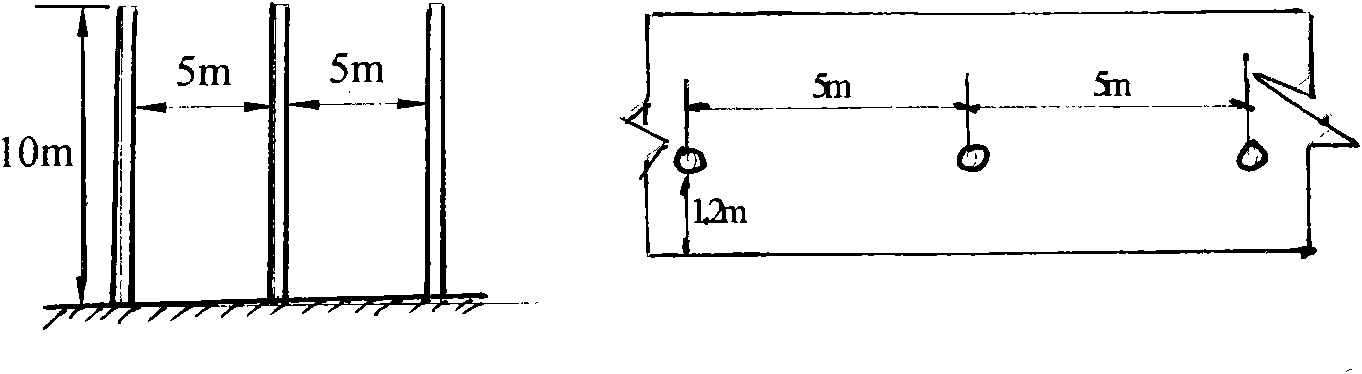

Pressure relief and consolidation synergizing prevention and control method for rock burst in deep coal drift

InactiveCN102220866AAvoid blindnessPrevent ground pressureOptical detectionBlastingRock burstDeep mining

The invention discloses a pressure relief and consolidation synergizing prevention and control method for rock burst in a deep coal drift. According to the method, based on deep hole photographic detection and analytic processing technology, discontinuous rupture distribution of the surrounding rocks in the deep coal drift and the evolution law of abutment pressure with mining are firstly detected, the deep hole blasting depth is determined according to the detection results and the pressure generated by deep blasting is relieved, and the range and consolidation method of barrier layers of the shallow surrounding rocks around the roadway surrounding rocks are finally determined; therefore, optimal synergy of pressure relief and consolidation is realized and and the aim of prevention and control of the rock burst in the deep mining coal drift is achieved.

Owner:SHANDONG UNIV OF SCI & TECH

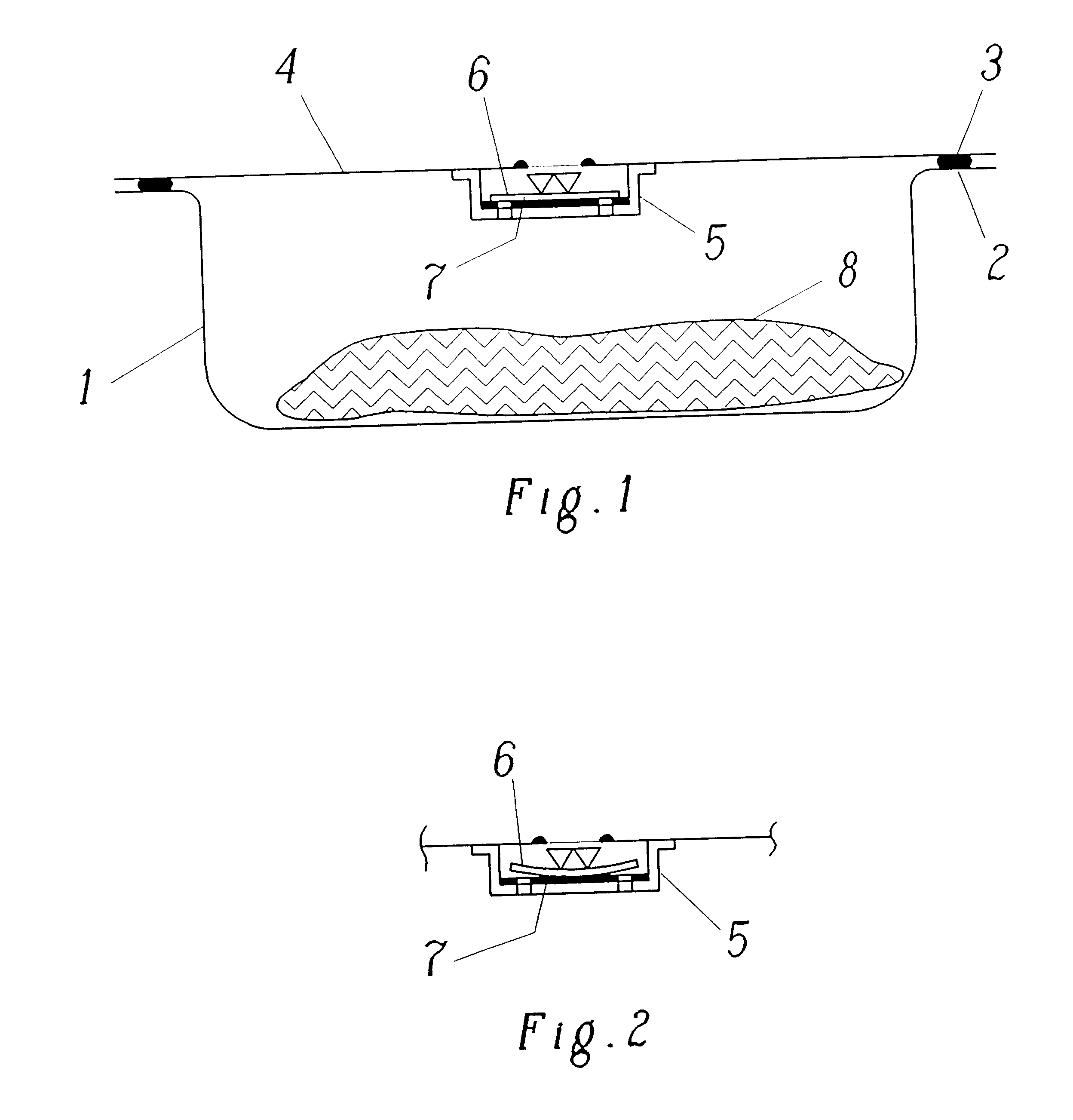

Microwavable food package having valve and method of use

InactiveUS6380524B1Reduce pressureAvoid decompressionReady-for-oven doughsClosuresMicrowave ovenProcess engineering

The microwavable shipping and / or retail package described here for heating food includes a material suitable for use in a microwave oven. The food disposed in the package is preferably at least partially raw. Taking into account the water content of the food, enough liquid is present in the package for the food to be cooked in a steam atmosphere which develops in the package when heated in a microwave oven. The package has a one-way valve in a wall, which opens automatically to the outside when there is an internal excess pressure, then closes again automatically after the pressure drops, thus limiting and / or reducing the vapor pressure that develops in the package during heating in a microwave oven. The valve membrane may automatically open and automatically close until the membrane deforms during heating, thereby causing said valve to remain open.

Owner:CREATIVE NEW FOOD DREAM STEAM

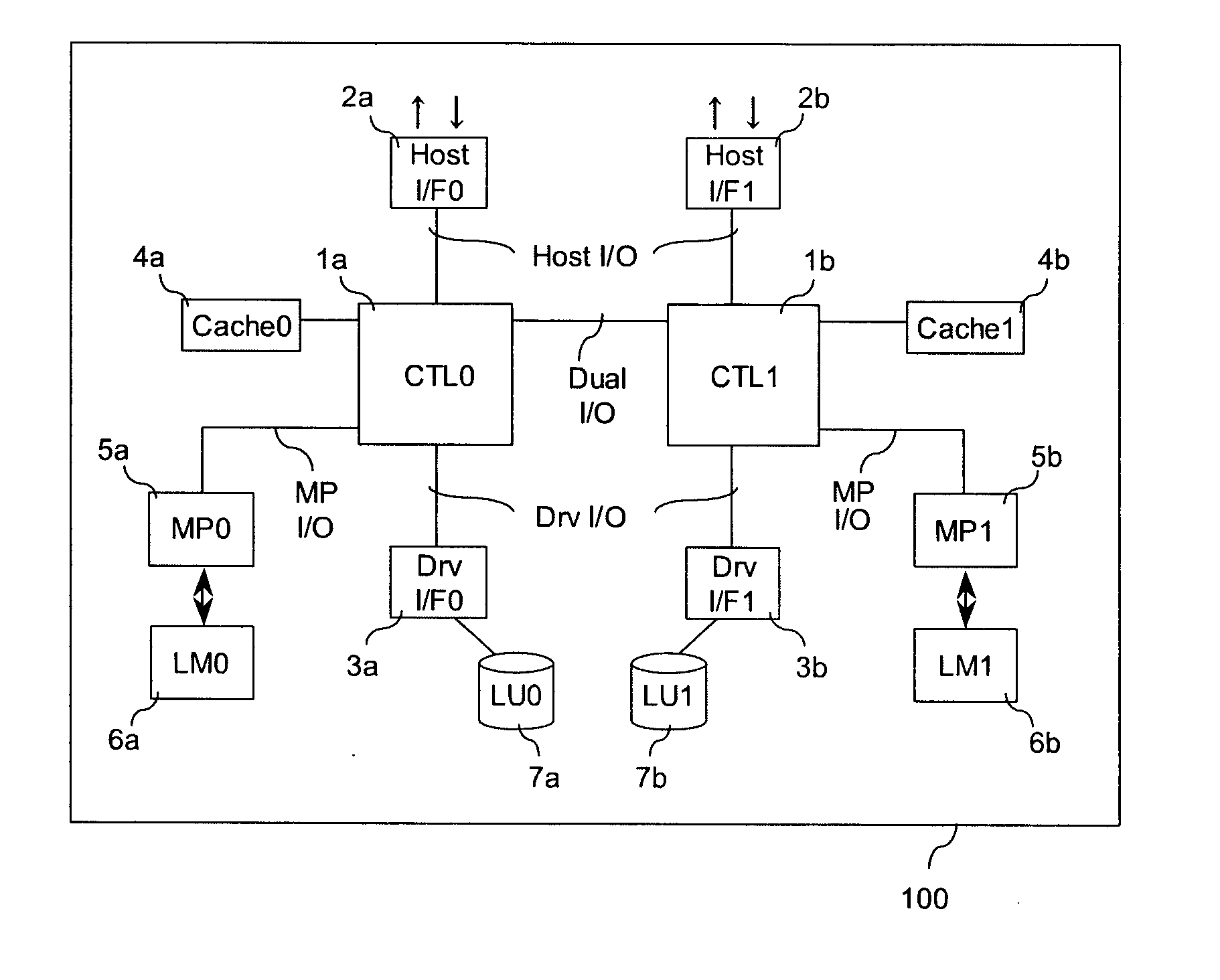

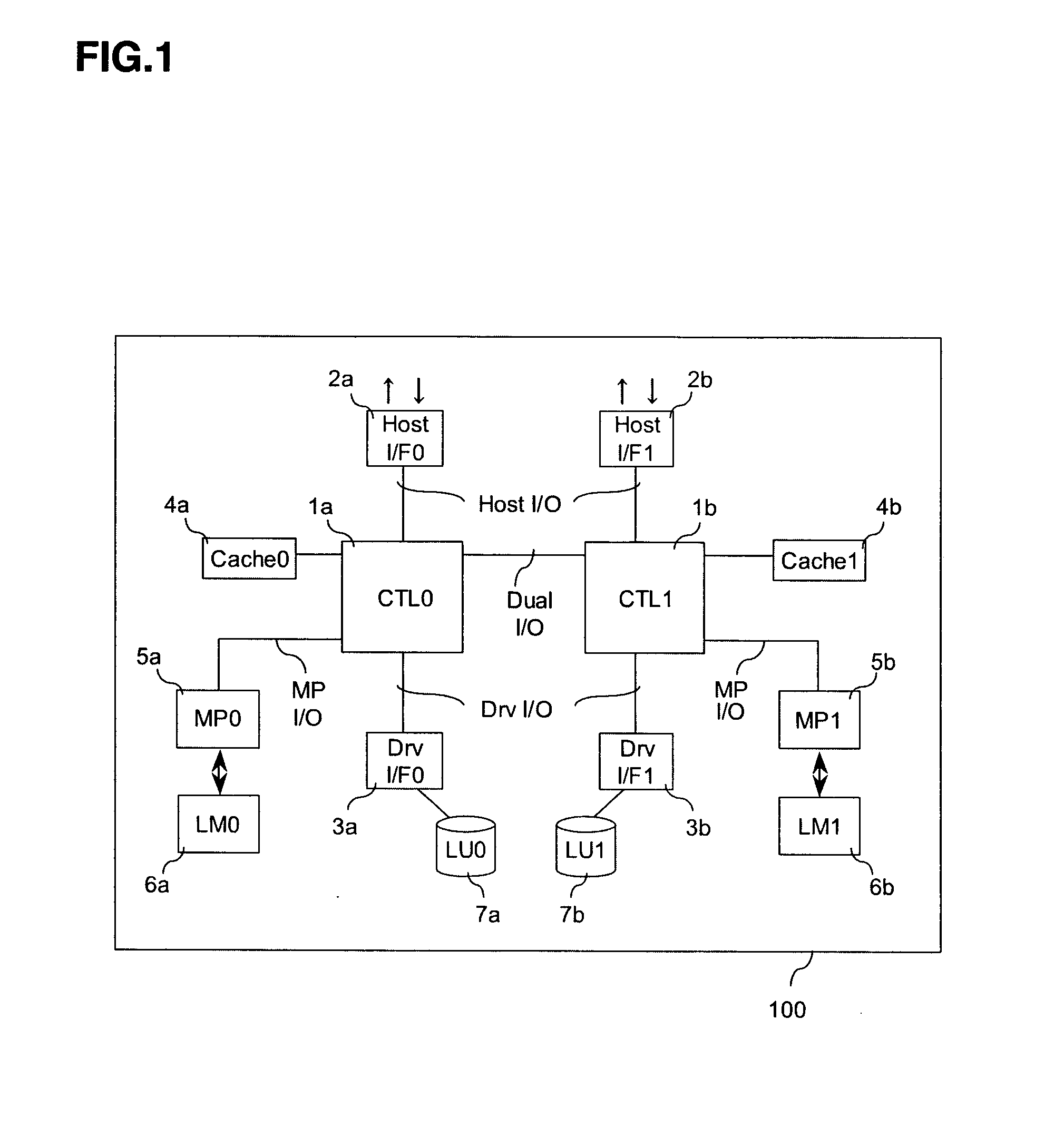

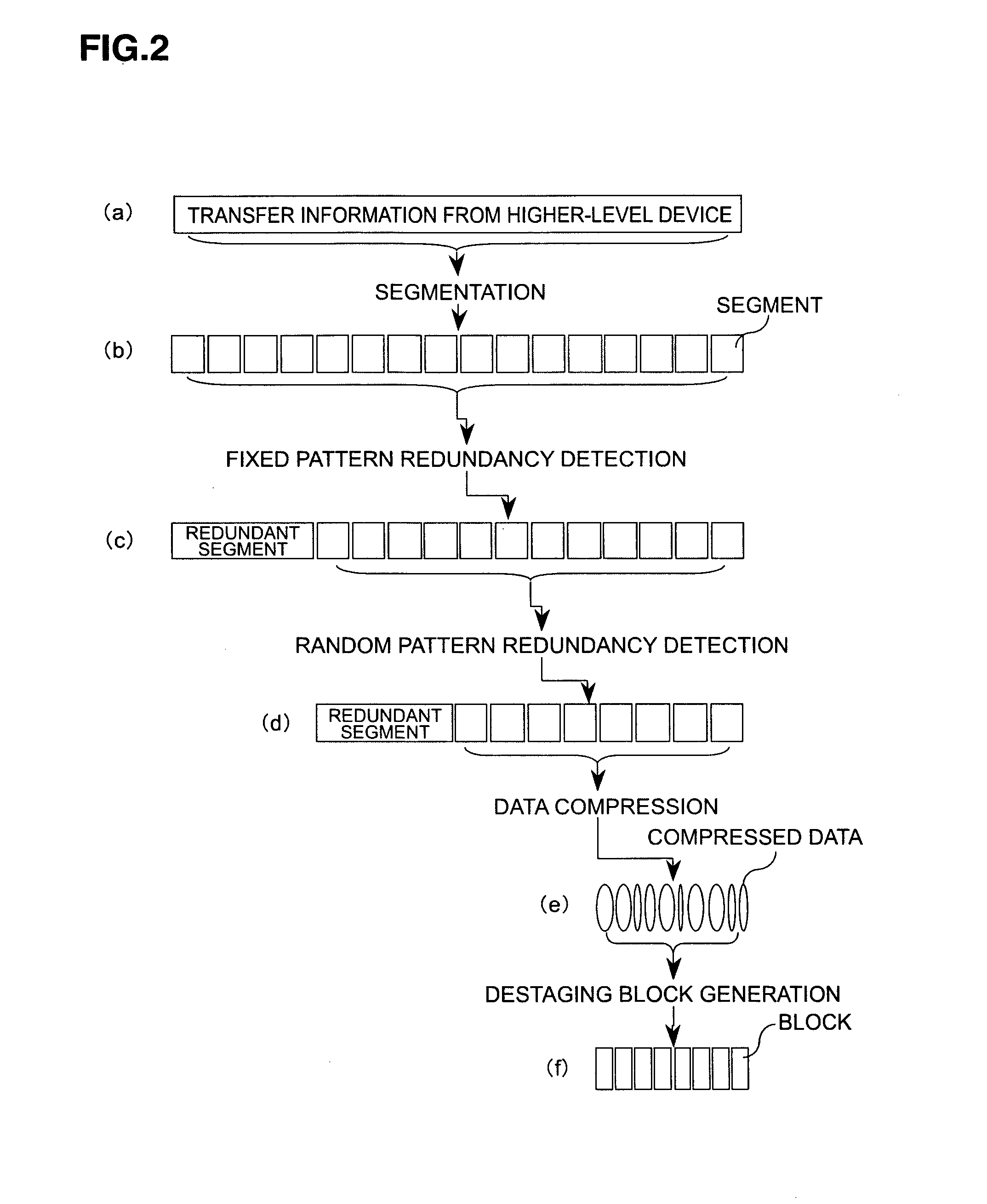

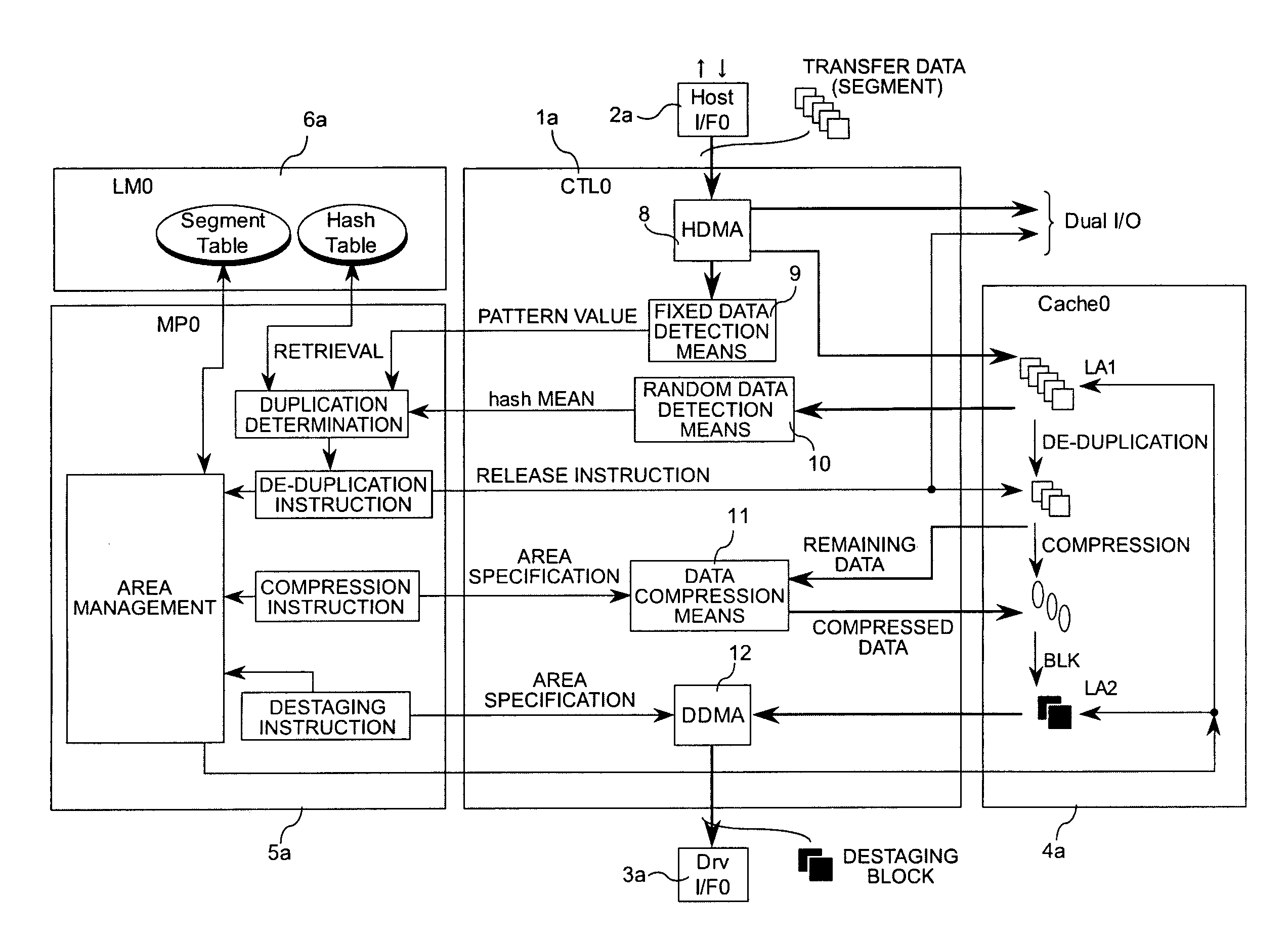

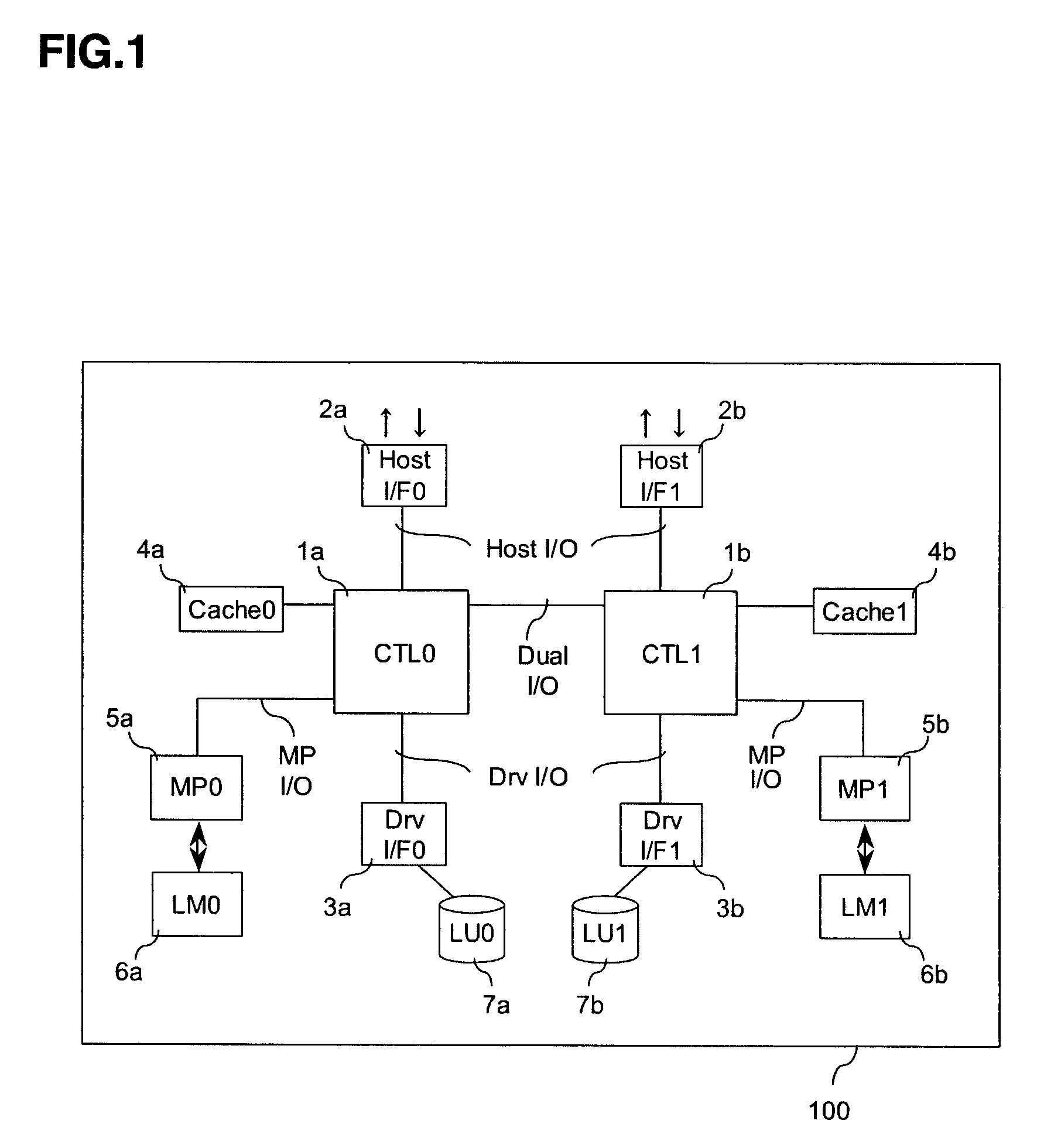

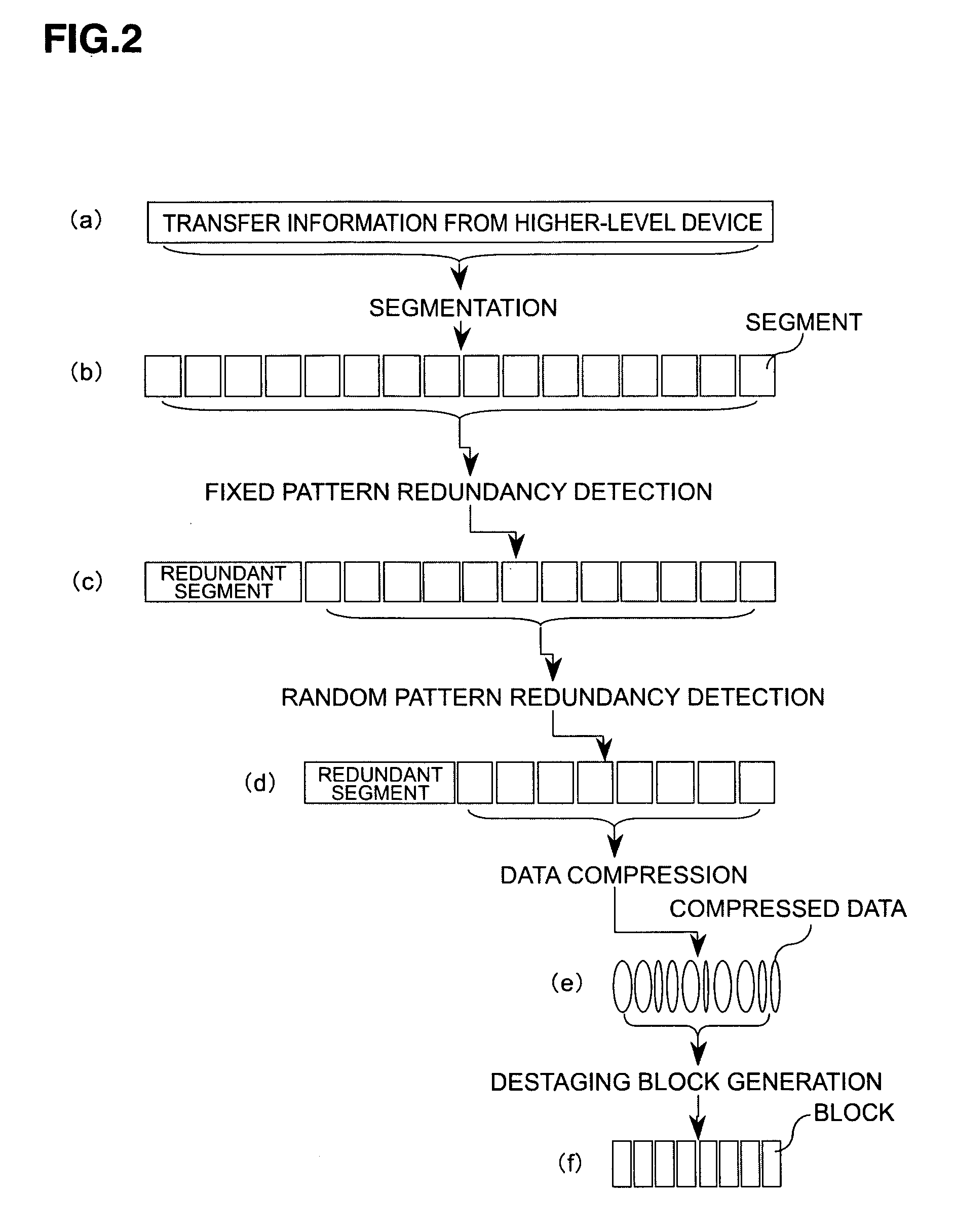

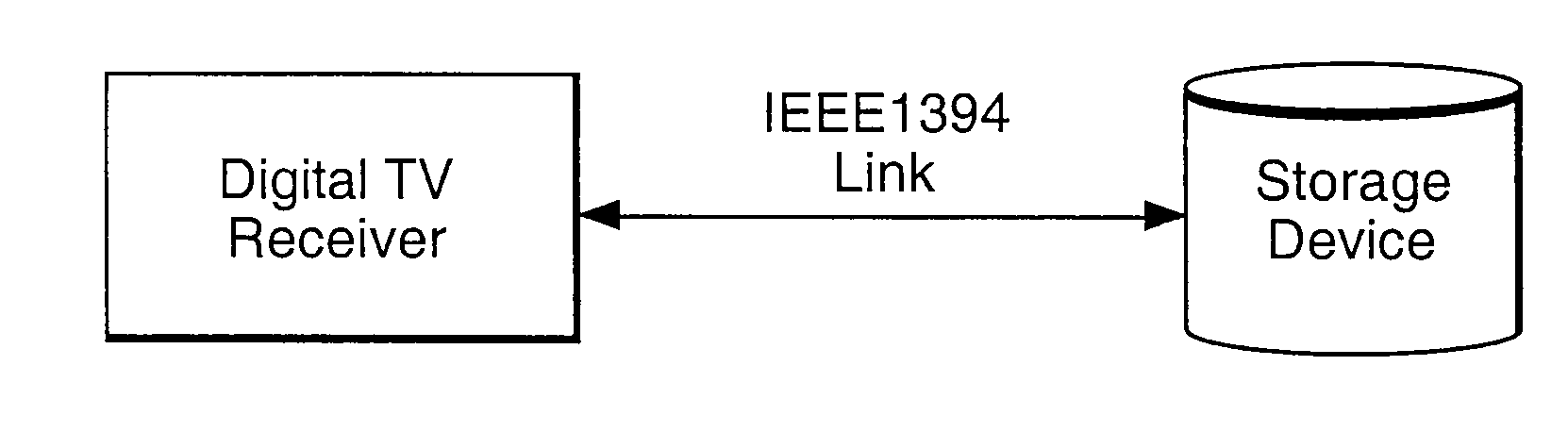

Storage apparatus and data processing method for the same

ActiveUS20110238914A1Improve efficiencyUtilize storage capacity of storageError detection/correctionMemory adressing/allocation/relocationData compressionParallel computing

The present invention aims for efficient use of storage capacity in a storage system by reducing the amount of time taken for processing including removing redundancy and data compression executed with respect to transferred data.Focusing on data patterns included in transferred data, the most suitable pattern is detected, and de-duplication processing is gradually executed. Data compression is then executed with data after de-duplication as a target. Determination of the decision for execution of gradual de-duplication processing, or execution of compression processing is made depending on the amount of data remaining at each processing stage and the system load.

