Patents

Literature

35results about How to "Reduce job cycle time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

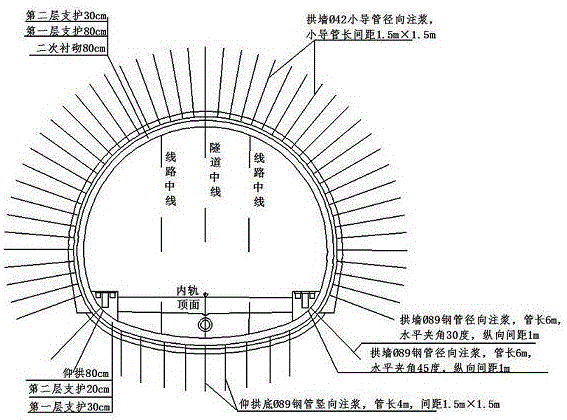

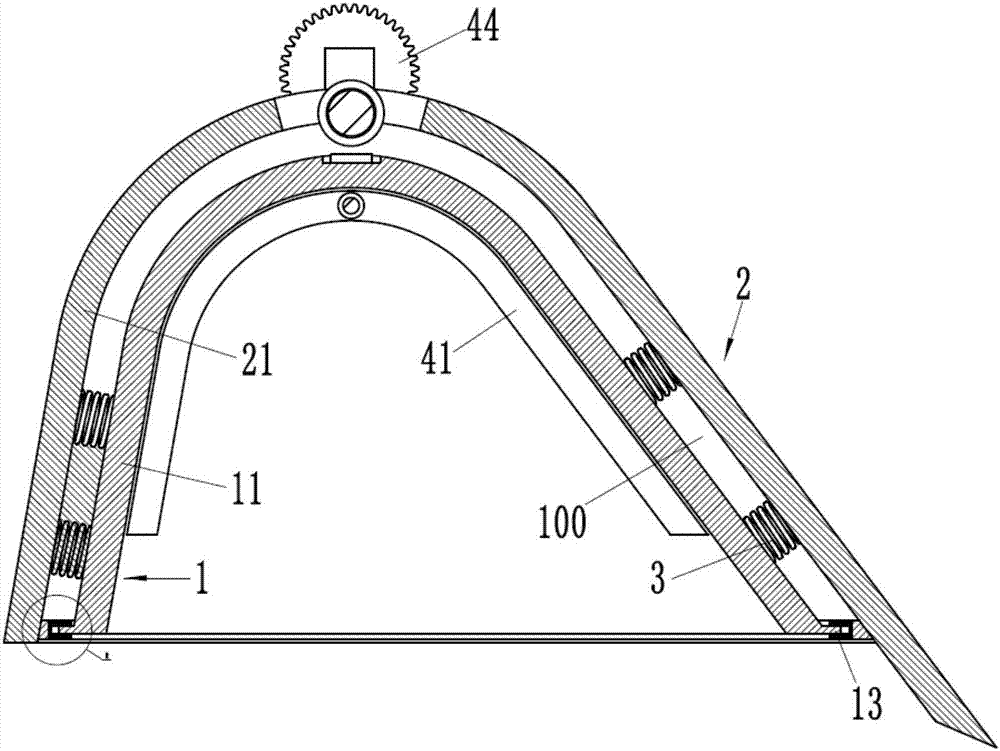

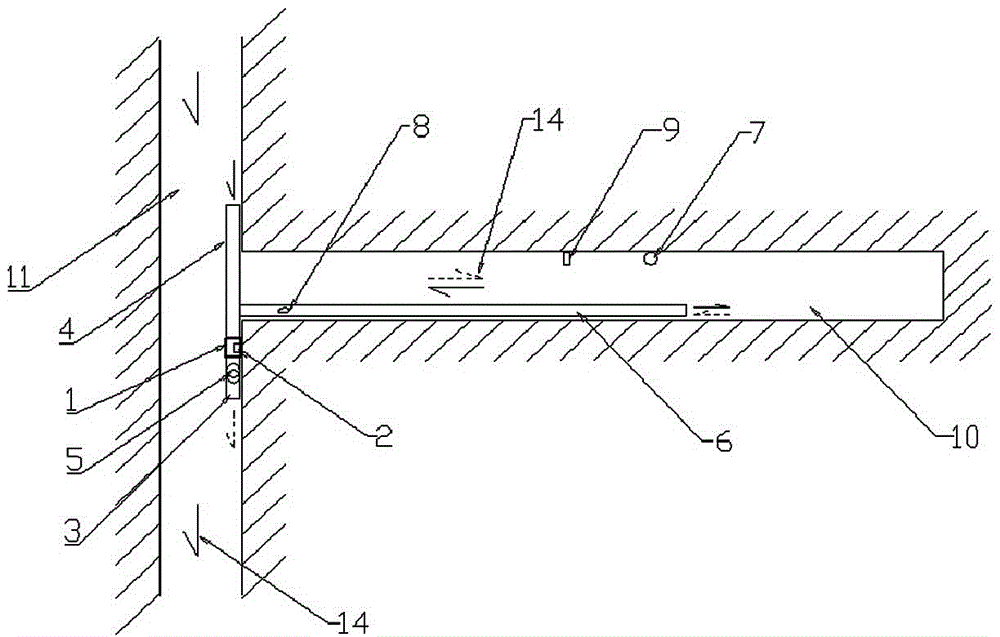

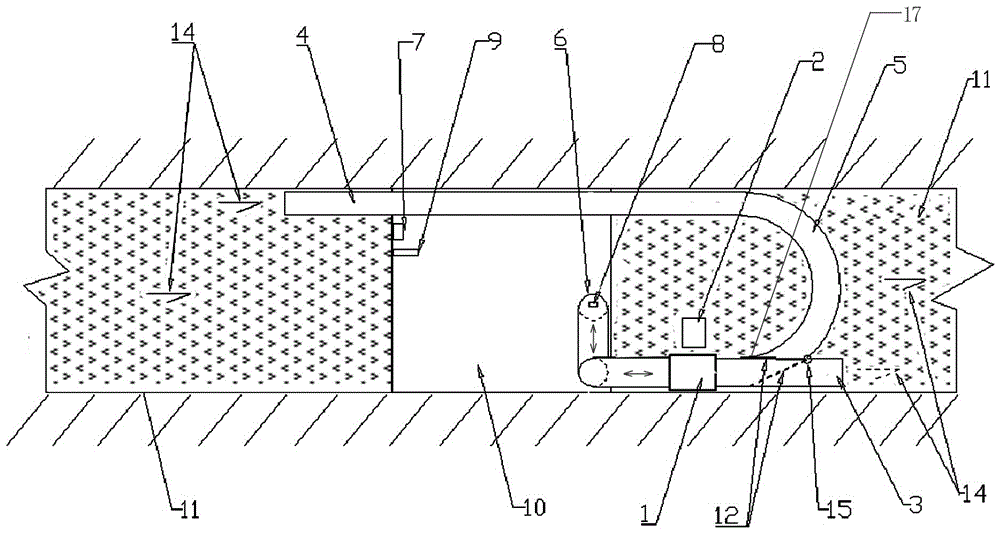

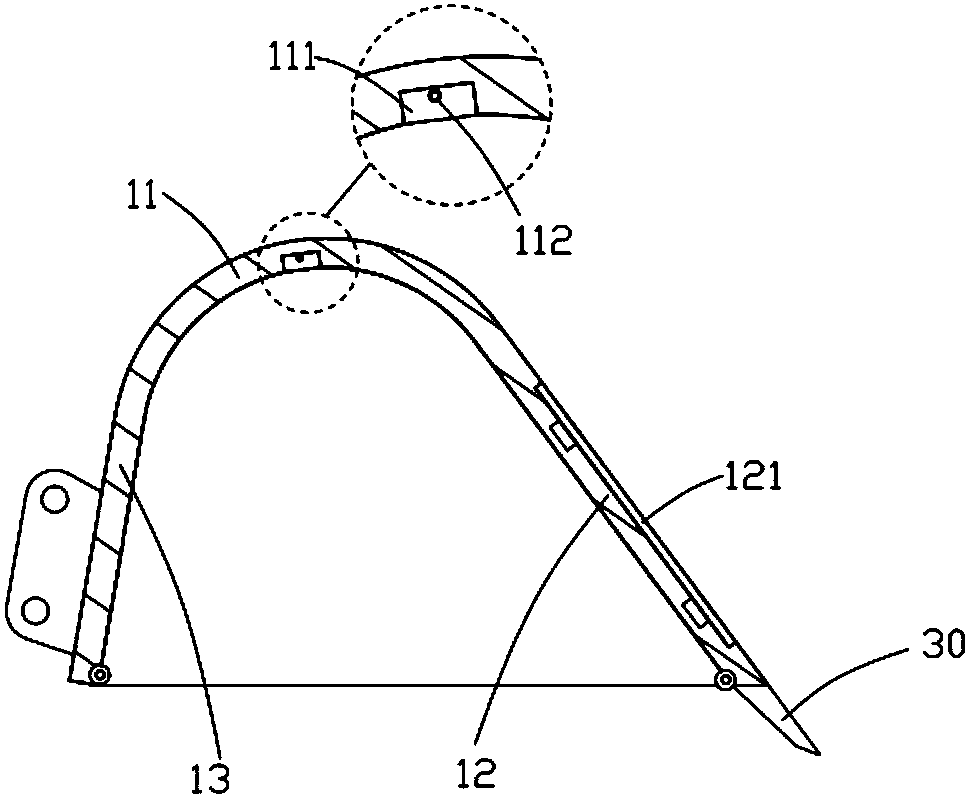

Construction method for soft rock deformation tunnel lining support dismantling-replacing arch

InactiveCN105781571AGuaranteed carrying capacityGuaranteed integrityUnderground chambersTunnel liningEngineeringLarge deformation

The invention provides a construction method for a soft rock deformation tunnel lining support dismantling-replacing arch. One-time whole section integral dismantling and replacing of a lining support is achieved. The construction method has the advantages that before dismantling and replacing, a lining which loses bearing capacity is subjected to grouting reinforcement treatment first, then a temporary cover arch is additionally arranged outside for reinforcement, and afterwards, the lining support is dismantled step by step, so that potential safety hazards caused by dismantling or removing of a temporary platform frame are avoided, and some security risks are avoided effectively. According to the construction method, the construction difficult problem of soft rock large deformation occurs during construction of a tunnel in special and complex geology is solved. Through the created novel construction method, the construction difficult problem of second lining cracking deformation needing remediation due to weak surrounding rock large deformation is solved. Through the construction method, safe, fast and economic treatment and remediation of the lining support and arch replacing construction are achieved, and the tunnel structure stability and construction safety are ensured effectively.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

