Constant-force tensioning mechanism and tufting machine

A technology of tensioning mechanism and constant force, which is applied in the field of constant force tensioning mechanism and tufting machine, can solve the problems of reducing the durability of tufted carpets, reducing the beauty of tufted carpets, and different sizes of loop piles, so as to achieve the goal of reducing hooks. Probability of threading and opening, improving aesthetics, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

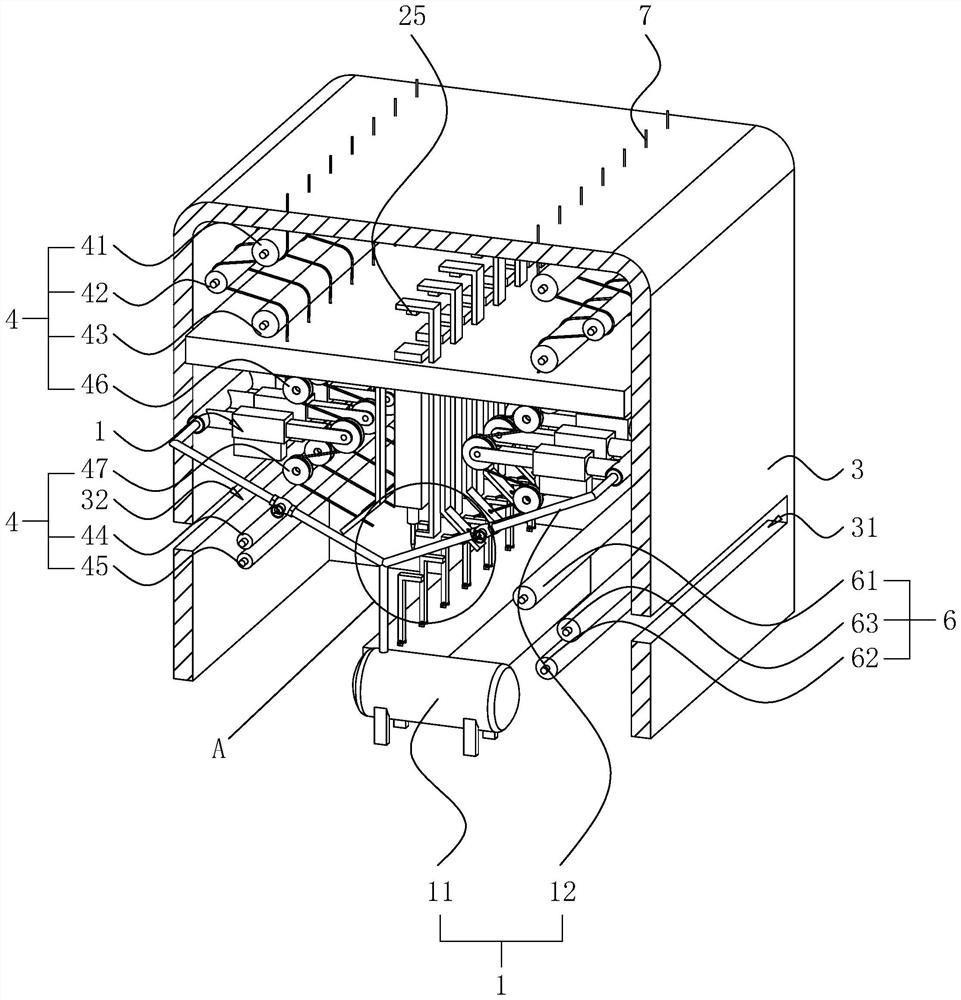

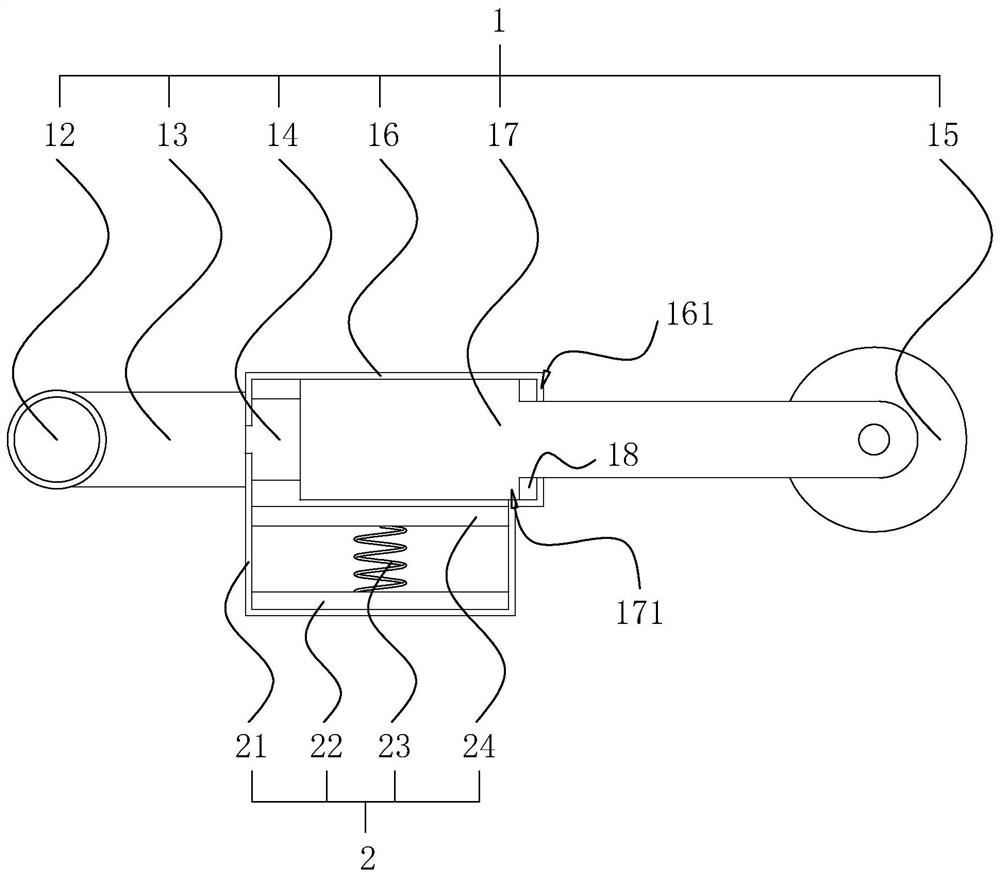

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

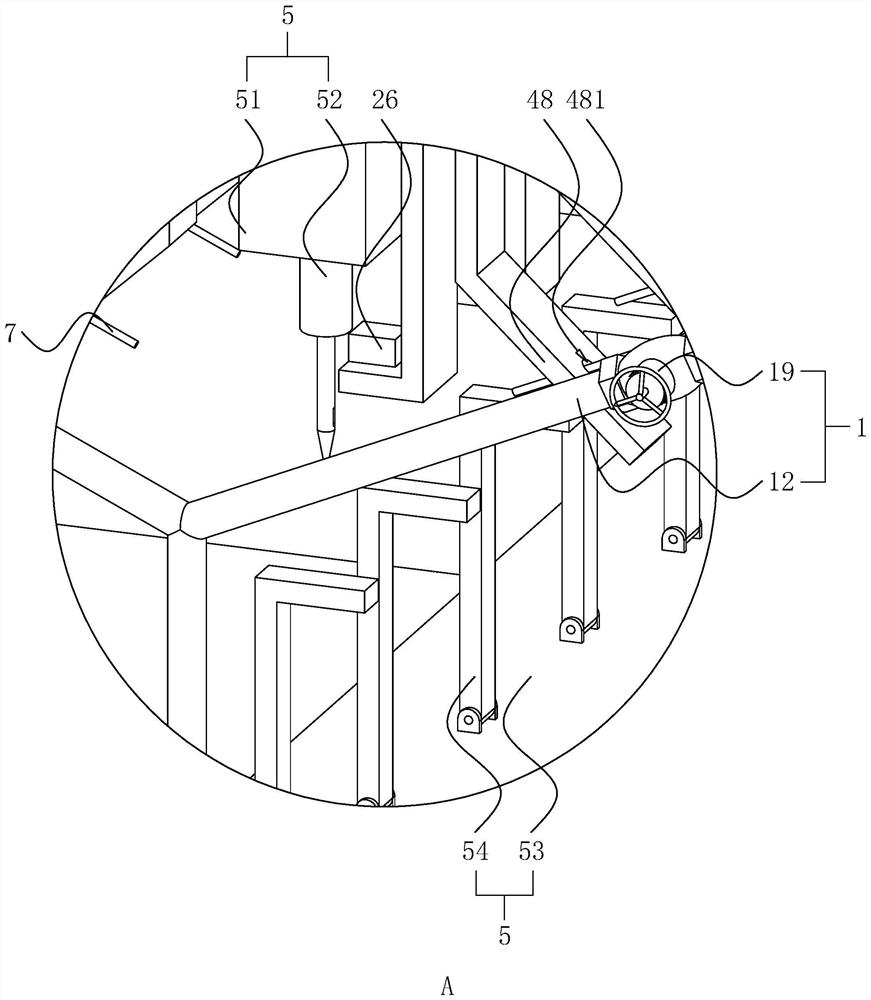

[0037] refer to figure 1 and figure 2 , the present embodiment proposes a tufting machine, comprising a support 3, on which a tufting mechanism 5 for tufting is arranged, and the tufting mechanism 5 includes a lancet seat 51, which is uniformly clamped along the length direction of itself on the lancet seat 51. A plurality of needles 52 are connected. The needle base 51 is driven by a driving device (not shown in the figure), so that the needle base 51 slides up and down with the bracket 3 along the length direction of the needle 52 .

[0038] The tufting mechanism 5 further includes a tufting needle base 53 and a tufting needle 54 , the tufting needle base 53 is arranged directly below the needle base 51 , and one tufting needle 54 corresponds to one needle 52 . The tufting needle base 53 is fixedly connected to the bracket 3 through bolts, and the tufti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com