Owner:HITACHI LTD

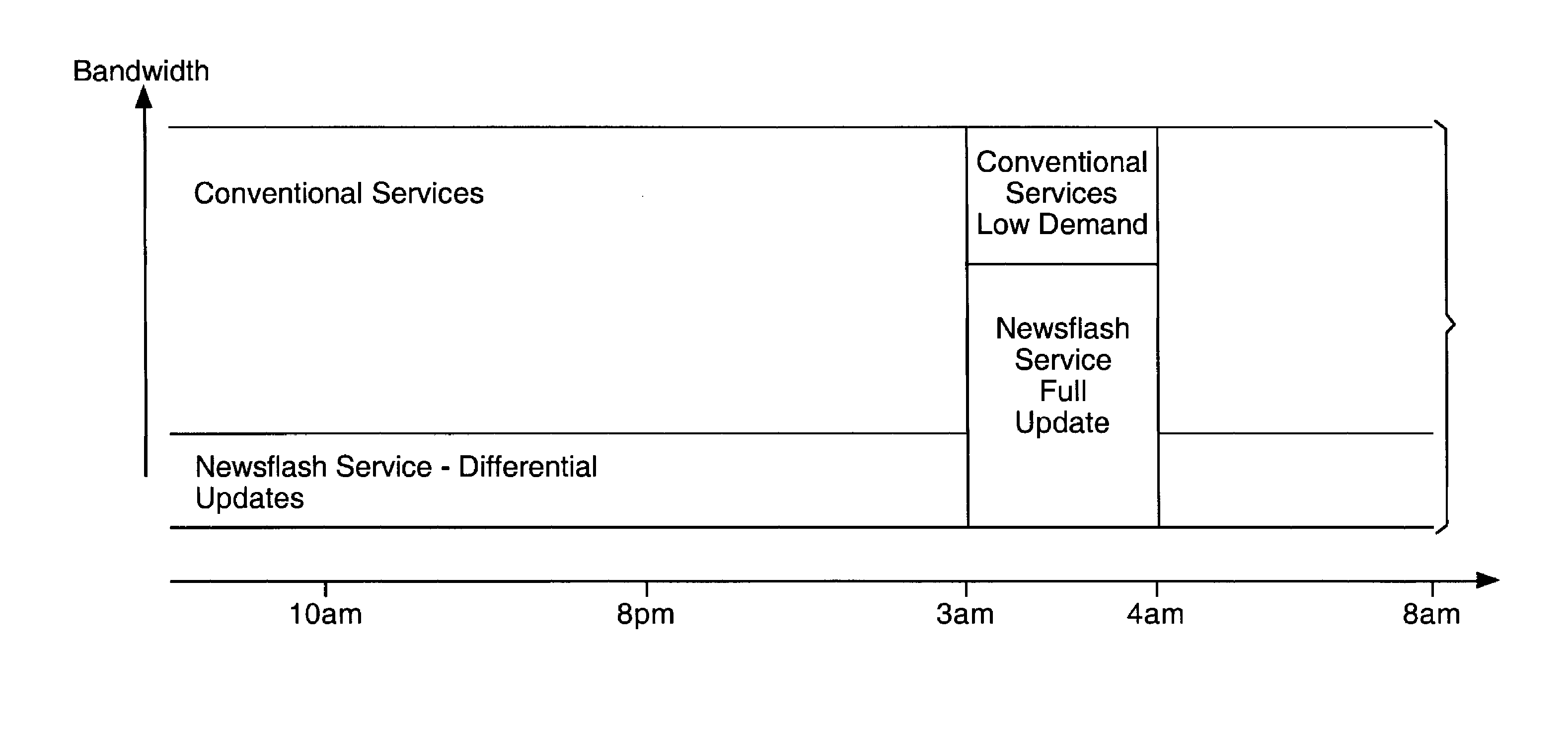

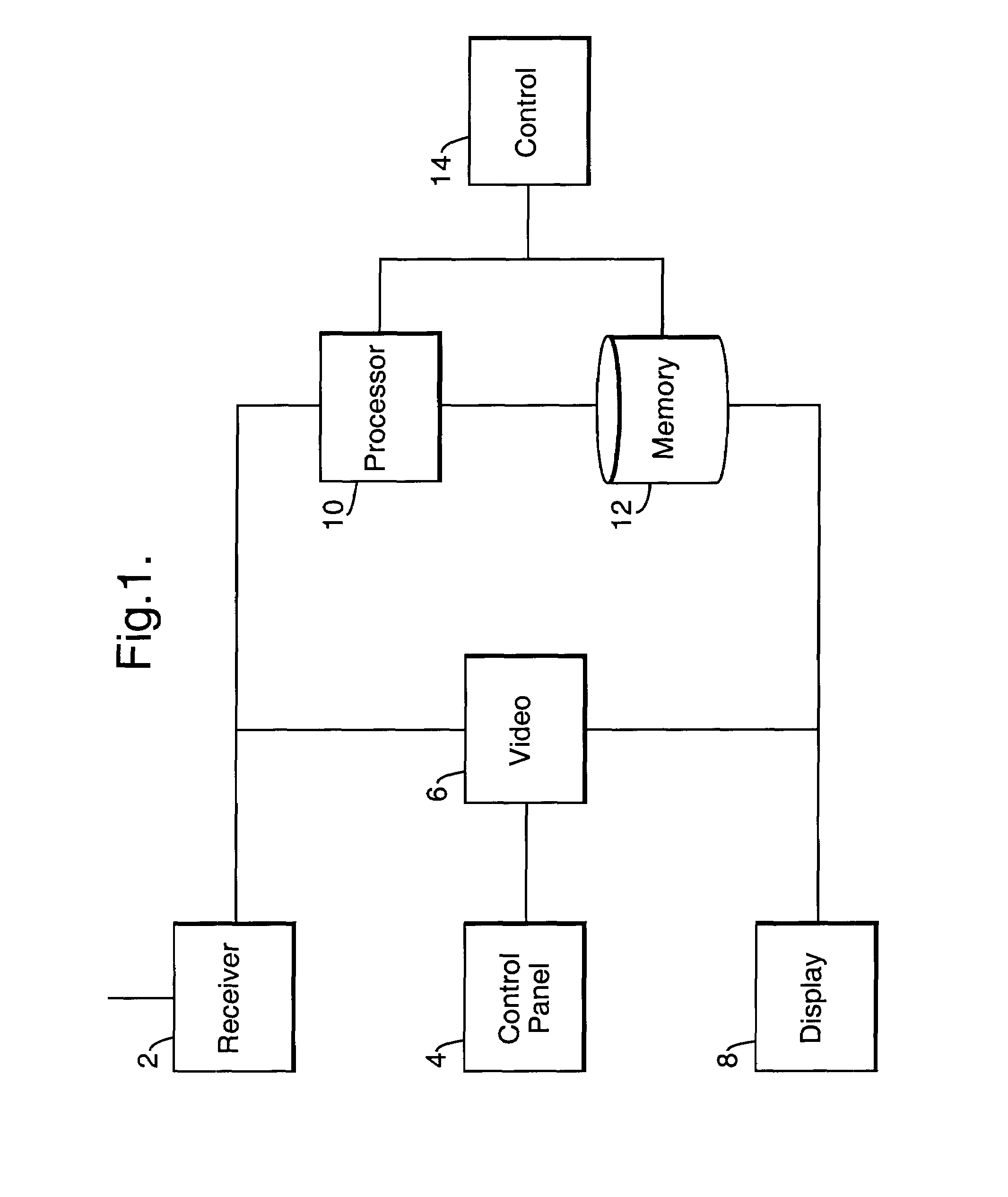

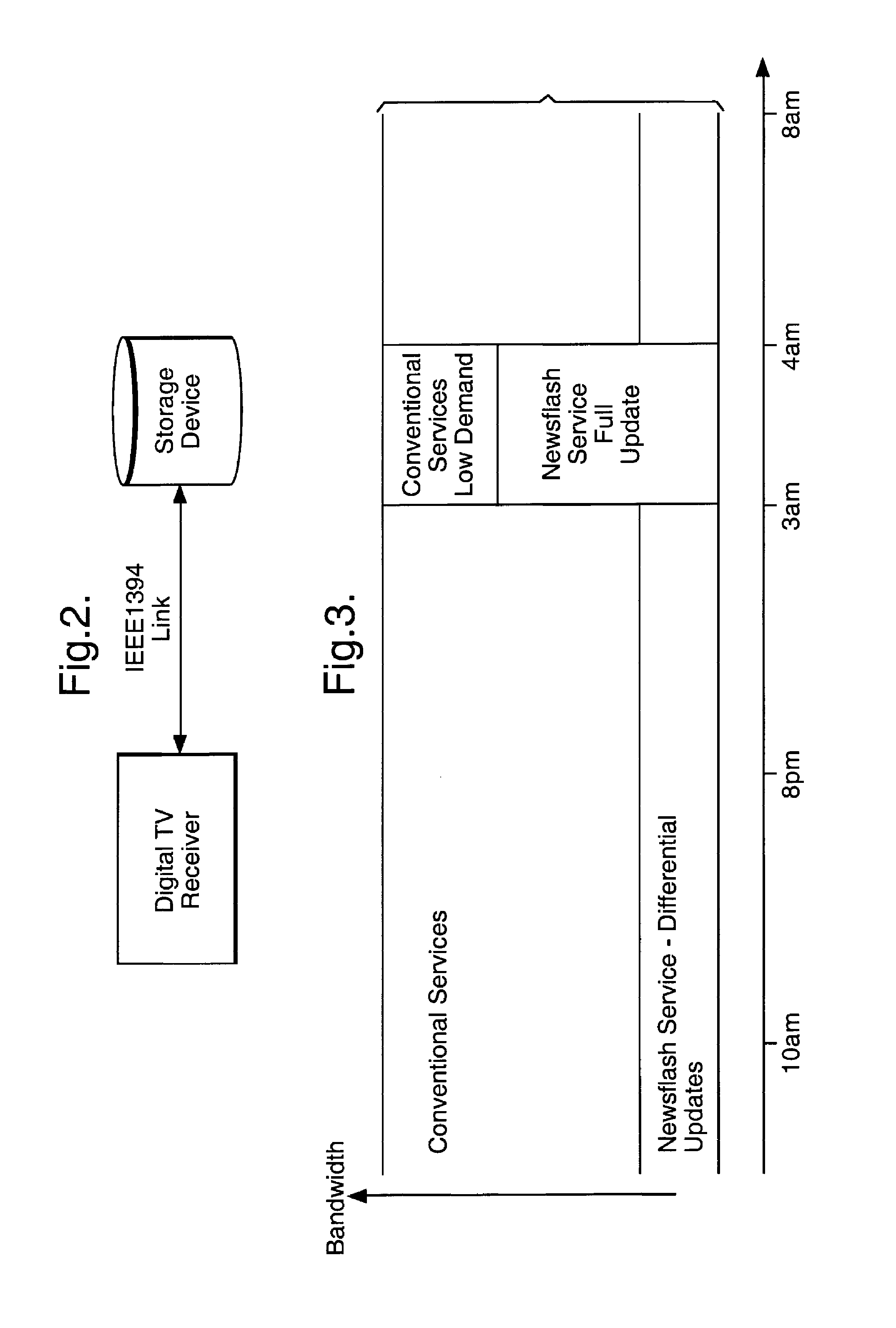

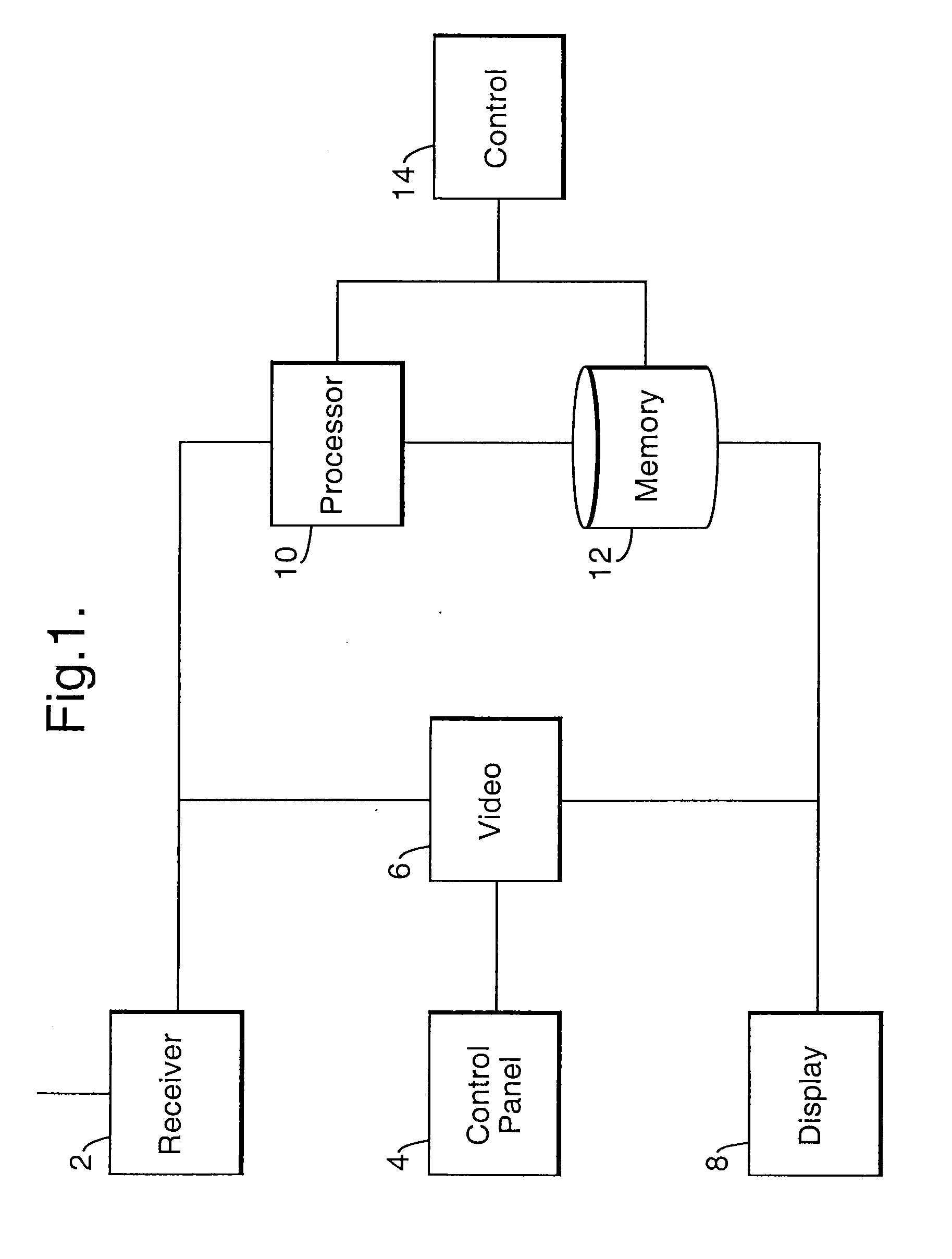

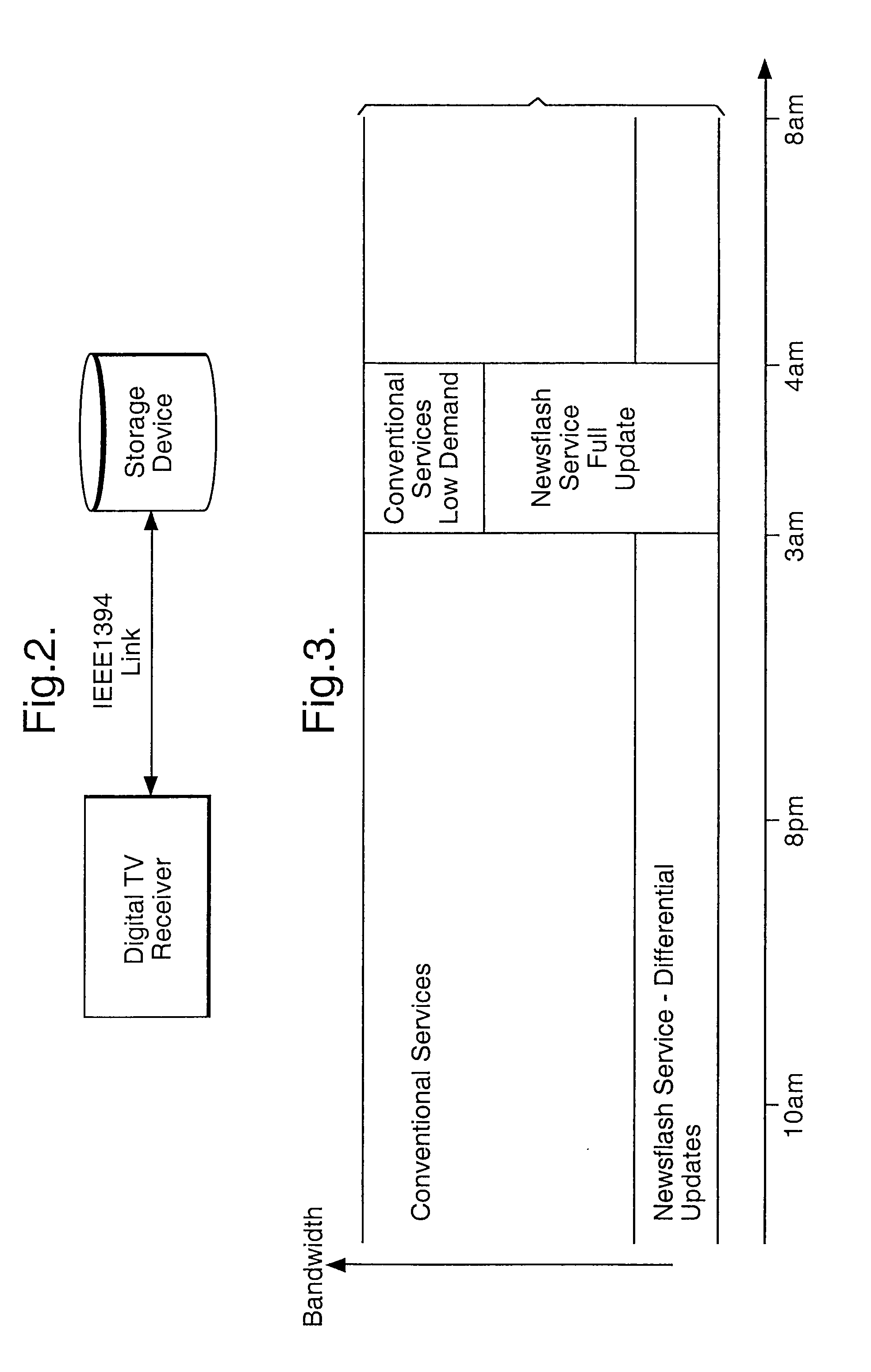

Data broadcast method

InactiveUS7685618B1Function provideSmall bandwidthTelevision system detailsPulse modulation television signal transmissionDigital dataCable television

A technique for broadcasting a broadcast data service together with broadcast digital television data as part of a broadcast signal, the broadcast data service comprising a plurality of data portions including data portions having digital data in non-real time. The technique comprising, during normal broadcasting, only broadcasting portions of the broadcast data service required to replace previous respective portions which have been changed and broadcasting television data of the broadcast data service as non-real time data.

Owner:SONY EUROPE BV

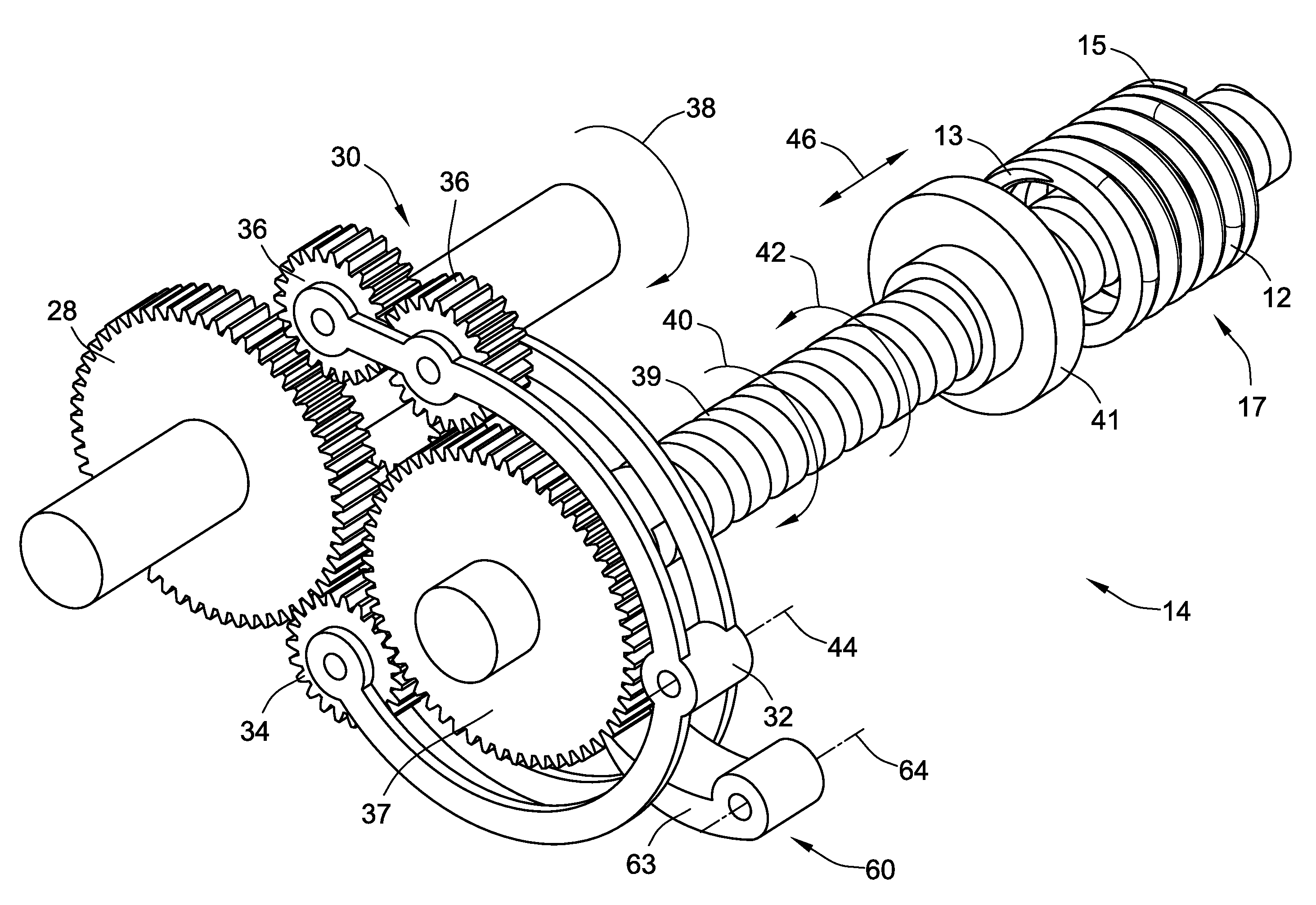

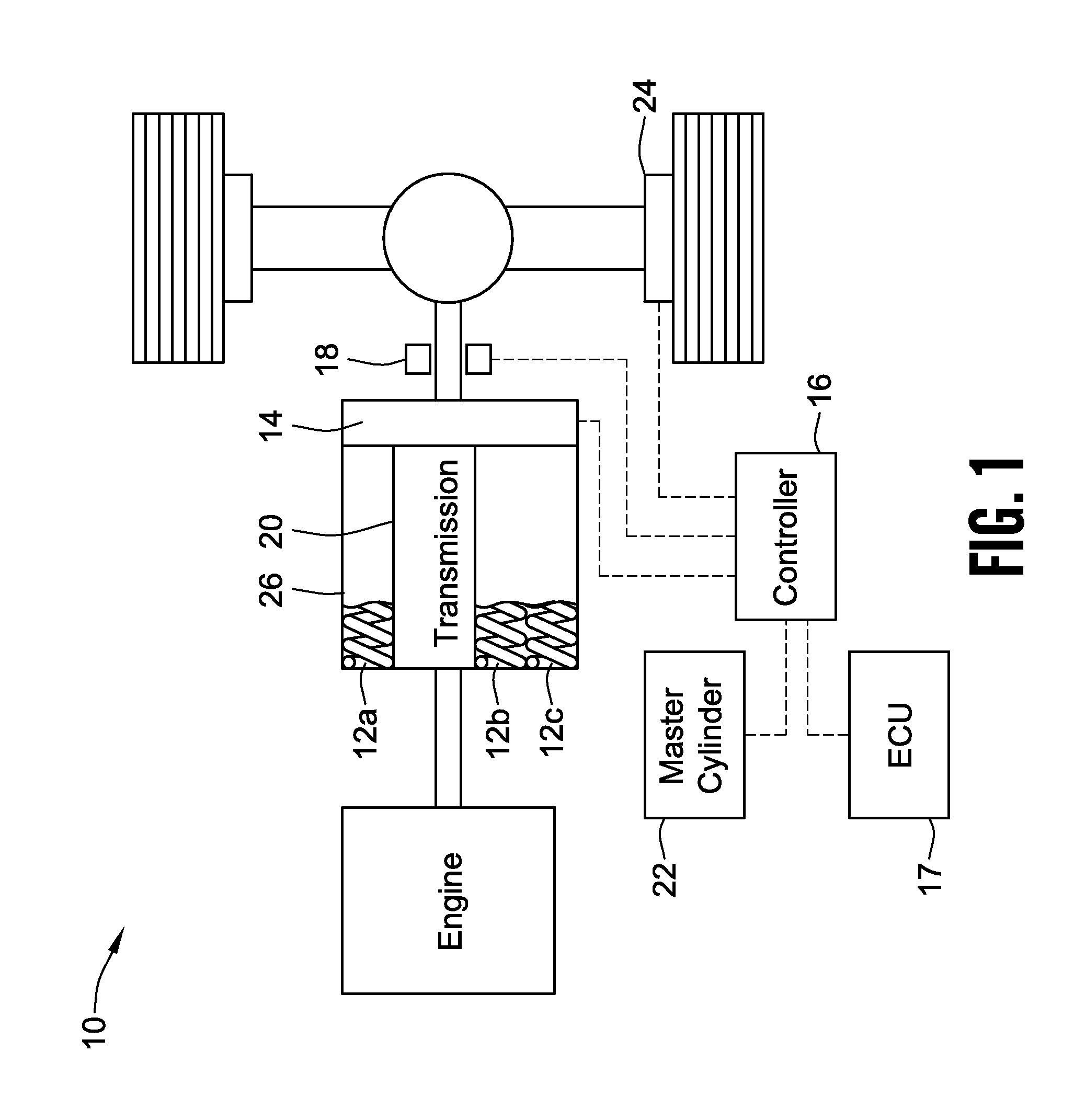

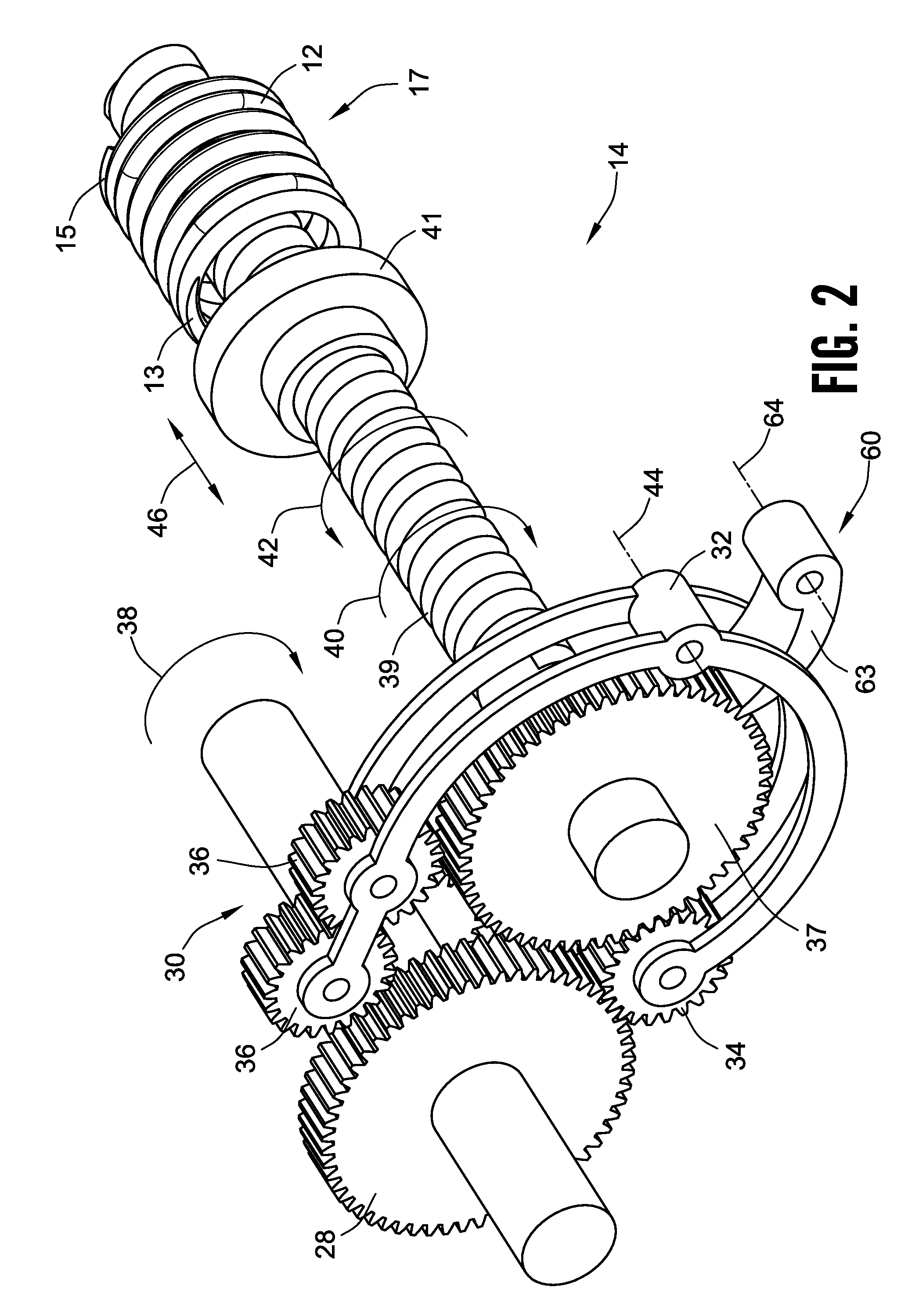

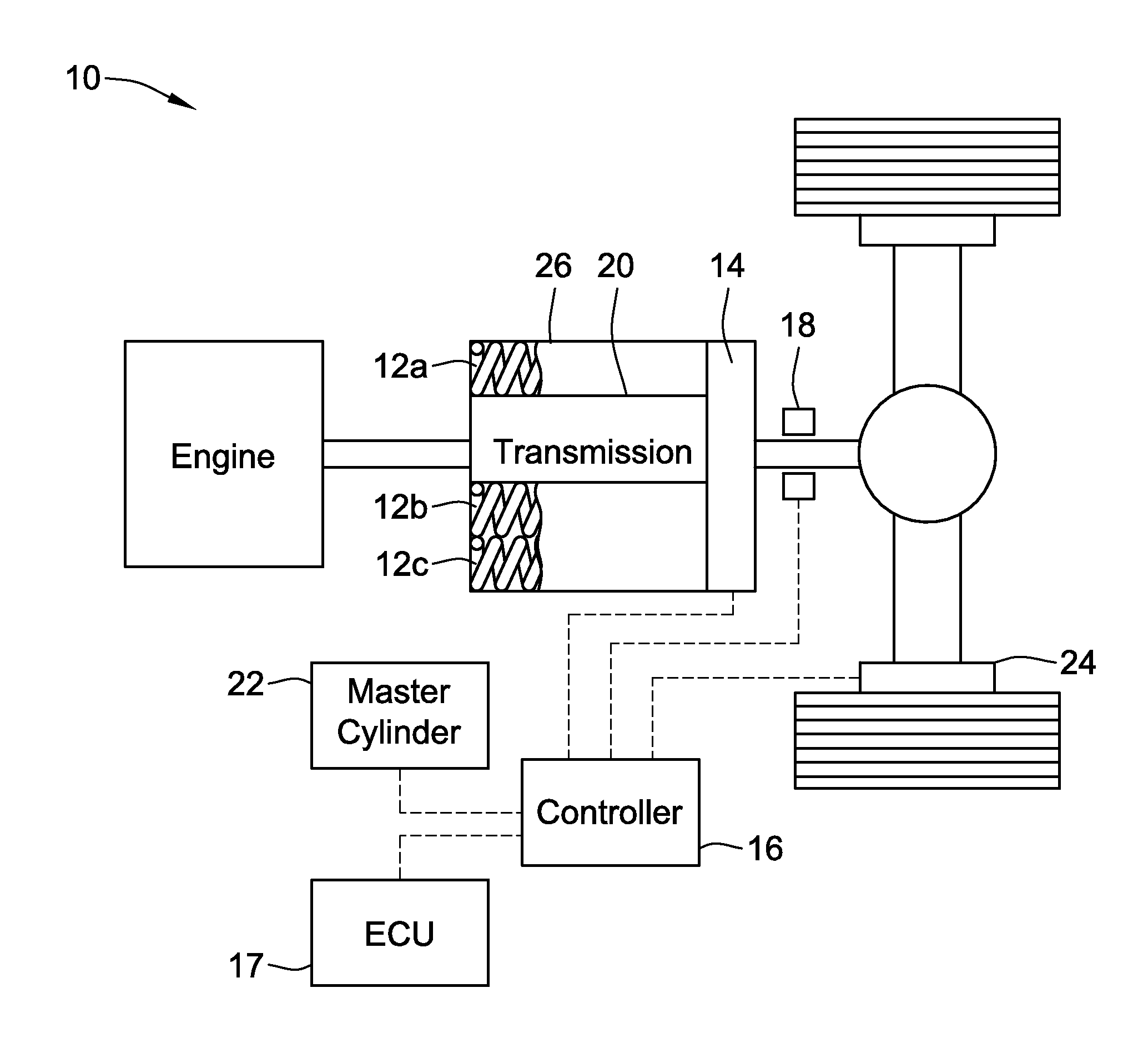

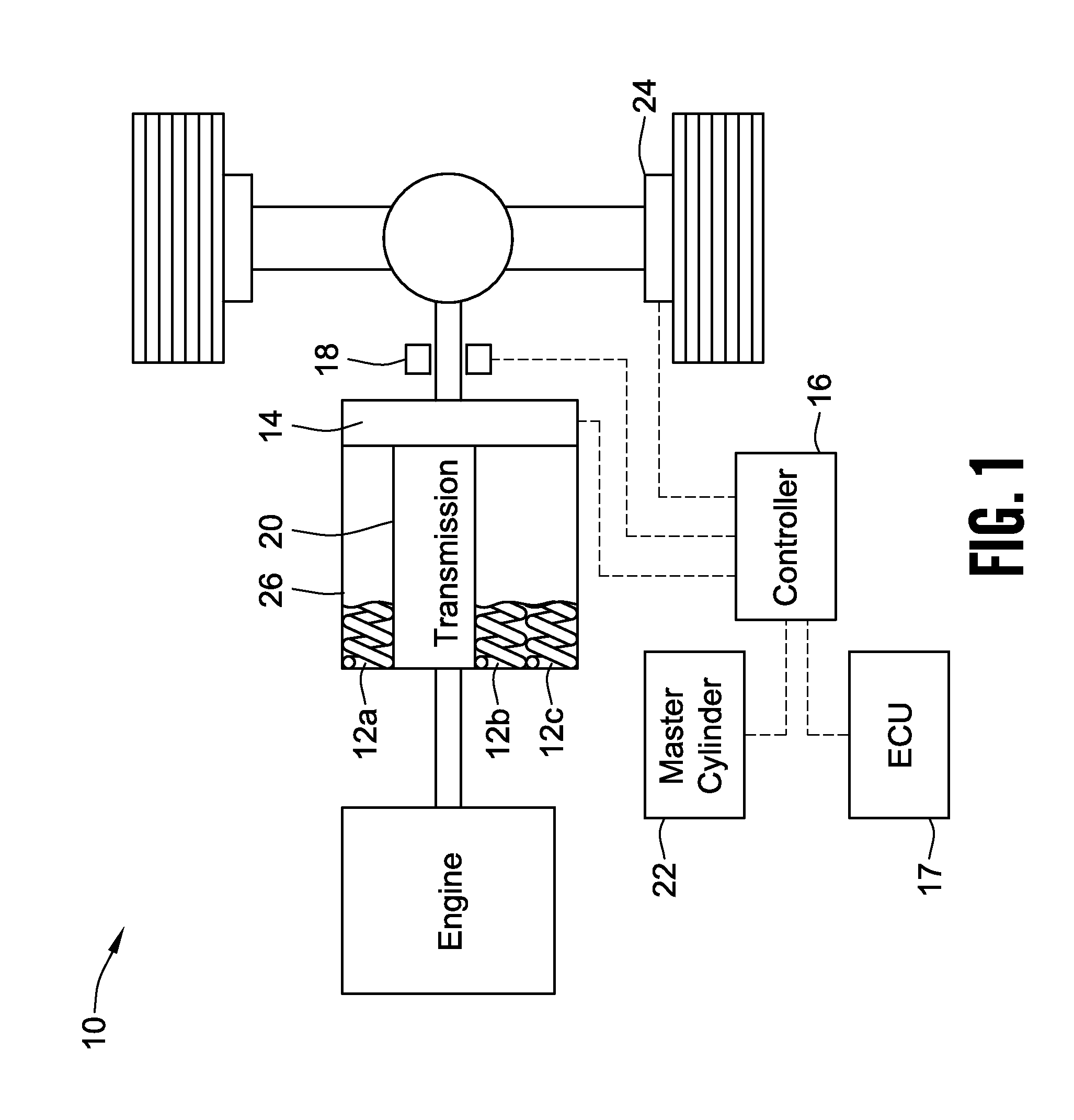

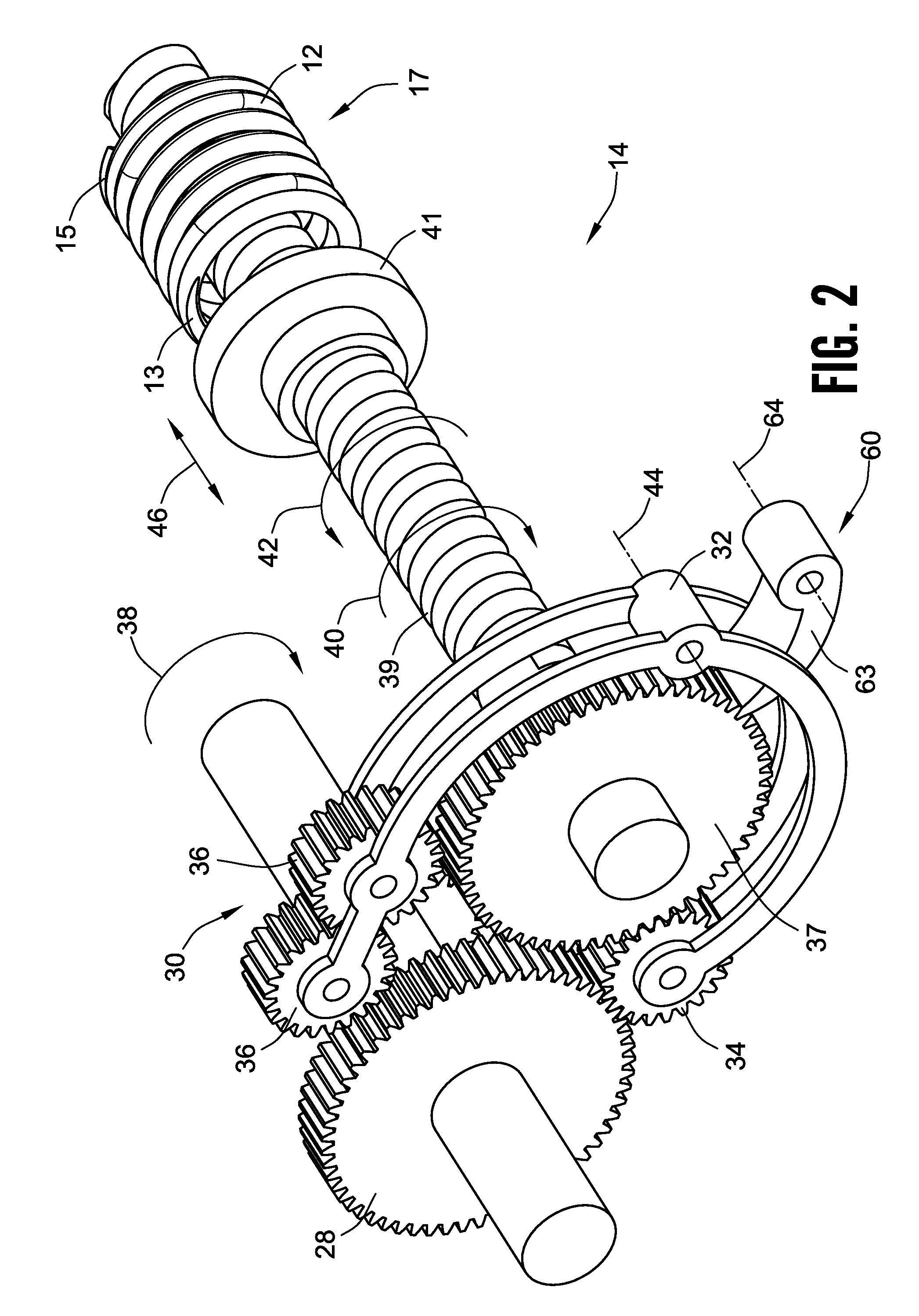

Regenerative Braking System

ActiveUS20110198143A1Avoid decompressionMaintaining stored energyAuxillary drivesBraking element arrangementsElectric generatorRegenerative brake

A regenerative braking system is provided. The regenerative braking system includes at least one energy storage medium operably connected to a coupler. The coupler is operable to selectively couple and decouple the energy storage medium with a drive train of motor vehicle, or an electric generator, or a combination of both. A control arrangement governs the operation of the coupler. A sensor of the control arrangement is operable to determine information relating to the relative deceleration and acceleration of the motor vehicle and send said information to the controller. The controller is operable to determine the amount of energy storage medium or mediums to be coupled to the drive train via the coupler.