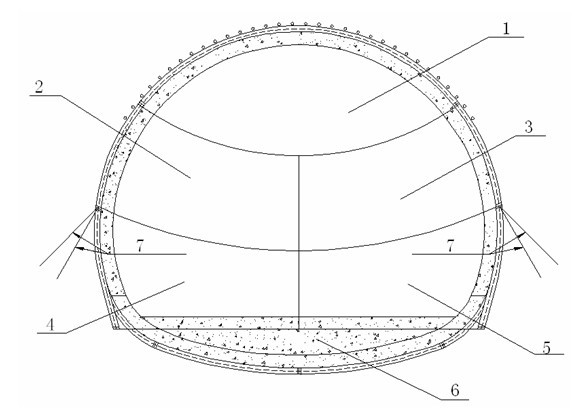

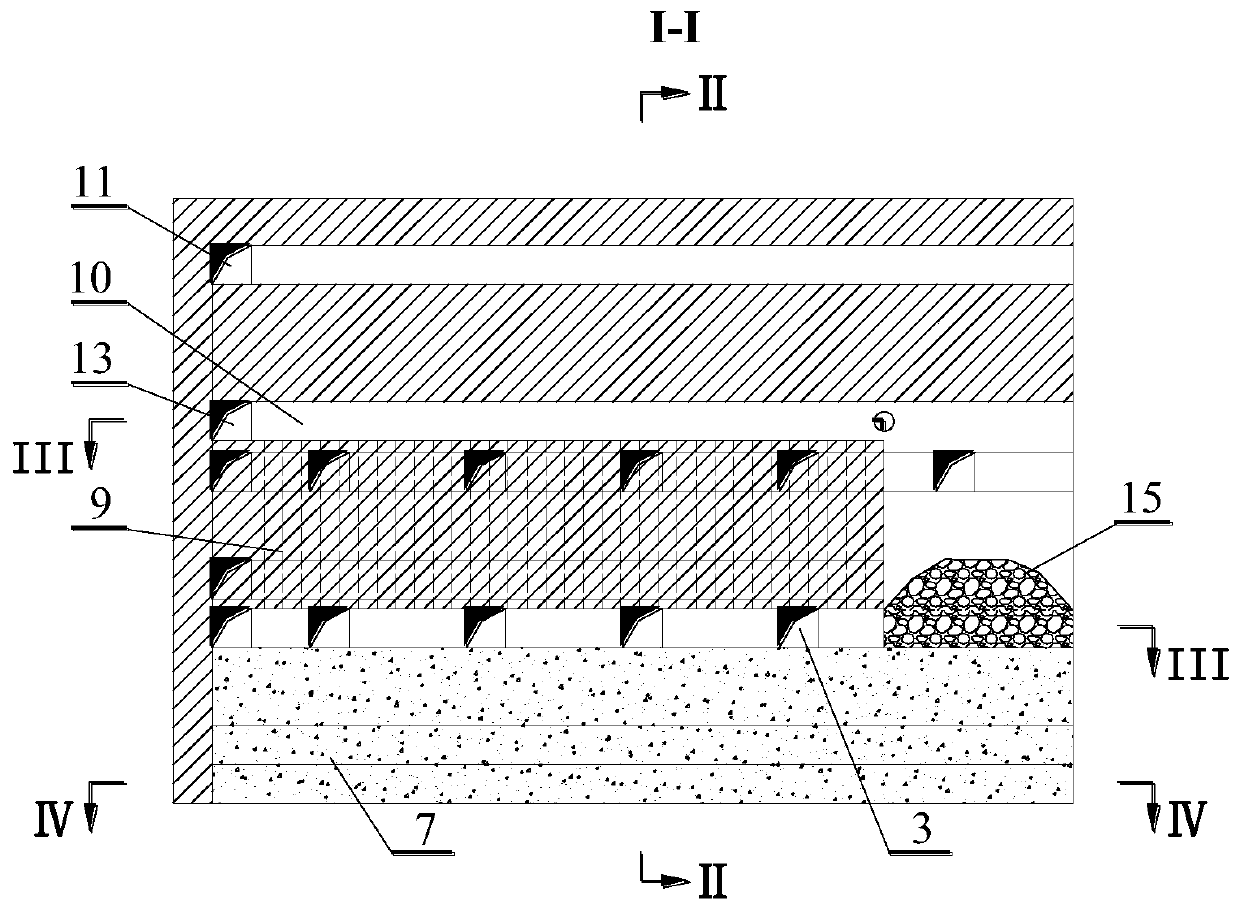

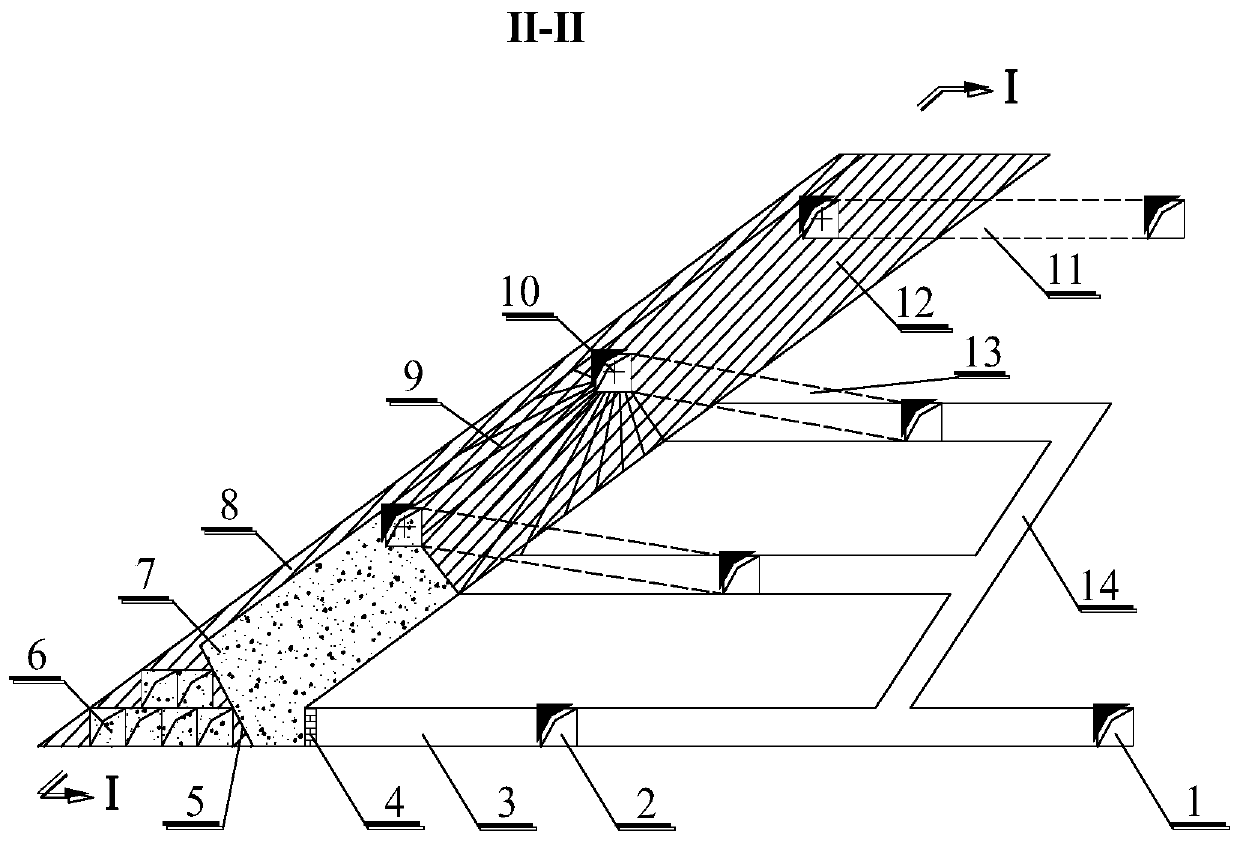

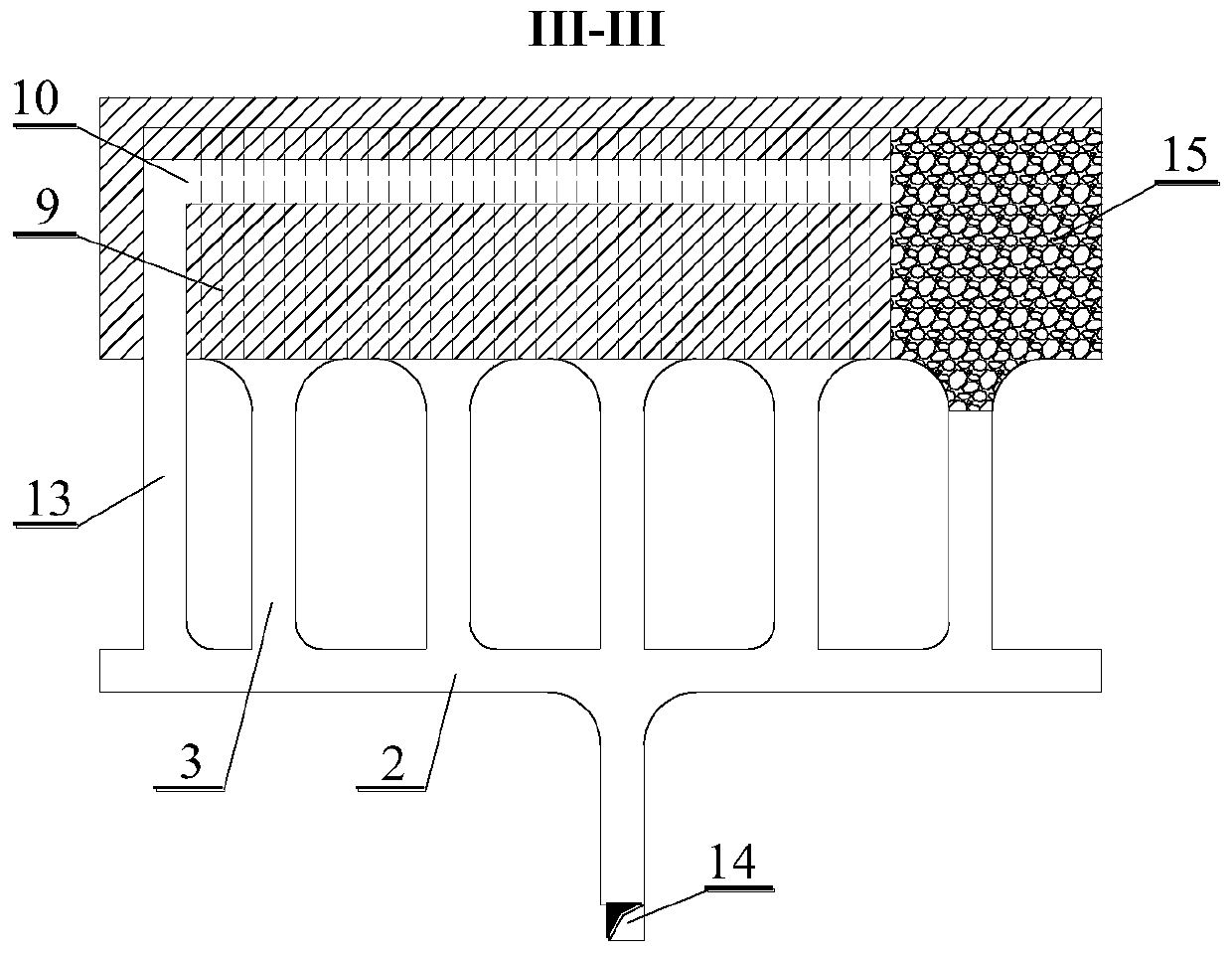

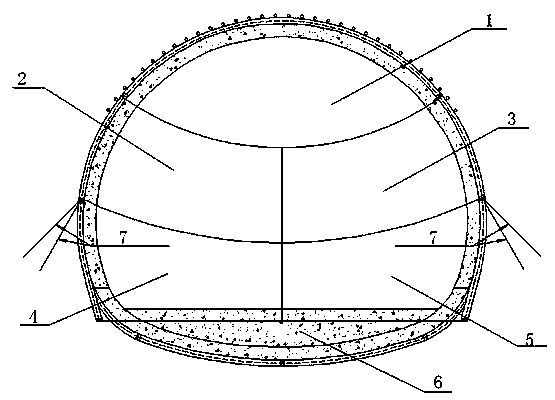

Large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method

ActiveCN102562075AMeet the requirements for enhanced controlsSpeed up early closure timesUnderground chambersTunnel liningShortest distanceRock tunnel

The invention discloses a large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method, which comprises the steps as follows: (1) annularly excavating an upper step of an upper part arc pilot tunnel, transferring excavated earthwork of the upper step to a lower step; (2) excavating a left part of a middle step about 4.5-5 meters behind the upper step, and transferring excavated earthwork to the lower step; (3) excavating a right part of the middle step about 3-4 meters behind the left part of the middle step, and transferring excavated earthwork to the lower step;(4) excavating a left part of the lower step about 6-8 meters behind the left part of the middle step or about 3-4 meters behind the right part of the middle step, and conveying excavated earthwork of the left part of the lower step out of the tunnel; (5) excavating a right part of the lower step about 3-4 meters behind the left part of the lower step, and conveying excavated earthwork of the lower step out of the tunnel; and (6) excavating the rest part of the tunnel bottom about 20-25 meters behind the right part of the lower step, excavating continuously according to the steps in a circulating and interlacing manner, and finally realizing tunnel excavating construction. The method can be used for building a large cross-section tunnel in a safe, rapid and economic manner.

