Method for recovering coal resources in upper adjacent layer and reducing stress concentration of upper adjacent layer

A technology of stress concentration and resource recovery, applied in drilling equipment and methods, earthwork drilling, surface mining, etc. The generation and transmission of high concentrated stress of the column, the large deformation of the roof of the surrounding rock of the roadway, etc., can achieve the effect of eliminating the large deformation phenomenon, reducing the loss, and weakening the high concentrated stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

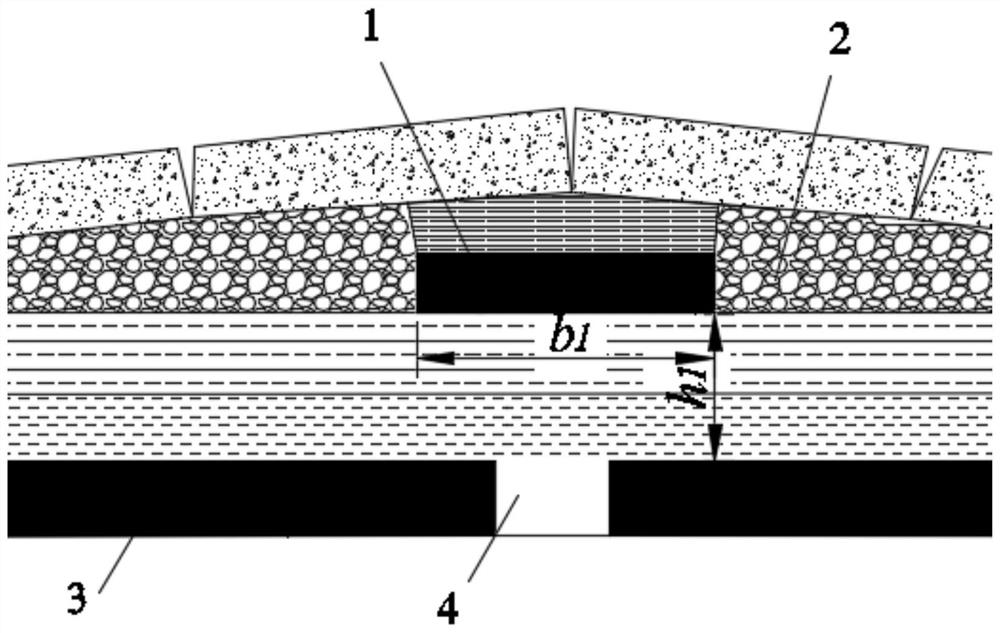

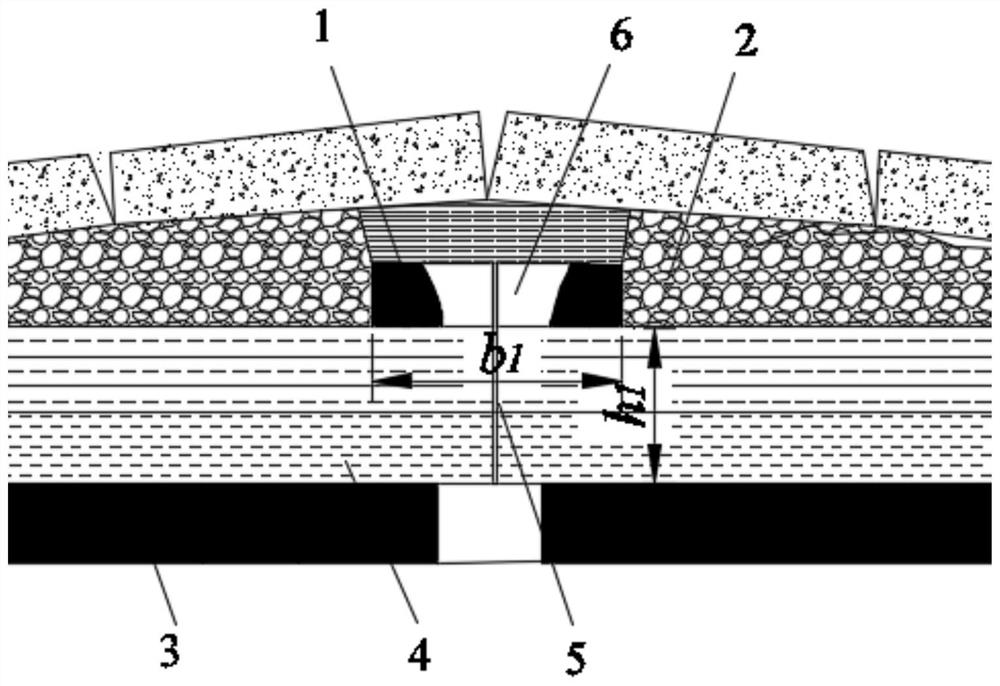

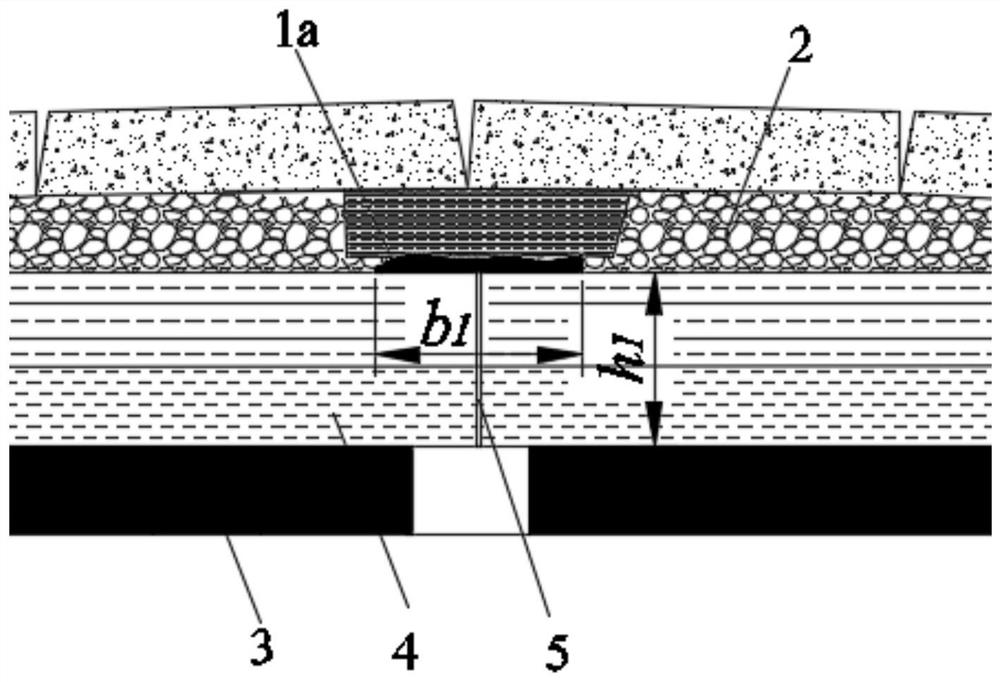

[0048] It is known that the width of coal pillar 1 left in the overlying coal seam is 5m, and the vertical distance h between the coal pillar and the mining face 1 is 15m, analyze the spatial position of the coal pillar and the mining face according to the conditions, and draw a profile, as shown in figure 1 shown. according to figure 1 , using the method described in the present invention, the drill pipe 5 passing upwardly through the section coal pillar in the lower mining coal seam enters the remaining coal pillar 1 with a width of 5m, and excavates by radial hydraulic jet or mechanical reaming An enlarged hole 6 with a diameter of 2m, the excavation of the enlarged hole 6 will cause the coal resources to be broken, and the broken coal will flow back to the coal-water separation device through the drill hole, so as to realize the recovery of abandoned coal resources, such as figure 2 As shown; through the recovery of abandoned coal resources in the upper adjacent layer, ...

Embodiment example 2

[0050] It is known that the width of the coal pillar 7 left in the overlying coal seam is 15m, and the vertical distance h between the coal pillar and the mining face 2 is 15m, analyze the spatial position of the coal pillar and the mining face according to the conditions, and draw a profile, as shown in Figure 4 shown. according to Figure 4 , using the method described in the present invention, the section coal pillar in the lower mining coal seam is arranged upwards to enter the abandoned coal resource area, and a diameter of 3m is excavated by means of radial hydraulic jet or mechanical reaming. Enlarging the hole 8, the excavation of the expanding hole 8 will lead to the fragmentation of coal resources, and the broken coal will flow back to the coal-water separation device through the borehole. 15m wide remaining coal pillar 7 arranges three boreholes in each row, such as Figure 5 As shown, the recovery of abandoned coal resources in the whole range can be realized; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com