Owner:GRAVINO MARC CHARLES

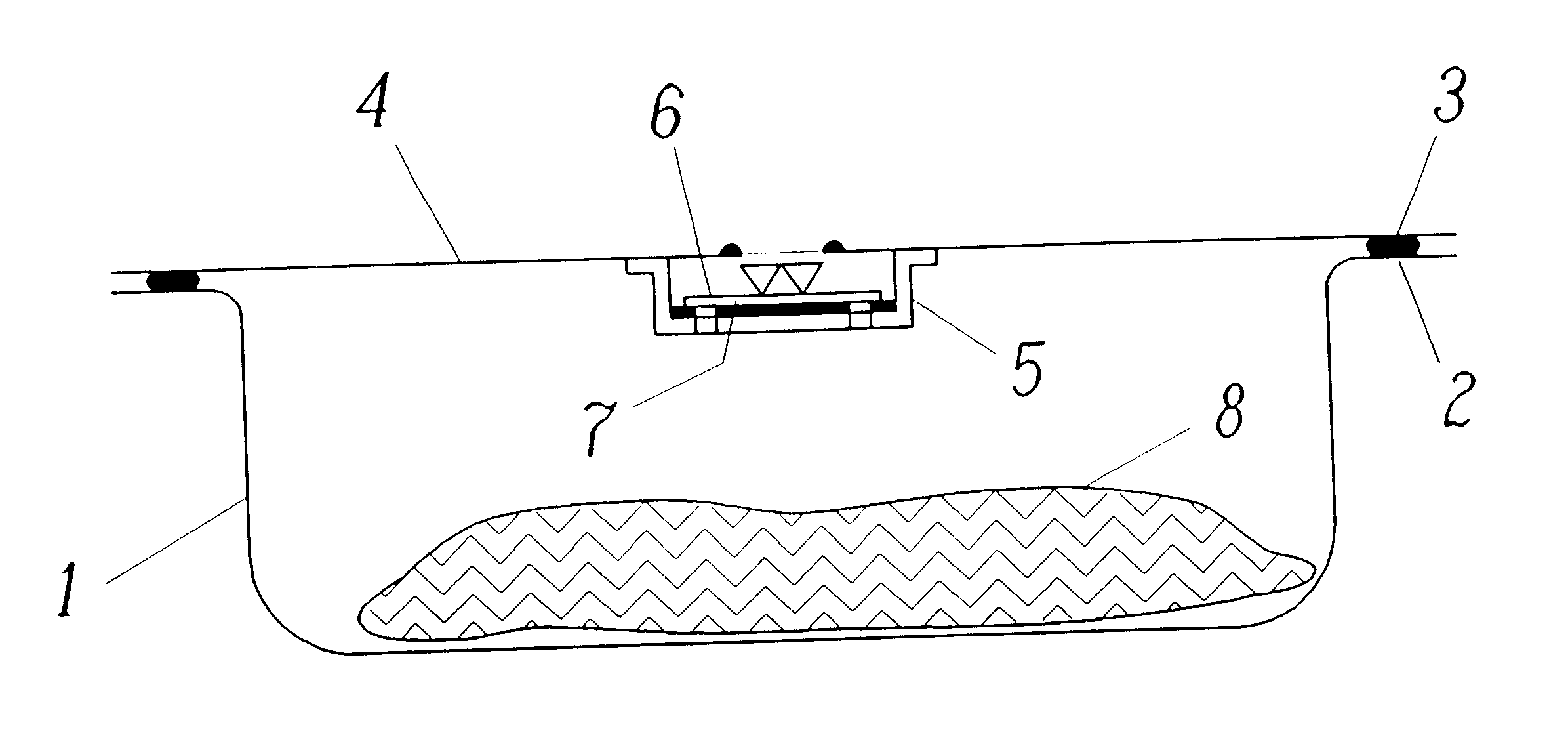

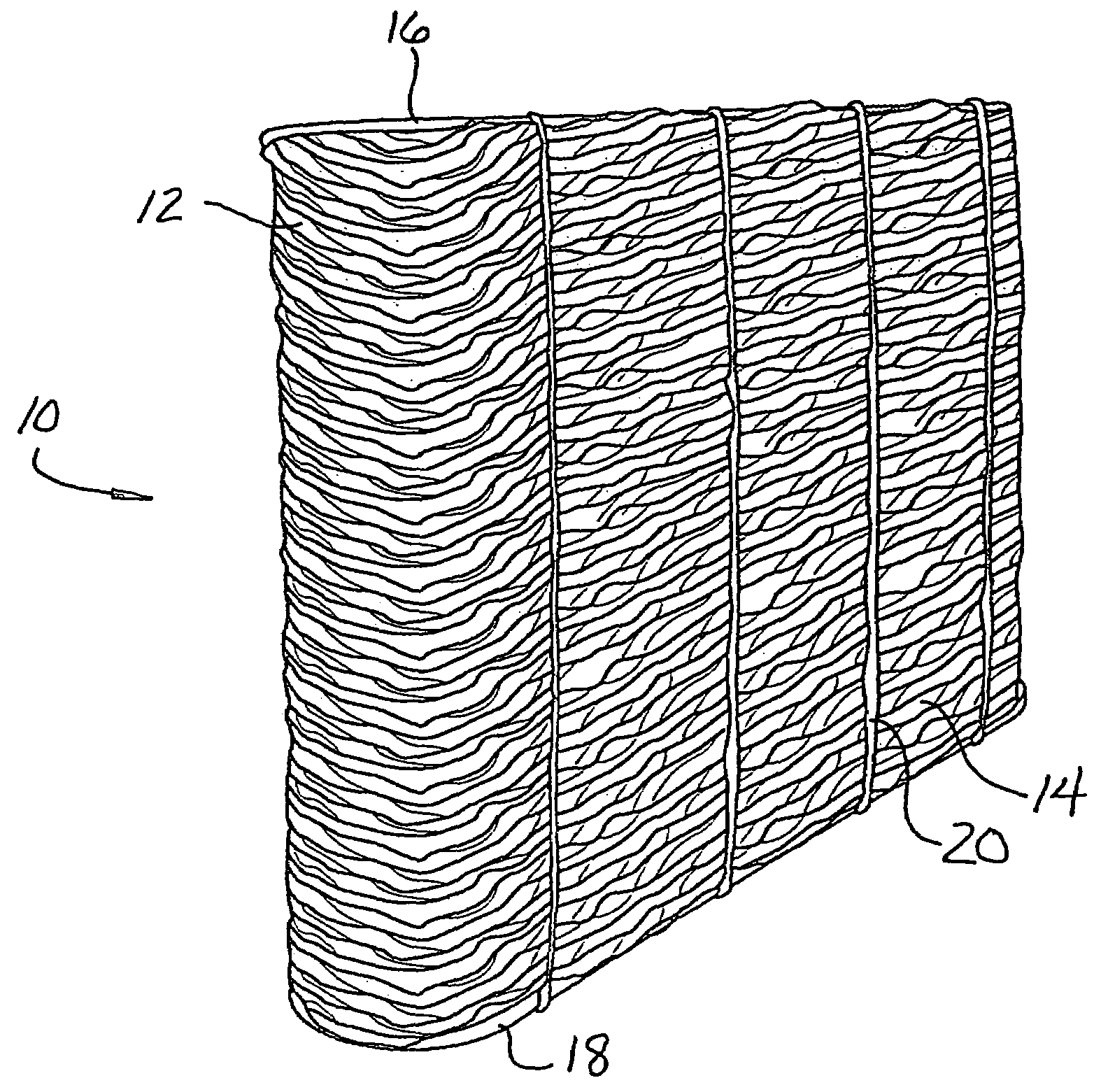

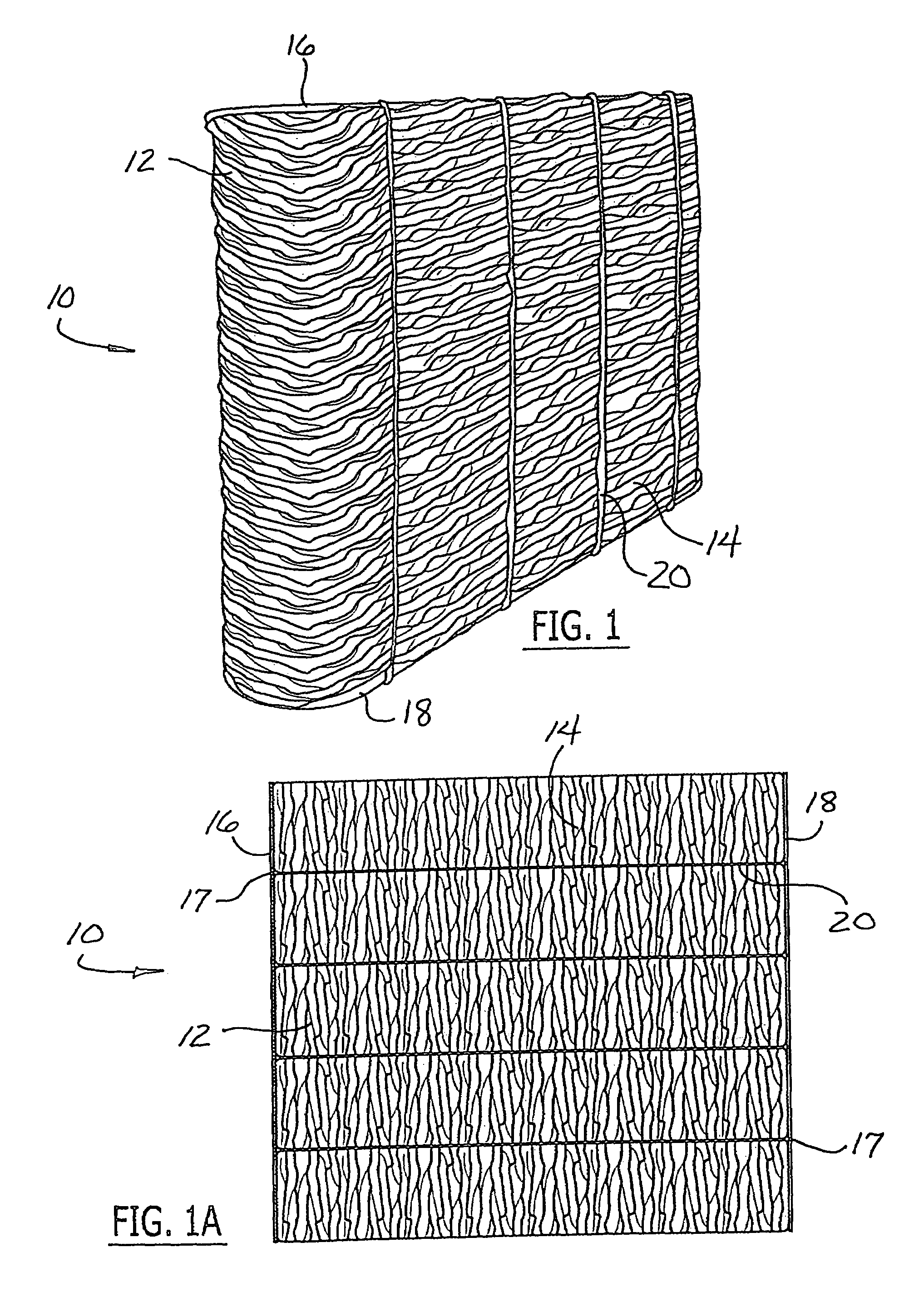

System and method for packaging cotton sliver

InactiveUS7410051B2Substantial rigidityAvoid decompressionContainers for flexible articlesFilament handlingHigh densityVolumetric Mass Density

Owner:PARKDALE MILLS

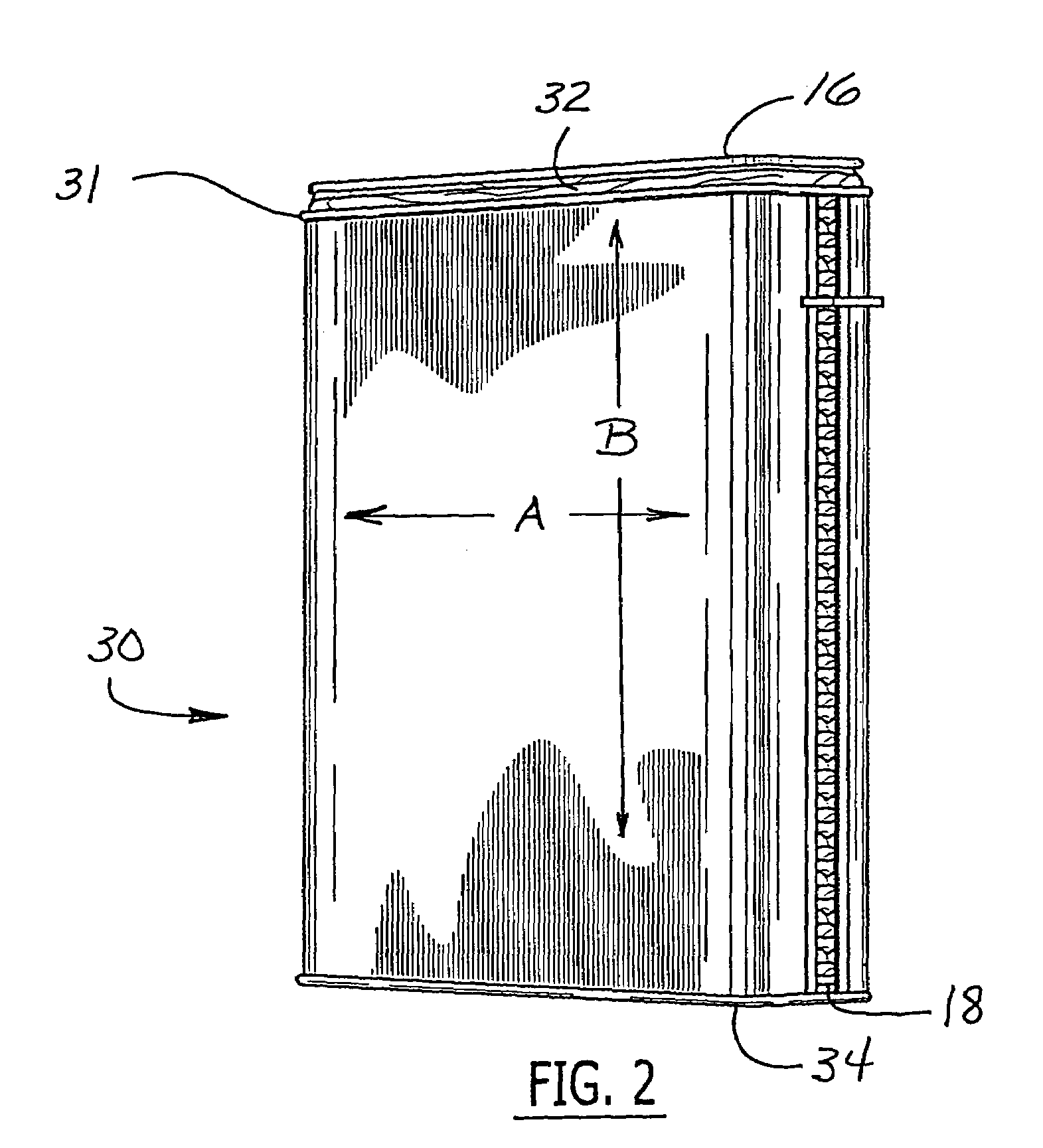

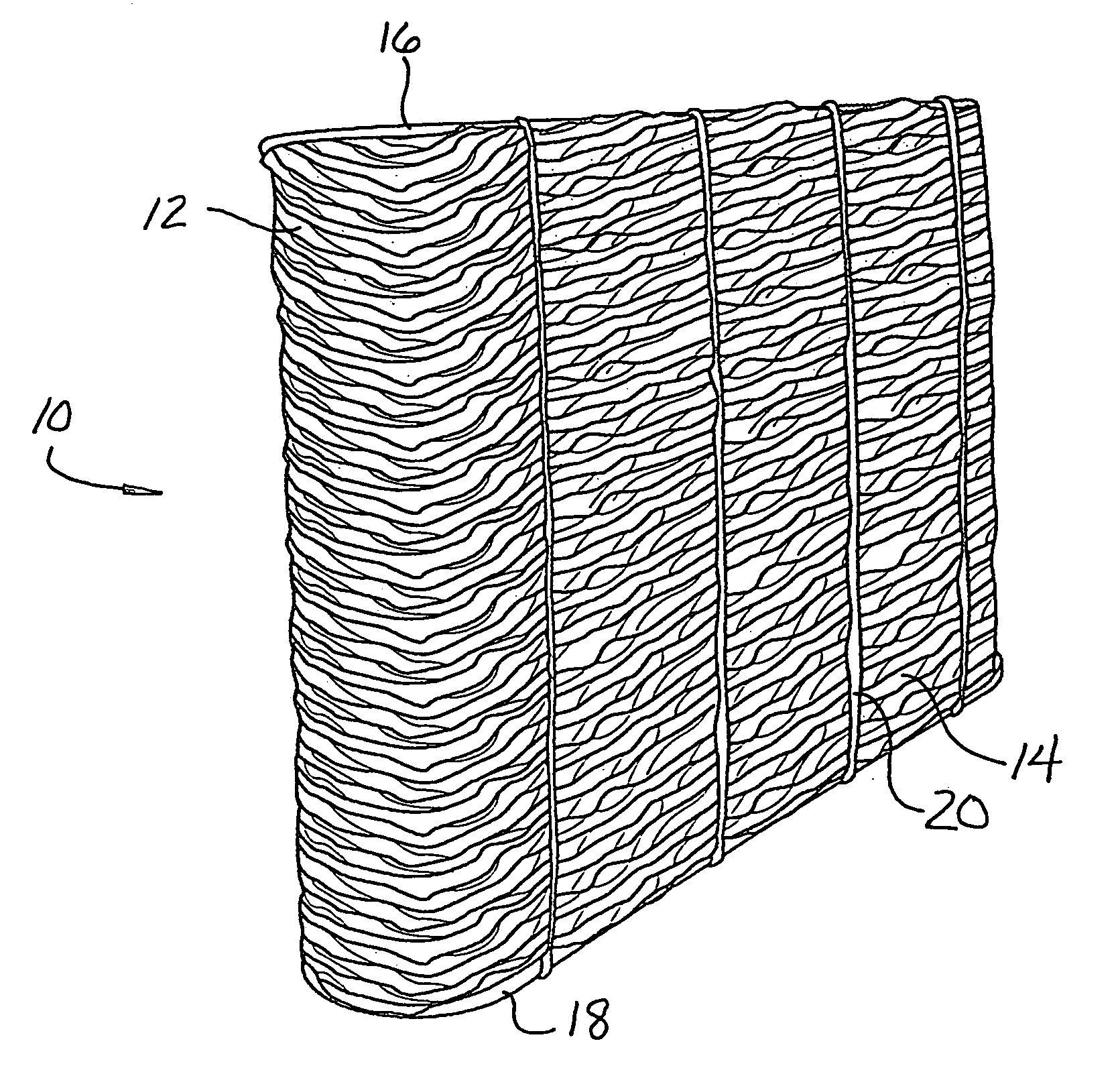

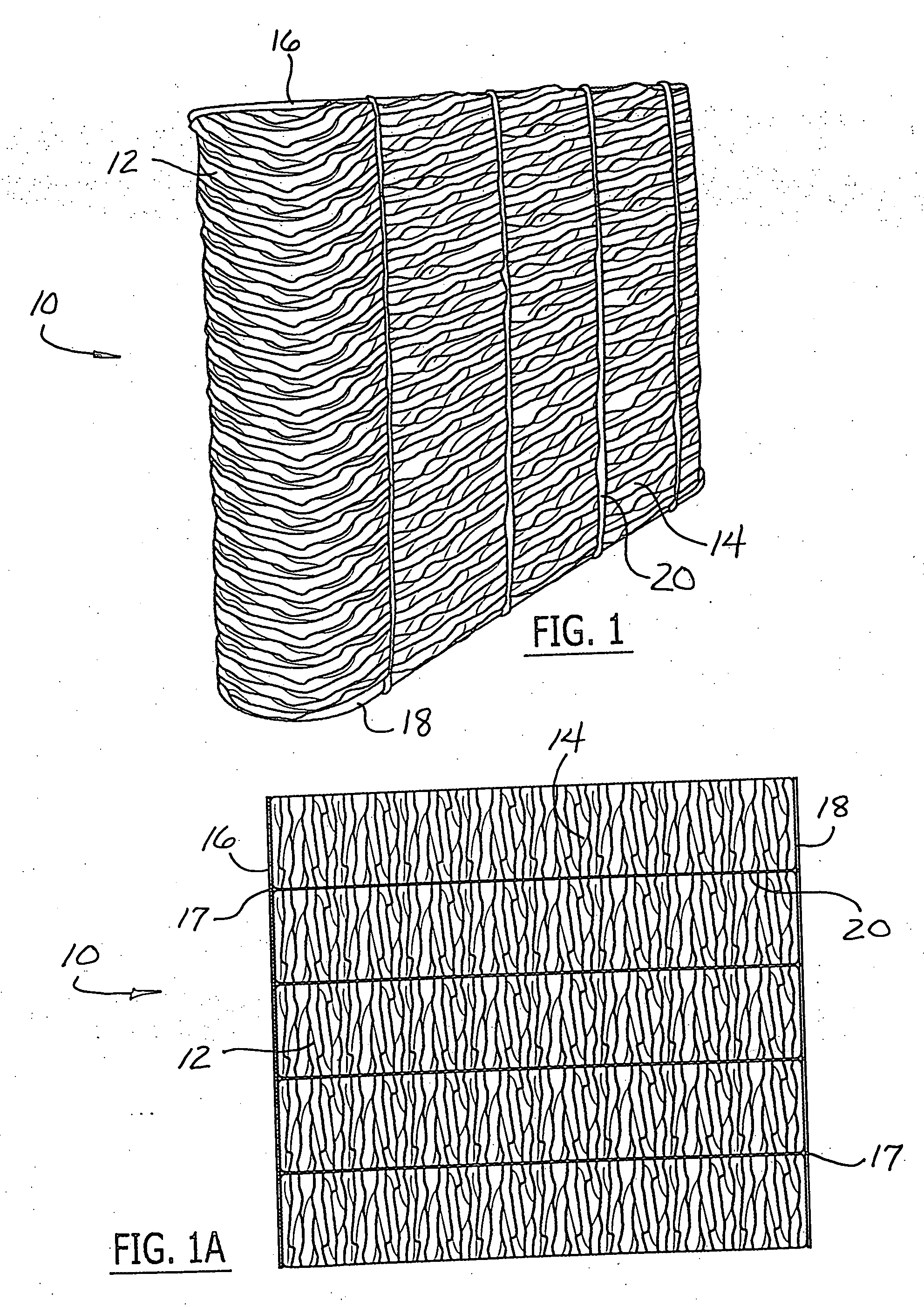

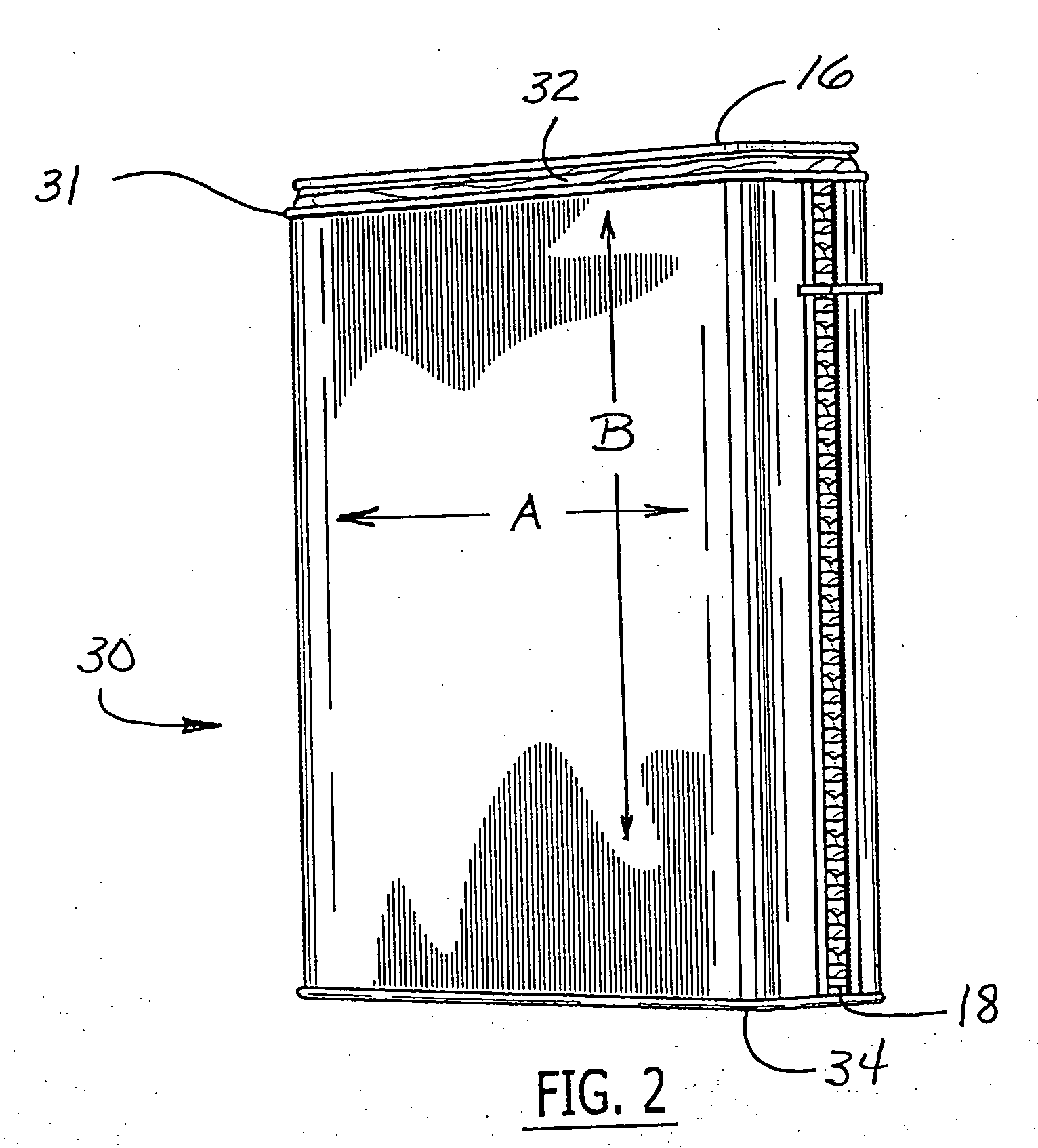

System and method for packaging cotton sliver

InactiveUS20060065554A1Efficient transportSubstantial rigidityContainers for flexible articlesFilament handlingHigh densityEngineering

A method for packaging cotton sliver for efficient transport includes the steps of laying the sliver in a uniform-density pattern onto a bottom cap, placing a top cap on the sliver, applying pressure to the top and bottom caps to compress the sliver to a higher second density at which the compressed sliver is rigid, and strapping the compressed sliver and caps in order to form a rigid package for handling and transport. A packaging system includes an oblong can that receives the sliver, a compression baler for compressing the sliver to a high density, and a strapping apparatus for strapping the compressed sliver and caps to retain the compression.

Owner:PARKDALE MILLS

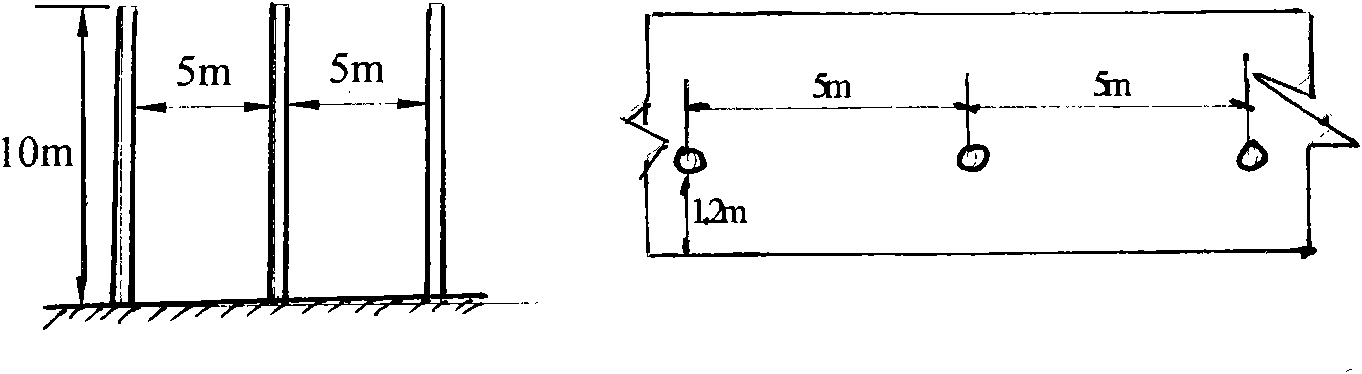

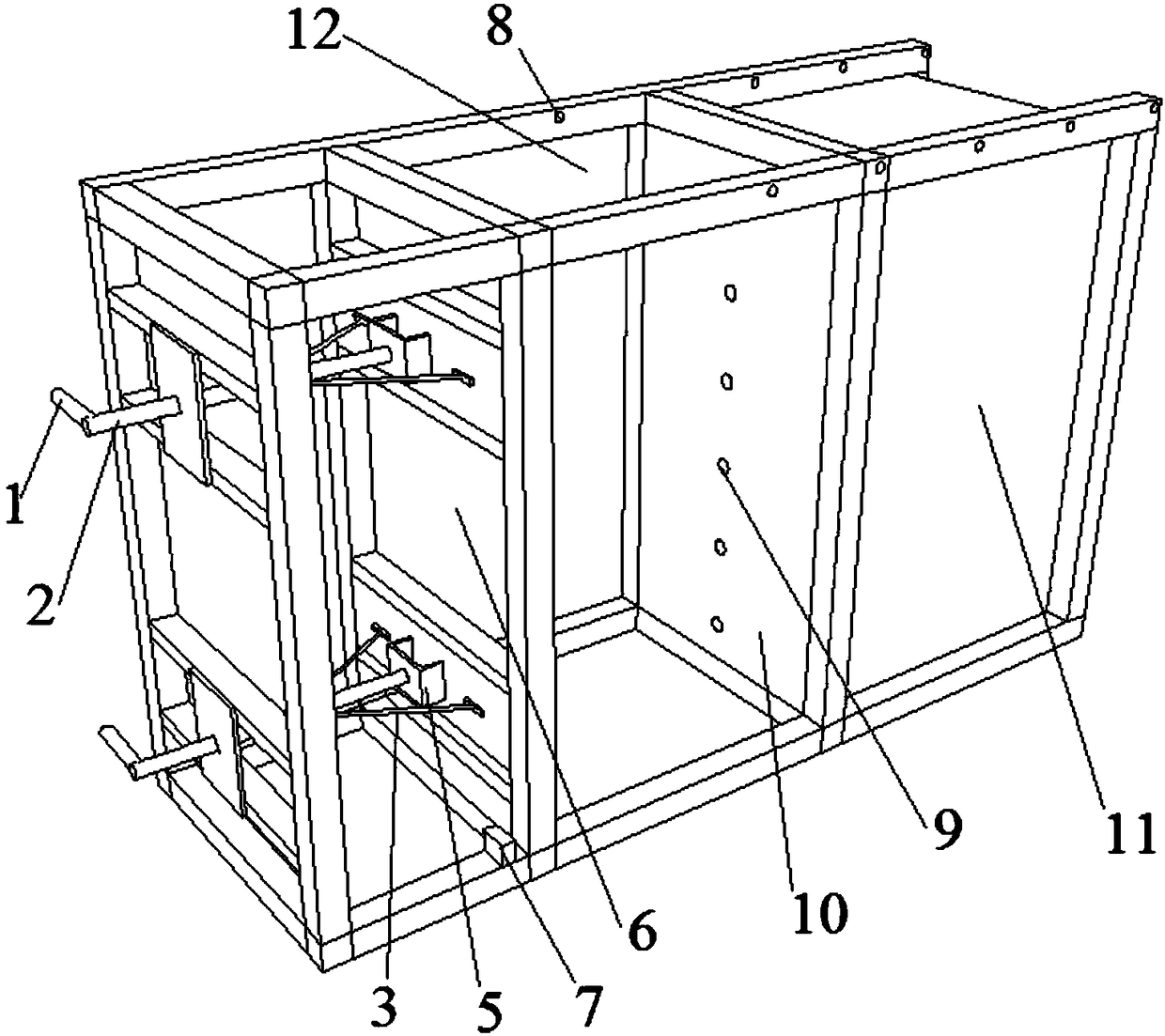

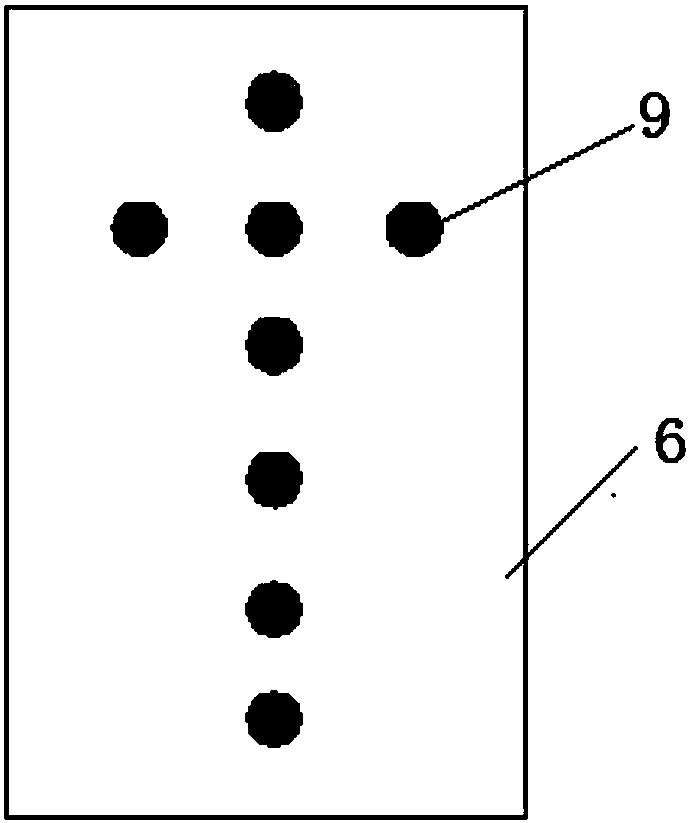

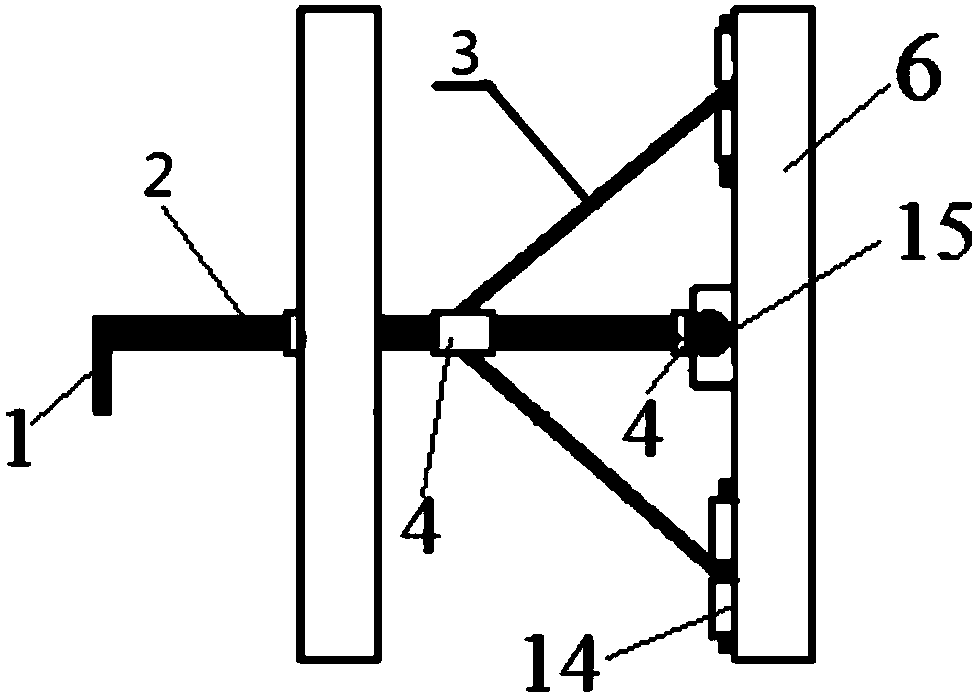

Device for measuring pressure of finite filling retaining wall under different displacement modes and testing method

InactiveCN108252340APressure controllableWide range of pressure changesFoundation testingRigid wallStressed state

The invention discloses a device for measuring pressure of a finite filling retaining wall under different displacement modes, which comprises a test box body and a box type framework; the test box body comprises a moving retaining wall and a fixing retaining wall, an upper part and a lower part of the moving retaining wall are connected with screws; an upper end and a lower end of the moving retaining wall are further provided with dial indicators; one side in opposite to the moving retaining wall is provided with the fixing retaining wall, two side walls of the test box body are rigid box bodies; the rigid wall bodies are fixedly connected with the box type framework; a fixing plate for fixing the screws is further arranged on the box type framework, a thread hole matched with the threadof the screws is arranged on the fixing plate; inside of the test box body is further provided with a pressure detecting device. The invention provides a test method. The test method can simulate thesoil body damage mode and the retaining wall soil pressure of the moving retaining wall under different displacement modes; several soil pressure detecting devices are arranged on the retaining wall;different nature stress states of the finite filling can be simulated, the soil pressure of the finite filling is measured in real time; the device is simple in structure and convenient to operate.