Owner:CCCC SECOND HIGHWAY ENG CO LTD +1

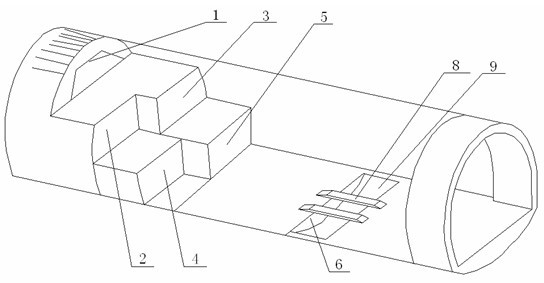

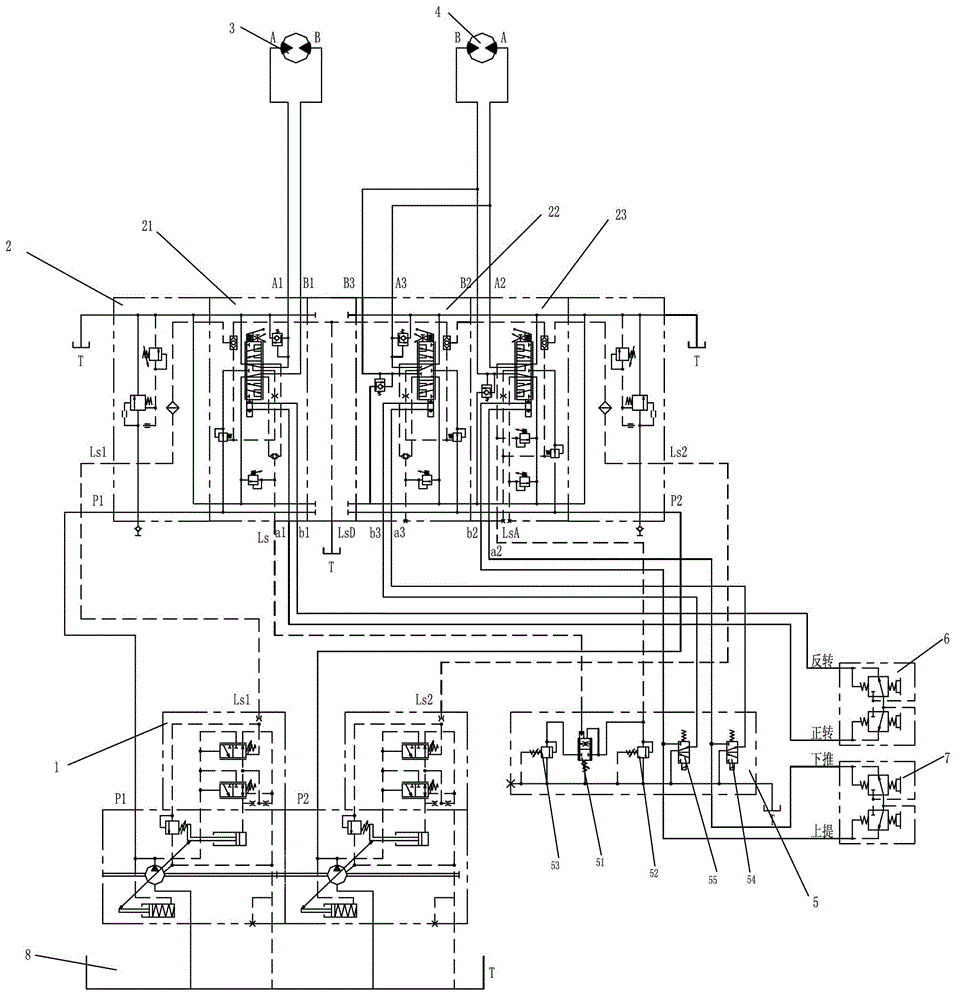

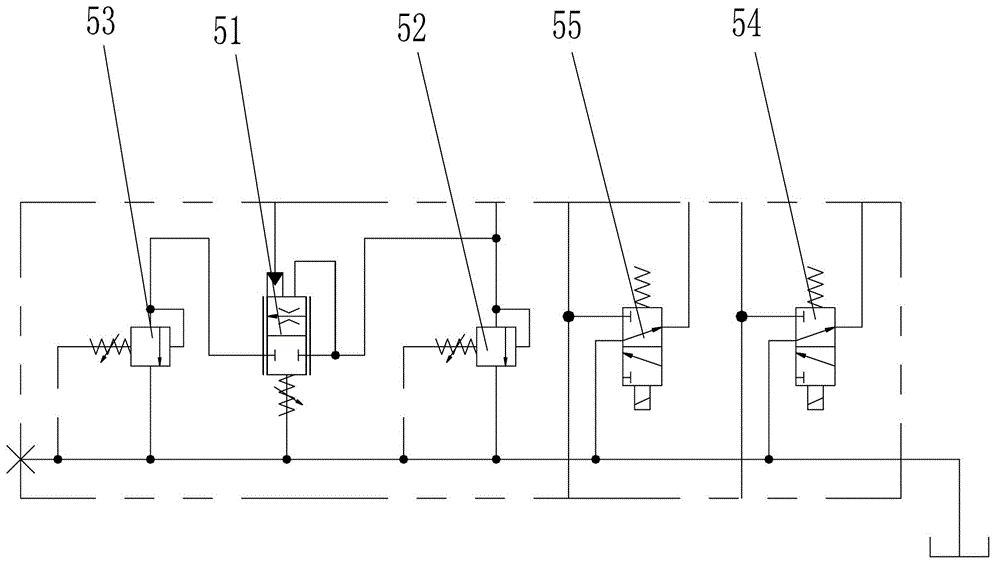

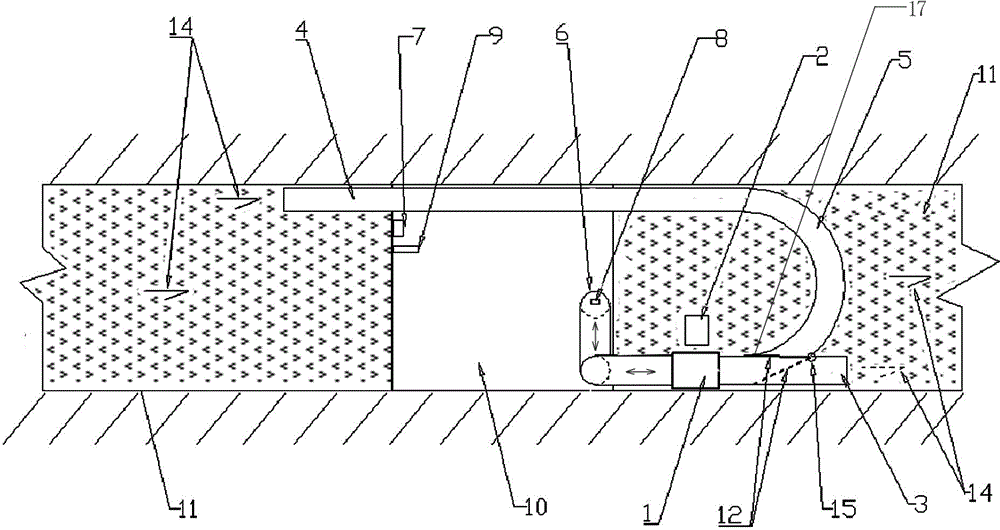

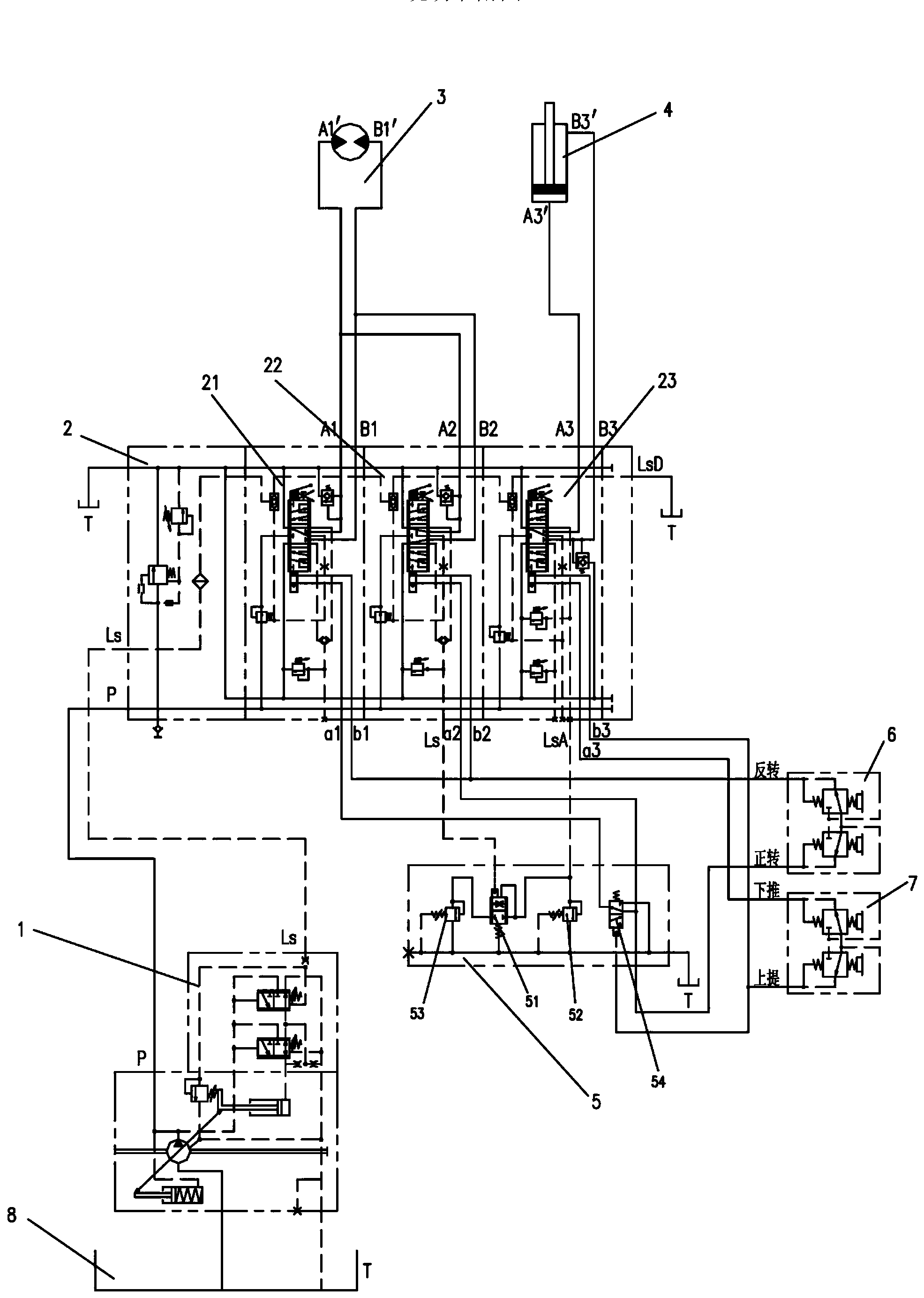

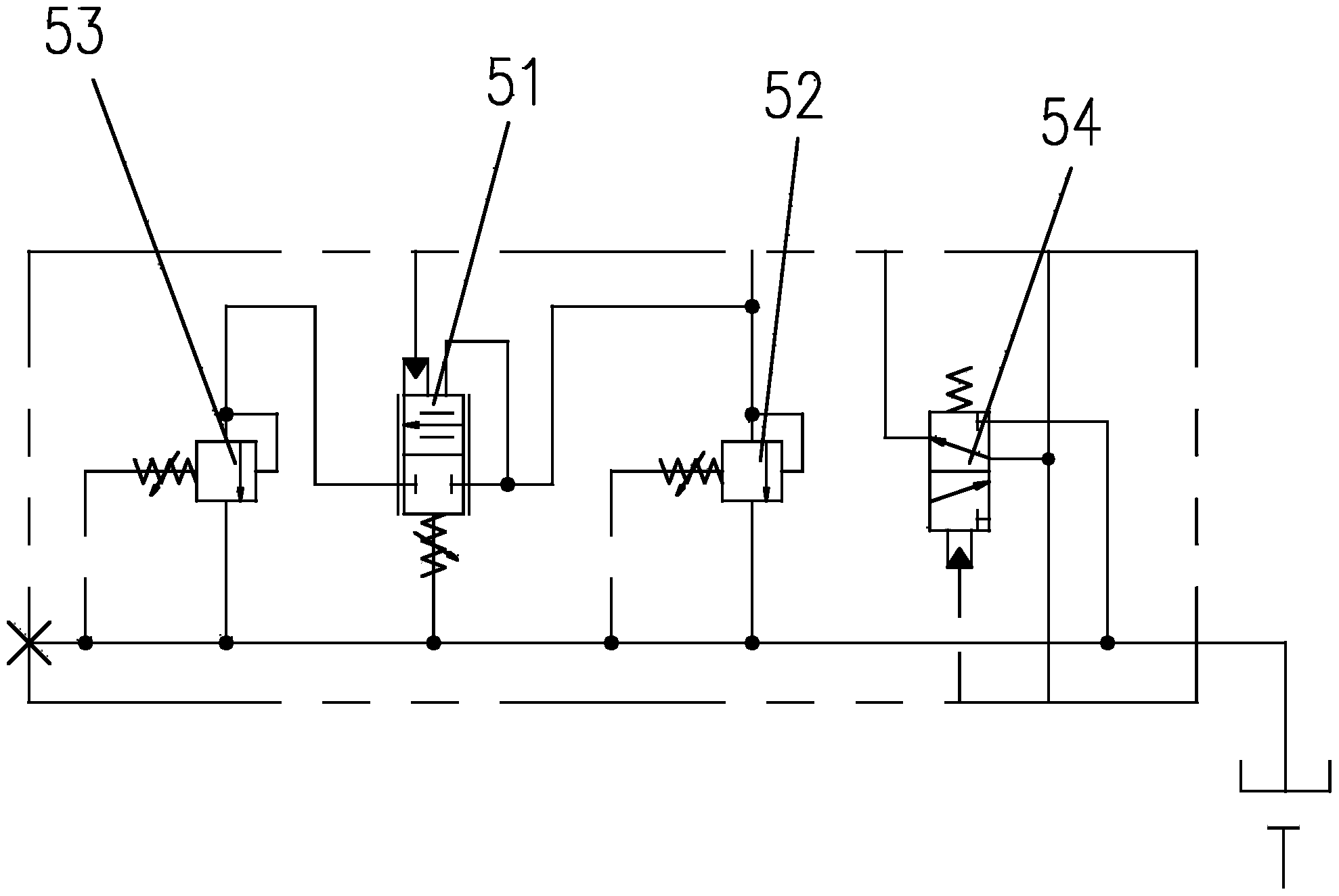

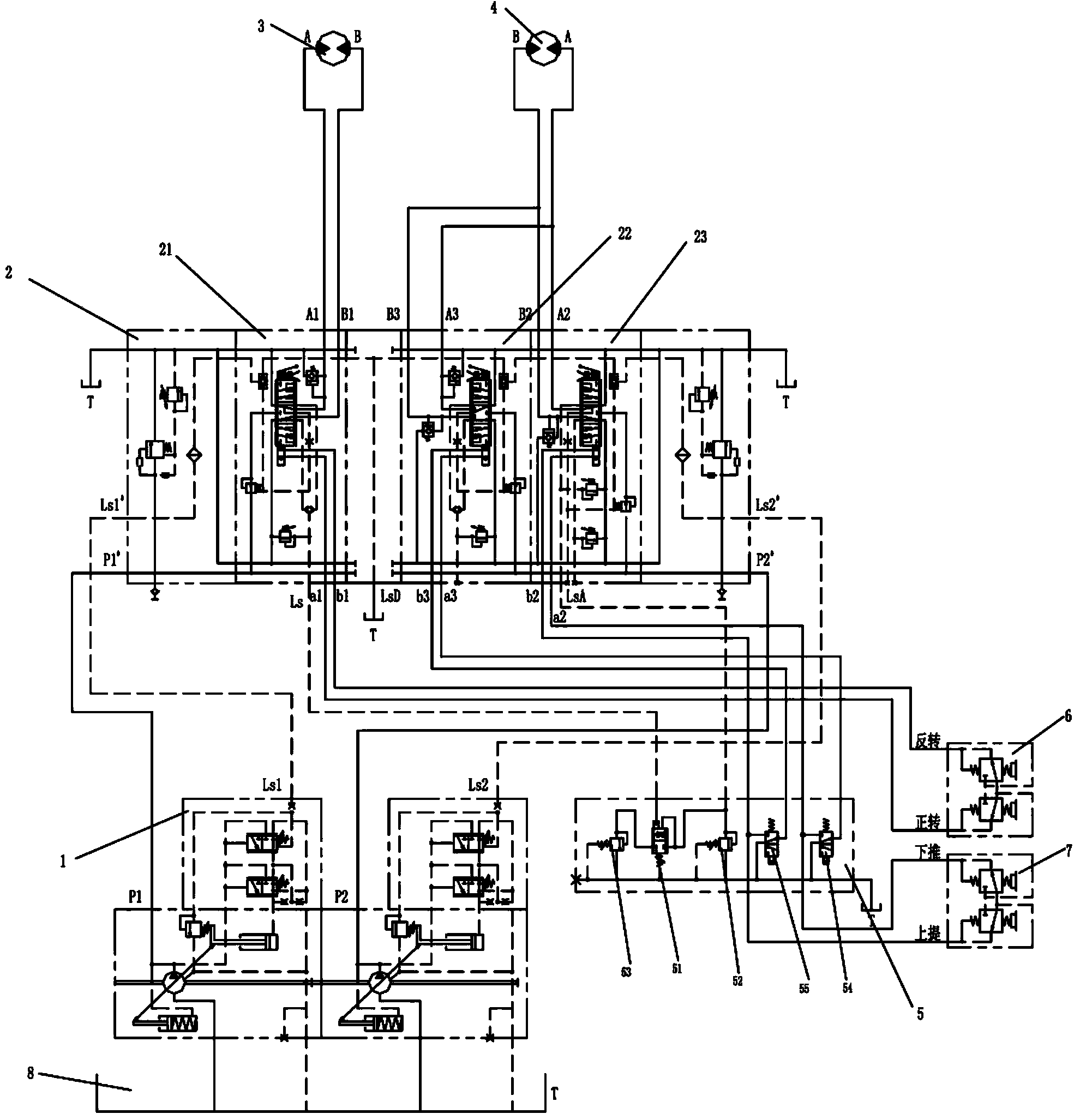

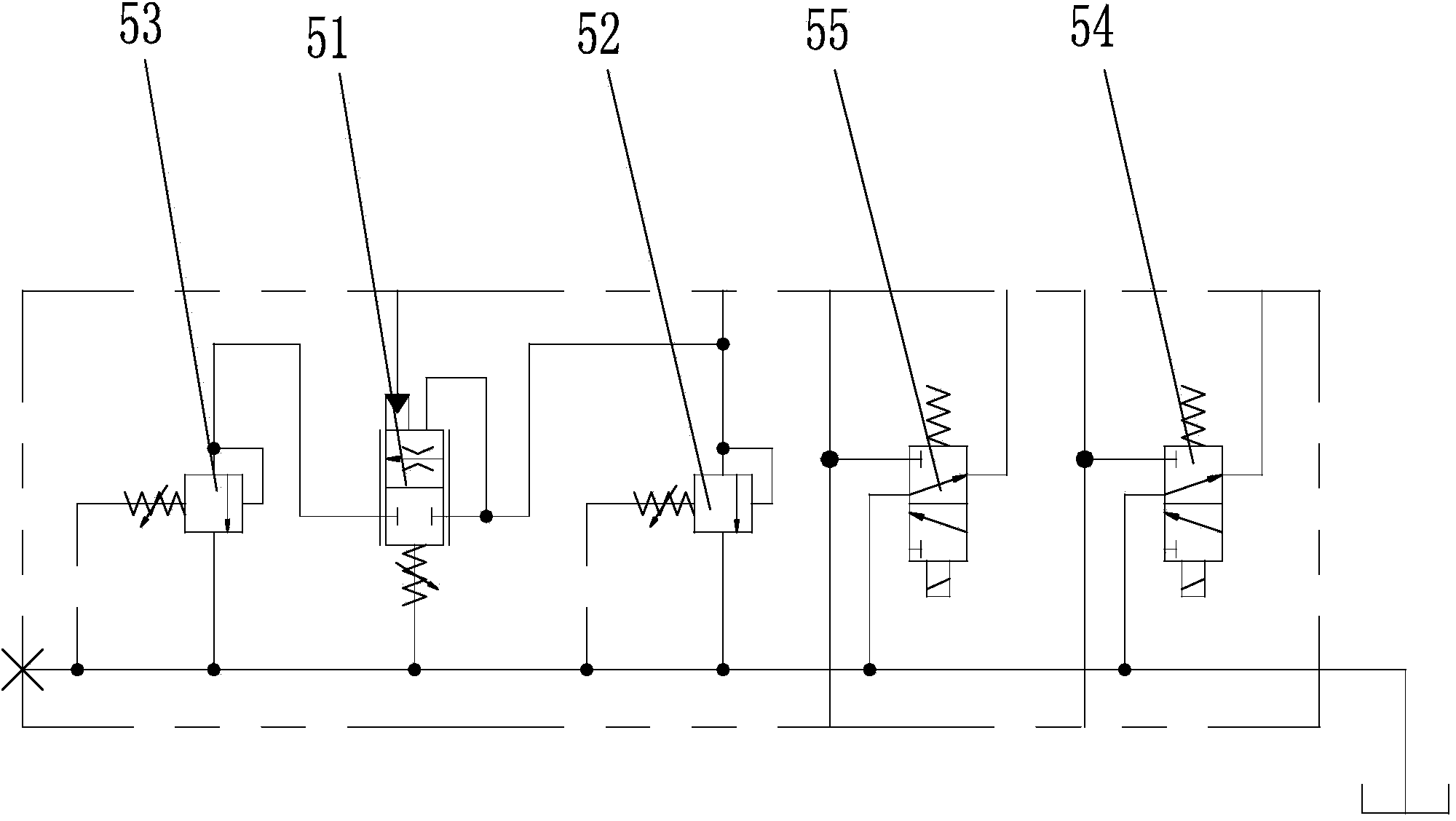

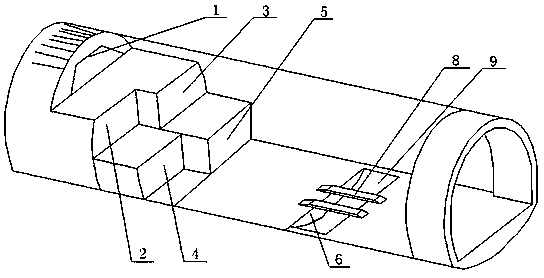

Double-pump hydraulic control loop of key drilling action of cutting drill rig

ActiveCN102747948AAvoid stuck drillPrevent slippingServomotor componentsServomotorsFuel tankEngineering

A double-pump hydraulic control loop of a key drilling action of a cutting drill rig comprises a double linkage load-sensitive variable pump set, a double oil intake linkage load-sensitive multi-way valve, a rotary motor, a propulsion motor, a drilling logic control block, a rotation guide handle, a propulsion guide handle, and a hydraulic oil tank. An oil inlet of the double linkage load-sensitive variable pump set is connected with the hydraulic oil tank. An oil outlet and a load-sensitive opening are connected with an oil inlet and a load-sensitive opening of the double oil intake linkage load-sensitive multi-way valve respectively. Each valve pressure difference compensator of the load-sensitive multi-way valve is provided with an external control opening. The external control openings are connected with the drilling logic control block. The rotation guide handle and the propulsion guide handle are connected with the drilling logic control block or a guide control opening of the load-sensitive multi-way valve. The double-pump hydraulic control loop has the advantages that power head rotation-proportion-controlled propulsion is achieved, independent load-sensitive control of rotation and propulsion is achieved, propulsion speed is increased, and the like.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

