A method for anti-shock ground pressure of all-coal roadway

An all-coal roadway and anti-shock technology, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems that the roadway surrounding rock properties have not been improved, and the interaction between synergistic components and surrounding rocks has not been considered, so as to achieve anti-shock Improvement of ground pressure performance, prevention of floor impact ground pressure, and reduction of reflected stress waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

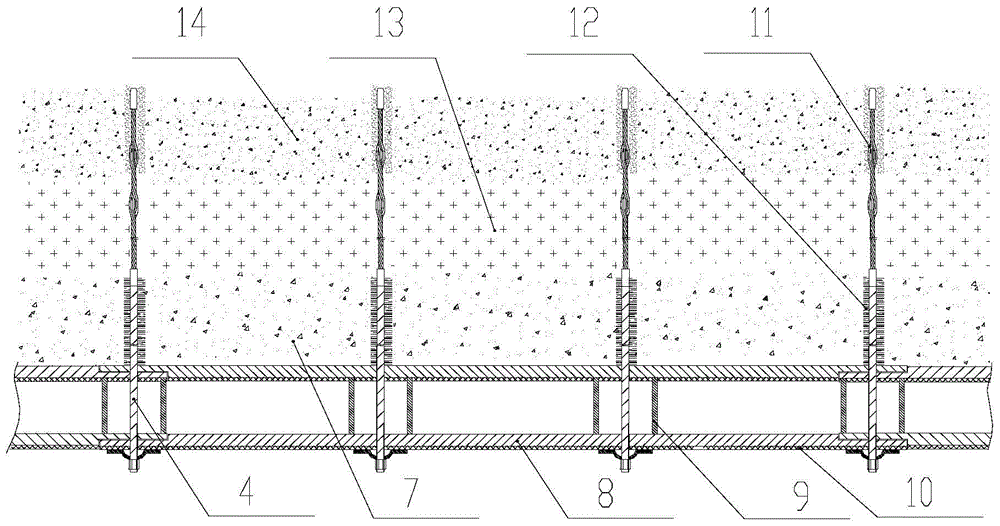

[0030] In a working face of a certain mine, the thickness of the coal seam is 12m, the occurrence of the coal seam is stable, and the air inlet lane is 21m 3The arched section of the straight wall is an all-coal roadway, which has a strong impact risk. During the excavation, a 90m long roadway was selected to carry out the following three types of support tests:

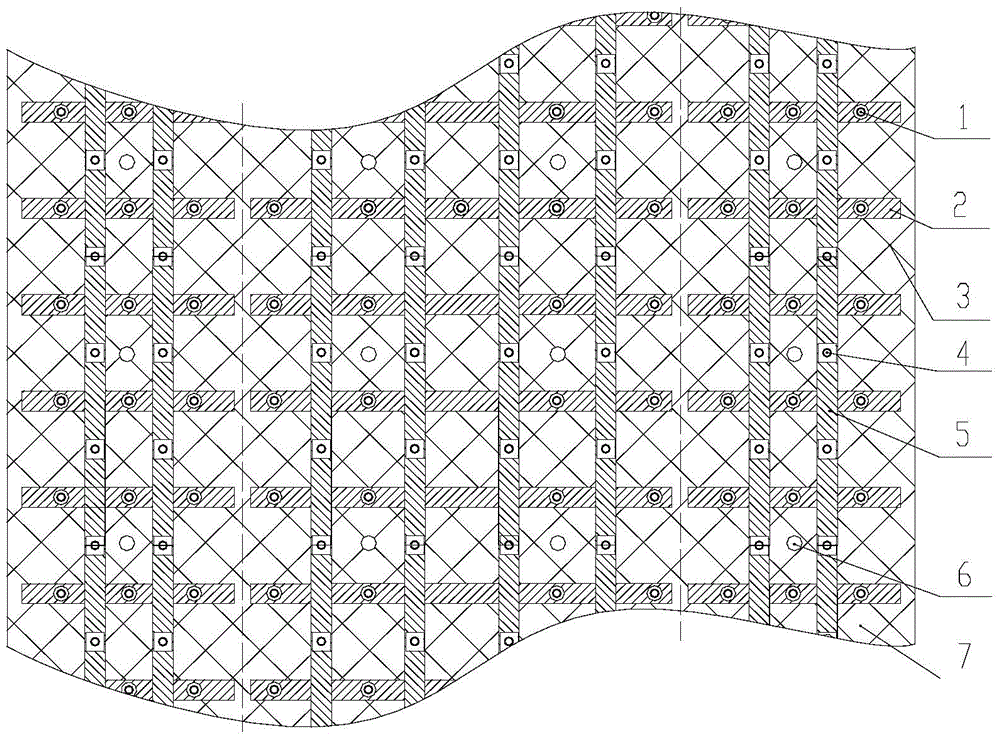

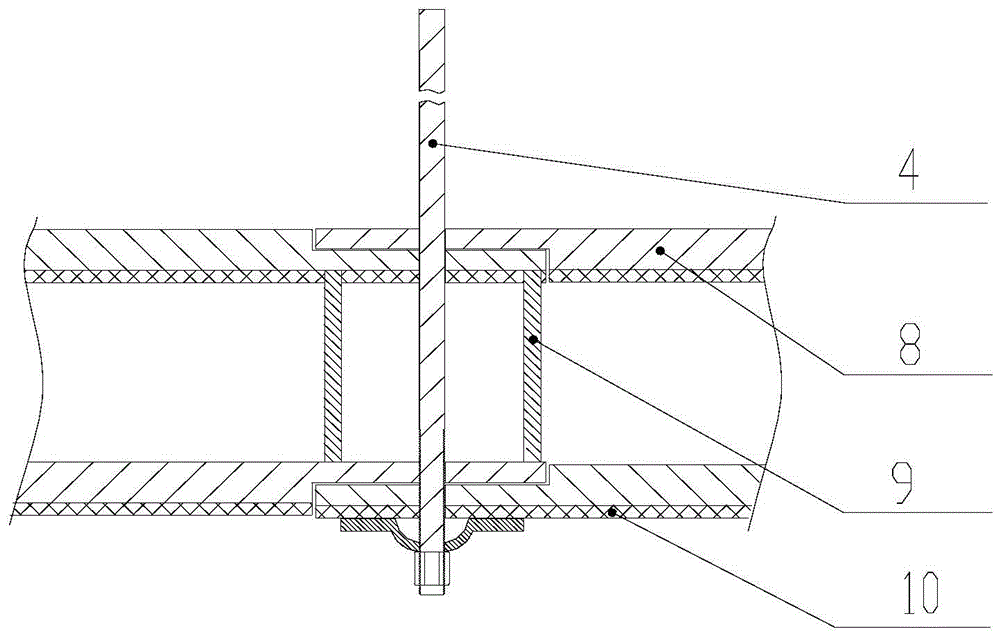

[0031] Test section 1: The length of the roadway is 30m, and it is supported by conventional anchor cables with steel strands, that is, the support method of "bolt + iron mesh + steel belt" plus steel strand anchor cables is adopted on the roof of the roadway. Among them, the anchor length is 2.2m, the spacing is 0.8m, the row spacing is 0.8m, the anchor cable diameter is 17.8mm, the length is 7m, the anchor cable spacing is 1.6m, and the row spacing is 1.2m. The two gangs are supported by "anchor + iron mesh + steel belt". The length of the anchor is 2.2m, the spacing is 0.8m, and the row spacing is 0.8m.

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com