Owner:CHANGAN UNIV

Regenerative braking system

ActiveUS8464821B2Avoid decompressionAuxillary drivesBraking element arrangementsRegenerative brakeMotorized vehicle

A regenerative braking system is provided. The regenerative braking system includes at least one energy storage medium operably connected to a coupler. The coupler is operable to selectively couple and decouple the energy storage medium with a drive train of motor vehicle, or an electric generator, or a combination of both. A control arrangement governs the operation of the coupler. A sensor of the control arrangement is operable to determine information relating to the relative deceleration and acceleration of the motor vehicle and send said information to the controller. The controller is operable to determine the amount of energy storage medium or mediums to be coupled to the drive train via the coupler.

Owner:GRAVINO MARC CHARLES

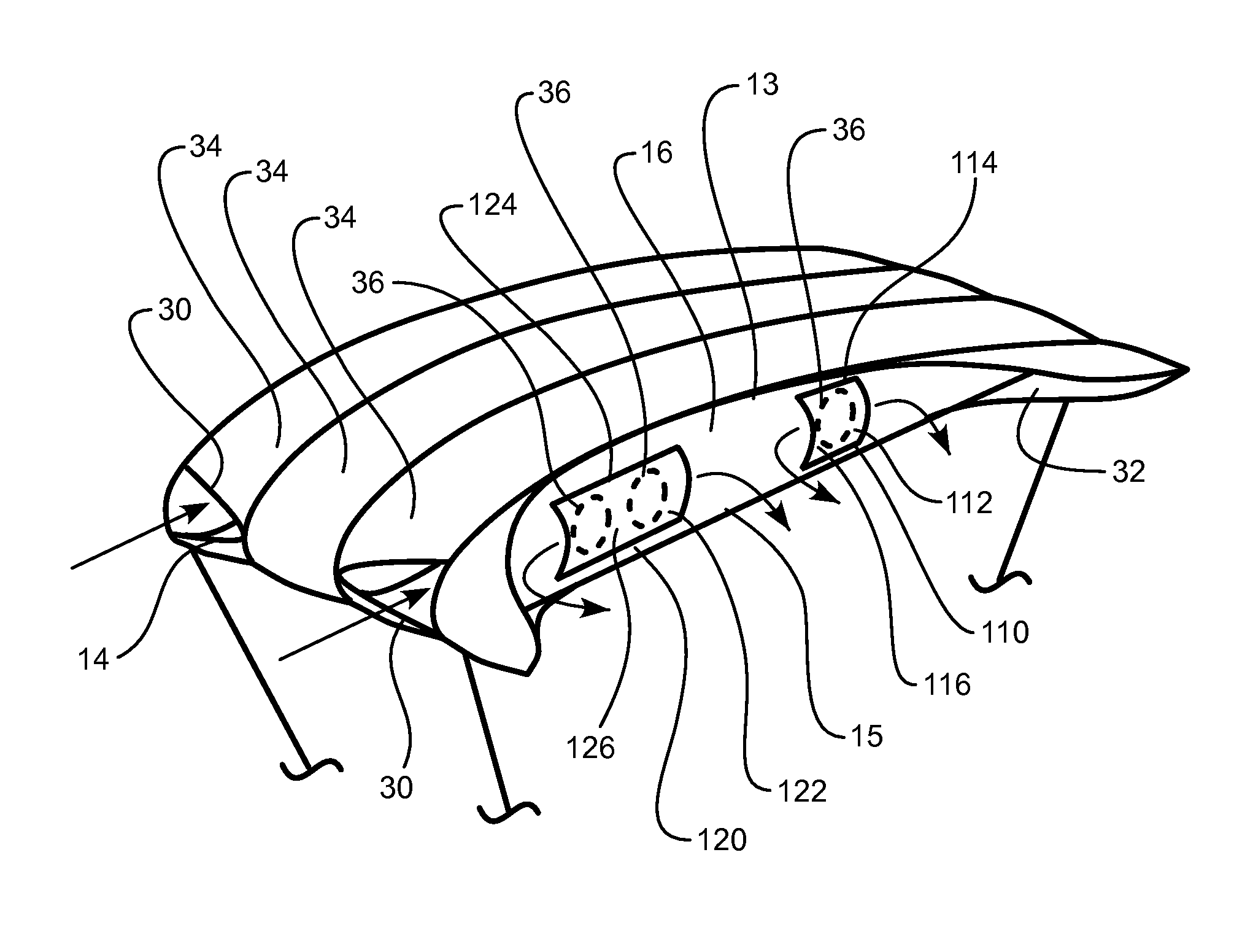

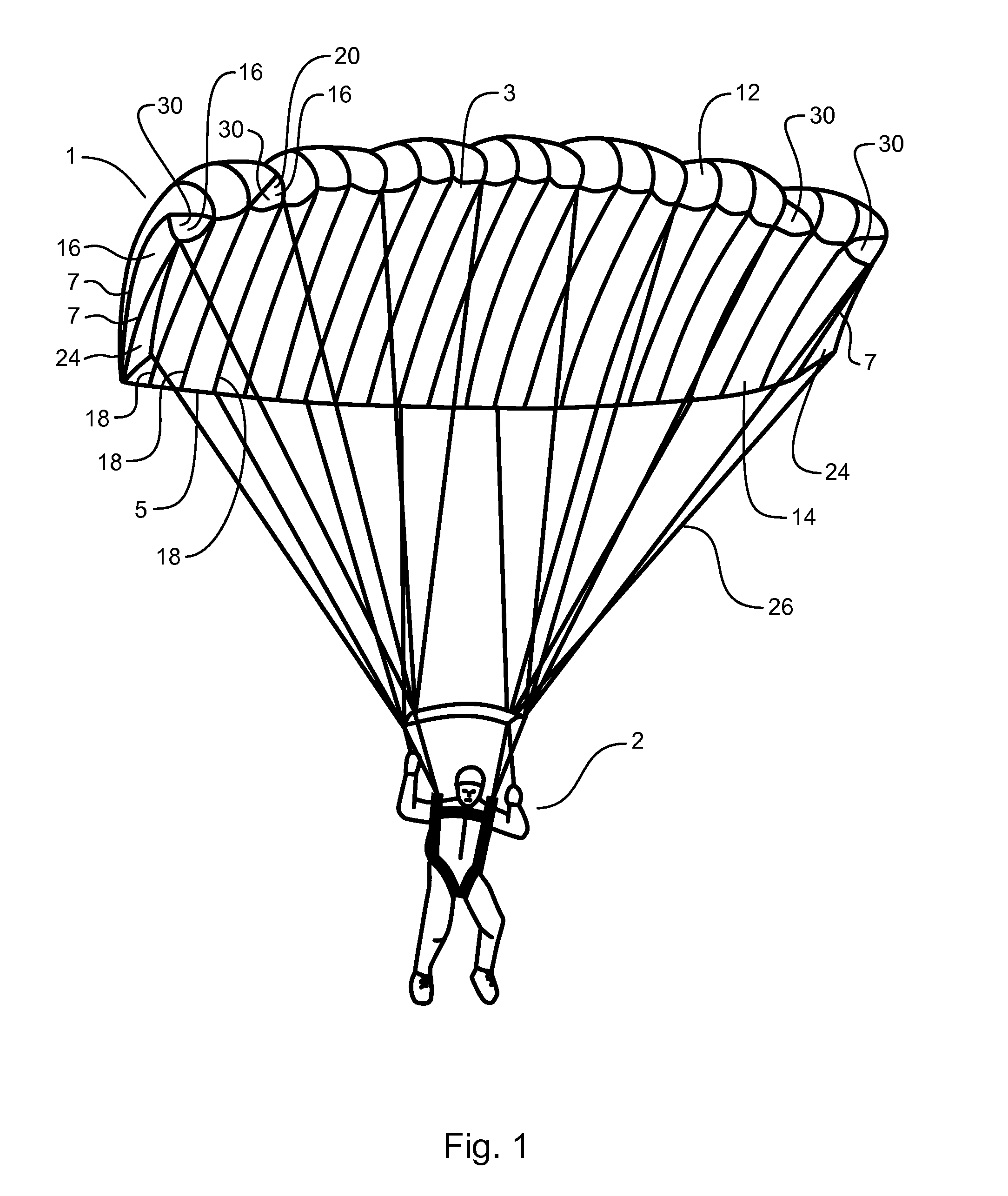

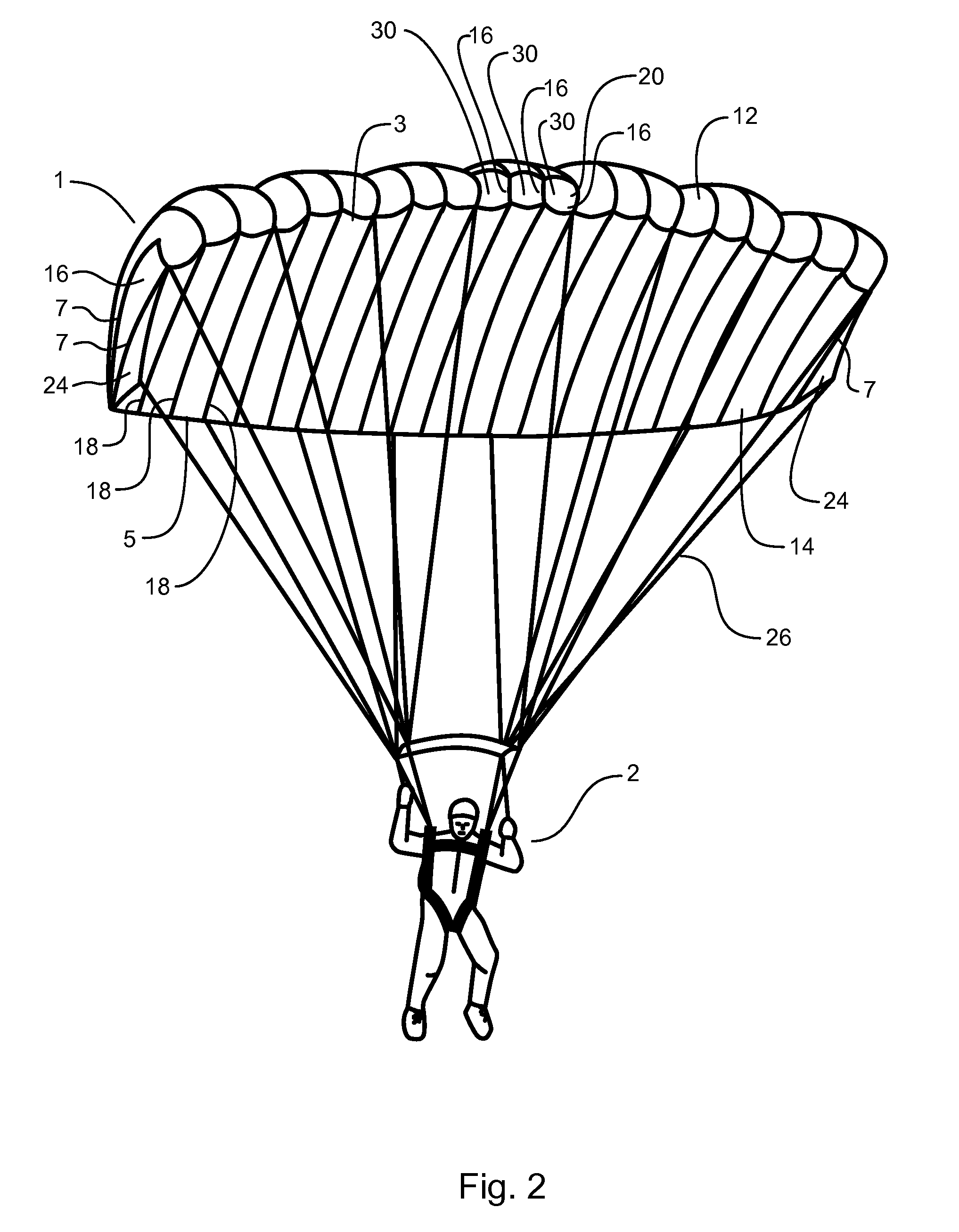

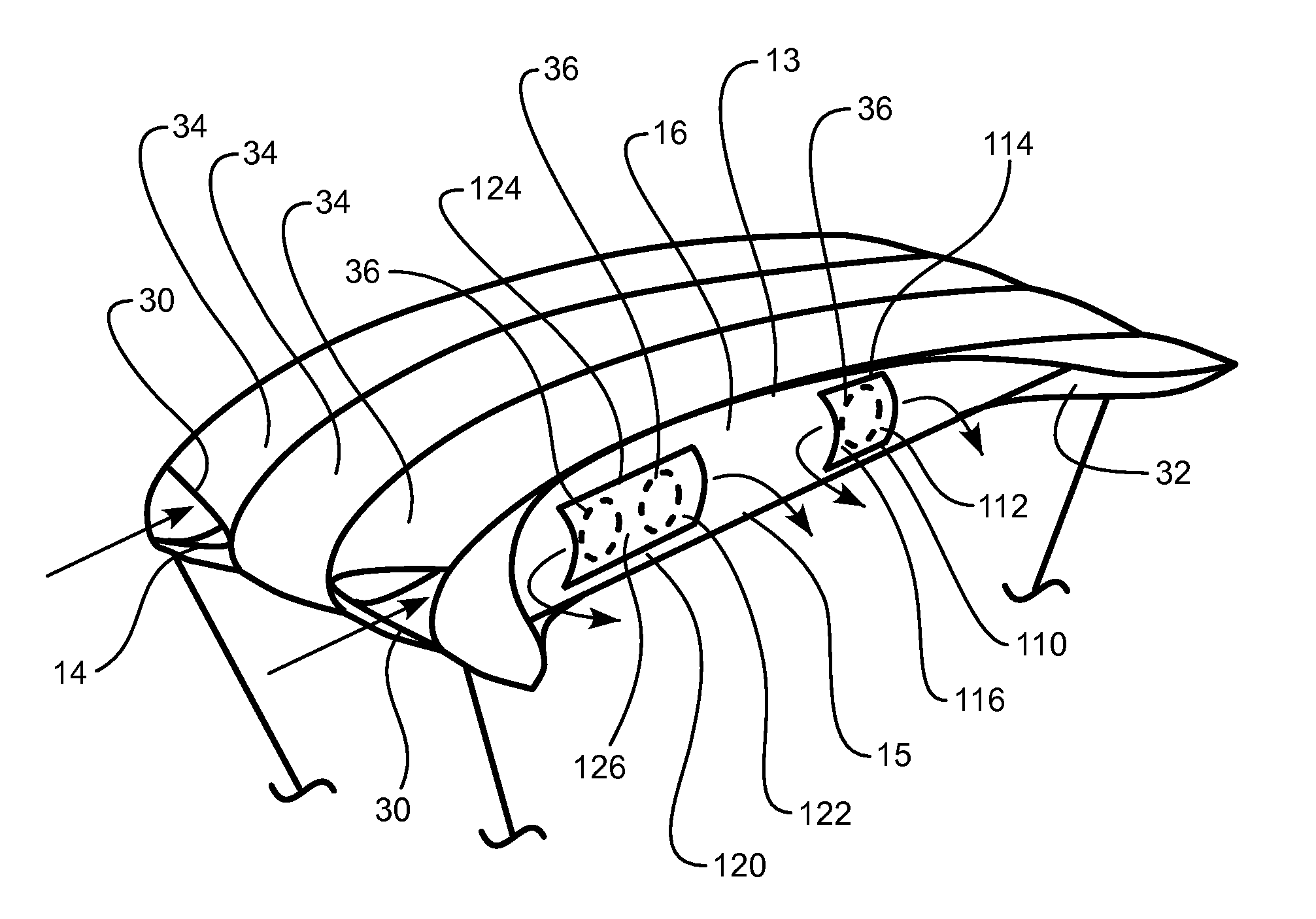

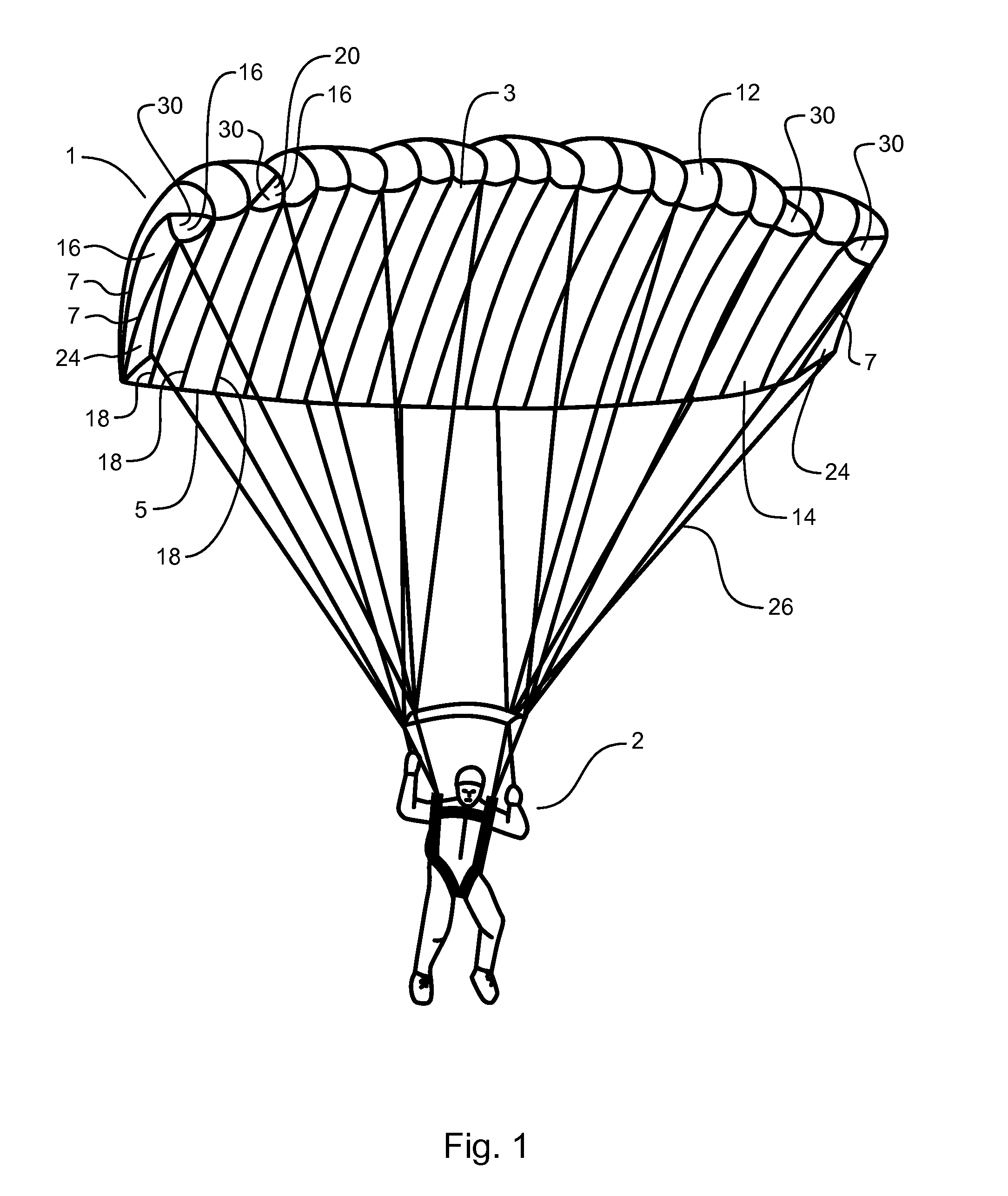

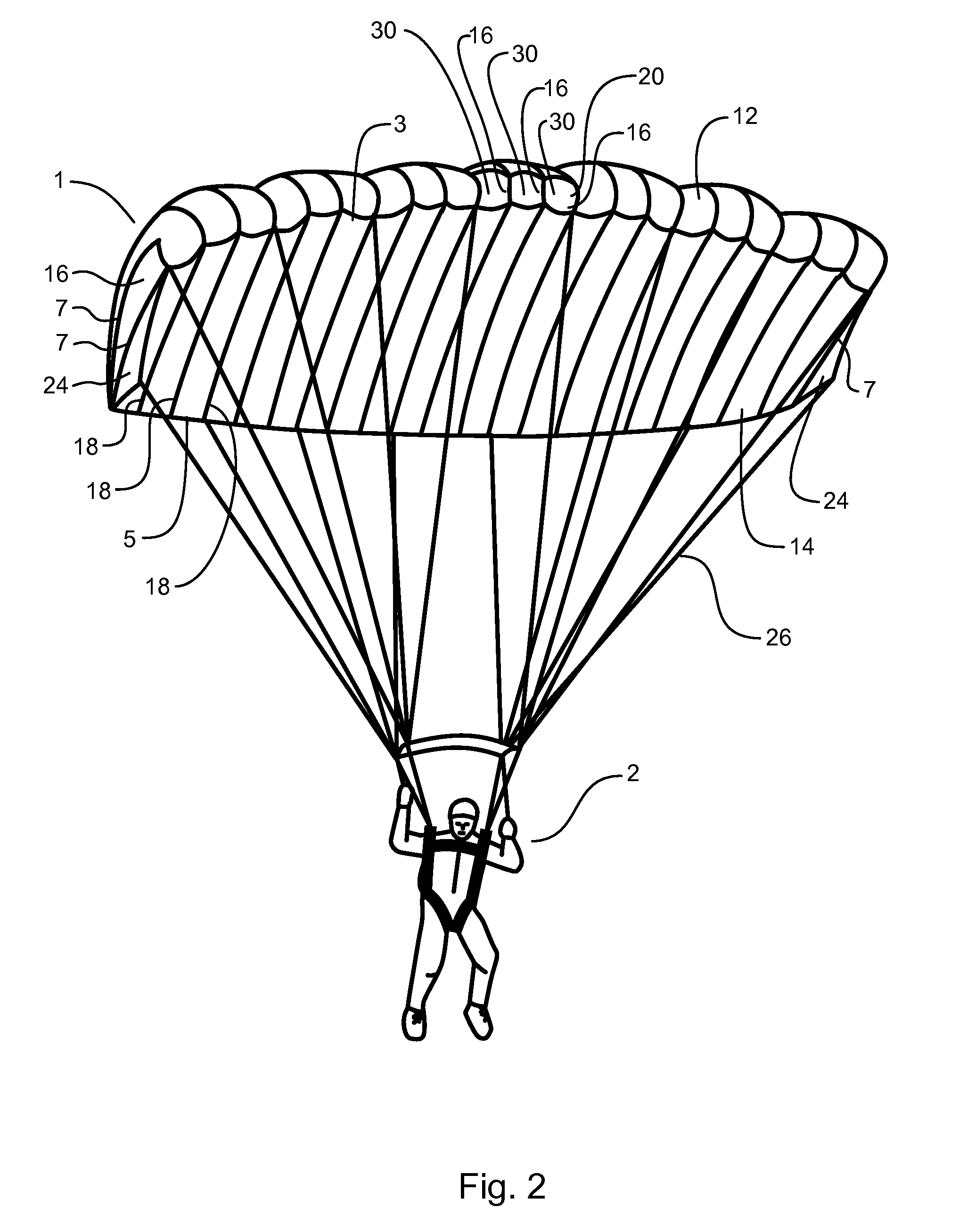

Parachute with one-way valve device

InactiveUS8215587B2Avoid decompressionMaintain rigidityAircraft stabilisationParachutesEngineeringAirspeed

A multi-celled ram-air parachute possessing one or more internal one-way valved air passages between at least two parachute cells to maintain positive air pressure within the parachute for the purpose of maintaining shape and rigidity when less than optimal airspeed is present thereby increasing a user's control and safety.

Owner:MULLINS CHARLES MICHAEL

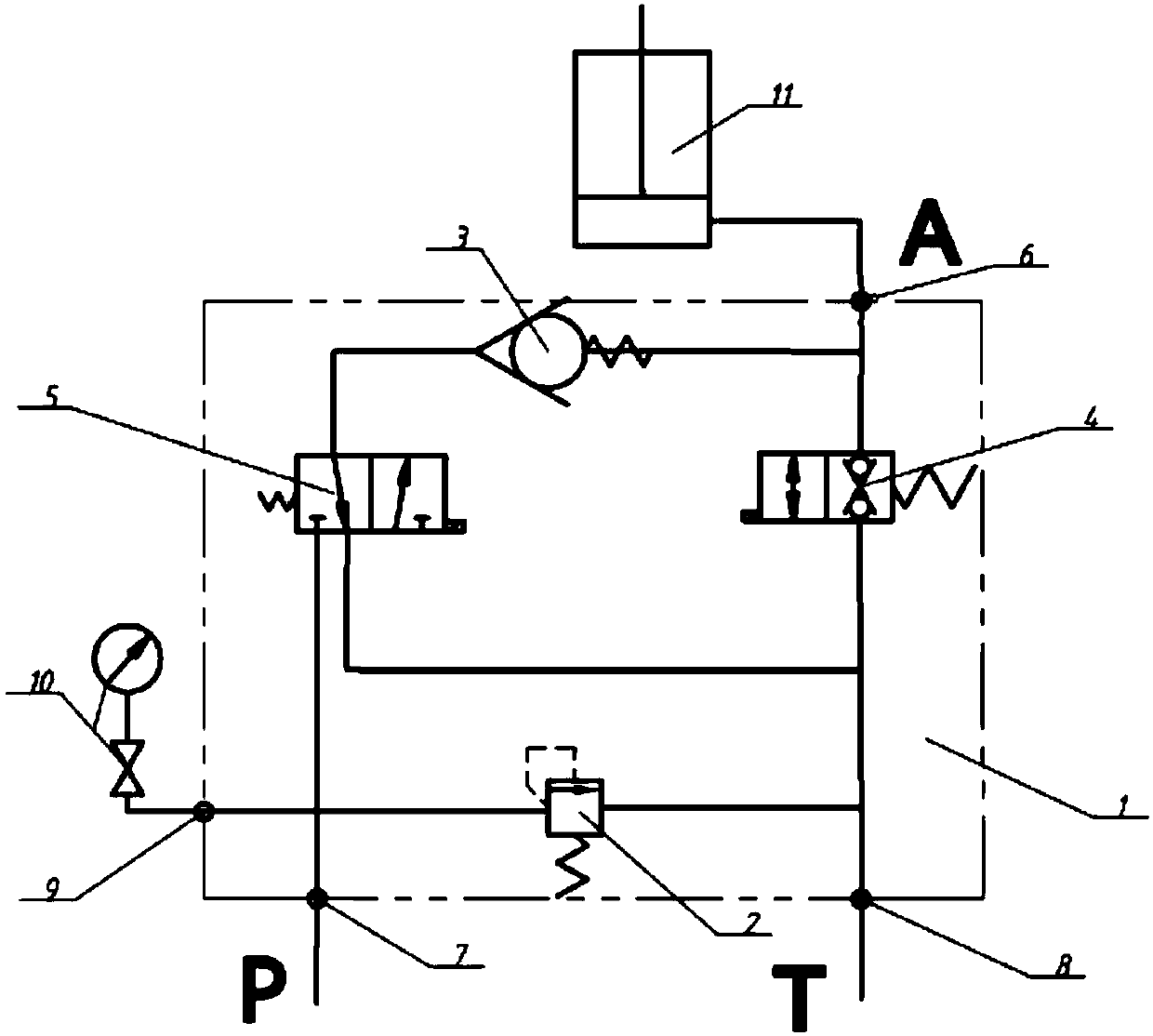

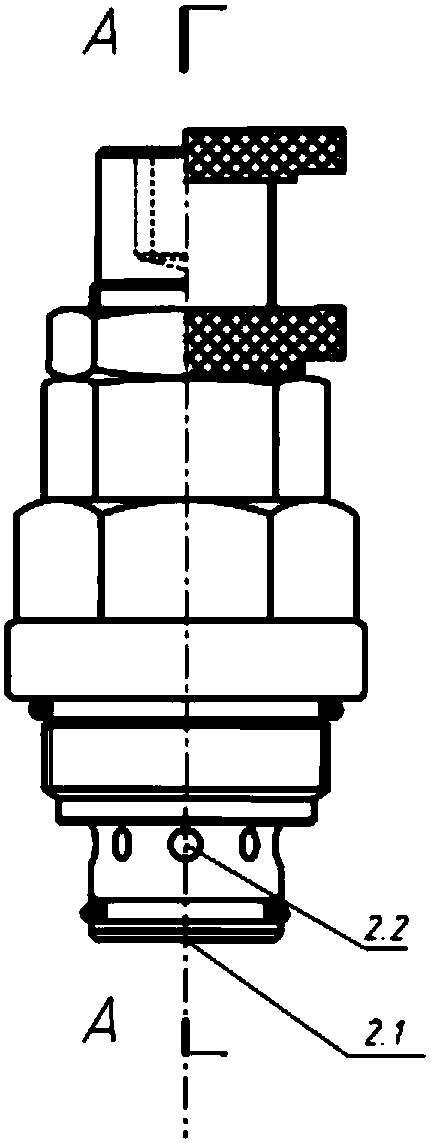

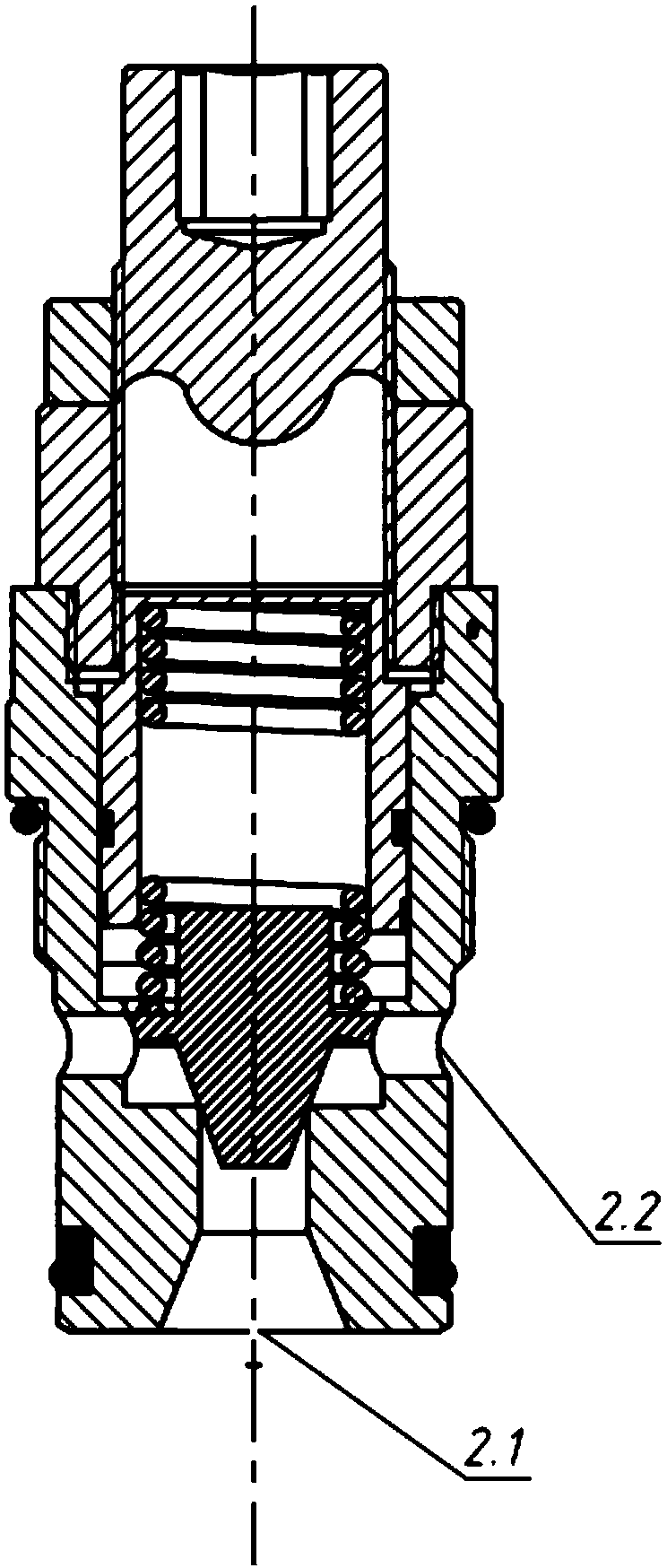

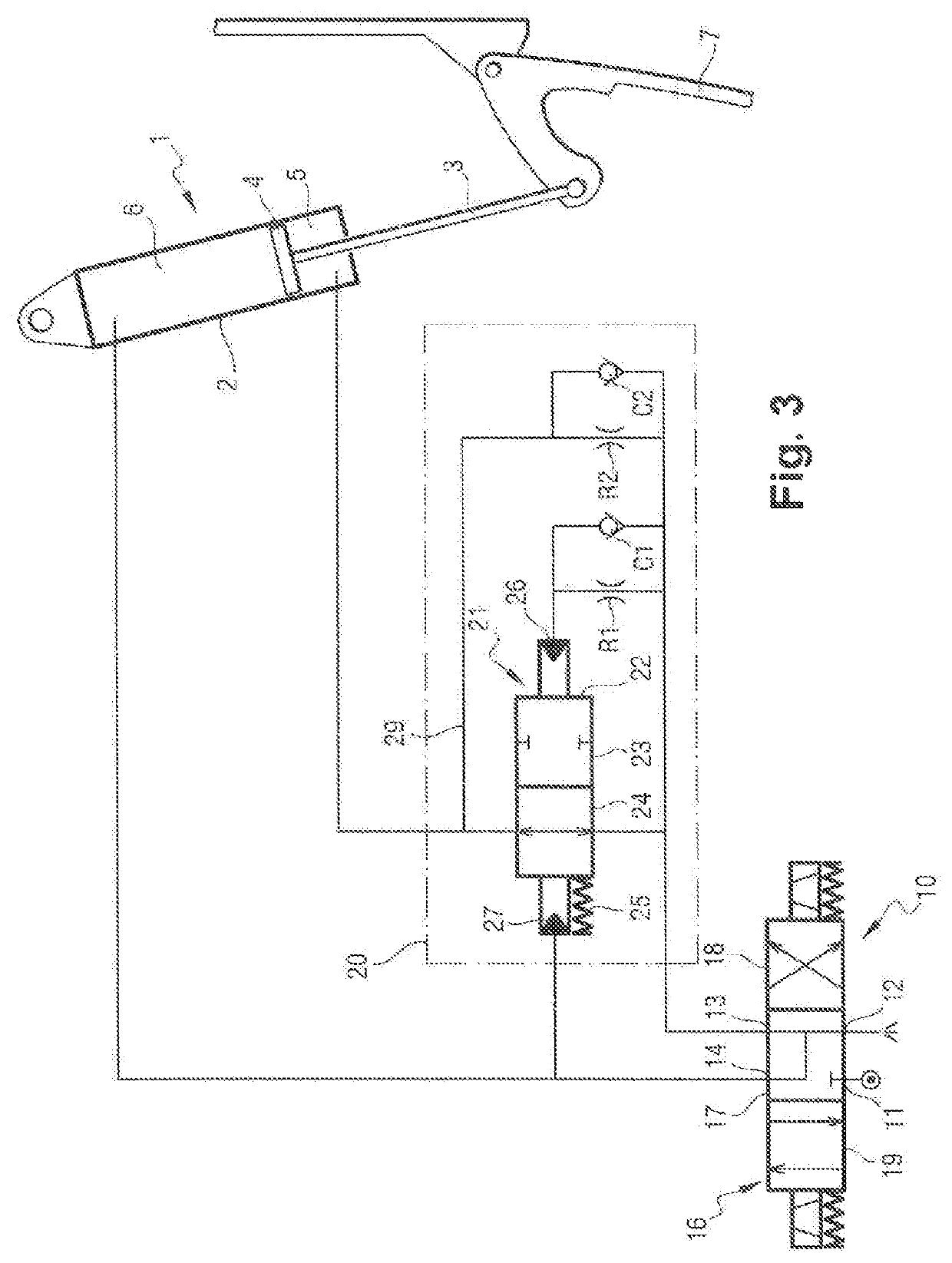

Control valve for electro-hydraulic suspension systems of small-and medium-horsepower tractors

PendingCN107642514ACompact structureEasy to controlFluid-pressure actuator testingAgricultural machinesHydraulic cylinderFuel tank

The invention belongs to the field of electro-hydraulic suspension systems and discloses a control valve for electro-hydraulic suspension systems of small-and medium-horsepower tractors. The control valve comprises a valve body, an overflow valve, a check valve, a two-position two-way electromagnetic valve, a two-position three-way electromagnetic valve, an oil outlet A, an oil inlet P, an oil return port T and a pressure testing oil port, and the overflow valve, the check valve, the two-position two-way electromagnetic valve, the two-position three-way electromagnetic valve, the oil outlet A,the oil inlet P, the oil return port T and the pressure testing oil port are mounted on the valve body through insertion. The valve body is internally provided with oil passages communicated with valve part oil ways, the oil inlet port P is connected with an oil cylinder, the pressure testing oil port is connected with a pressure meter and a switch, the oil outlet A is connected with a hydrauliccylinder, and the oil return port T is connected with an oil tank. The control valve has advantages of cost saving, compact structure, high response speed, convenience in connection with external oilways and hydraulic cylinders and convenience in electronic control.