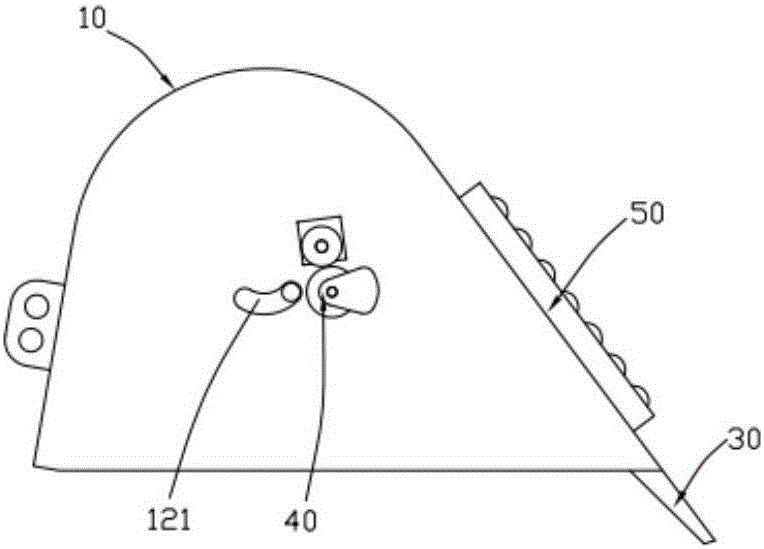

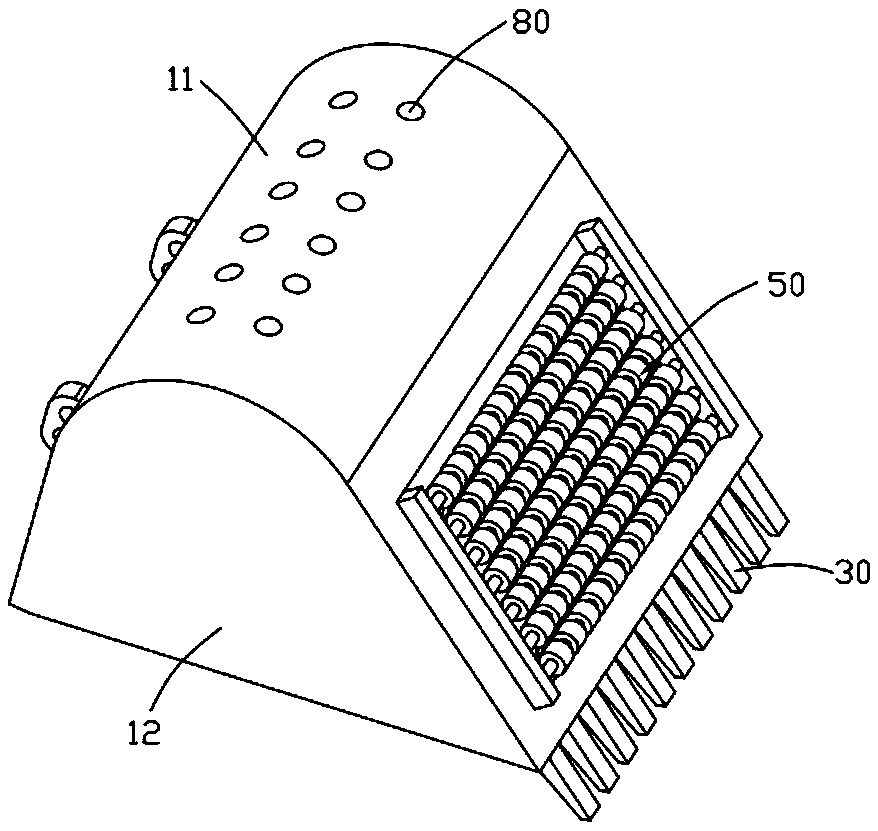

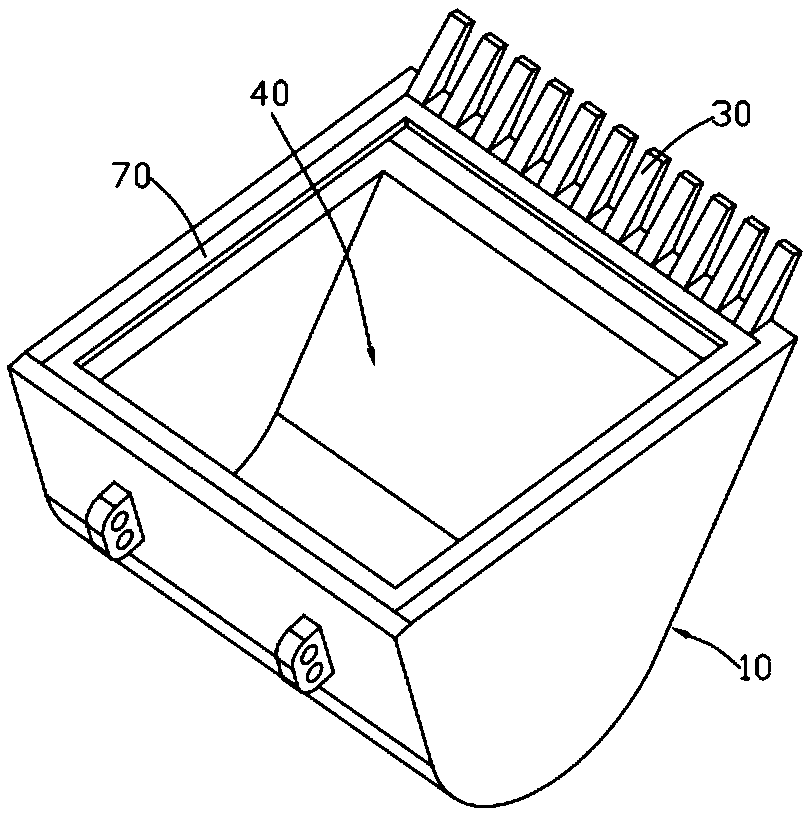

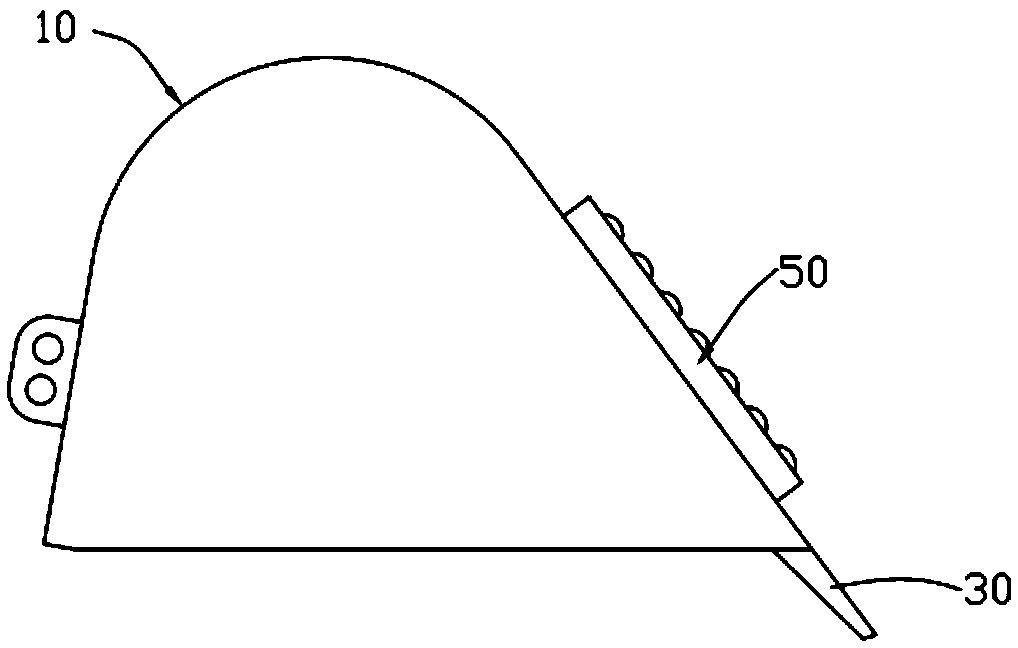

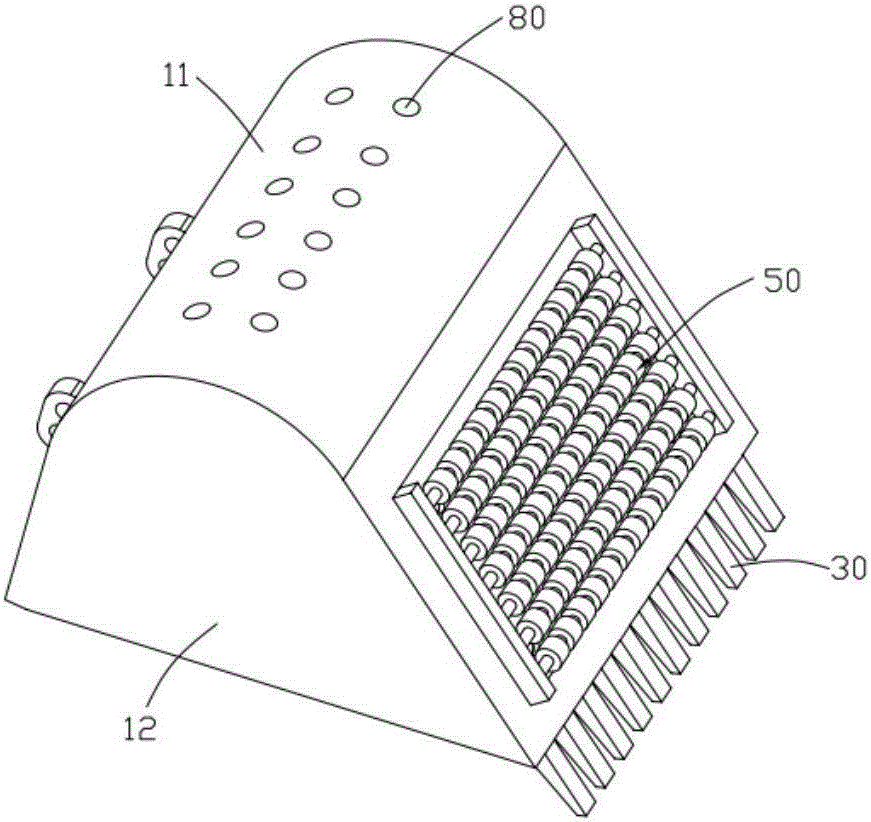

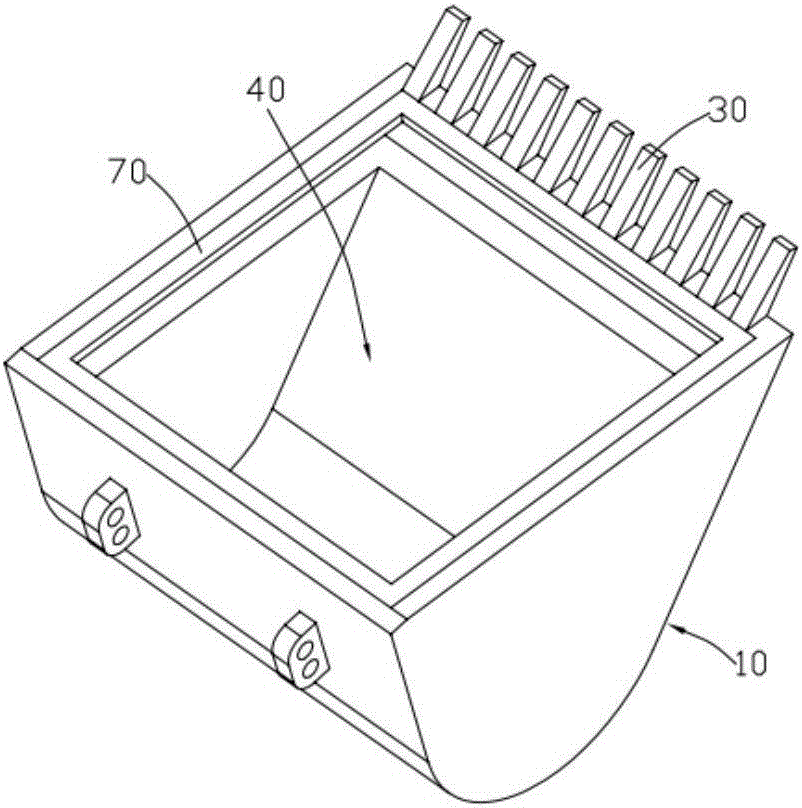

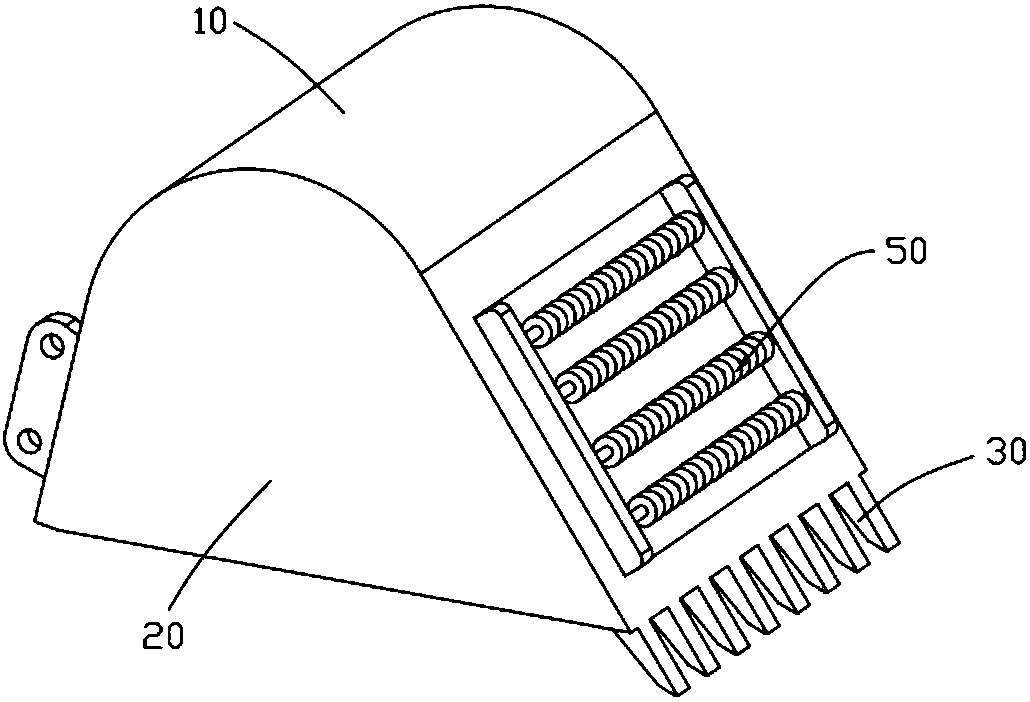

Soil sticking preventing type excavator bucket

InactiveCN107090862AEffective uninstallIncrease effective bucket capacityMechanical machines/dredgersEngineeringCycle time

The invention discloses an excavator bucket for preventing clay, including a built-in bucket and an external bucket, a plurality of springs are arranged in the middle cavity formed by the built-in bucket and the external bucket, and the built-in bucket is connected floatingly by the spring In the external bucket, the inside of the internal bucket is provided with a soil shaking mechanism, and the openings of the internal bucket and the external bucket are provided with seals to prevent soil from entering the middle cavity. The invention can effectively unload the soil in the bucket, reduce the working cycle time of the excavator, and increase the effective bucket capacity of the bucket.

Owner:HUZHOU ZHONGCHEN CONSTR

