Novel coal mine rock burst treatment method

A technology for rock burst and coal mine, applied in the field of rock burst control of new coal mines, can solve problems such as difficult support, flooded working face, waste of resources, etc., to improve resource recovery rate, eliminate stress concentration, and avoid rock burst Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

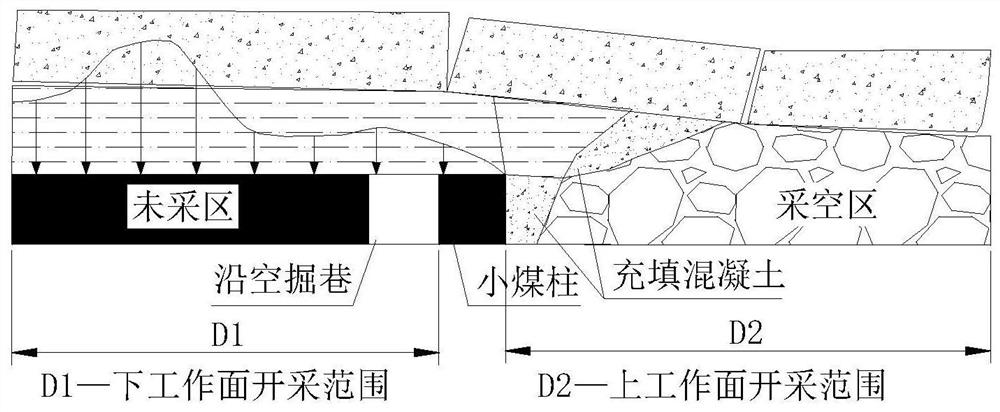

[0054] If gob excavation is carried out from the stop production line of the working face to the production line (from the withdrawal channel to the cut eye), the back mining shall be completed at the working face for more than half a year; If the direction of the retraction channel) is excavated along the gob, it needs to be half a year behind the working face and the lagging distance is more than 1000m (Ordos area);

[0055] After mining, low-level caving zones and fissure zones formed rapidly, and local stressed arches in corner areas were formed accordingly. One side of the stressed arch is supported by the coal side and the roof in the unmined area as the arch foot, and the other side is supported by the goaf caving zone. The stressed area can be called the internal stress area, and the source of force is the goaf The fractured arch at the boundary of the area determines that the corner area of the working face becomes a low stress area instead.

[0056] The coal mine ...

Embodiment 2

[0066] Such as Figure 4 Shown, the second working face forming method, the steps are as follows

[0067] a. Back mining at the first fully mechanized mining face to form a goaf;

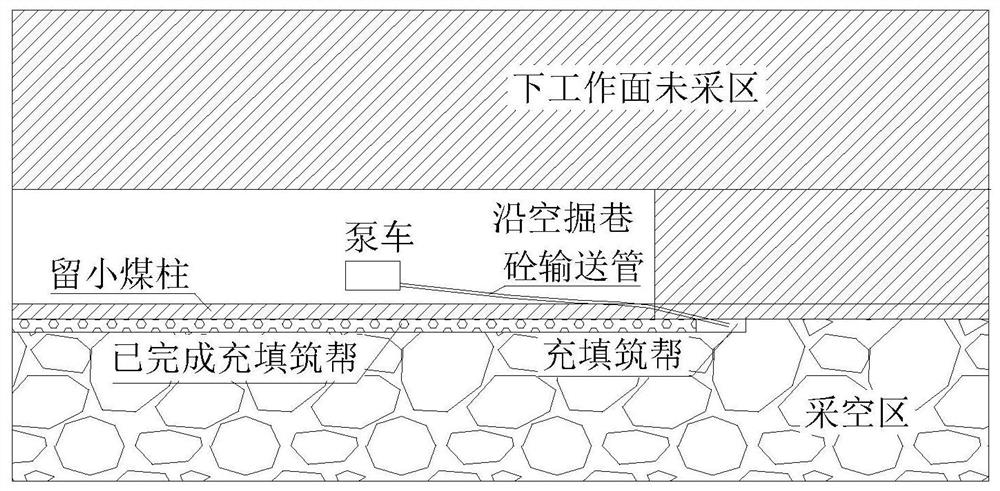

[0068] b. After the roof movement of the goaf in the first mining face becomes stable, start from the cutting eye or stop production line, leaving a small coal pillar with a width of 3.0-8.0m along the boundary of the goaf to excavate the new working face along the trench.

[0069] c. Before the roadway excavation, drill the corner area of the goaf in advance, install the pipeline and pour the flexible concrete slurry. After solidification, a retaining wall will be formed to isolate the goaf and support the roof.

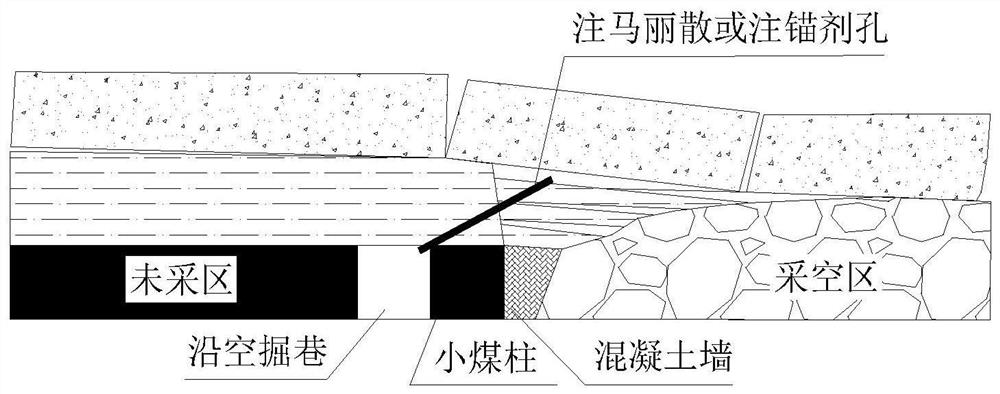

[0070] d. Excavate the roadway along the solidified concrete retaining wall.

[0071] e. Adopt the full-length anchoring method to support the roadway.

[0072] f. Lag excavation for a certain distance to pour Malisan or anchoring agent into the surrounding rock of the roadway, mainly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com