Owner:NANJING AGRICULTURAL UNIVERSITY

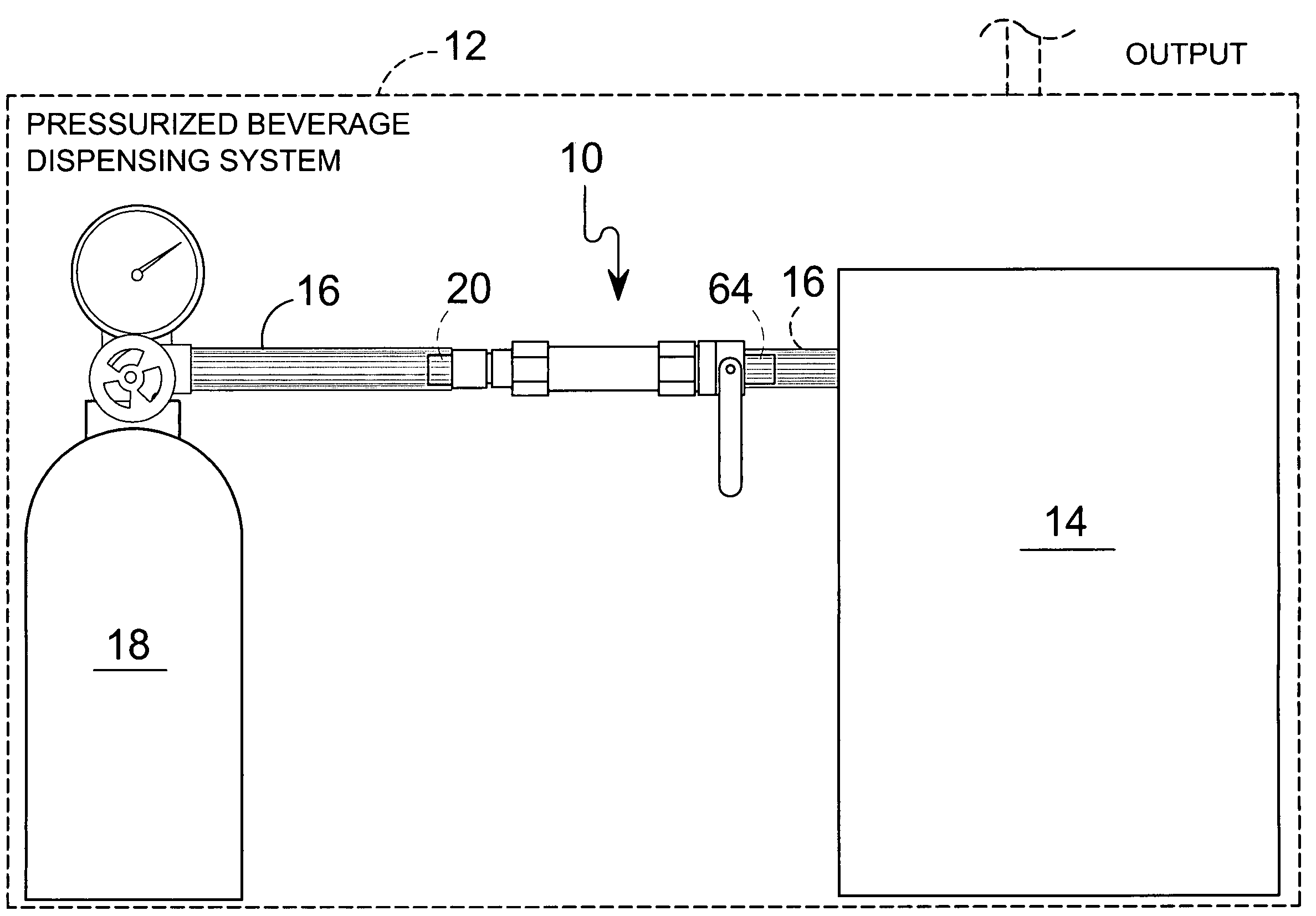

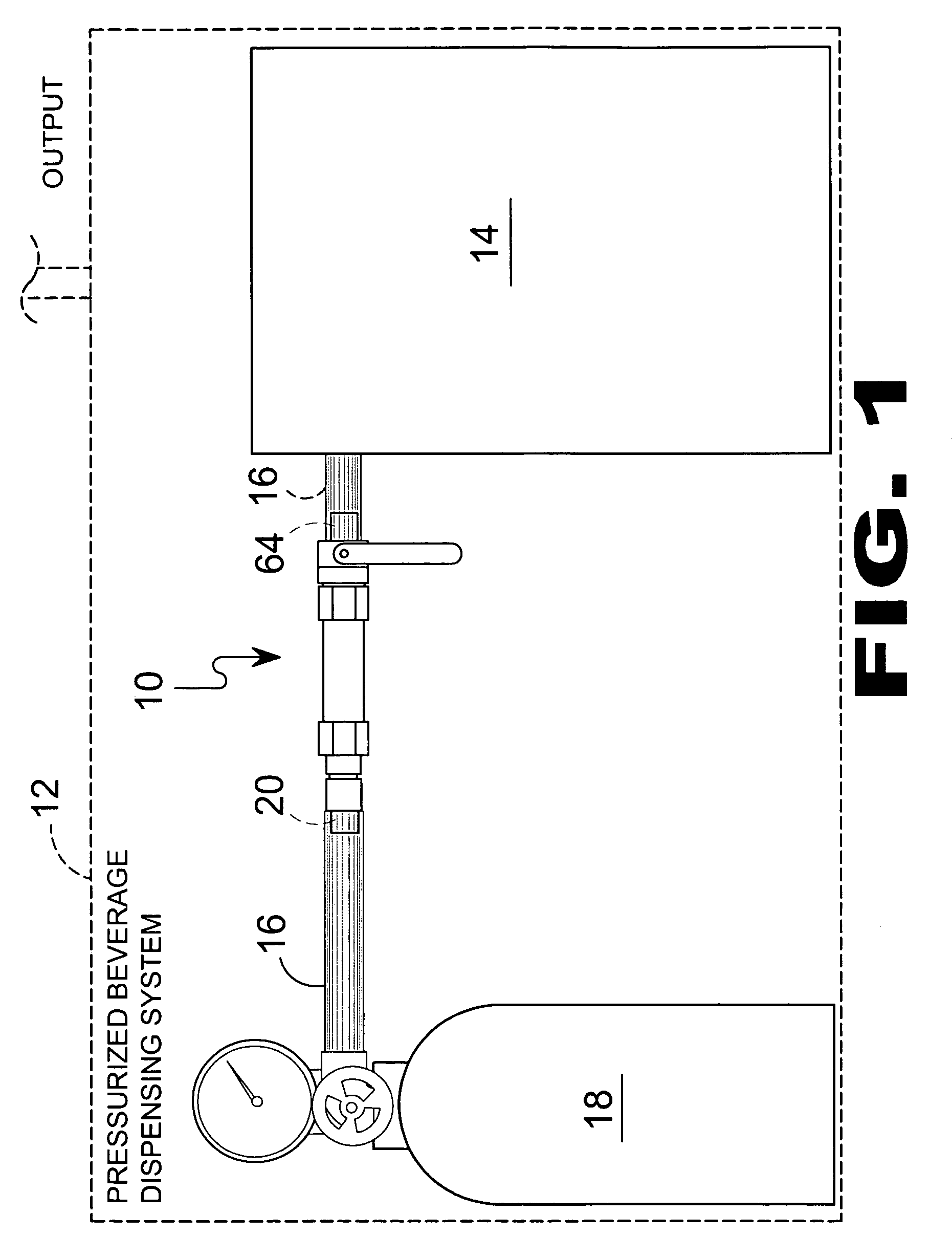

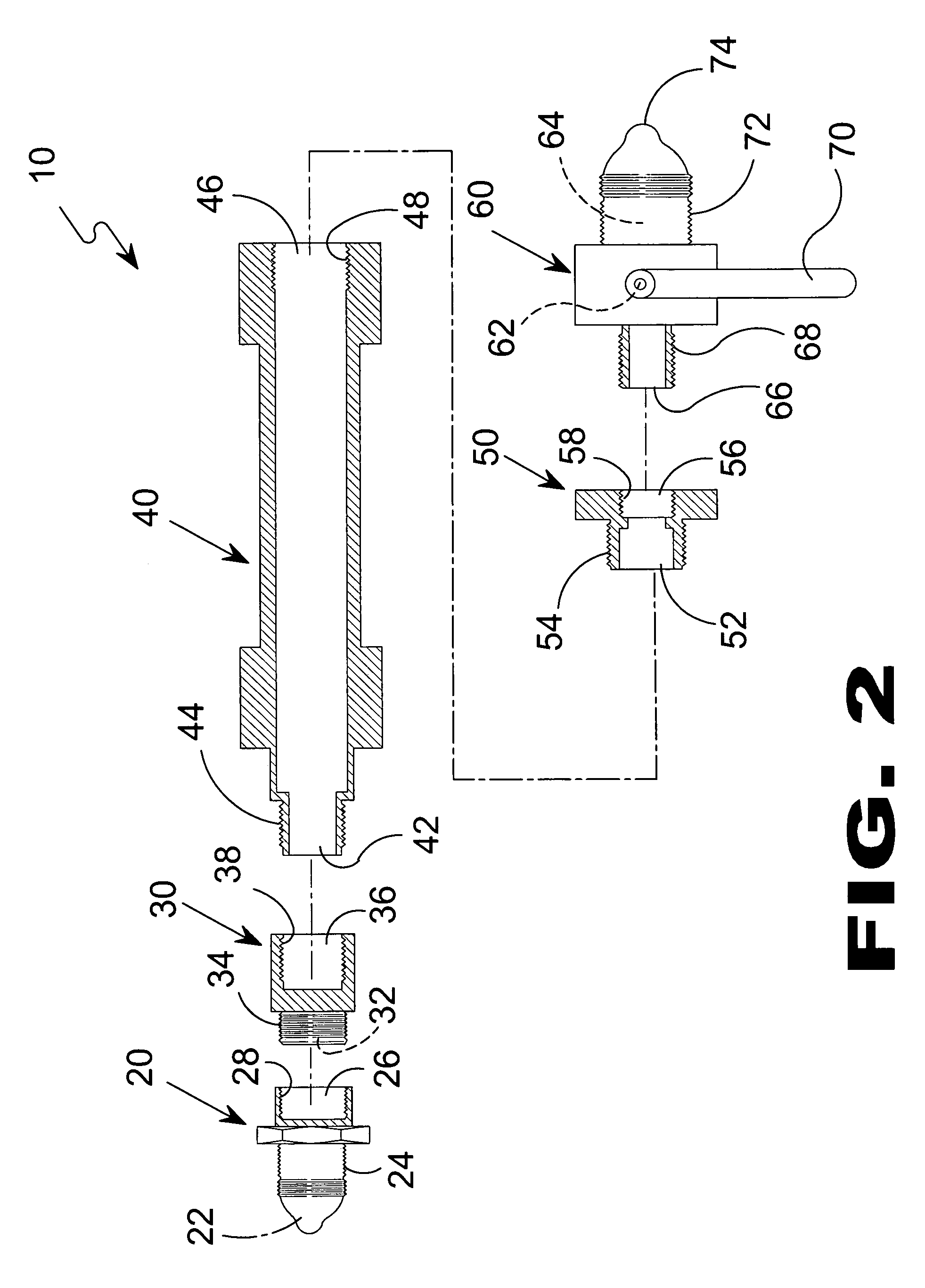

Pressure activated shutoff valve

InactiveUS7273069B1Cost savingLow costVessel mounting detailsVessel geometry/arrangement/sizeCarbonationBall valve

An apparatus for providing a pressurized gas inline valve assembly incorporating a check valve to maintain pressure above a selectable psi and a ball valve for selectively shutting off gas flow. The apparatus is preferably positioned approximate the gas source in a beverage dispensing system that uses carbon dioxide for carbonation, preservative and propellant. Preferably, the apparatus is designed to maintain the system pressure above the threshold pressure that when below said threshold pressure the carbon dioxide would revert to its inoperative dry ice solid state as opposed to its operative liquid state.

Owner:NELSON BURT

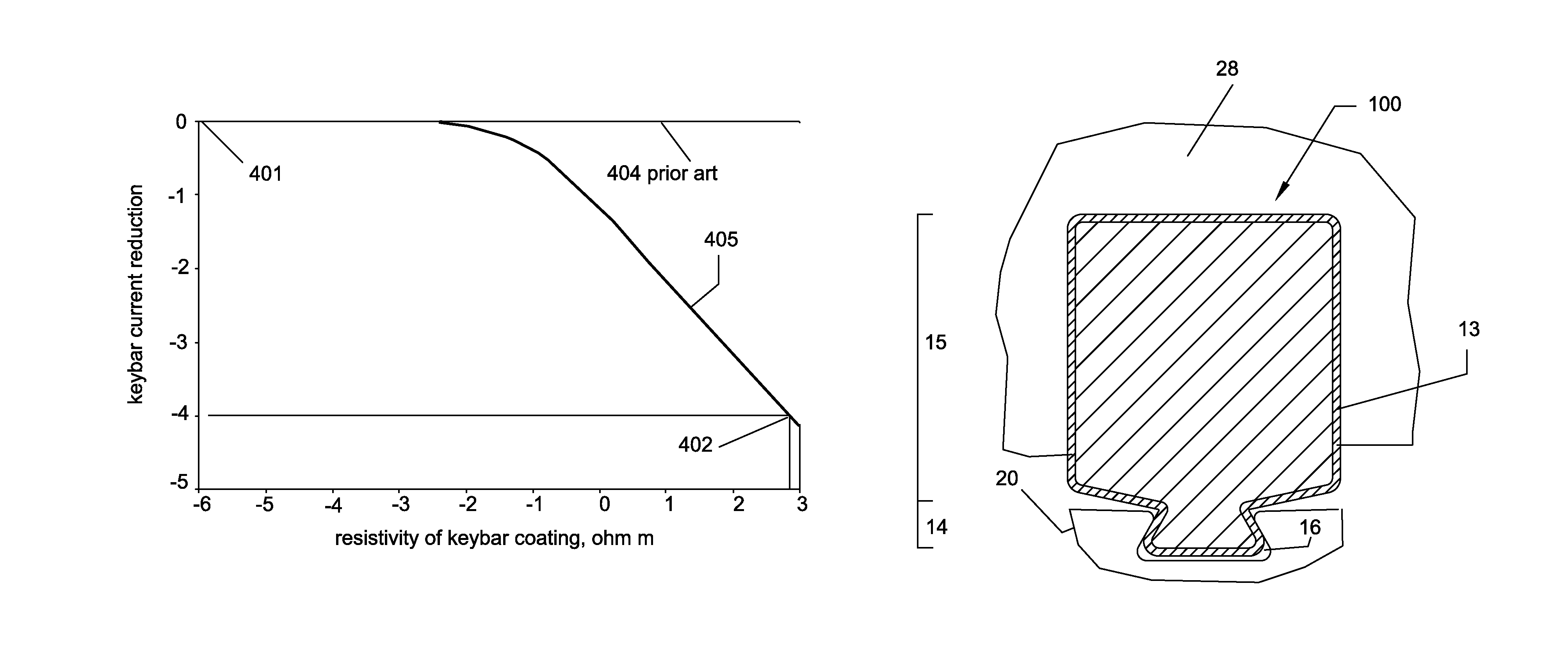

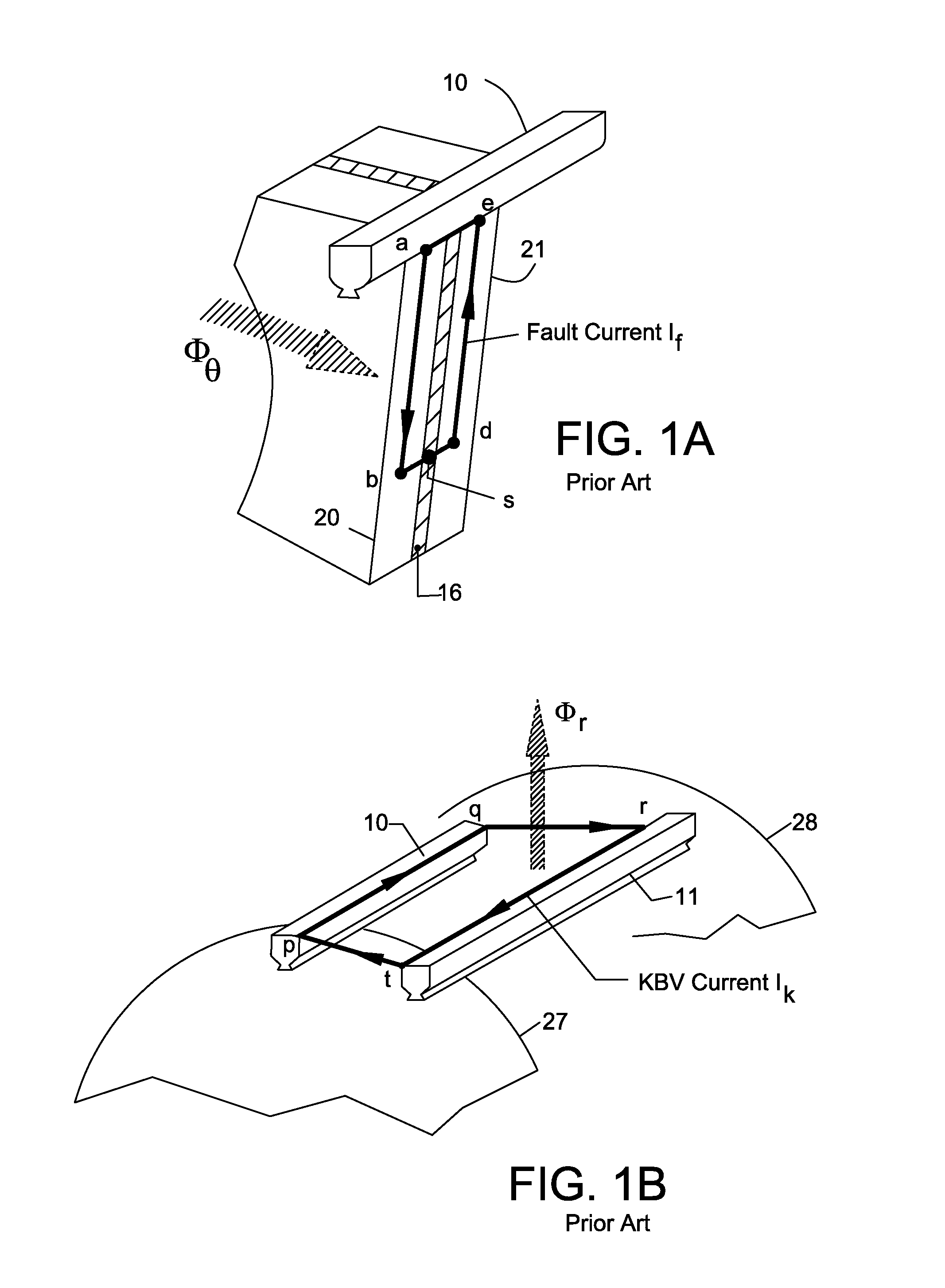

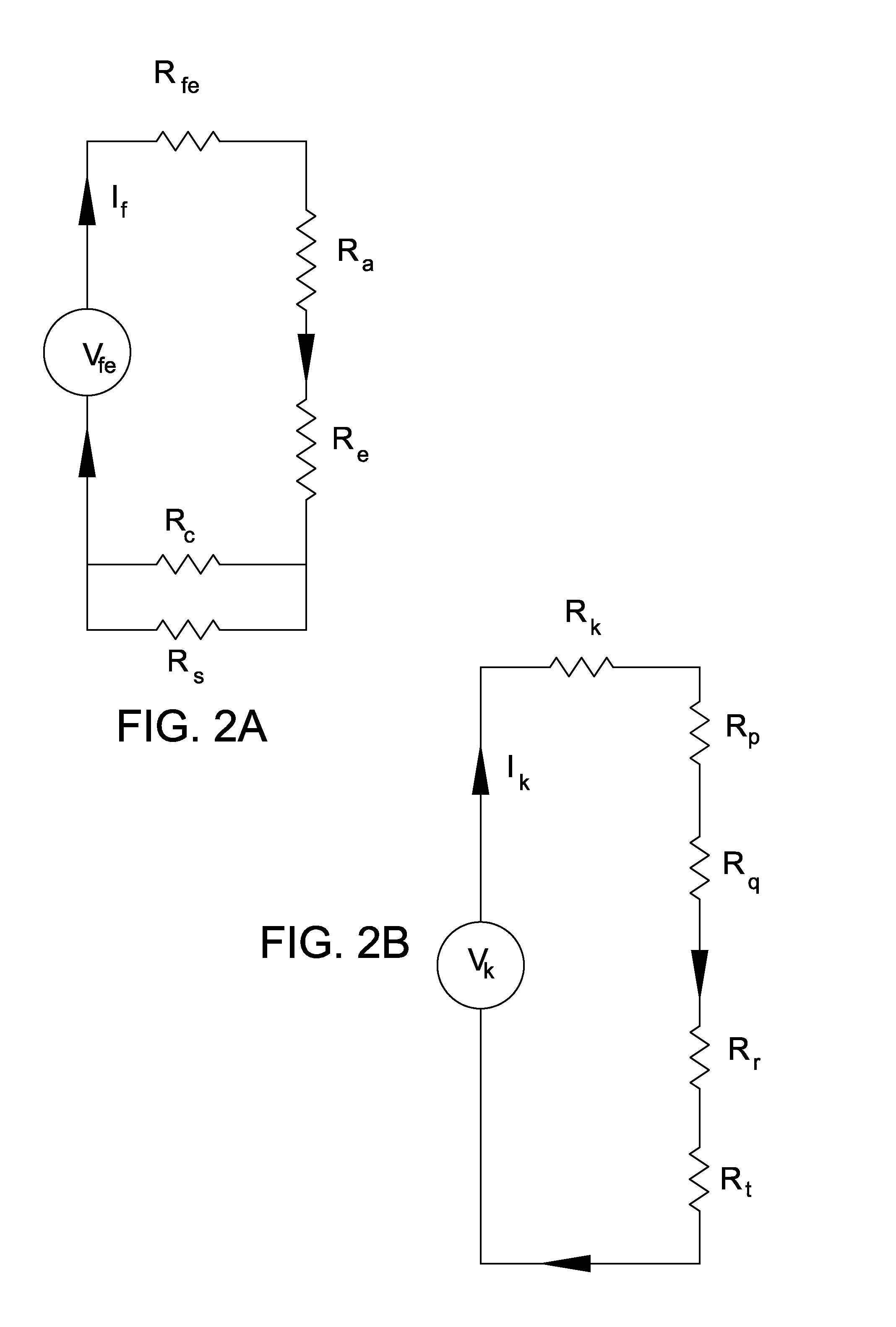

Coated keybar to protect electric machines

InactiveUS8829769B1Prevent deratingHigh leading power factor operating conditionAssociation with grounding devicesBoltsHigh resistanceElectrical resistance and conductance

A keybar or clamping bolt with a high-resistivity coating to protect an electric machine. The coating engages the laminations, flanges and frame rings and forms a part of electrical circuits through which harmful eddy currents circulate. One class of eddy currents, viz., core-fault currents, due to edge burrs or insulation defects, are forced to flow through this coating. The high resistance of the coating weakens the fault currents, preventing creation of hotspots that can cause core failure. Such coated keybar is in inexpensive alternative to traditional recoating and / or core-fault detection. Another class of eddy currents, viz., keybar currents, caused by over-fluxing, are also forced to flow through this coating. The high resistance of the coating weakens the keybar currents, so prevents core-end overheating. A coated keybar also allows the machine to operate at higher leading power factor. It also prevents core-decompression hence protects the machine against loose laminations.

Owner:RAO DANTAM K

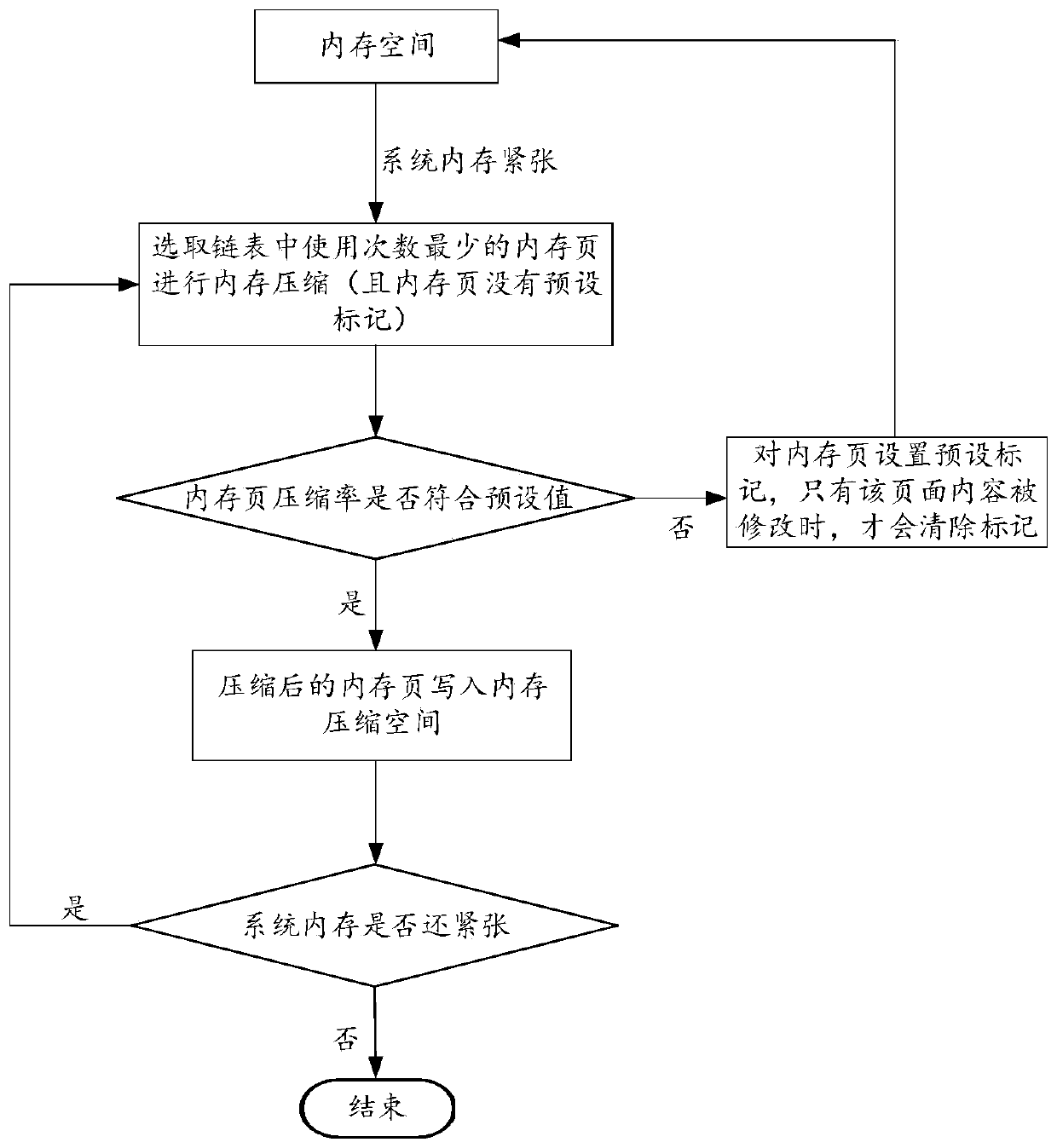

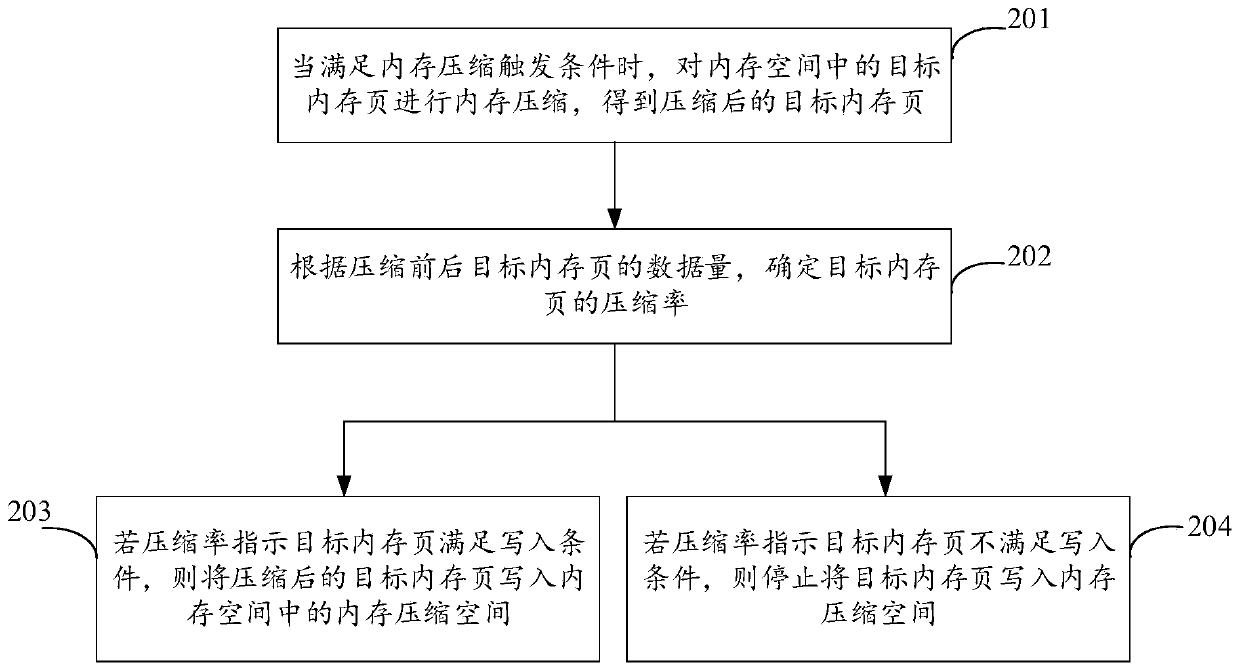

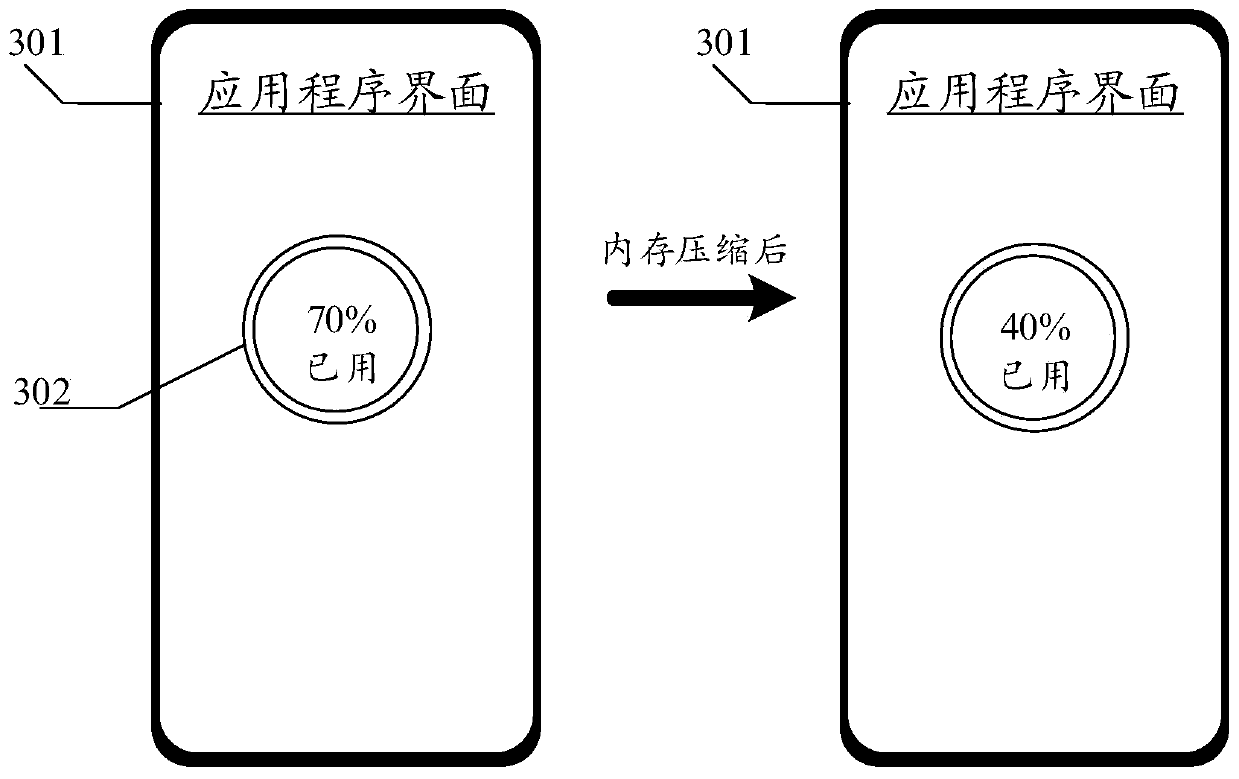

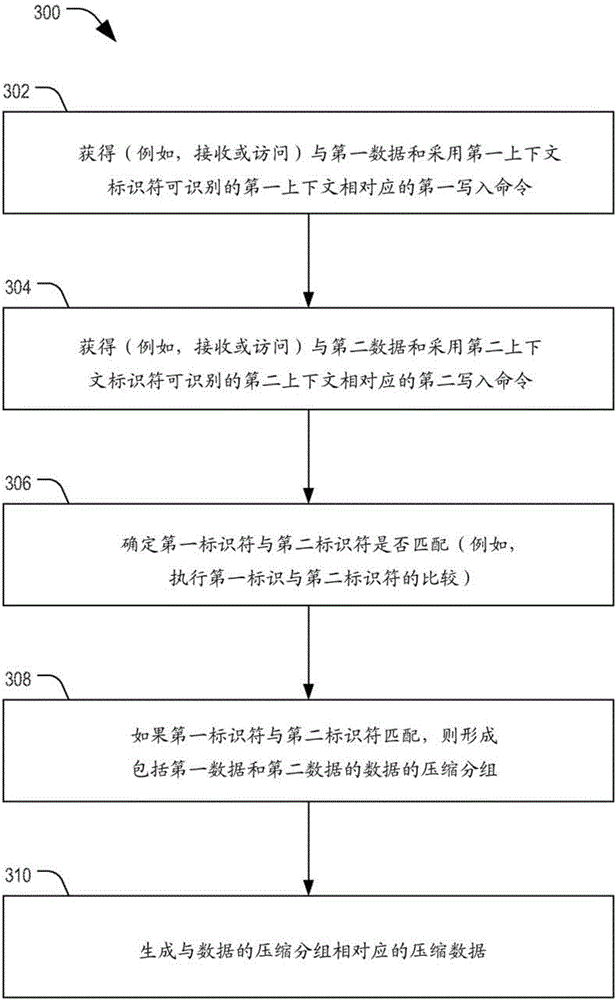

Memory compression method and device, terminal and storage medium

ActiveCN110457235AFree memory spaceAvoid decompressionMemory adressing/allocation/relocationMemory compactionCompression ratio

The embodiment of the invention discloses a memory compression method and device, a terminal and a storage medium, and belongs to the field of memory compression. The method comprises the following steps: when a memory compression triggering condition is met, performing memory compression on a target memory page in a memory space to obtain a compressed target memory page; determining the compression rate of the target memory page according to the data volume of the target memory page before and after compression; if the compression rate indicates that the target memory page meets a writing condition, writing the compressed target memory page into a memory compression space in the memory space; and if the compression rate indicates that the target memory page does not meet the writing condition, stopping writing the target memory page into the memory compression space. By setting the write-in condition and refusing to write the memory pages which do not meet the write-in condition intothe memory compression space, the useless decompression process of the CPU is reduced, and the overall compression ratio of the memory compression space is further improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Storage system and data processing method for the same

ActiveUS8161211B2Improve efficiencyUtilization capacityError detection/correctionMemory adressing/allocation/relocationData compressionParallel computing

The present invention aims for efficient use of storage capacity in a storage system by reducing the amount of time taken for processing including removing redundancy and data compression executed with respect to transferred data.Focusing on data patterns included in transferred data, the most suitable pattern is detected, and de-duplication processing is gradually executed. Data compression is then executed with data after de-duplication as a target. Determination of the decision for execution of gradual de-duplication processing, or execution of compression processing is made depending on the amount of data remaining at each processing stage and the system load.

Owner:HITACHI LTD

Dispensing tip, reaction kit using the same, and dispensing tip drive mechanism

To prevent aerosol in a dispensing tip from contaminating the outside of the tip and a solution to be dispensed. The dispensing tip (20) has a dispensing nozzle (19) positioned at its forward end, a syringe connected to the base end of the dispensing nozzle (19) and having a cavity therein, and a plunger (22) for performing suction and discharge of a liquid from the dispensing nozzle (19) by sliding in the cylinder (21) of the syringe. A separating member is placed between the base end side of the plunger (22) and the base end side of the cylinder (22), and the separating member has airtightness separating the inside of the nozzle (19) from the outside and flexibility allowing the plunger (22) to slide over the separating member.