Special bucket for excavator

InactiveCN107059966AEffective uninstallIncrease effective bucket capacityMechanical machines/dredgersExcavatorCycle time

The invention discloses a special bucket for an excavator. The special bucket for the excavator comprises an internal bucket and an external bucket; multiple springs are arranged in a middle cavity formed by the internal bucket and the external bucket; the internal bucket is connected into the external bucket through the springs in a floating manner; a soil scraping mechanism is arranged in the internal bucket; and a sealing piece for preventing soil from entering the middle cavity is arranged in the opening of the internal bucket and the external bucket. The special bucket for the excavator can effectively and thoroughly unload soil in the buckets, shortens the operation circulating time of the excavator, and improves the effective capacity of the buckets.

Owner:HUZHOU ZHONGCHEN CONSTR

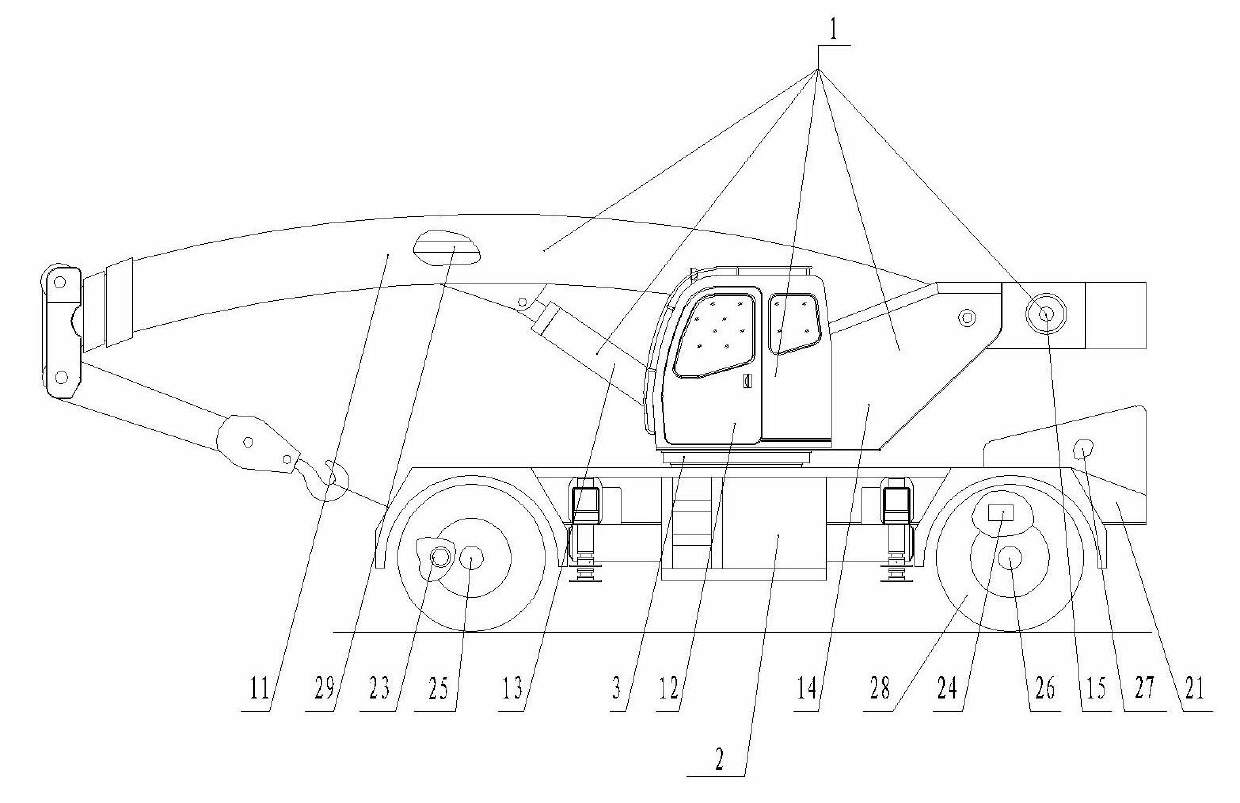

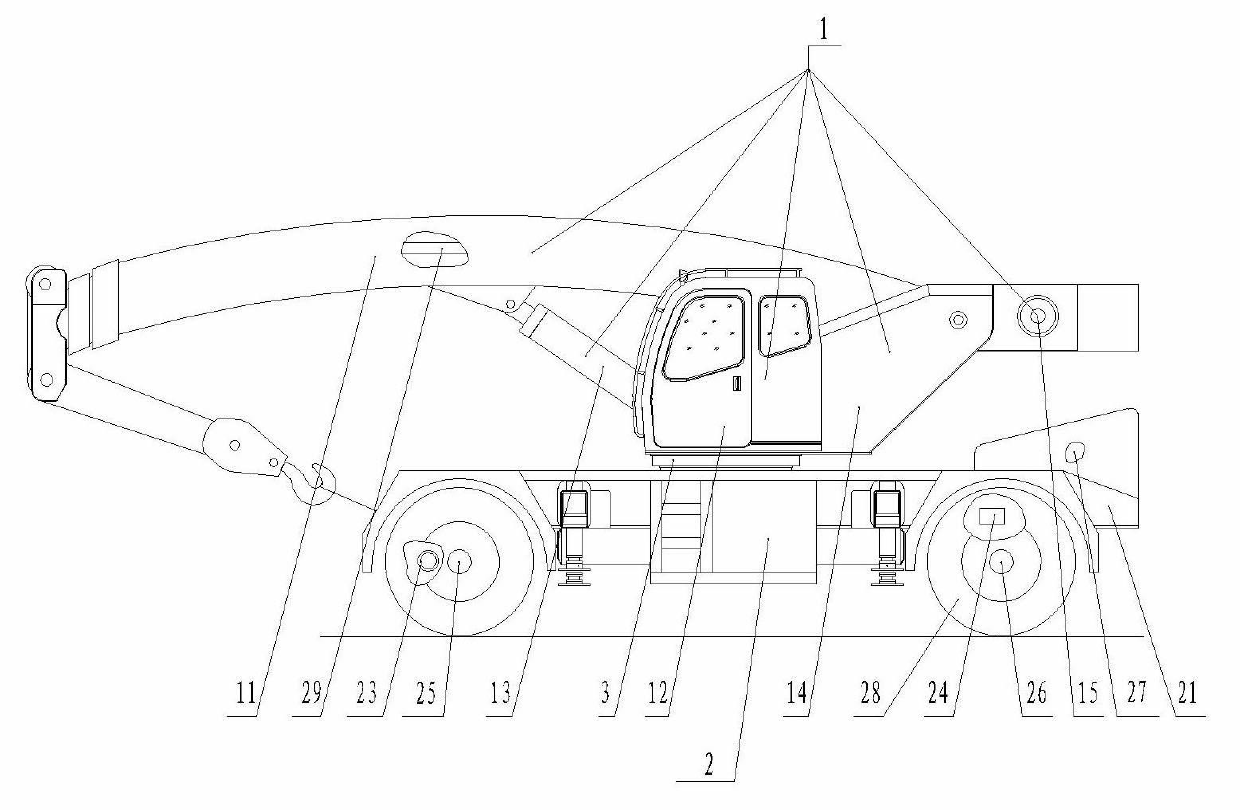

Rough-terrain wheeled crane

ActiveCN102180412ATake advantage ofImprove work efficiencyVehicle fittings for liftingFluid steeringTerrainEngineering

