Onboard continuous grooving pressure relief coal mining equipment and onboard continuous grooving pressure relief coal mining method

A coal mining method and trough forming technology, which are applied to mining equipment, mining equipment, cutting machinery, etc., can solve problems such as inability to construct, rock burst, and long time consumption, and achieve short time consumption, prevention of rock burst, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] For alluvial mines, a single outburst dangerous coal seam with a buried depth of 523m and an average thickness of 3m has an inclination angle of 6°-12°. The relative gas content of the coal seam is 13m3 / t, and the gas pressure is 1.8MPa. The immediate roof of the coal seam is sandstone, and the floor is carbonaceous mudstone or mudstone.

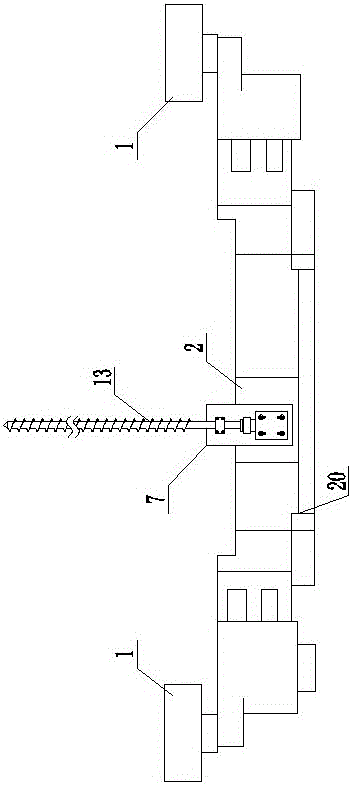

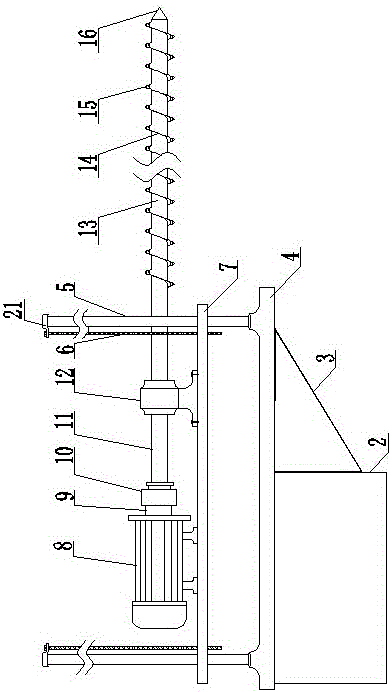

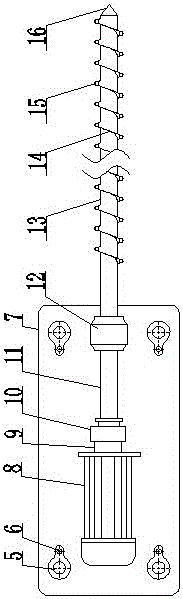

[0035] Such as Figure 1-Figure 5As shown, a kind of airborne continuous trough pressure relief coal mining equipment of the present invention includes a coal shearer 20, and the front side of the electric control box 2 of the coal shearer 20 is provided with a tripod 3, the tripod 3 and the electric control box 2 A rectangular fixed plate 4 is arranged horizontally on the top, and a lifting device is arranged on the fixed plate 4, and a height-adjustable operating platform 7 is arranged in the middle of the lifting device, and a cutting device is arranged on the operating platform 7;

[0036] The lifting device comprises a column 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com