Owner:SHIMADZU SEISAKUSHO CO LTD

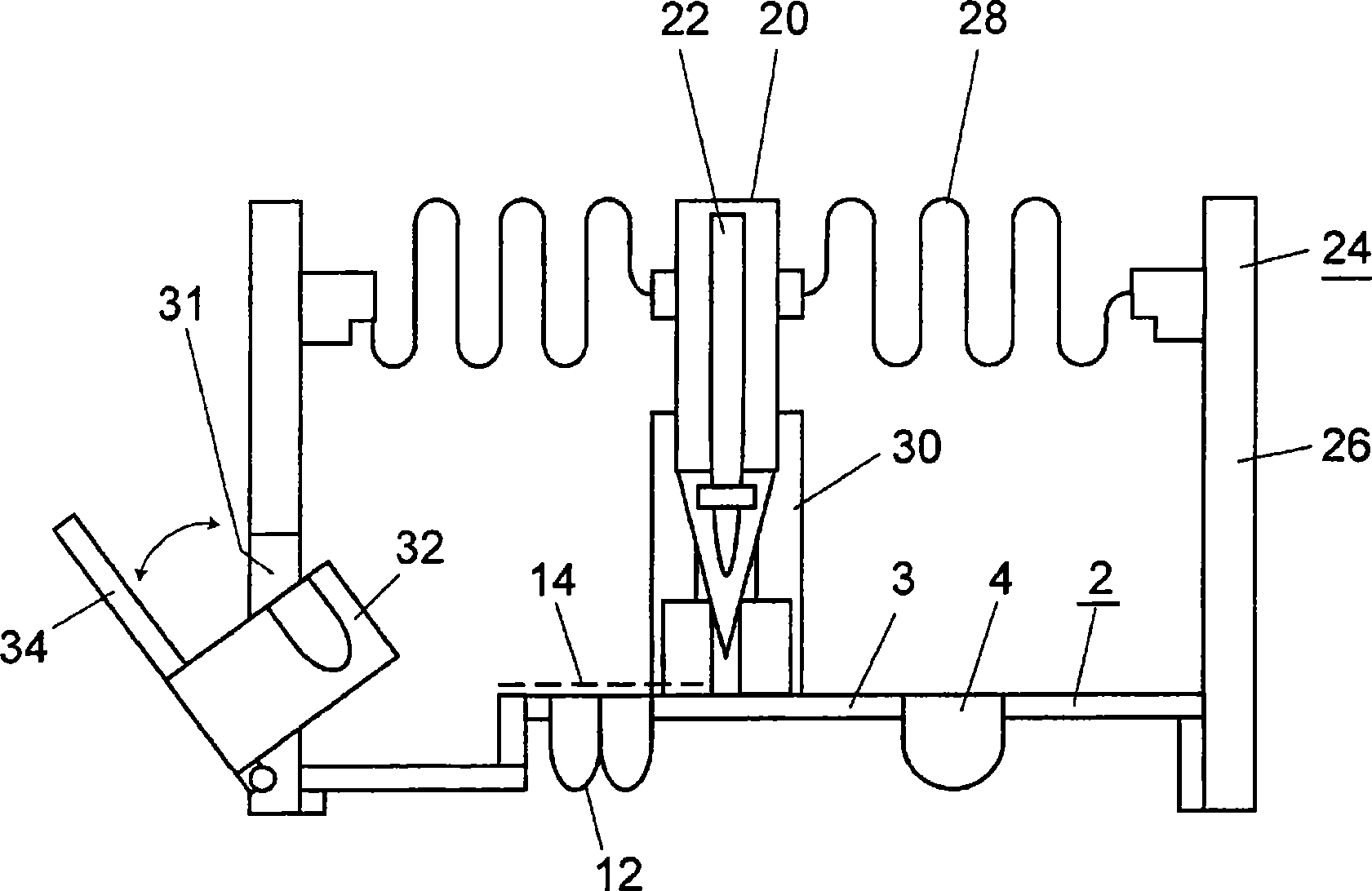

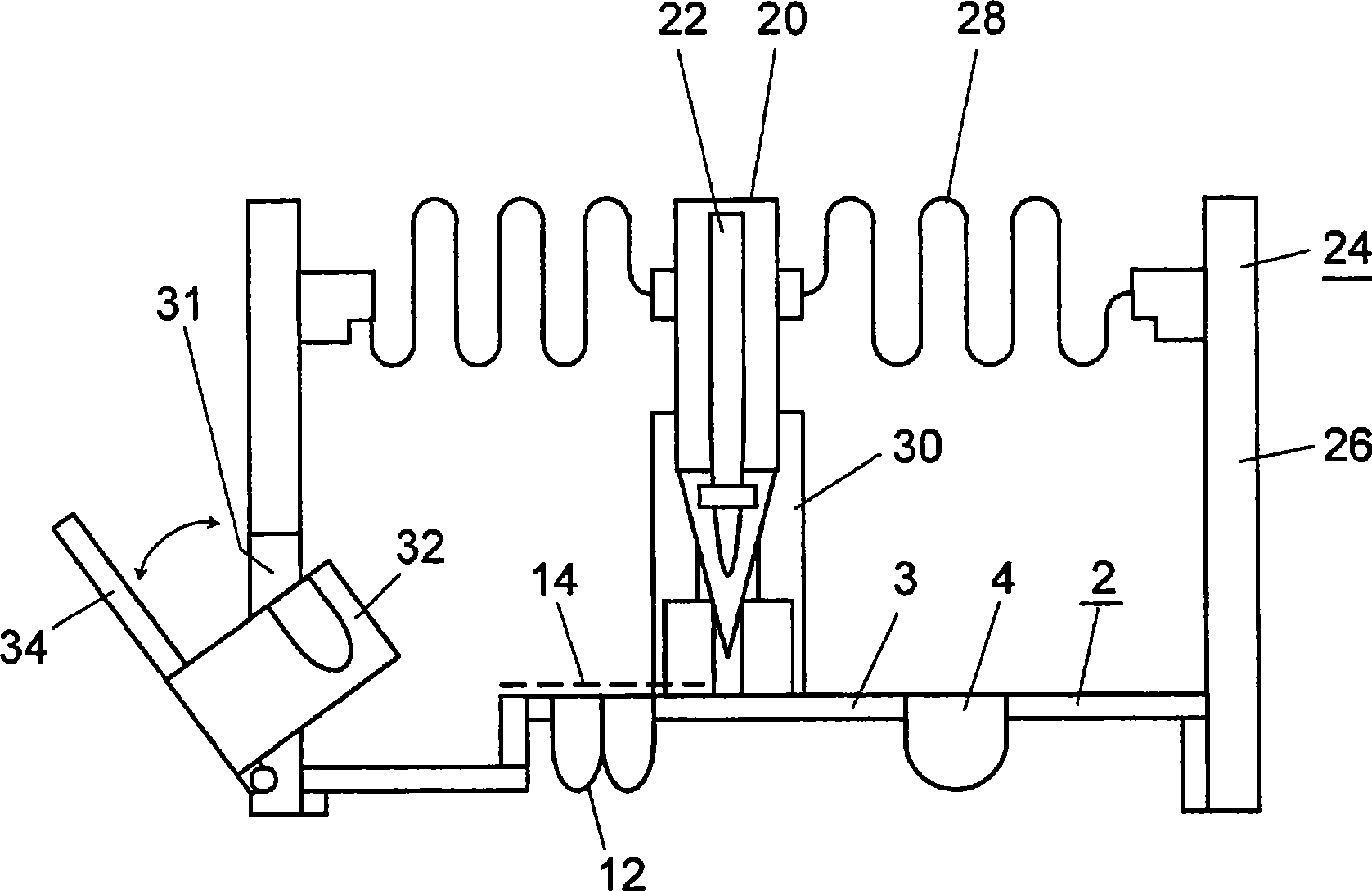

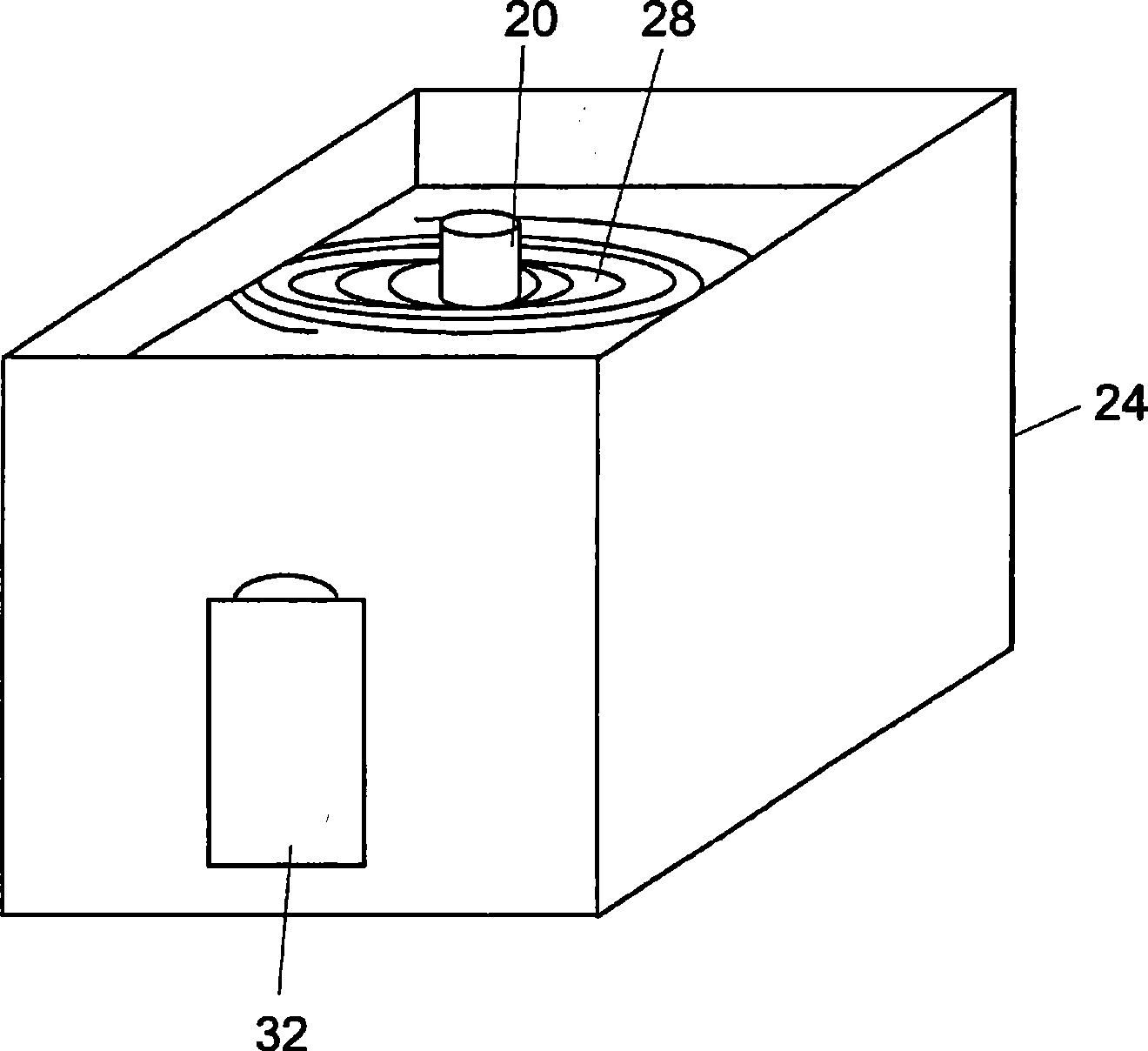

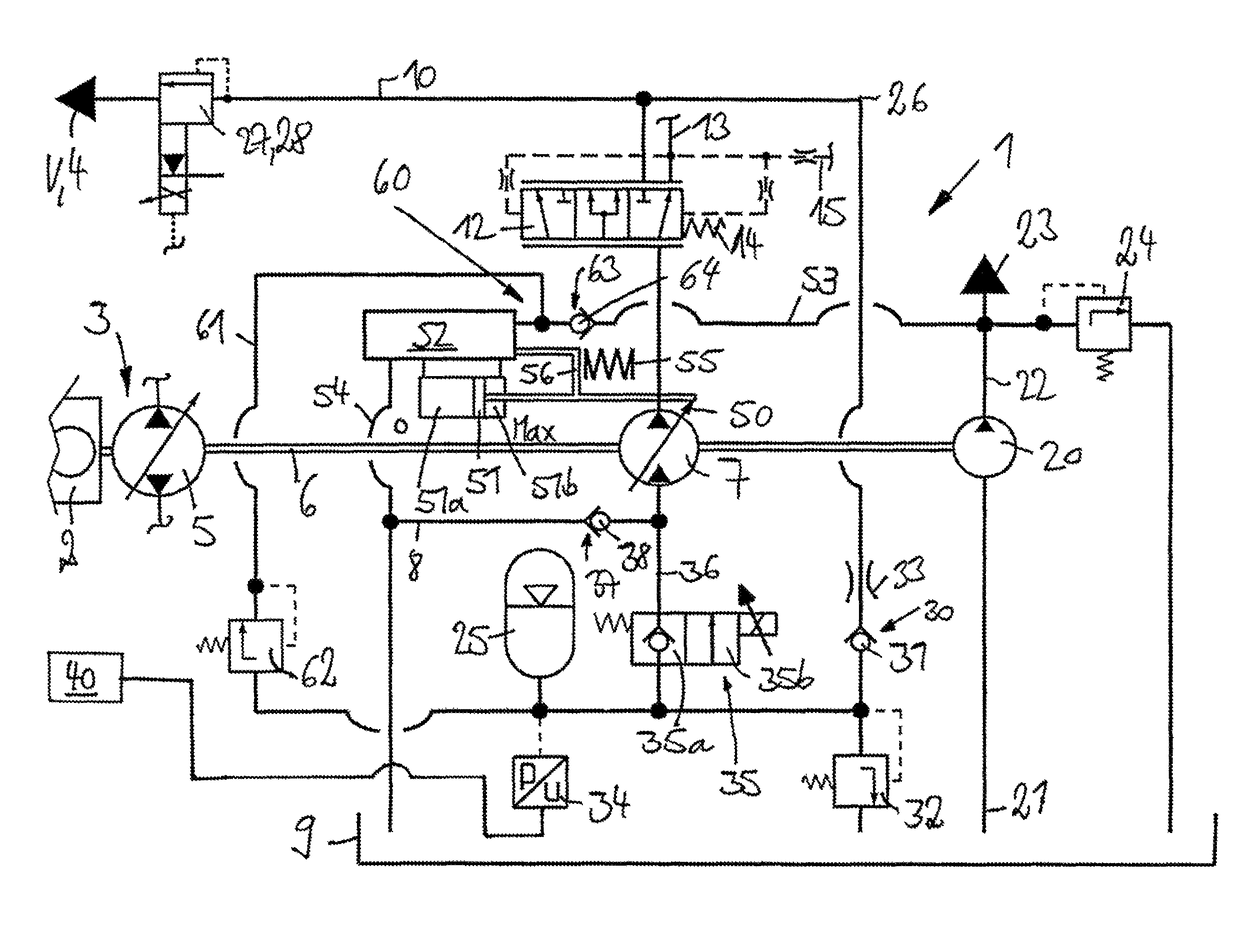

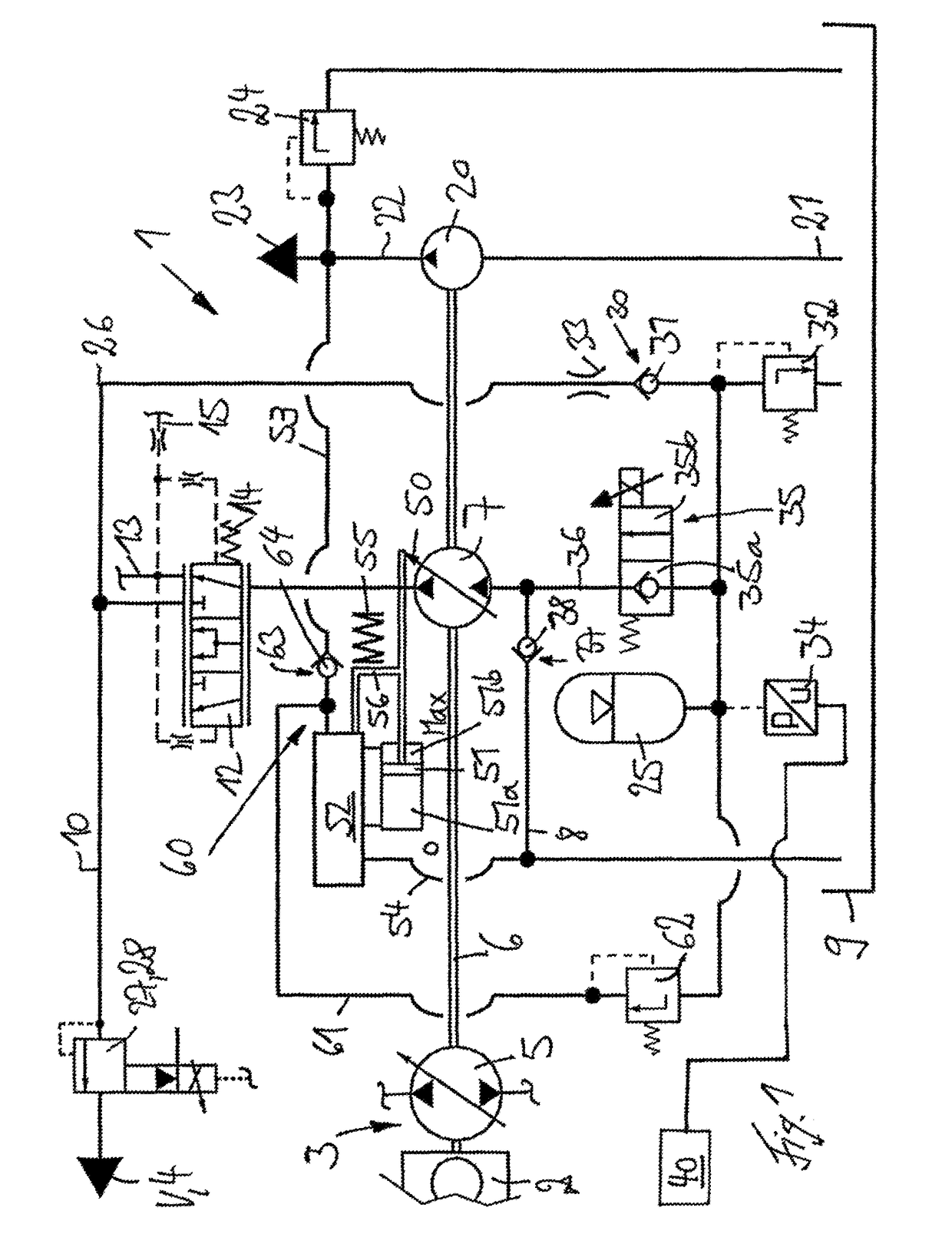

Hydrostatic power unit as hydraulic starter of an internal combustion engine

InactiveUS9709046B2Improvement effortsIncrease expensesHybrid vehiclesStarters with fluid-driven auxillary enginesEngineeringHydraulic fluid

A variable displacement hydrostatic power unit (7) is in a drive connection with an internal combustion engine (2). When operated as a pump, the power unit (7) delivers hydraulic fluid to at least one consumer (V). When operated as a motor, the power unit (7) is a hydraulic starter for the internal combustion engine (2) and is supplied with hydraulic fluid from a hydraulic accumulator (25). The displacement volume of the power unit (7) is set by a displacement volume control device (50) actuated by a positioning device (52). The displacement volume control device (50) is displaced into a position with maximum displacement volume by a corresponding actuation of the positioning device (52) chronologically prior to the shutoff of the internal combustion engine (2). A securing device (60) holds the displacement volume control device (50) in the maximum displacement volume position when the internal combustion engine (2) is shut off.

Owner:LINDE HYDRAULICS

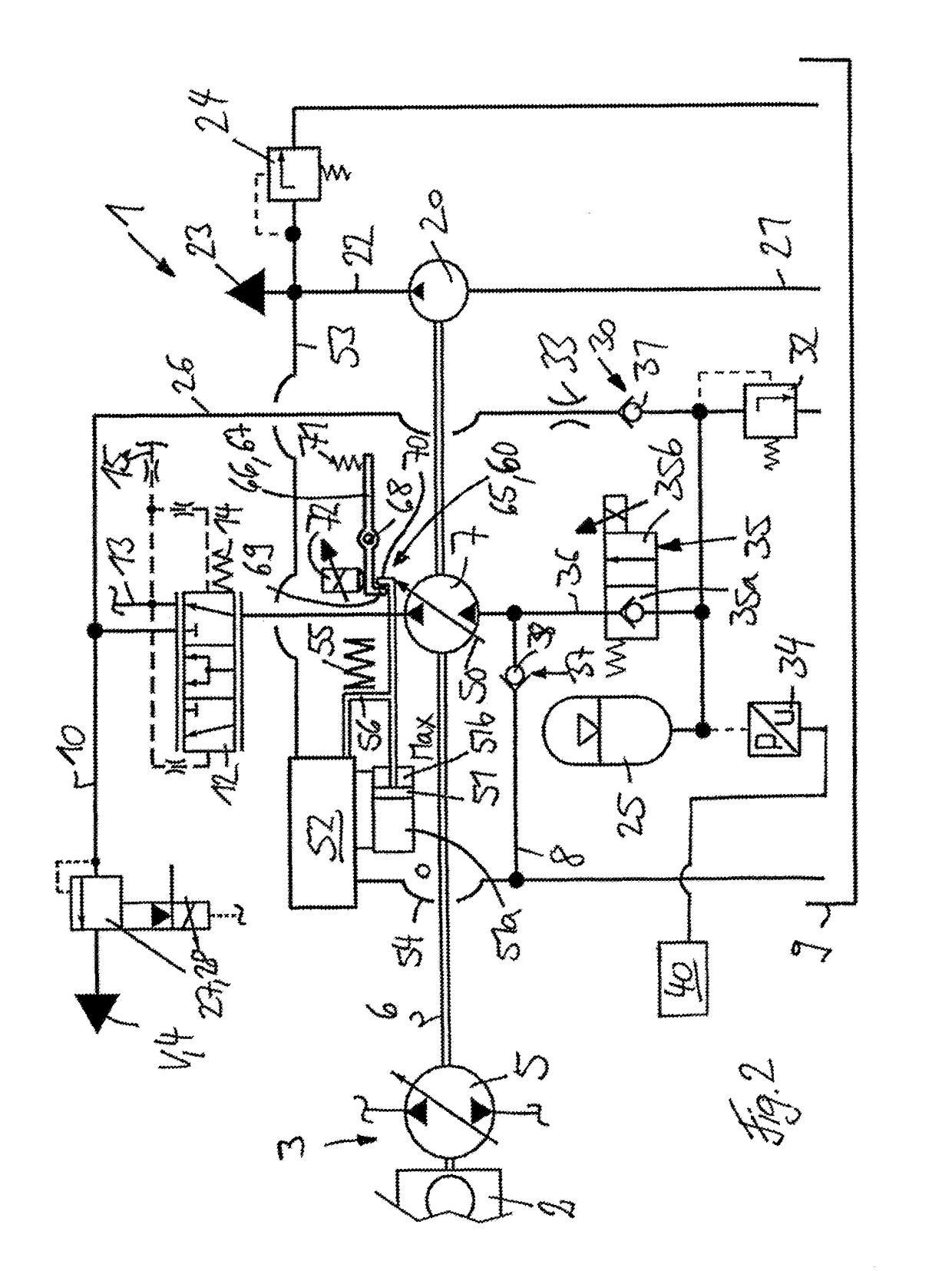

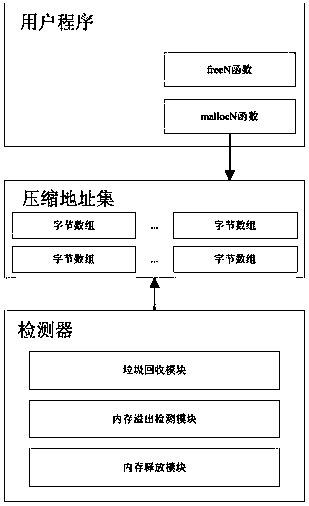

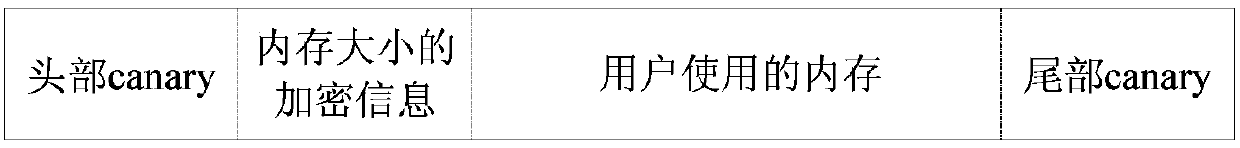

Method for dynamically detecting memory overflow on GPU based on address compression technology

ActiveCN107908954AAvoid decompressionMemory adressing/allocation/relocationPlatform integrity maintainanceArray data structureByte

The invention relates to detection on memory overflow in the field of GPU security, and in particular relates to a method for dynamically detecting memory overflow on a GPU based on an address compression technology. The method disclosed by the invention comprises the steps of: enabling a user program to distribute a memory by using a mallocN function, inserting a canary, compressing an address ina compression address set composed of multiple byte arrays, and marking the memory to be released by using a freeN function; and performing garbage collection or dynamic capacity expansion of the compression address set by utilizing a garbage collection module of a detector; decompressing the address by utilizing a memory overflow detection module of the detector, and performing memory overflow check; and releasing the memory marked by the freeN by utilizing a memory releasing module of the detector. As shown in the figure 1, the system can realize memory overflow detection, which is transparent to the user program and little in performance influence when less memory is consumed.

Owner:HUNAN UNIV

Parachute with One-Way Valve Device

InactiveUS20110260004A1Avoid decompressionMaintain rigidityAircraft stabilisationParachutesPositive airway pressureEngineering

A multi-celled ram-air parachute possessing one or more internal one-way valved air passages between at least two parachute cells to maintain positive air pressure within the parachute for the purpose of maintaining shape and rigidity when less than optimal airspeed is present thereby increasing a user's control and safety.

Owner:MULLINS CHARLES MICHAEL

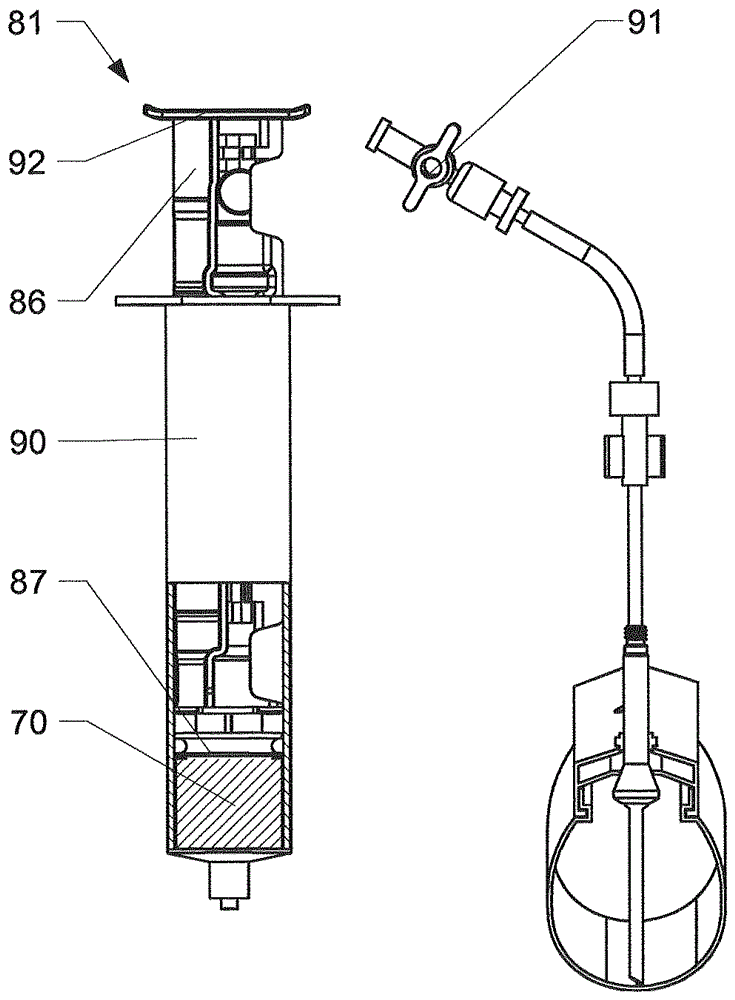

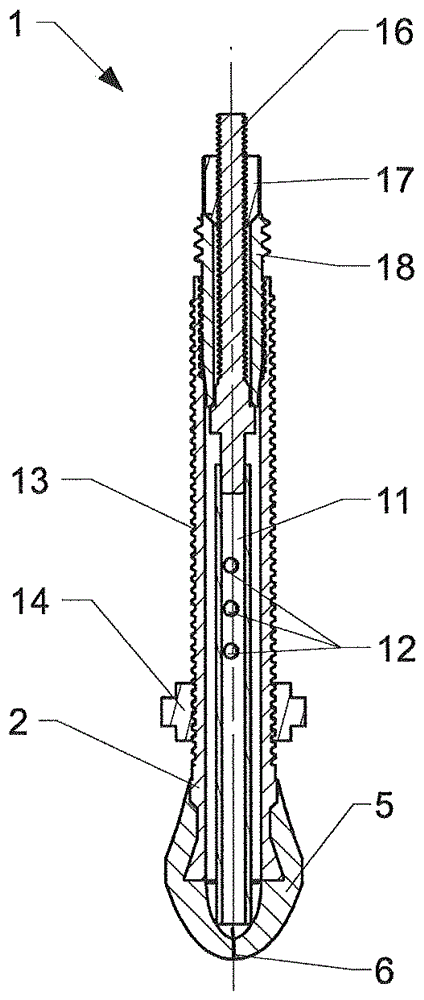

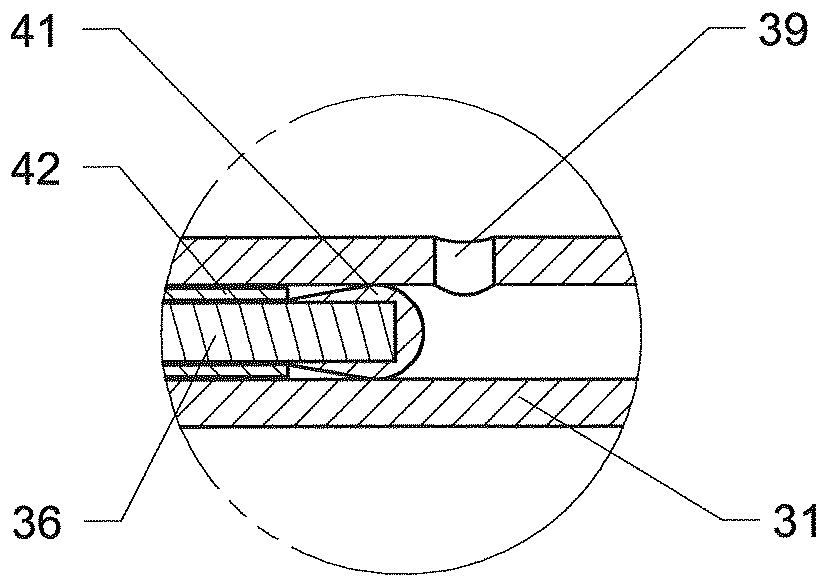

Valve for tubeless tires

ActiveCN106536233ATake your time positioningAvoid decompressionTyre-inflating valvesBicycle tyresTubeless tireSealant

The invention is directed to a valve stem system (1) for tubeless wheels. The valve stem system (1) comprises a valve stem body (2) with a first end (3) and a second end (4), wherein the second end (4) is located in a tire / rim-volume when mounted at the wheel. A first valve element (5) is arranged at the second end (4) of the valve stem body (2). The first valve element (5) is a self-sealing one-way valve. The invention further concerns a probe (30) for a valve stem system, a method to test the amount of sealant in a wheel and a refilling assembly (80) for the wheel.