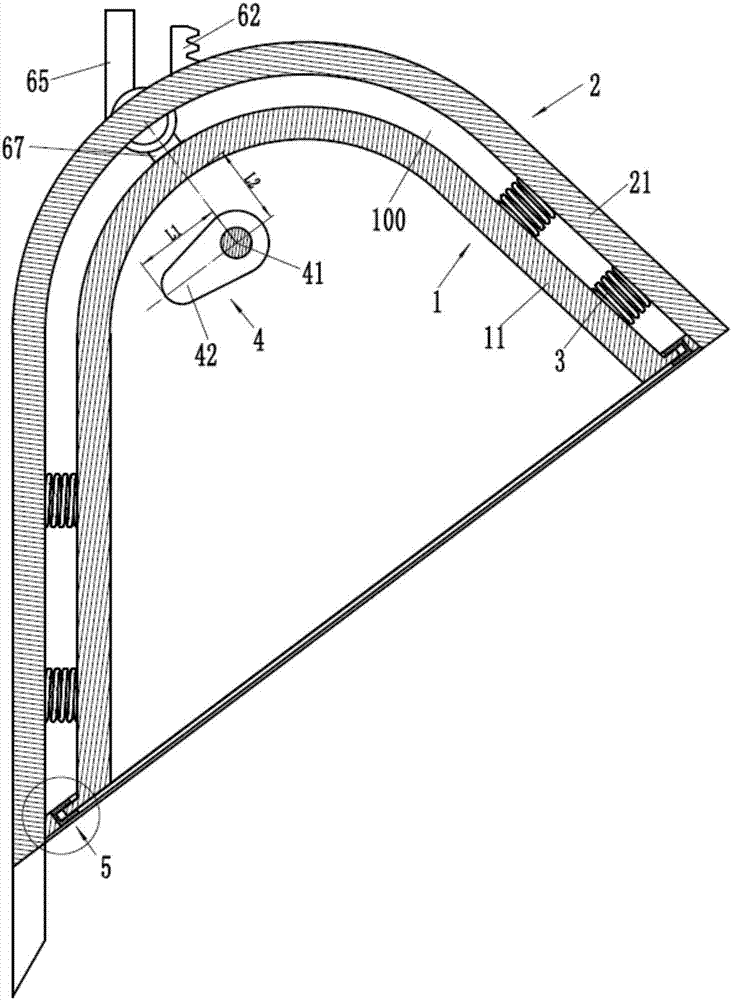

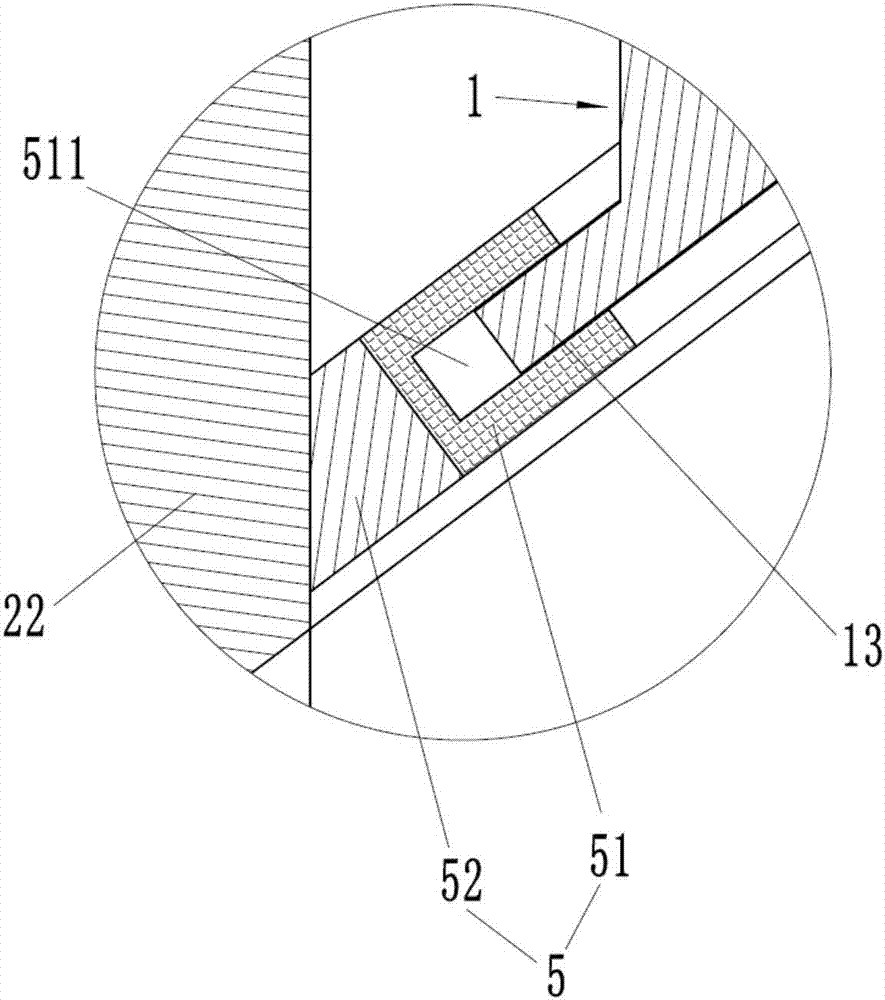

The utility model discloses a rough-terrain wheeled crane of which all actions are driven in a full-hydraulic manner, and the rough-terrain wheeled crane can realize stepless speed change and has stable speed according to different work conditions, has the advantages of small impact, simple chassis arrangement, light complete vehicle weight, and is portable, safe and reliable in operation. The rough-terrain wheeled crane is provided with an electrohydraulic control system, a driving device and a steering device which are used for realizing fast switch among a plurality of driving modes and steering modes, thereby achieving small turning radius, fully exerting the power performances of an engine, improving the fuel oil economy and saving energy resources. The rough-terrain wheeled crane has a special underframe of an integral box type closed structure and is separately and rigidly suspended, an arc-shaped crane arm and an X-shaped telescopic support leg ensure good cross-country performance, mechanical property and working condition adapting performance of the entire rough-terrain wheeled crane during running and operating. The rough-terrain wheeled crane is convenient to maintain, and especially suitable for small construction places such as airports, oil fields, ports, wharfs, storehouses and other building sites.

Owner:湖南中铁五新重工有限公司

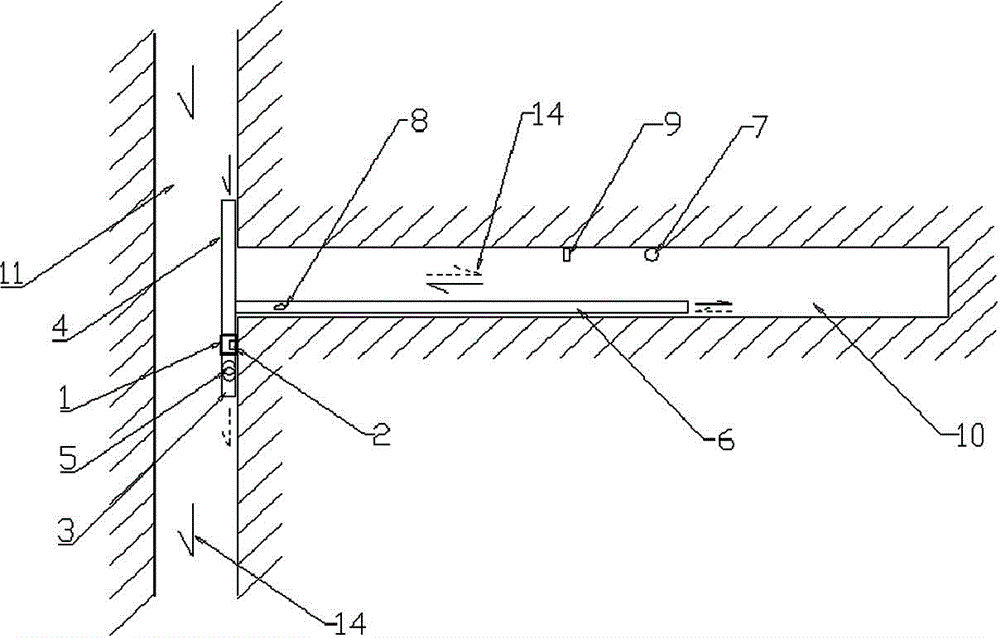

Underground blind tunnel ventilation system

ActiveCN104481570AShort ventilation timeImprove efficiencyDust removalFire preventionDust explosionTunnel ventilation

The invention relates to a ventilation system, in particular to an underground blind tunnel ventilation system. Local ventilating fans of the system are arranged in a crossdrift, one inlet-outlet of the local ventilating fans is formed in a working face range of a blind tunnel through a drainage air barrel, the other inlet-outlet is connected to a branch barrel with an opening facing the wind direction and a branch barrel with an opening opposite to the wind direction in the crossdrift through a tee joint respectively, an air channel switching valve plate for opening and closing the two branch barrels is installed at the position of the tee joint, a smoke dust sensor is arranged at the rear end of the drainage air barrel, a smoke dust sensor is also arranged at the front end close to the drainage air barrel, of the blind tunnel, and the smoke dust sensors are connected with a fan control module through data lines. The problem that traditional system smoke dust air flows are in relatively-balanced low-efficiency state is solved, smoke dust close to the head-on position performs outwards diffuses and moves to an effective suction distance or effective range of the air barrel so as to effectively improve the smoke dust explosion efficiency in blind tunnel tunneling operation work.

