Method for preventing hard top plate type rock burst on basis of carbon dioxide blasting

A technology of carbon dioxide and rock burst, which is applied to earthwork drilling, discharge machinery, etc., can solve problems such as high cost and potential safety hazards, and achieve the effect of simple method, good safety and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The embodiment of the present invention is illustrated by taking a certain mine in Shaanxi as an example. It is a rock burst mine. Explosive blasting was used to relieve pressure in the past. The effect is average and there are potential safety hazards.

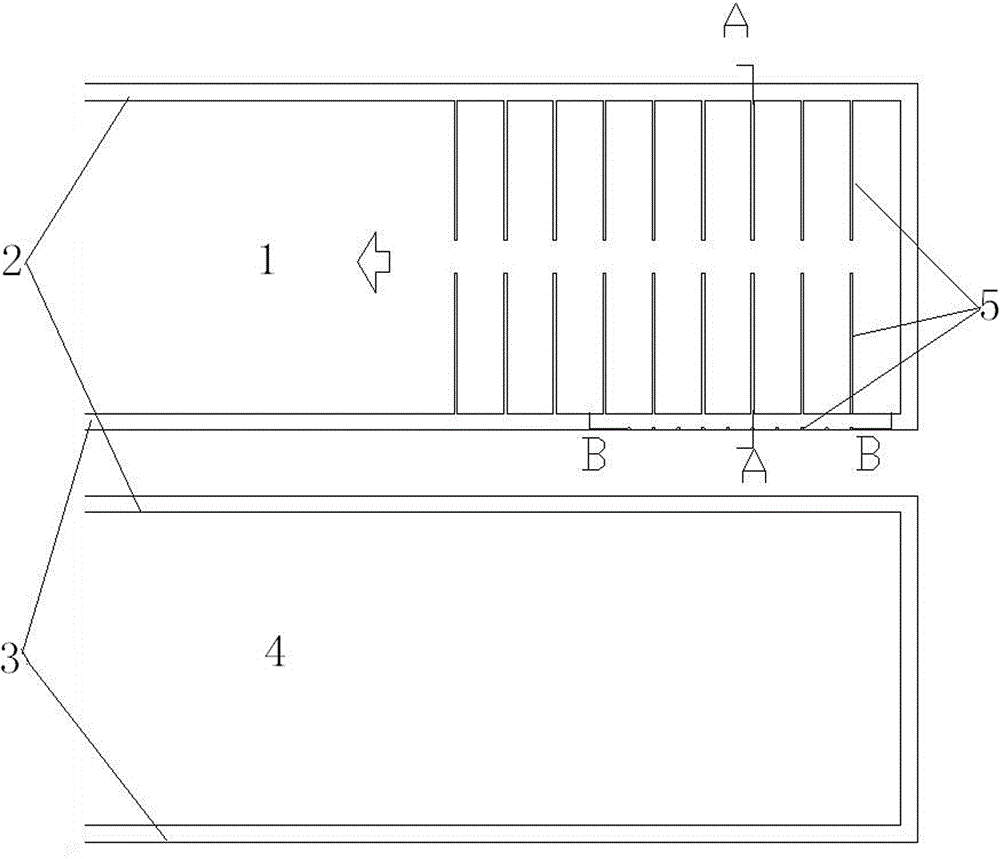

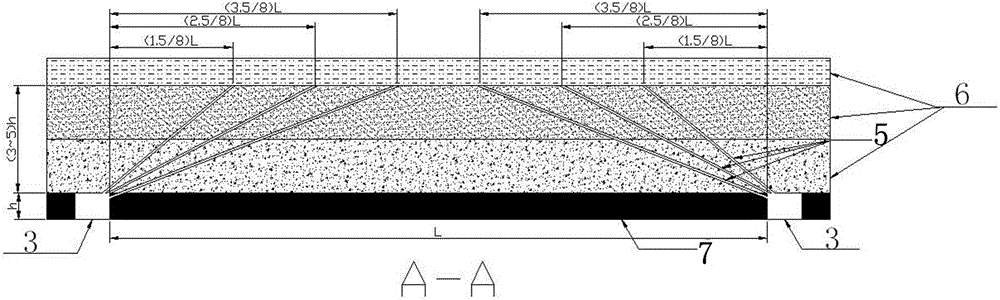

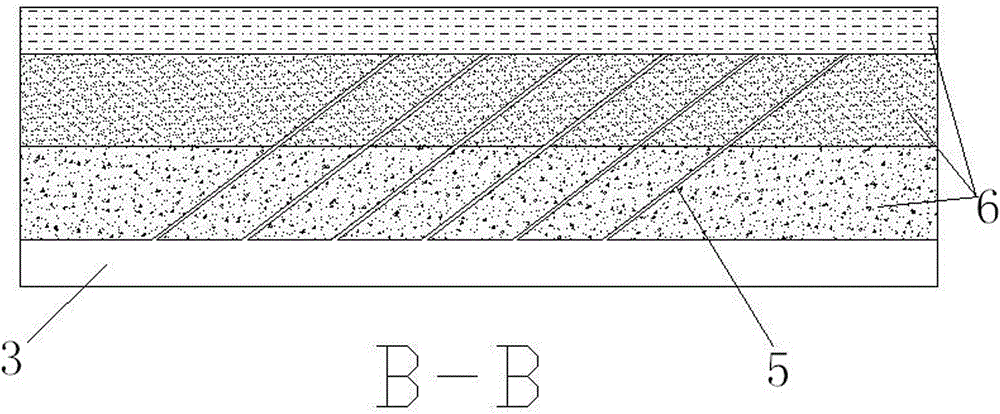

[0025] The method for preventing and controlling hard rock burst based on carbon dioxide blasting of the present invention is used to relieve pressure. The length of the working face is 200m, the coal thickness is 10m, and the roof is mainly made of hard sandstone. The drilling rig model used is ZDY4000S, the diameter of the drill pipe is 60mm and the carbon dioxide cracker, such as Figure 1~Figure 3 shown, follow the steps below:

[0026] (1) Top-cutting blasting of the roof strata directly above the working face: before mining the working face 1, the transport roadway 2 and the return air roadway 3 on both sides of the working face 1 are respectively near the top corners of the working face, Several groups of boreh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com