Owner:SPORT COMPONENTS

Pressure relief and consolidation synergizing prevention and control method for rock burst in deep coal drift

InactiveCN102220866BAccurately determine the distributionAvoid blindnessOptical detectionBlastingCoalDeep hole

Owner:SHANDONG UNIV OF SCI & TECH

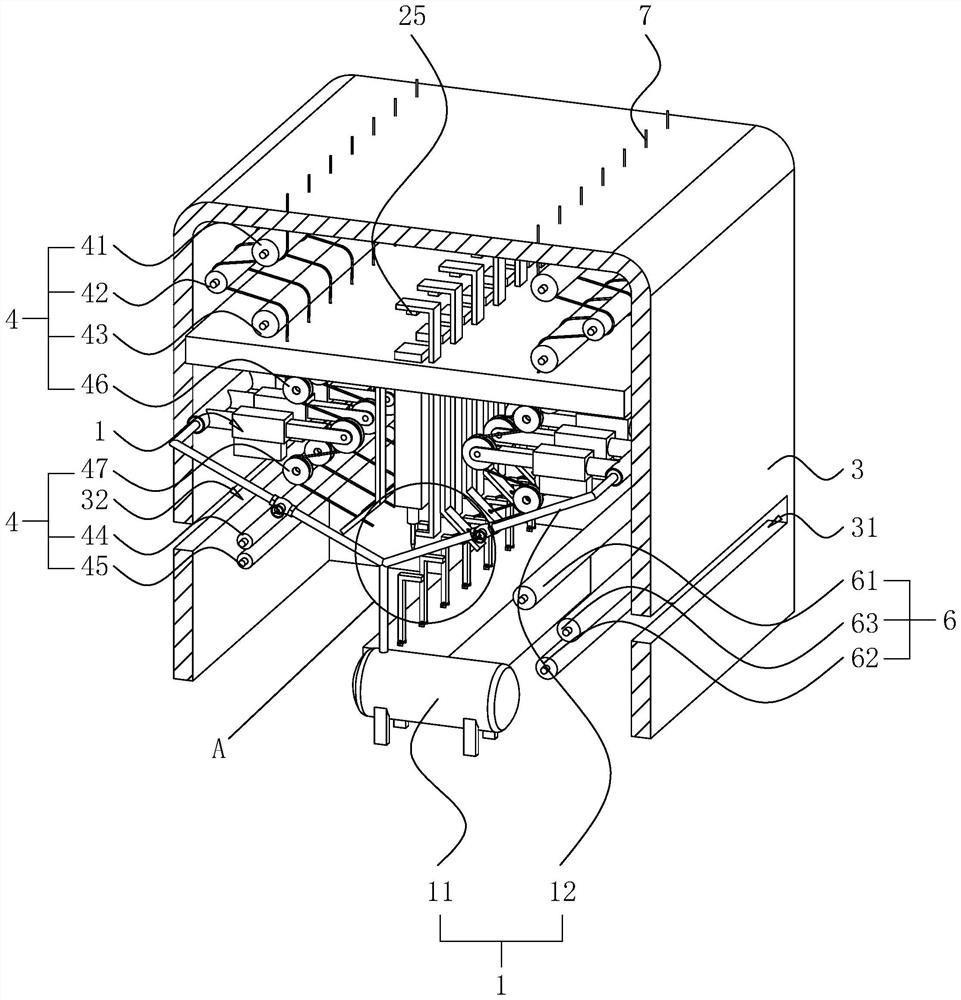

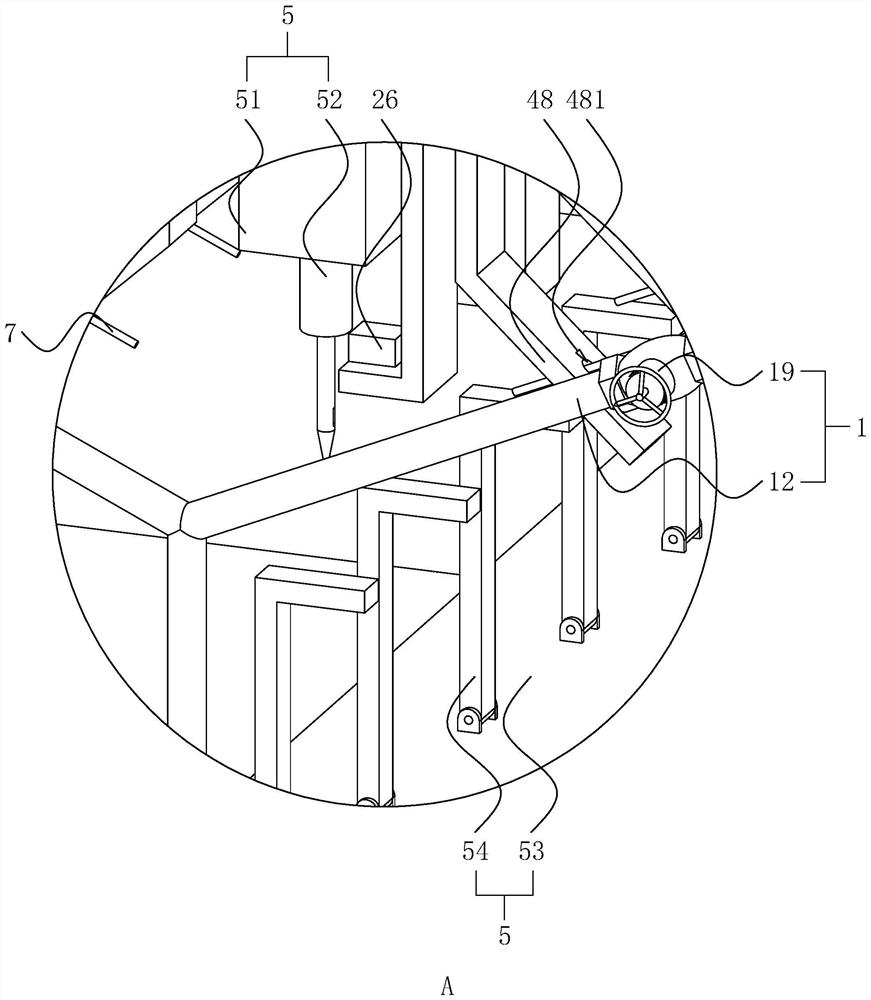

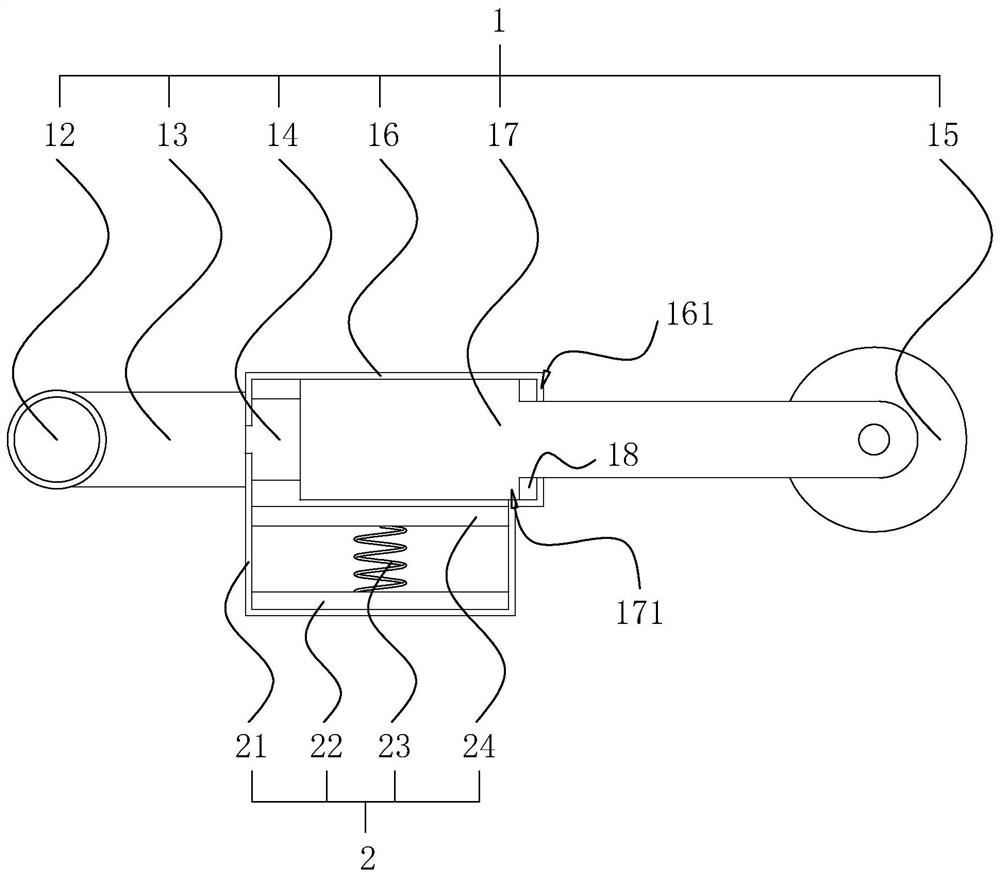

Constant-force tensioning mechanism and tufting machine

The invention relates to a constant-force tensioning mechanism and a tufting machine, and relates to the technical field of tufted carpet processing. The constant-force tensioning mechanism comprisesan air pump, a main pipe, branch pipes, pistons and a first pulley, wherein the air pipe communicates with an air outlet port of the air pump; a plurality of the branch pipes are arranged and communicate with the main pipe separately; the branch pipes are arranged in a manner of being uniformly distributed in the length direction of the main pipe; a plurality of the pistons are also arranged and form one-to-one correspondence with the branch pipes; the diameter of each piston is adaptive to the diameter of the corresponding branch pipe; each piston is slidably connected with the correspondingbranch pipe in the length direction of the corresponding branch pipe; the first pulley is connected to one end away from the main pipe, of each piston; and a fiber yarn is wound on the peripheral surface of the first pulley and in rolling connection with the first pulley. The tufting machine comprises a frame, a loading mechanism, a tufting mechanism, an unloading mechanism and the constant-forcetensioning mechanism. According to the constant-force tensioning mechanism and the tufting machine, under the action of a tufting needle and the constant-force tensioning mechanism, the fiber yarn isuniformly pulled into ring-shaped tufts on a base cloth, so that the aesthetic feeling of a tufted carpet is improved, and the durability of the tufted carpet is improved.

Owner:山东容润丰地毯有限公司

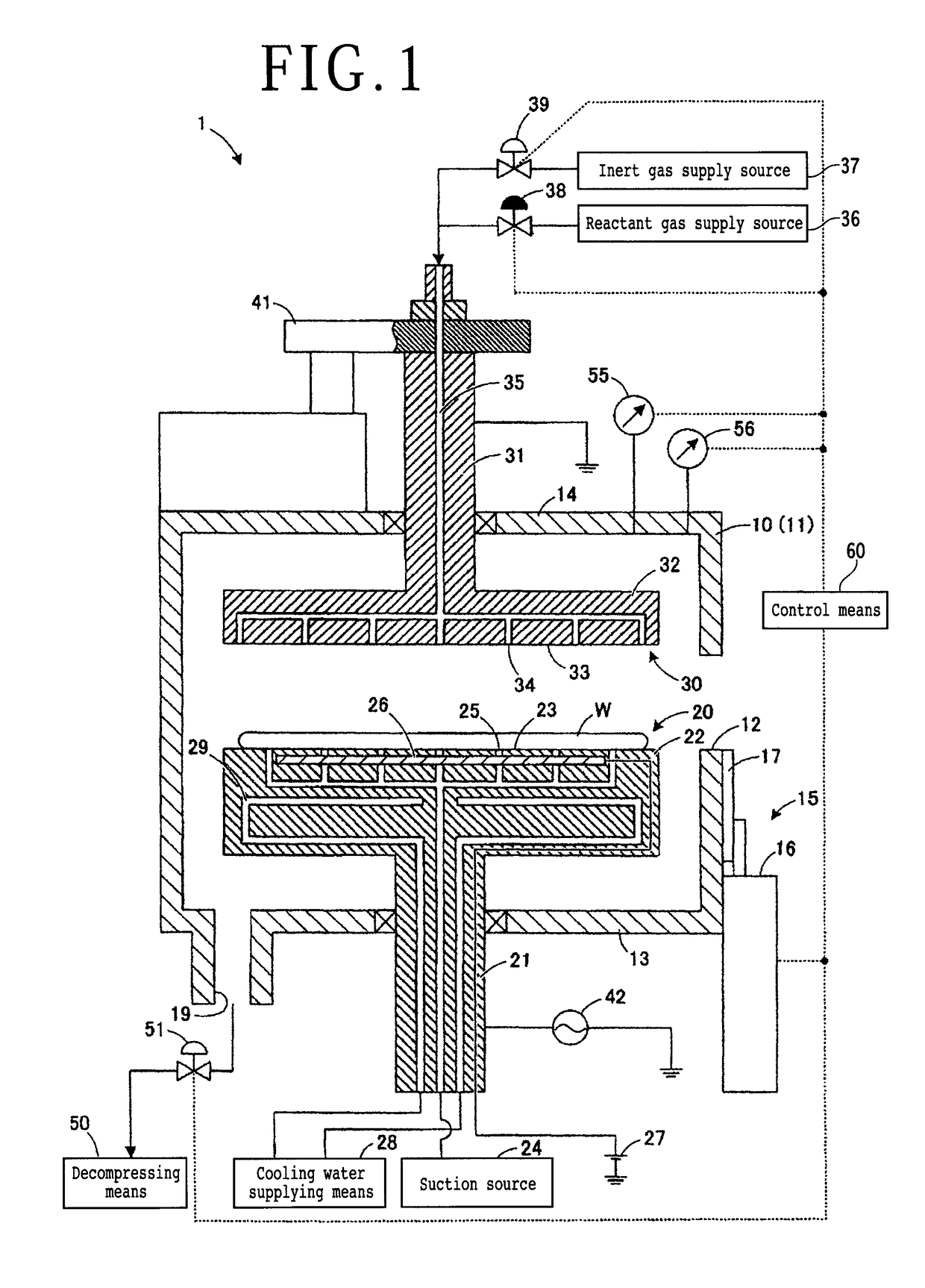

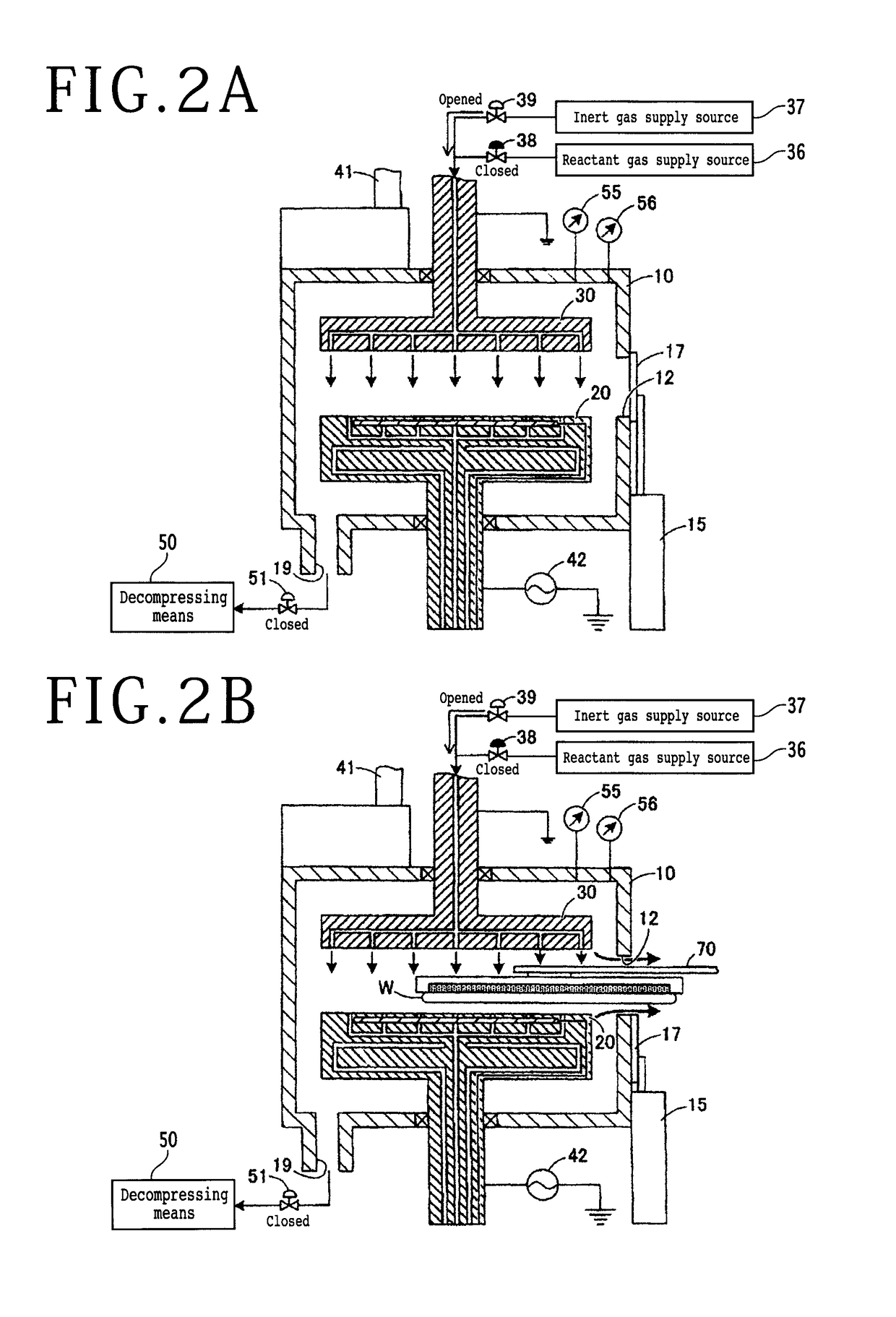

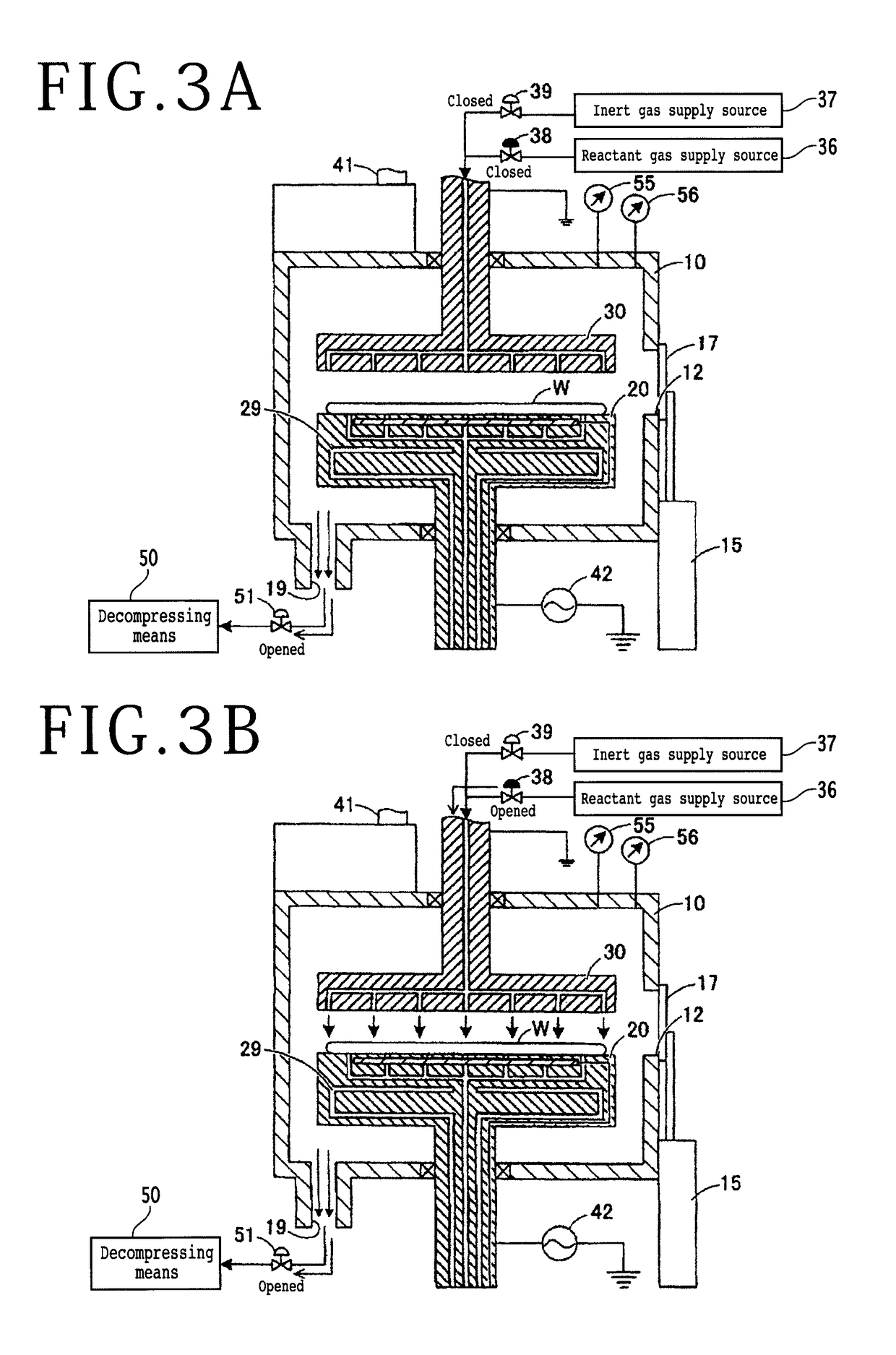

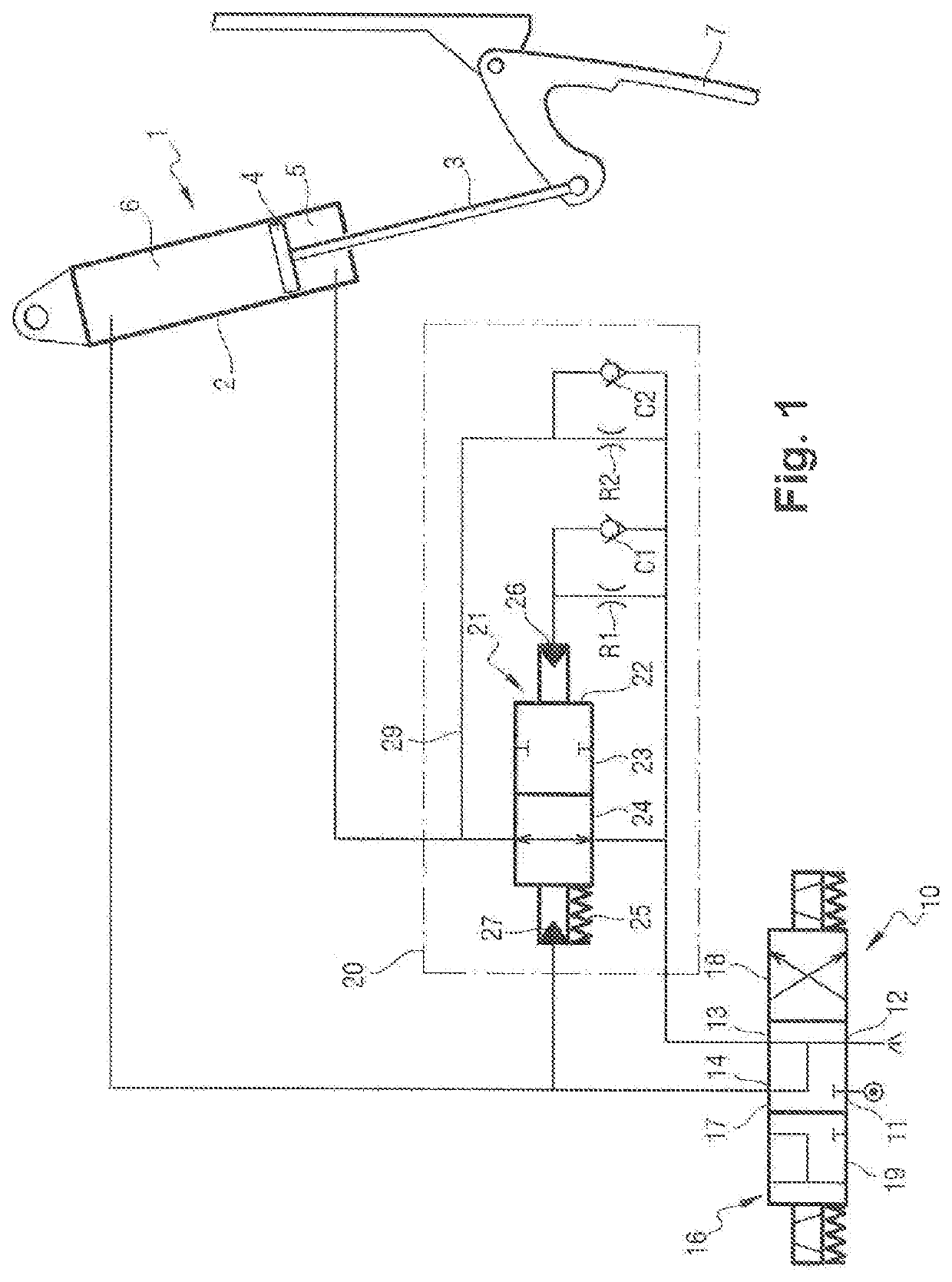

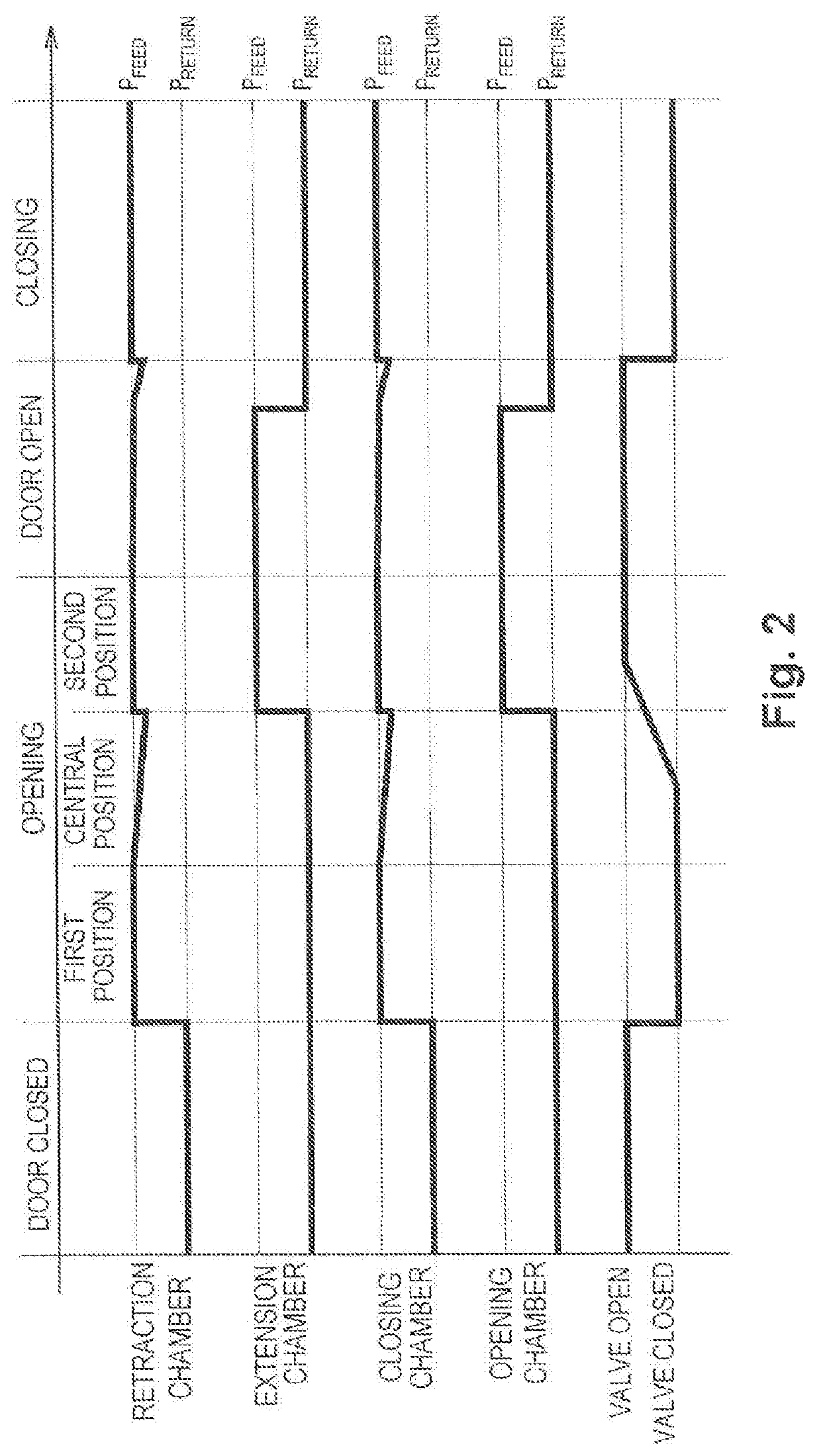

Decompression processing apparatus

ActiveUS10175588B2Shorten the timeAvoid it happening againSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringElectrical and Electronics engineering

Disclosed herein is a decompression processing apparatus for processing a wafer in a decompressed state including a chamber having a decompressing unit configured to decompress the inside of the chamber, an opening and closing door configured to open and close a carrying-in-and-out opening for carrying the wafer into and out of the chamber, and an inert gas supply source configured to supply an inert gas to the inside of the chamber. The inside of the chamber is maintained in a dry state by continuing to supply the inert gas in a state in which the opening and closing door is opened.

Owner:DISCO CORP

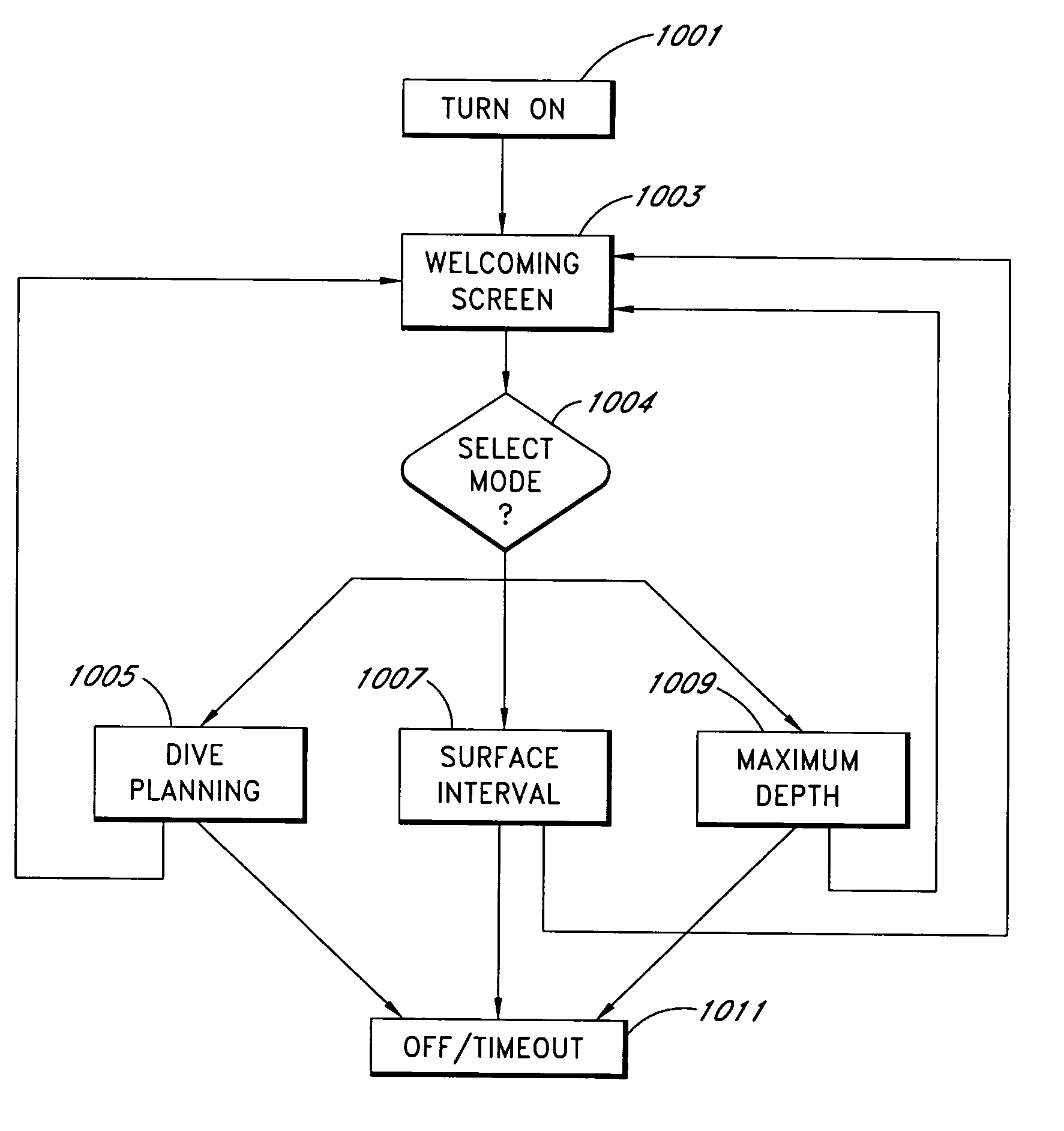

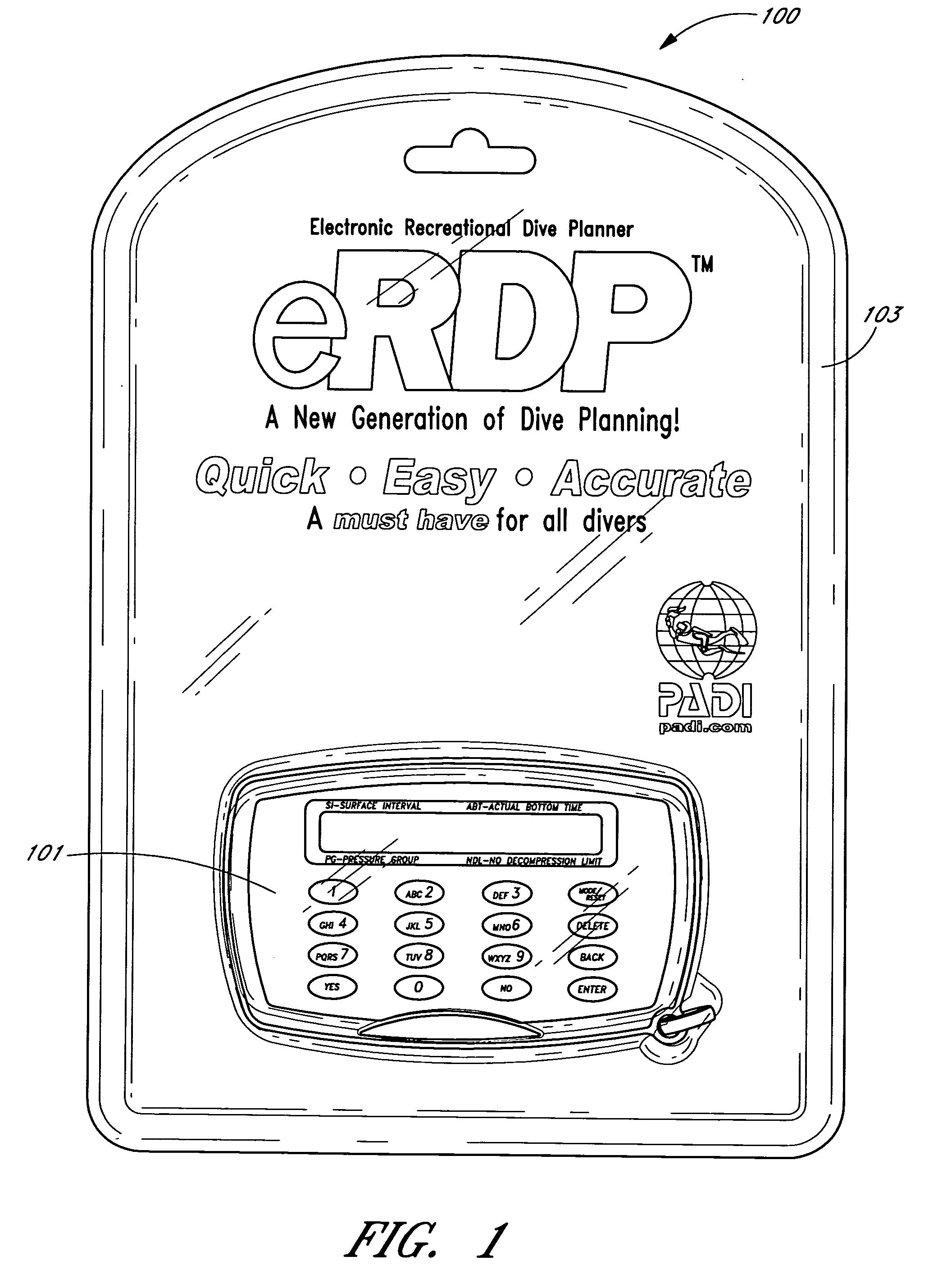

Systems and methods for electronic dive table planner

InactiveUS20070277628A1Low costEasy to useMachines/enginesLubrication indication devicesDecompression sicknessTime limit

Aspects of the present disclosure include an easy to use electronic no-decompression table for use in recreational dive planning in order to avoid decompression sickness. In one embodiment, the electronic no-decompression calculator is a portable handheld unit. The user is requested to enter at least one relevant piece of information about a dive and that information is used to automatically compute depth, bottom time, and surface interval time limits as well as pressure group categorizations. In one embodiment, an information tablet is provided with information relevant to planning a dive.

