Valve for tubeless tires

A technology for tires and inner tubes, applied in tire inflation valves, tire parts, transportation and packaging, etc., can solve problems such as unclear sealants, and achieve the effect of compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

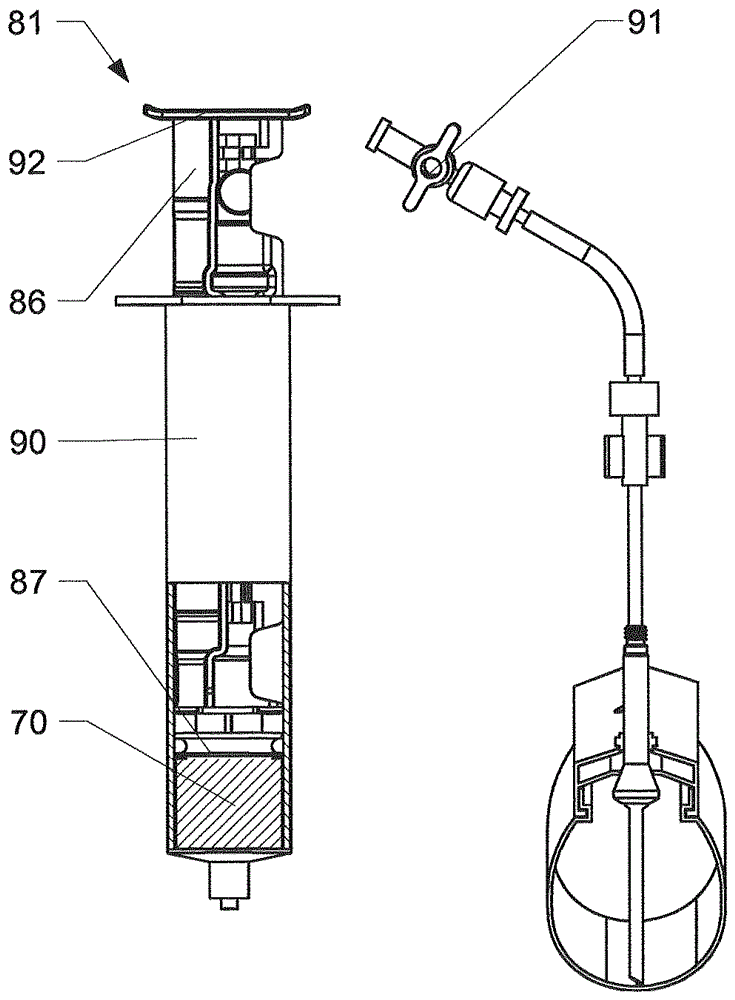

[0094] figure 1 An embodiment of a valve stem system 1 is shown mounted on a wheel rim 50 (in particular a tubeless wheel) comprising a mounted tire 60 . The tire 60 is filled with a sealant 70 to seal the tire. The stem system 1 protrudes towards the outer (central) surface of the rim and is fastened at the rim 50 using nuts 14 .

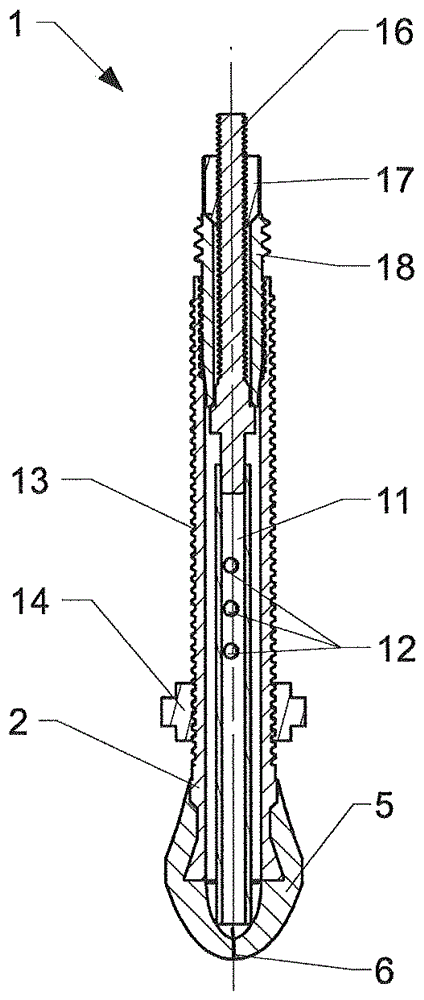

[0095] figure 2 An embodiment of a valve stem system 1 comprising a tubular valve stem body 2 and a first valve element 5 is shown. The valve stem body 2 has a first end 3 and a second end 4 connected by a passage extending through the valve body 2 in the longitudinal direction. A cap 15 is provided which is screwable at the first end 3 of the valve stem body 2 . The cover 15 protects the inner volume of the valve stem body 2 from contamination and may act as an additional sealing element to prevent the passage of pressurized gas through the valve stem body 2 . The first valve element 5 is arranged at the second end 4 of the valve stem body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com