Sludge carbon fertilizer and production method thereof

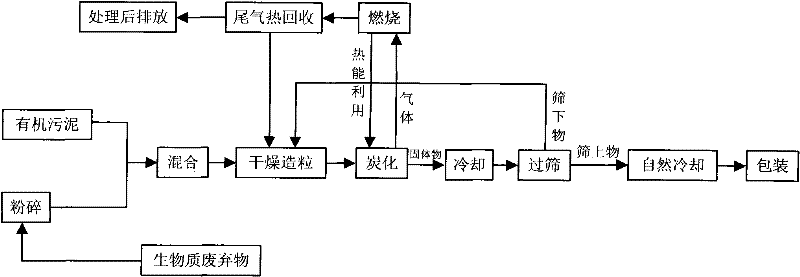

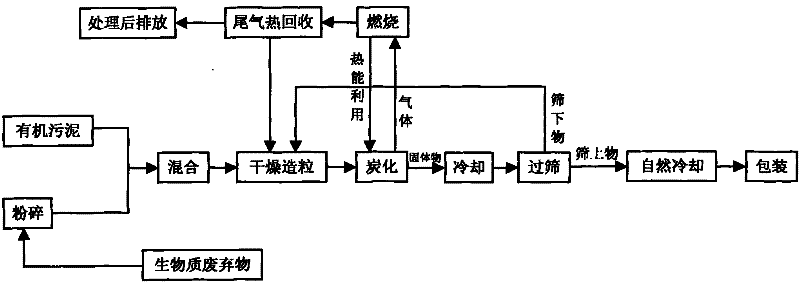

A production method, sludge charcoal technology, applied in the direction of bio-organic part treatment, waste fuel, etc., can solve the problems of ineffective recycling of resources, serious environmental pollution, etc., and achieve the effect of enhancing lodging resistance, prolonging fertilizer efficiency, and fixing fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Take 10kg of sludge (moisture content 80%) and 5kg of sawdust from a domestic sewage treatment plant. After mixing and stirring, spread it on a sun-drying field and dry it under direct sunlight until the moisture content is 30%. Large coagulums are broken down to less than 20mm in diameter. Heat the experimental muffle furnace (the muffle furnace is a closed high-temperature furnace for experiments, which can replace the carbonization furnace in the test) to 750°C, put the mixture into the tray, put it in the muffle furnace, and heat it for 15 minutes. Take it out after cooling down to get about 4kg of sludge charcoal fertilizer.

[0052] Experimentally measured, the final black granular solid obtained:

[0053] The diameter is 2~8mm;

[0054] The specific surface area is 195m 3 / g;

[0055] Nitrogen content: 2.21%;

[0056] Phosphorus content: 8.24%;

[0057] Potassium content: 1.97%.

Embodiment 2

[0059] Take 10 tons of sludge from a domestic sewage treatment plant (moisture content 80%), crush bamboo, branches, etc. into wood chips (bamboo chips) with a diameter of 1 to 15 mm, and take 3 tons of charcoal powder from a charcoal factory. tons (1-15mm in diameter), fully mixed, with a total weight of 15 tons; the material is transported to the KJG paddle dryer, and the material is heated by indirect heating with heat-conducting oil (the temperature of the heat-conducting oil is 160°C). Drying, and the material is fully mixed and granulated through the rolling and stirring of the blades inside the dryer. After 25 minutes, the material is dried to a moisture content of 30%, and enters the BMS sludge carbonization furnace through a closed spiral conveying pipe; the temperature of the carbonization furnace Preheat to 760°C, start to receive the material, and after 18 minutes of carbonization, it becomes black carbonization. After the charcoal is cooled to 200°C by a tubular w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com