Owner:DAKA DEVMENT HONG KONG +1

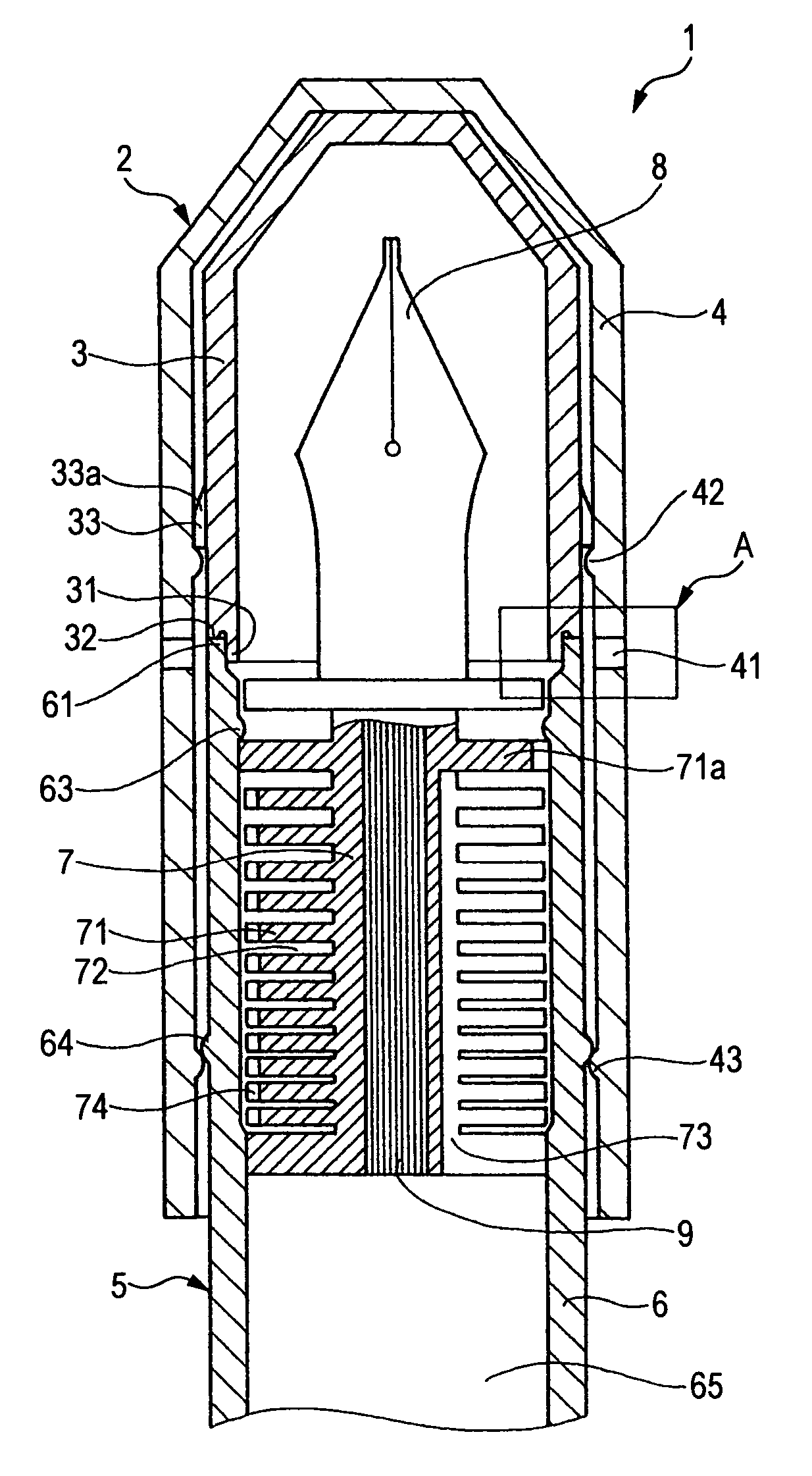

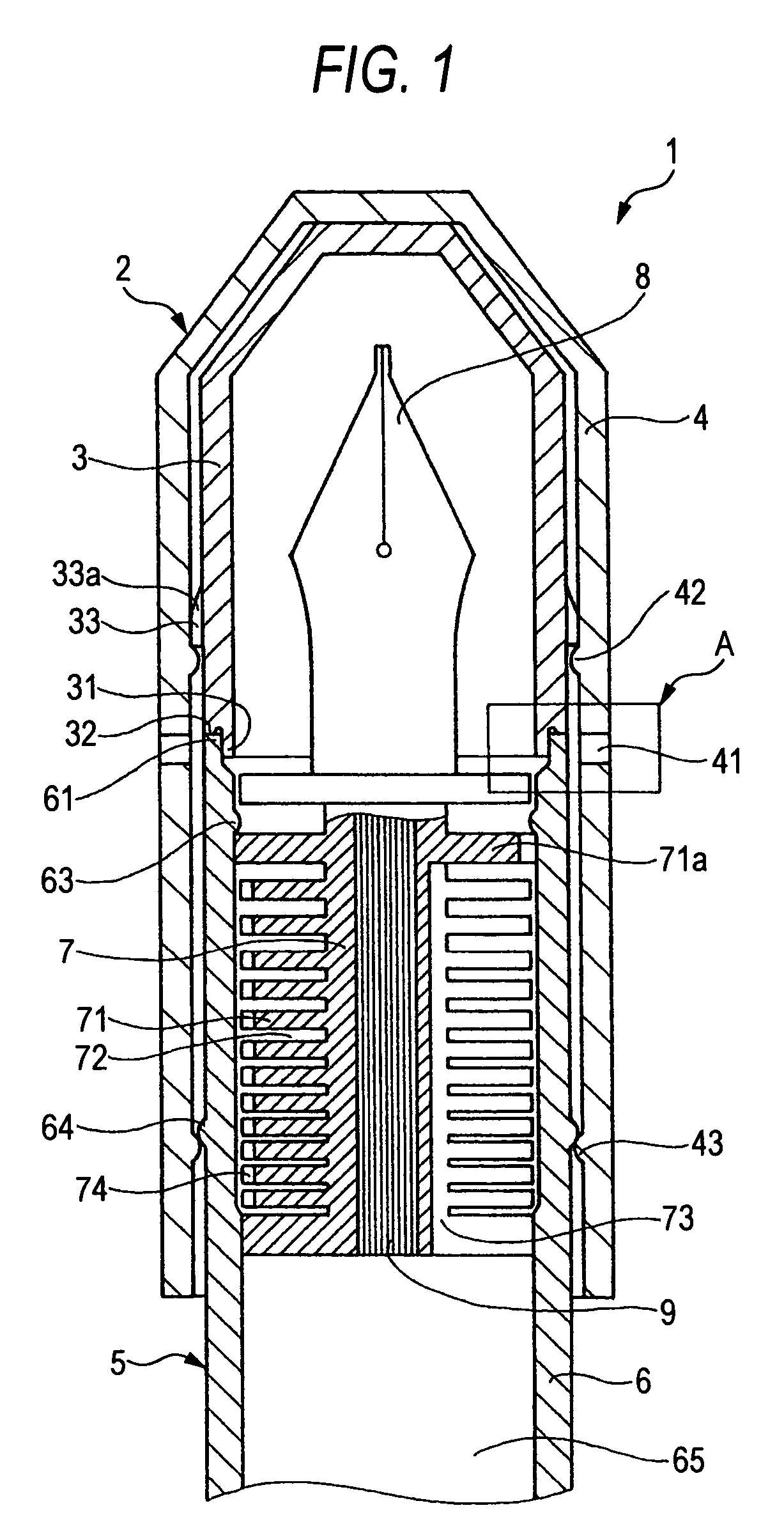

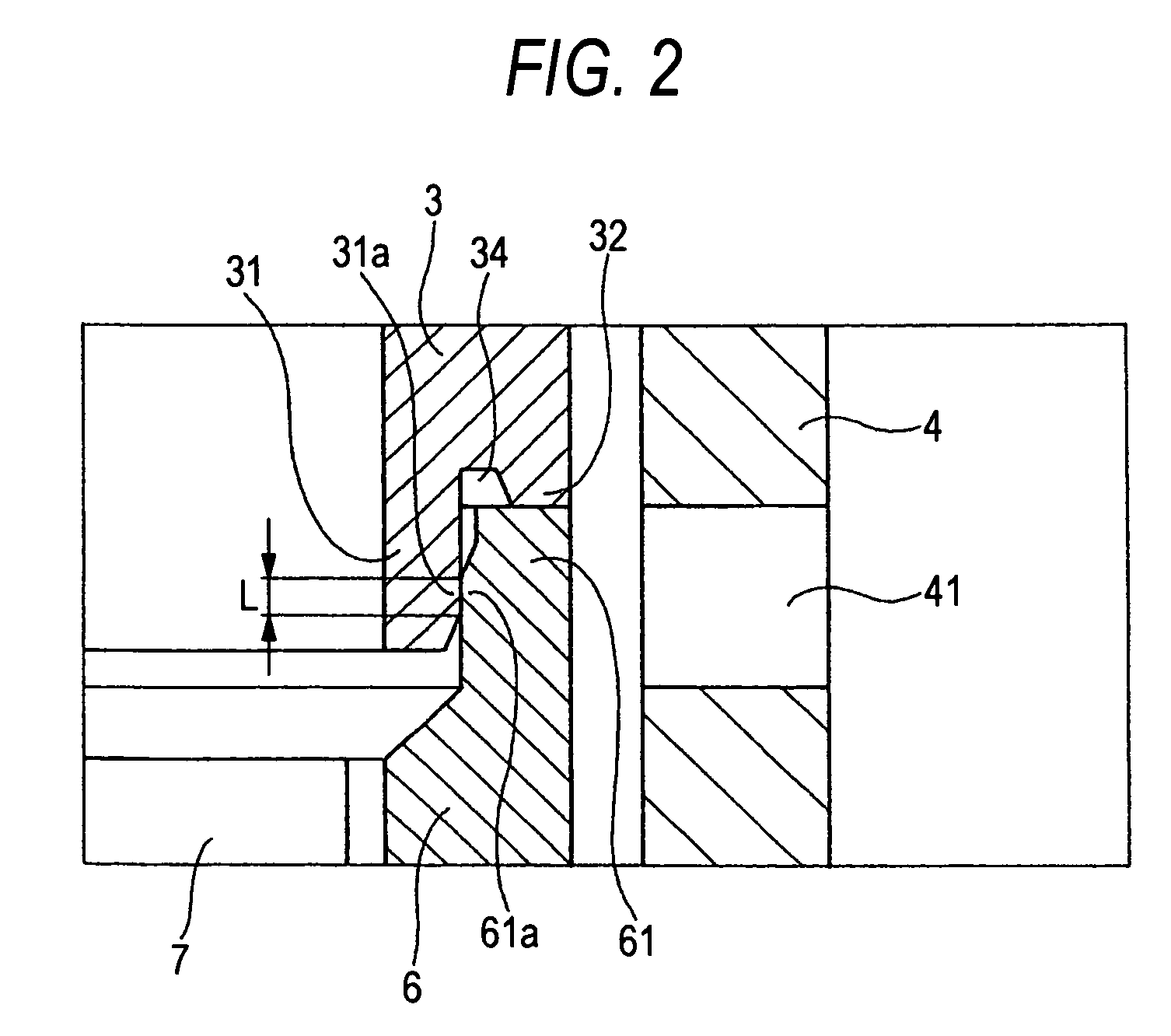

Writing implement

ActiveUS7942598B2Avoid damagePressurization of the air in the inside of the cap can be avoided sufficientlyWriting connectorsBall-point pensFace sealEngineering

The outer surface of an inner cap 3 is fixedly secured to the inner surface of an outer cap 4. In the opened end portion of the inner cap 3, there is formed a rear end shell portion 31 which projects backwardly. On the outer peripheral surface of the rear end shell portion 31, there is provided a ring-shaped outward facing seal portion. In the front end portion of a barrel 6, there is formed a front end shell portion 61 projecting forwardly. In the inner peripheral surface of the front end shell portion 61, there is formed a ring-shaped inward facing seal portion. When a cap 2 is mounted on the pen tip 8 side of the barrel 6, the outward facing seal portion can be closely contacted with the inward facing seal portion in the radial direction.

Owner:THE PILOT INK CO LTD

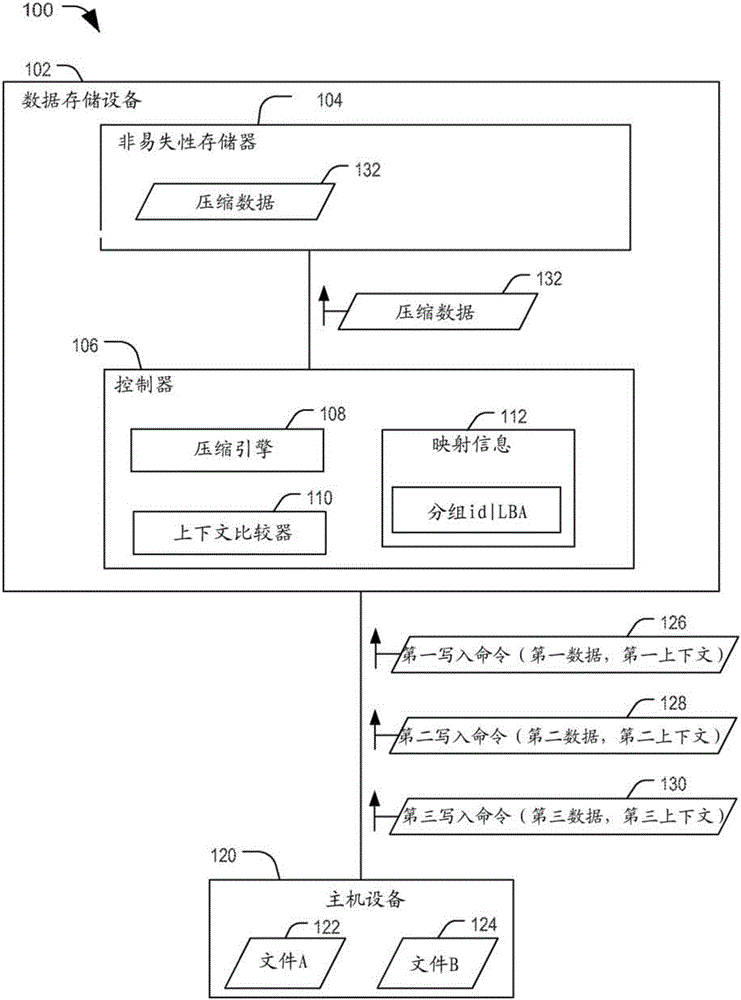

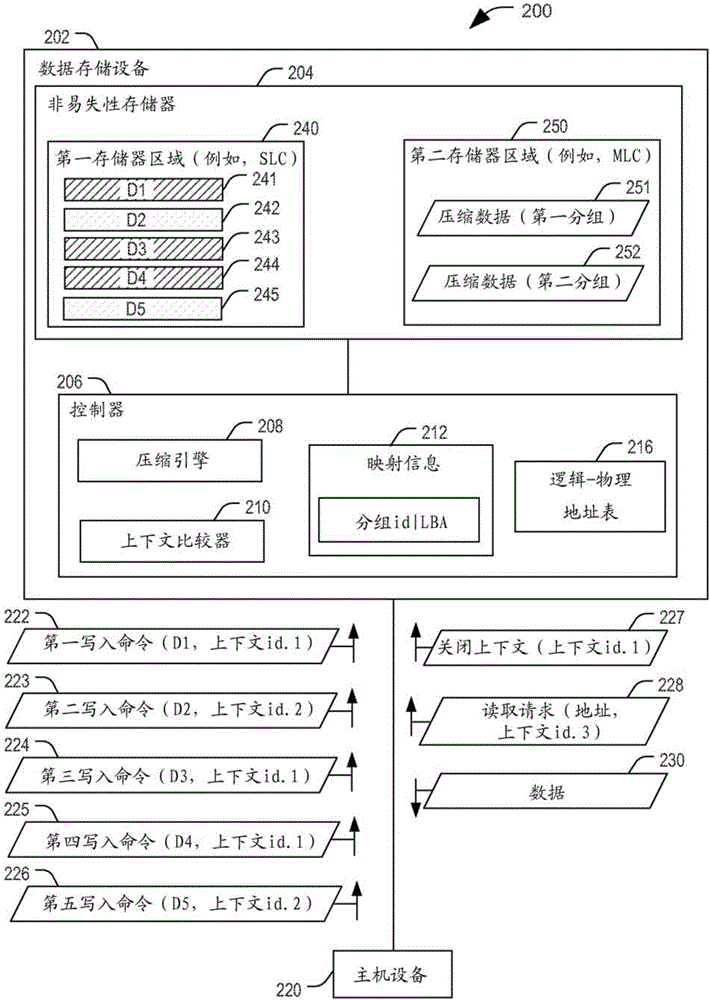

Systems and methods of compressing data

ActiveCN105874420AAvoid decompressionEfficient use ofInput/output to record carriersMachine learningTheoretical computer science

Owner:SANDISK TECH LLC

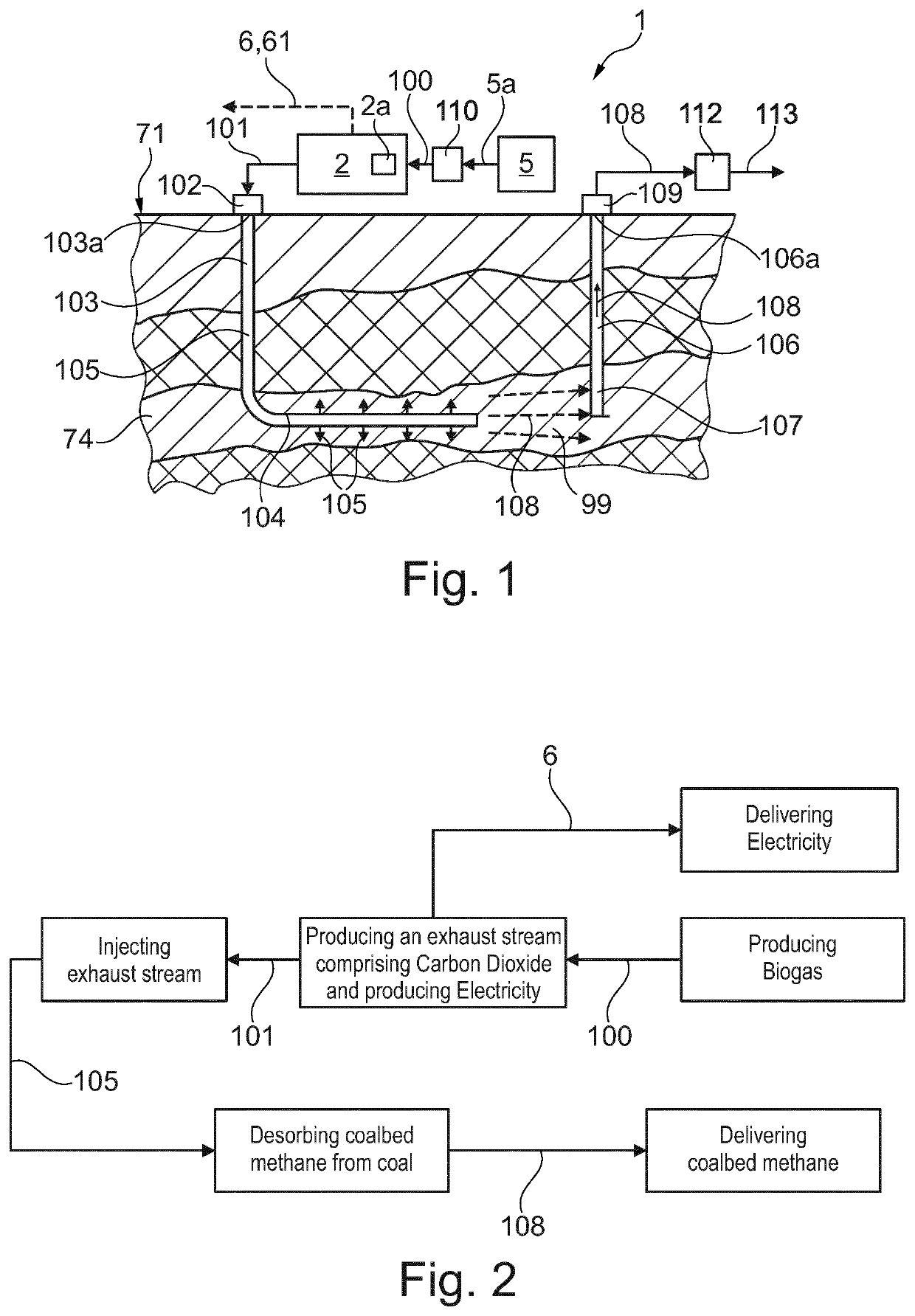

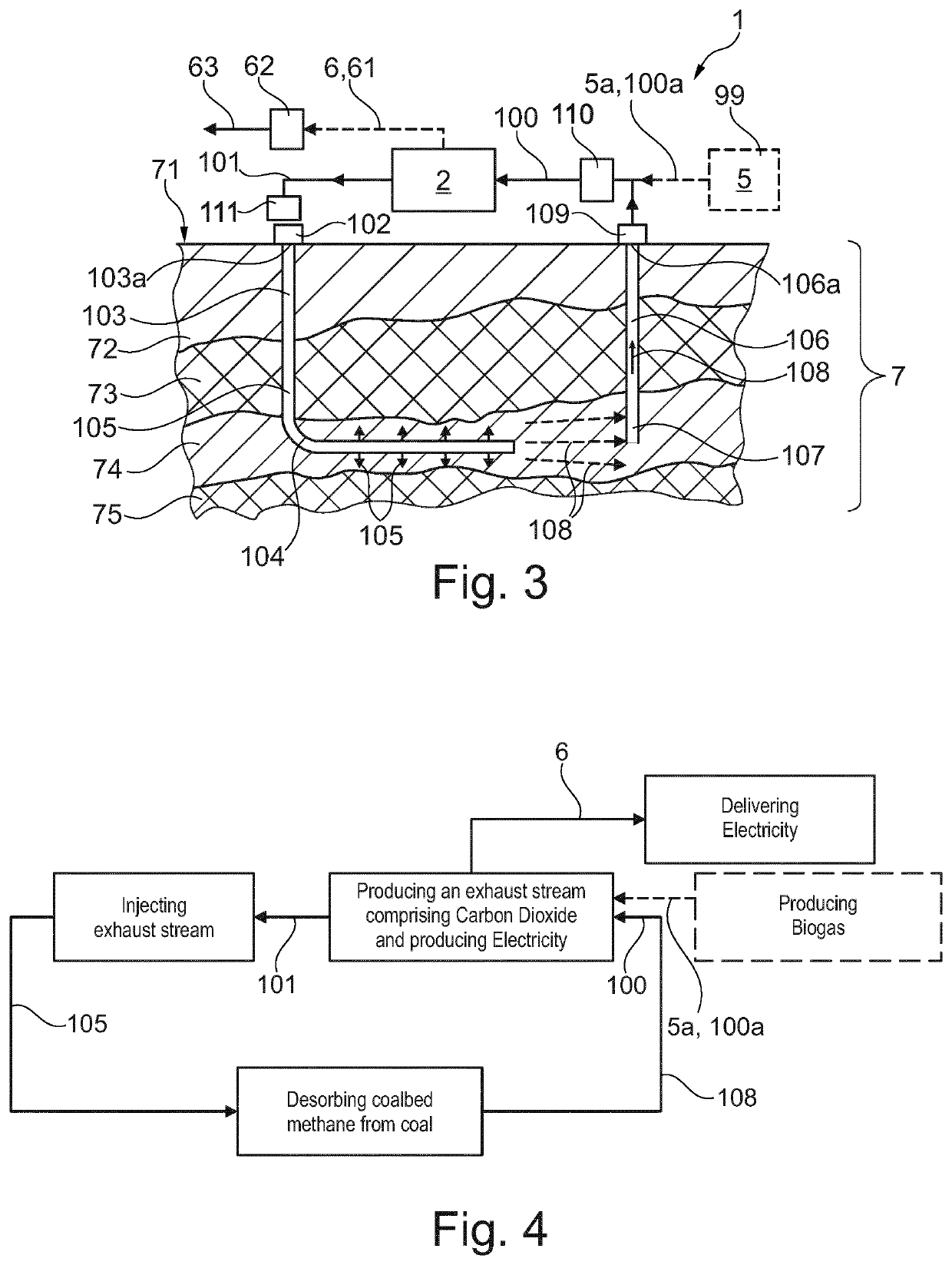

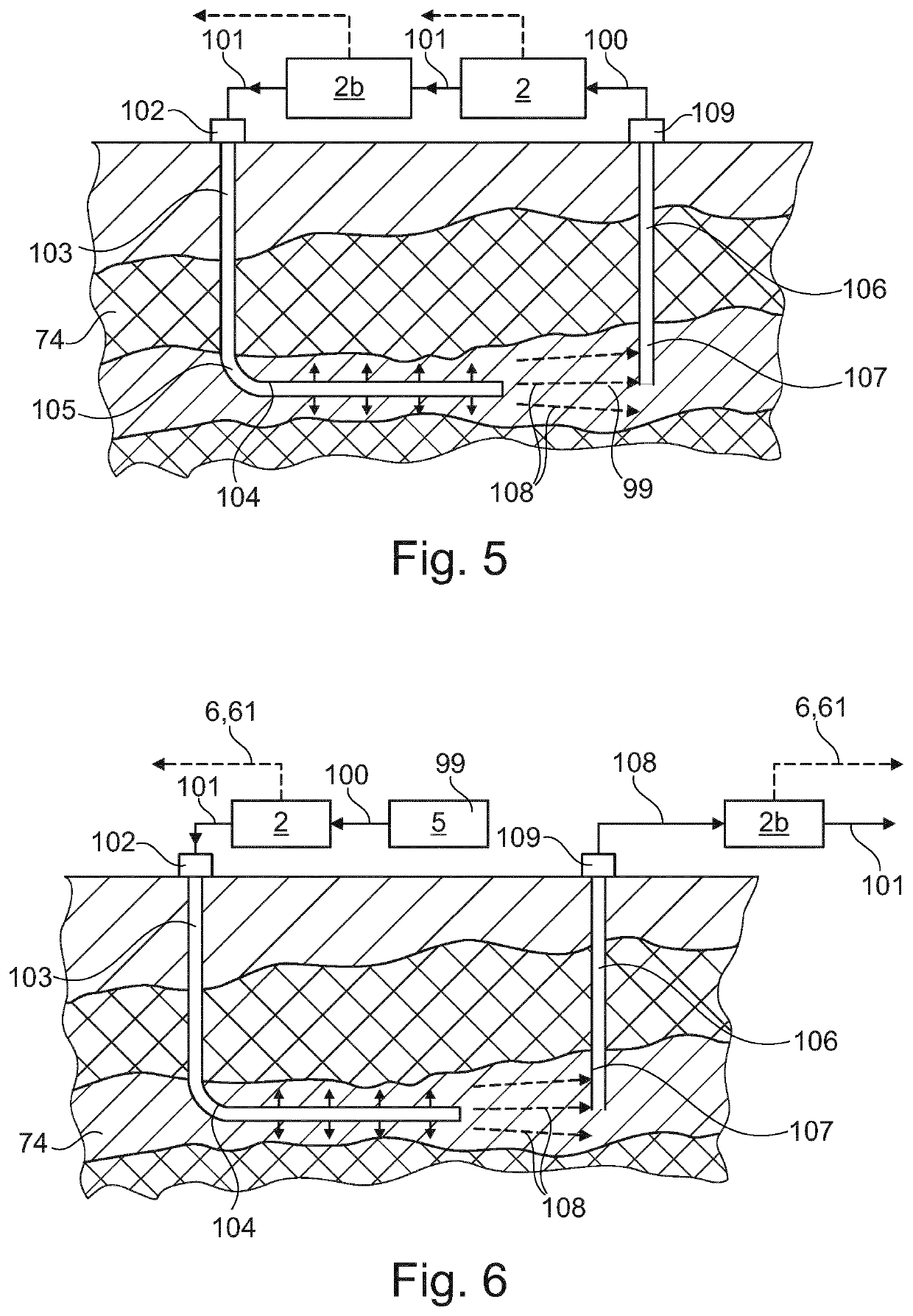

Method and system for removing carbon dioxide

PendingUS20210331115A1Reduce the amount of solutionKeep for a long timeGas treatmentElectrolysis componentsThermodynamicsFuel cells

The method and system for removing CO2 from the atmosphere or the ocean having the steps of, feeding a solid oxide fuel cell (SOFC) system with a gaseous hydrocarbon feed, converting the gaseous hydrocarbon feed in the SOFC system into an anode exhaust stream having carbon dioxide CO2, the SOFC system thereby producing electricity; injecting the anode exhaust stream as an injection gas into an underground coal bed; in the underground coal bed the injection gas causing coal bed methane (CBM) to desorb from the coal and CO2 to adsorb onto the coal; extracting the coal bed methane (CBM) from the underground coal bed; and discharging a production gas having the coal bed methane (CBM) from the underground coal bed.

Owner:EZ ENERGIES GMBH

Data broadcast method

InactiveUS20100153987A1Small bandwidthReduce bandwidth requirementsTelevision system detailsPulse modulation television signal transmissionData setData transformation

A system for providing requested data sets of broadcast data service transmitted as part of a broadcast signal, including a broadcast headend configured to receive a data request from a receiver, and configured to broadcast requested data sets to the receiver in response to the data request from the receiver, a processor configured to periodically extract all of the requested data sets of the broadcast data service from a broadcast carousel included in the broadcast signal, a memory configured to store all of the requested data sets of the broadcast data service, defining a plurality of digital-audio / video-data-sets including television clips, a first controller configured to allow selection from a list of the plurality of sets of the digital-audio / video-data-sets, and a second controller responsive to a user initiated selection signal to cause the memory to output a user selected one of the plurality of digital-audio / video-data sets selected from the list, wherein the processor converts the digital-audio / video-data of the requested data sets of the broadcast data service into real time audio / video data.

Owner:SONY EUROPE BV

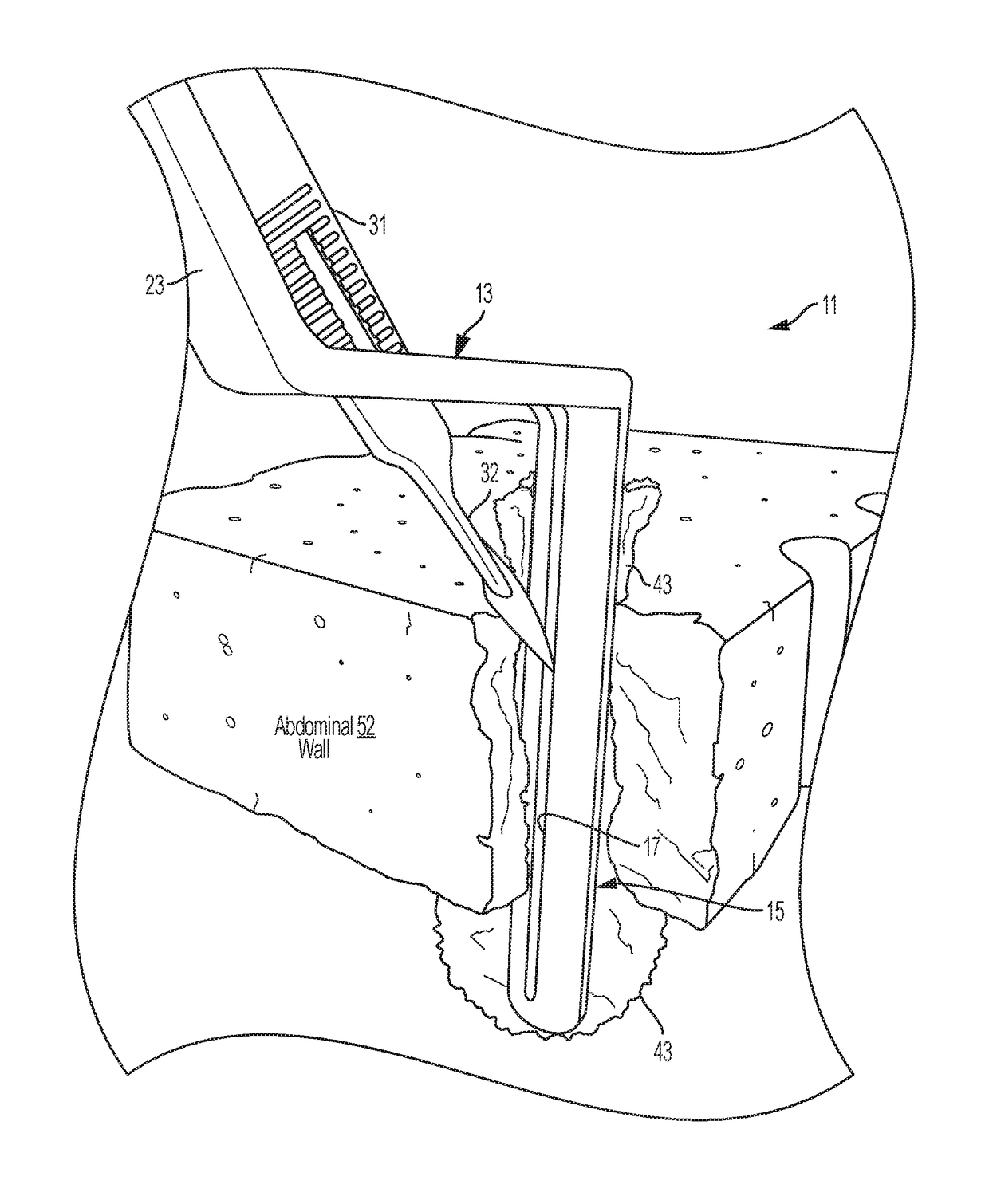

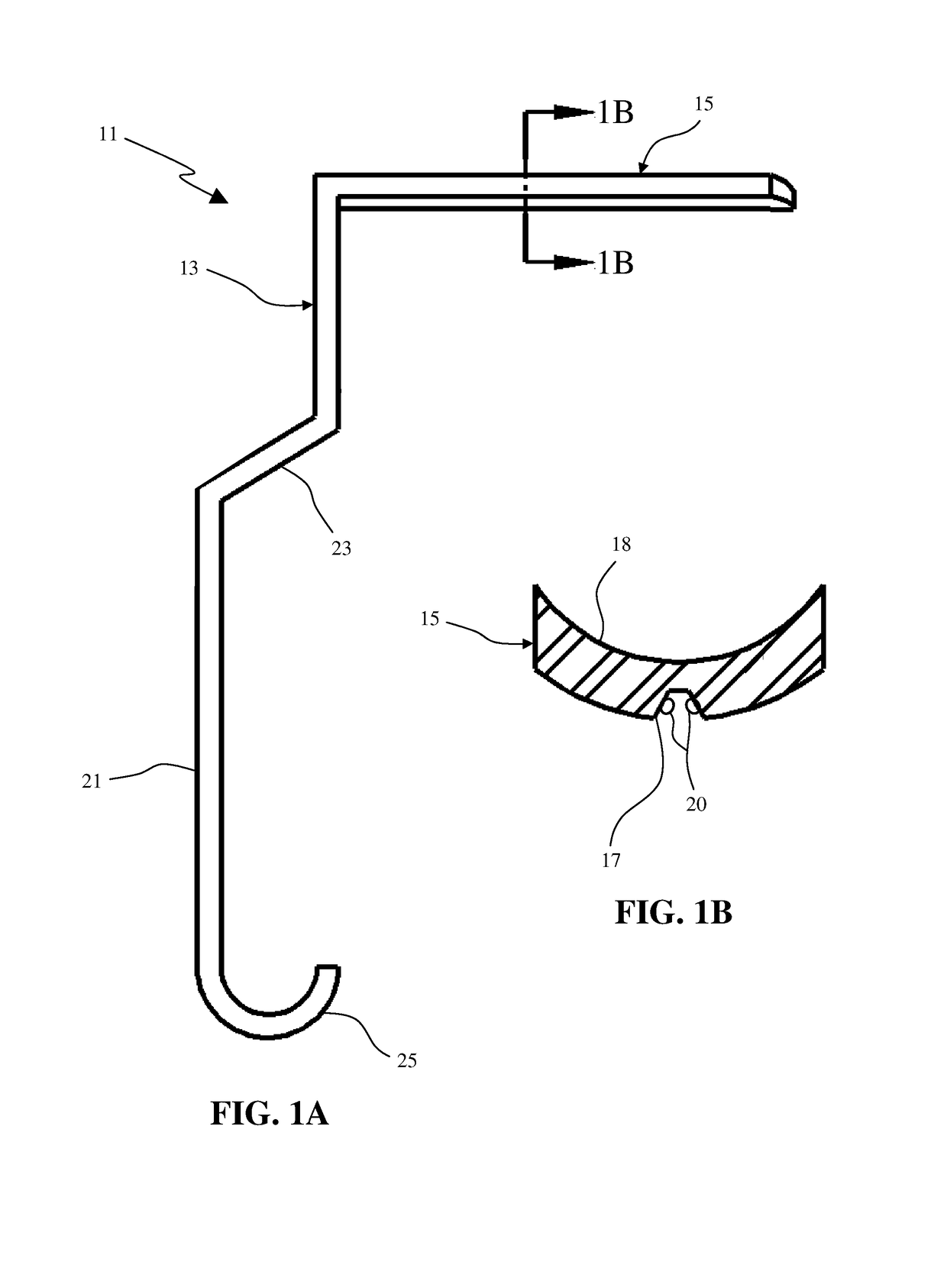

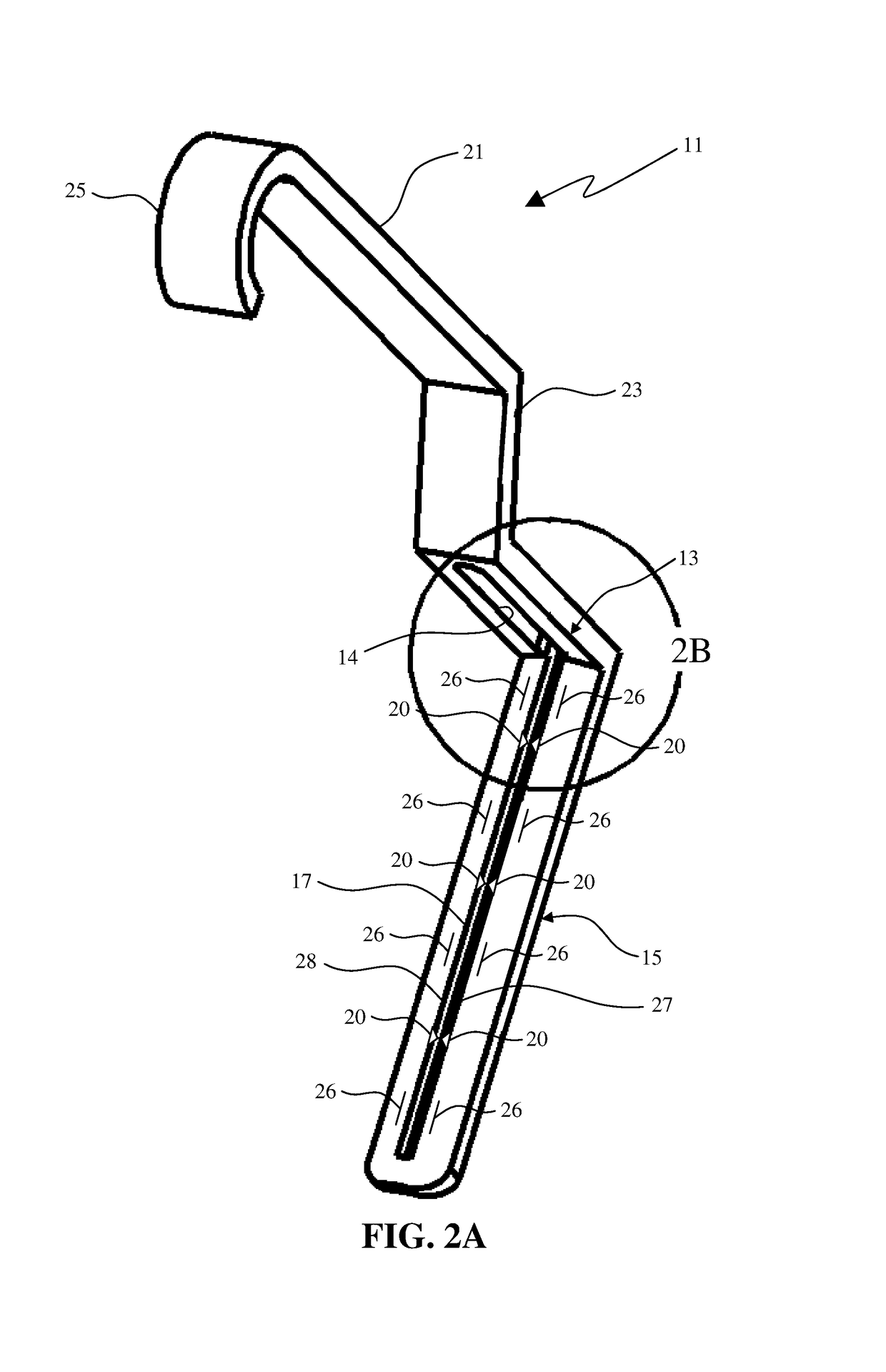

Device and method for safely expanding minimally invasive surgical incisions

An insertion tongue of the retractor device may be pushed into the subject through the trocar incision, along one side of the organ. The tip of the insertion tongue pushes the impacted organ and its endoscopic recovery bag slightly away from the cavity wall. A scalpel is passed through the insertion guide with the tip of the scalpel blade in the retention guide on the back of the insertion tongue, and with the sharp side of the scalpel blade facing away from the organ and from the tongue of the retractor device. The scalpel is then passed down through the cavity wall, with its tip in the retention guide, while tension on the retractor device handle away from the organ, and gentle outward traction on the organ (and bag) permits removal of the organ (and bag) as soon as the opening is just large enough to allow it.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com