Mining method for hanging wall surrounding rock broken inclined medium thick orebody

A mining method and thick ore body technology, which is applied in ground mining, mining equipment, underground mining, etc., can solve the problem of difficult support for the roof of the surrounding rock on the upper wall, large open space of medium and deep hole blasting, and large hidden dangers of operation safety, etc. problems, to achieve the effect of solving ventilation safety problems, stabilizing the ore body, and reducing cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

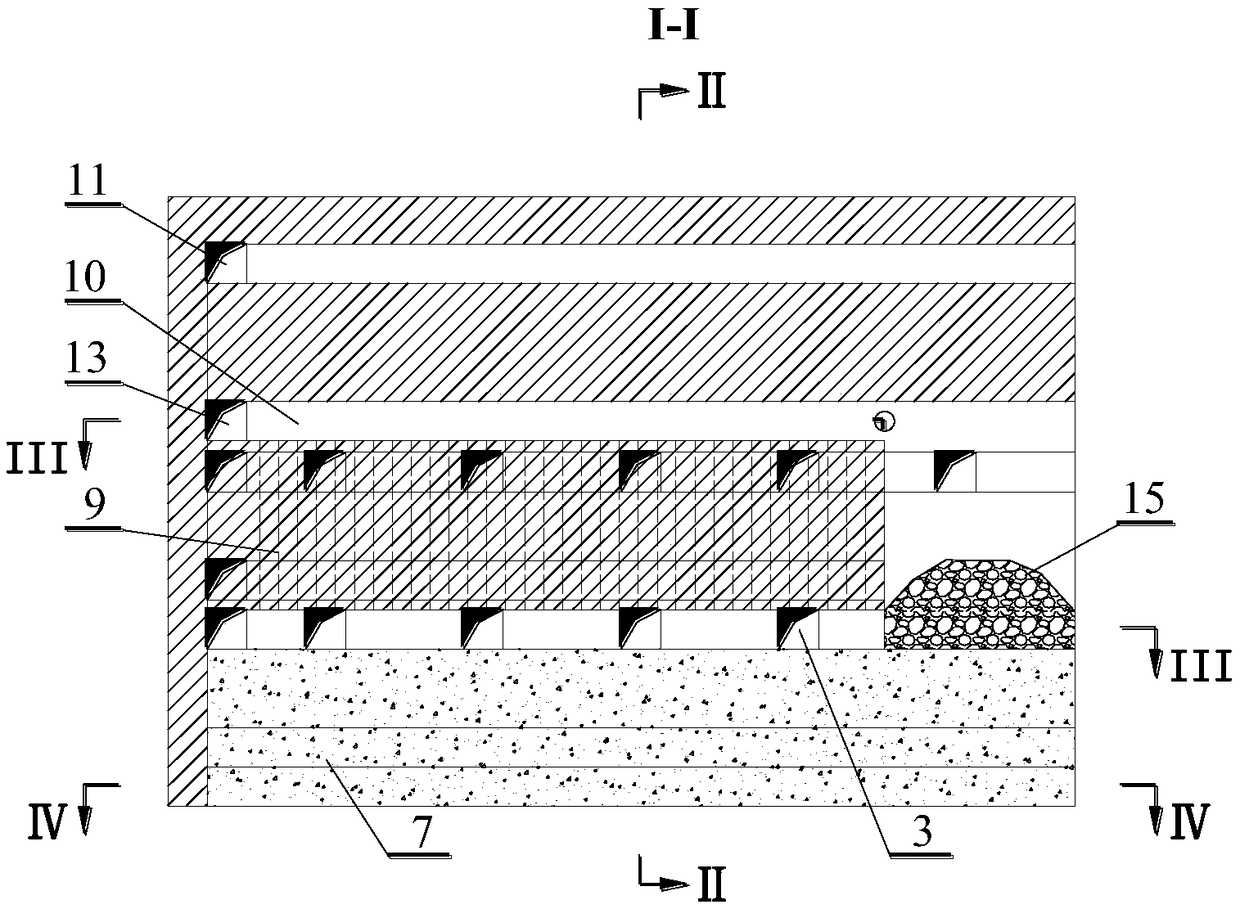

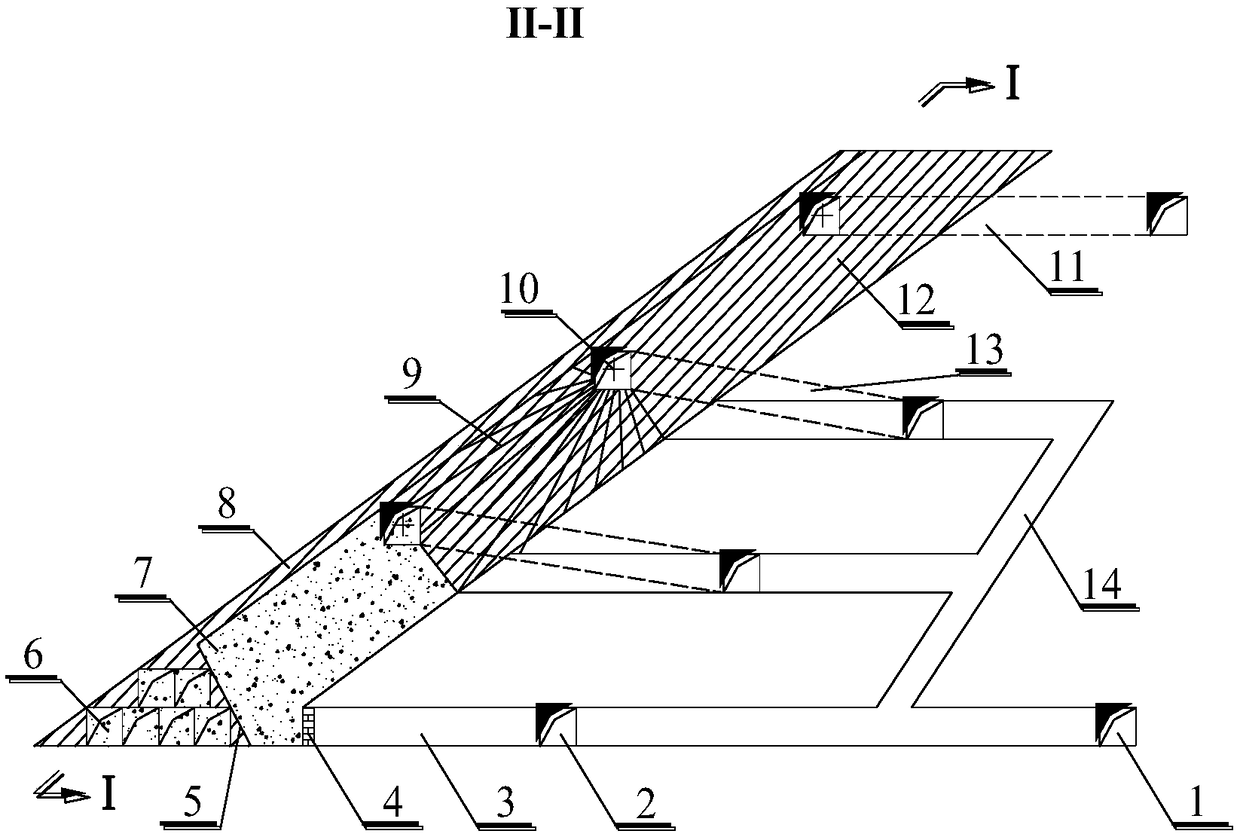

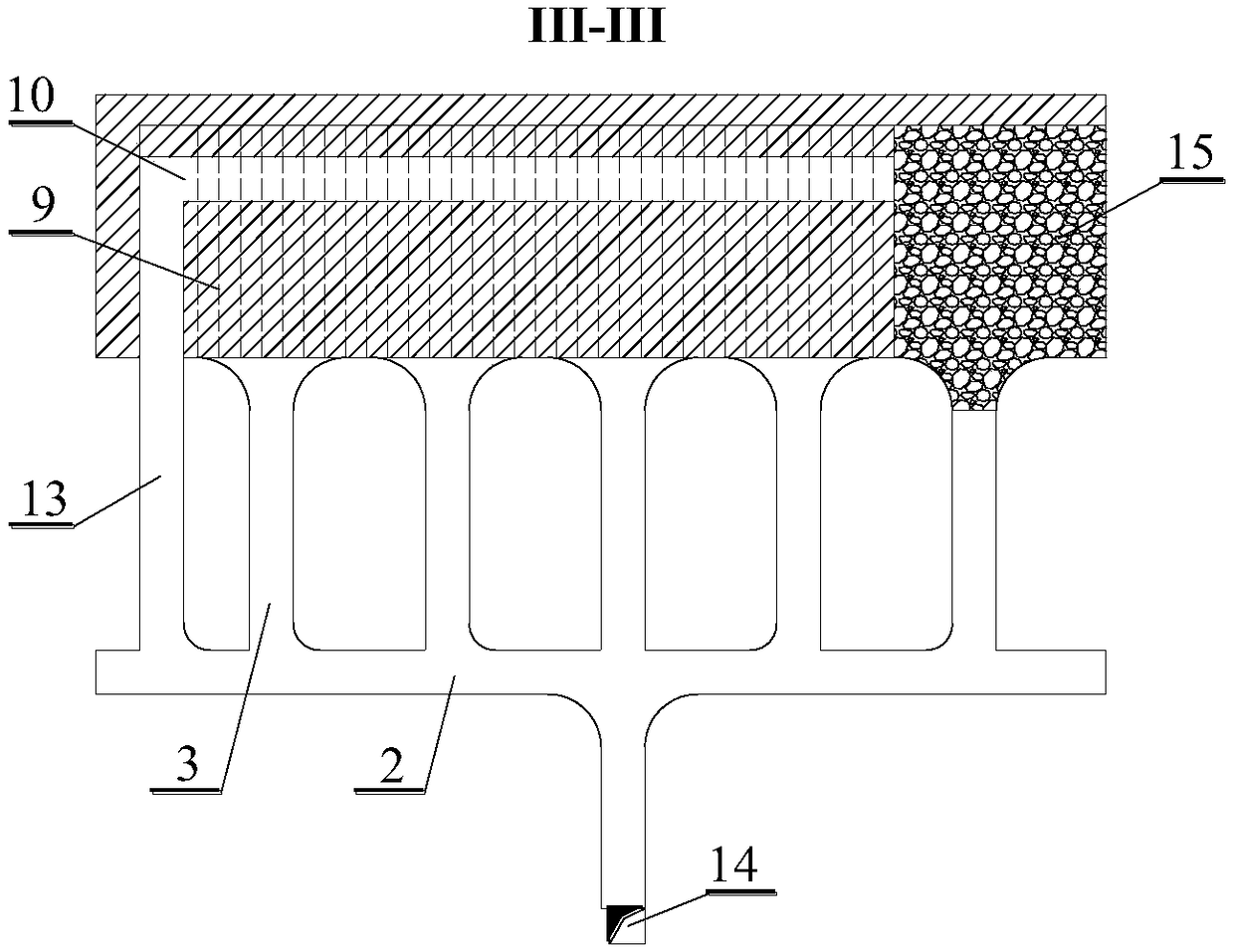

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] see Figure 1-Figure 4 , the diagram is a schematic diagram of the internal structure of the mining area adopting a mining method of the present invention for the mining method of the broken and inclined medium-thick ore body of the hanging wall surrounding rock, and the specific mining implementation steps are as follows:

[0031] Step 1) Divide the ore body into stopes along the strike of the ore body 12, the true thickness of the hanging wall pillar 8 reserved in each stope is 1-1.5m, and the thickness of the stope is the thickness of the ore body excluding the reserved hanging wall pillar 8 After the true thickness, stope length is set to 15 ~ 20m. During the mining process, the method of mining every other stope is adopted, and the transportation is carried out in stages, and the stage is divided into sections. The height of the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com