Owner:YILIANG CHIHONG MINING IND

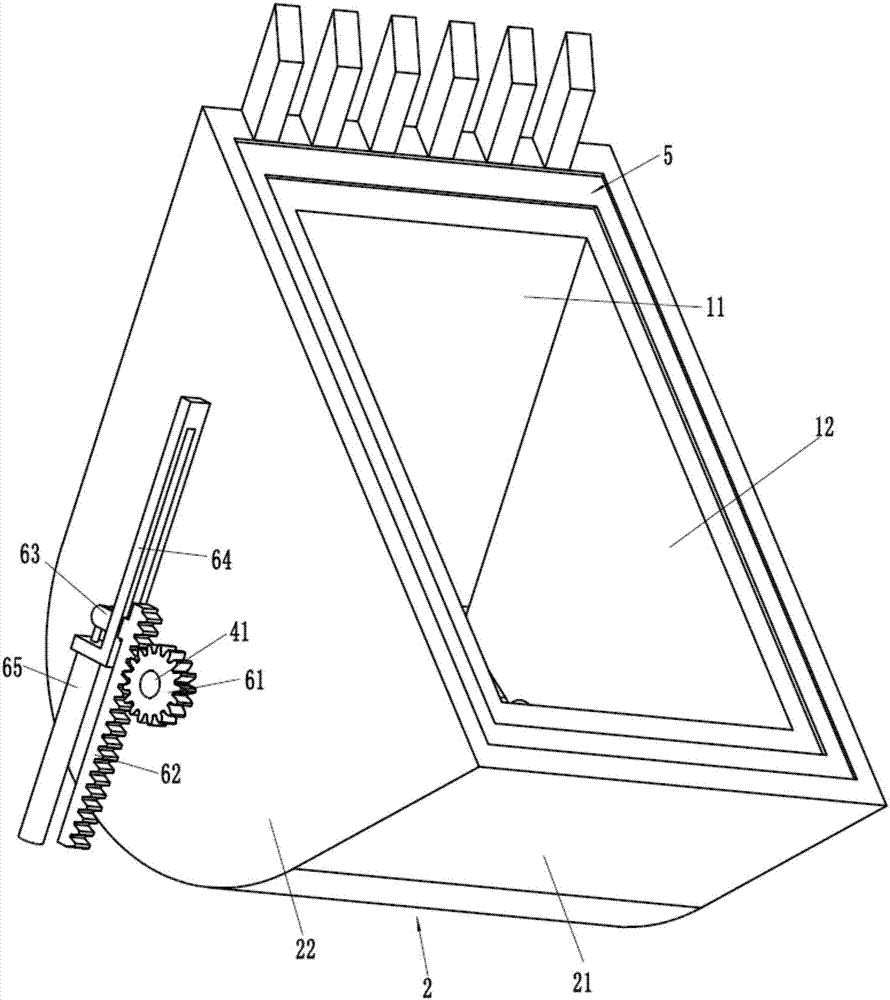

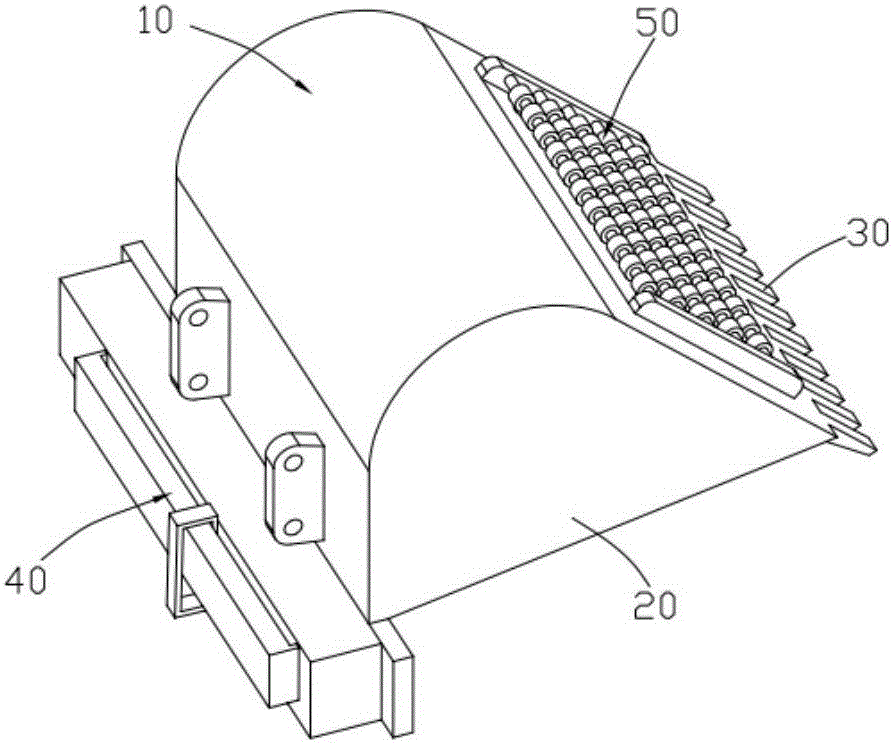

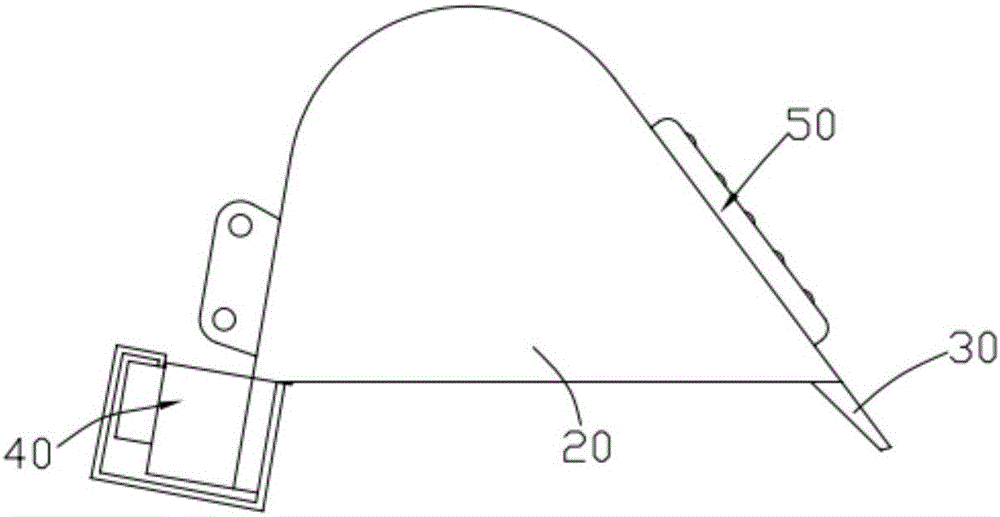

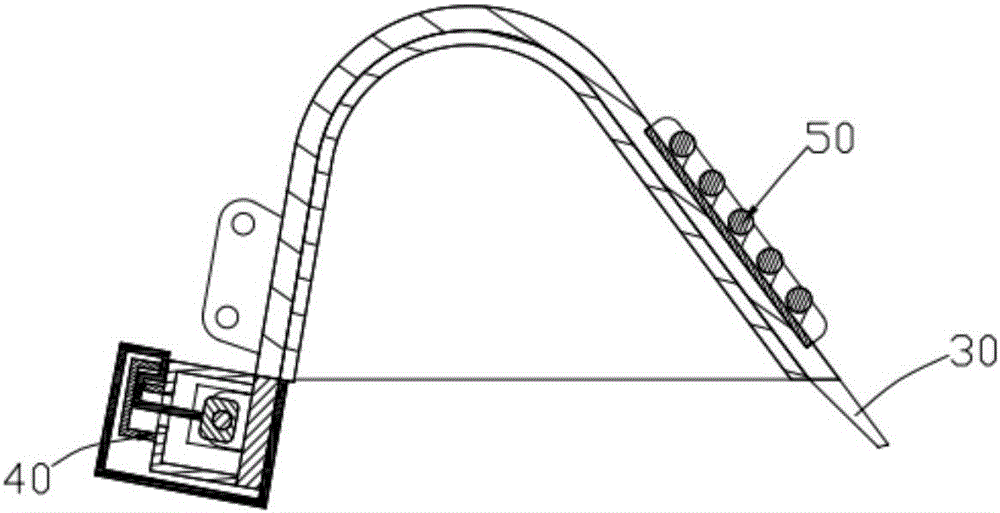

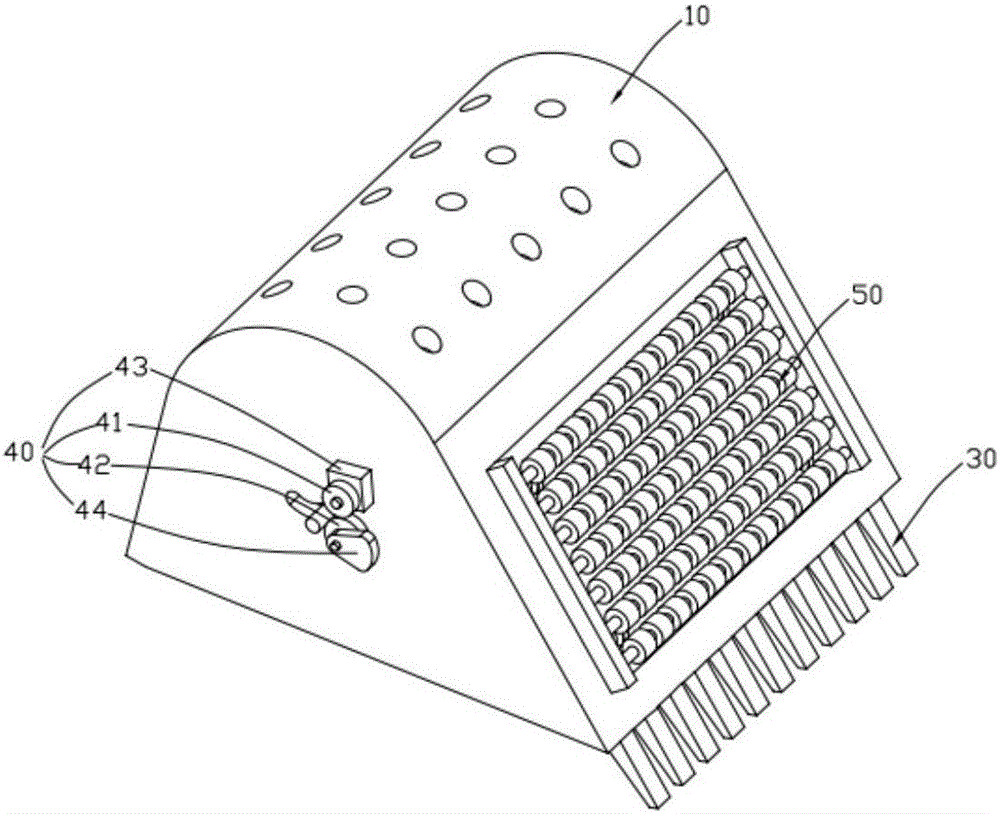

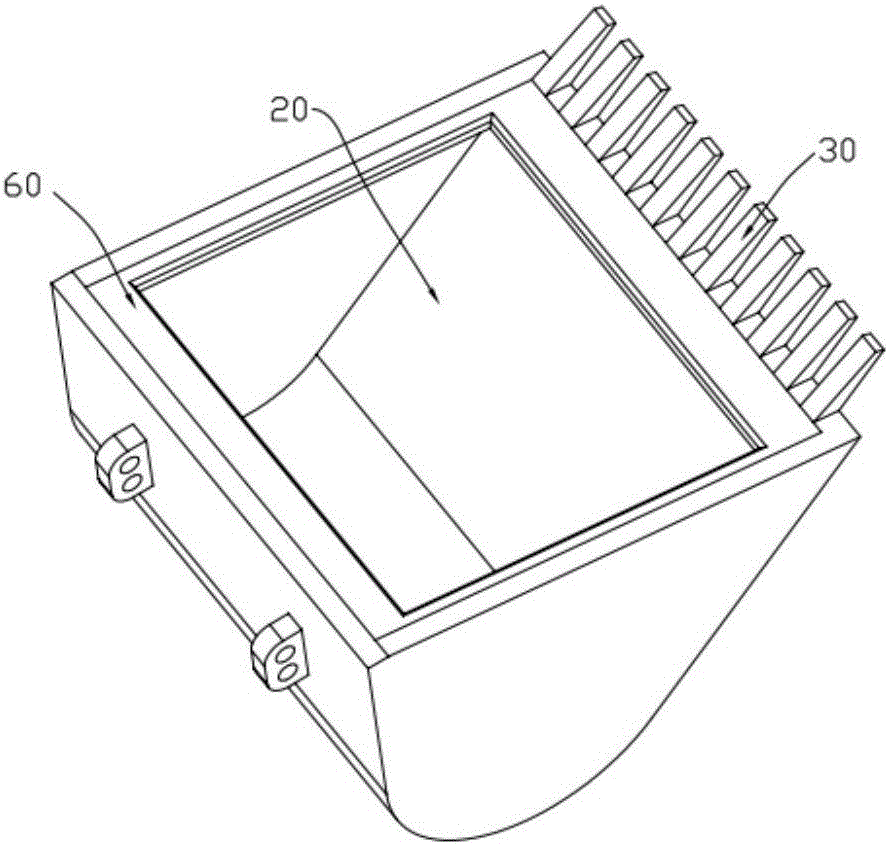

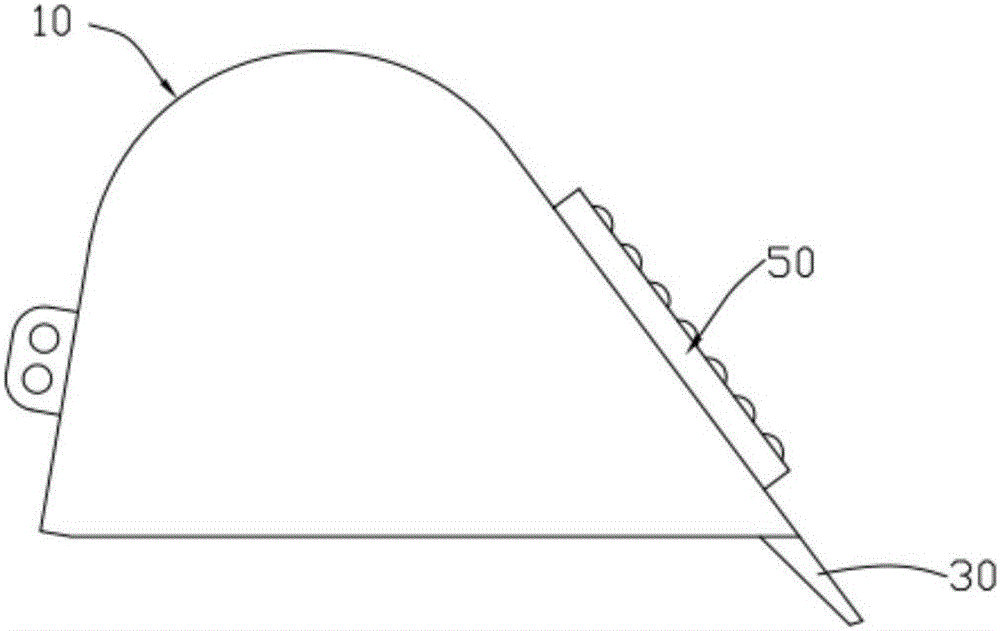

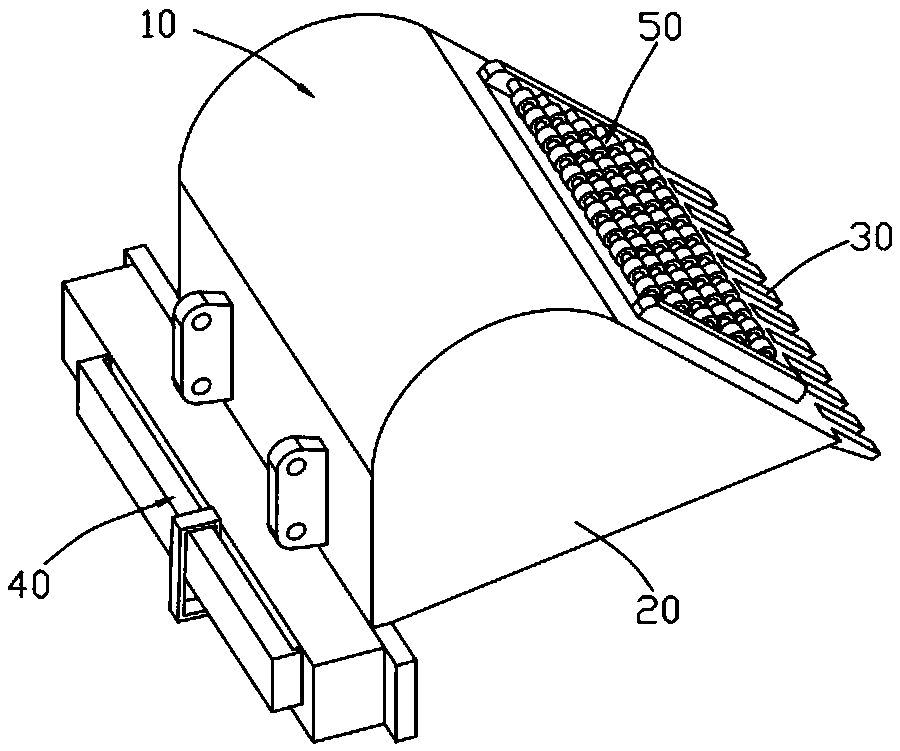

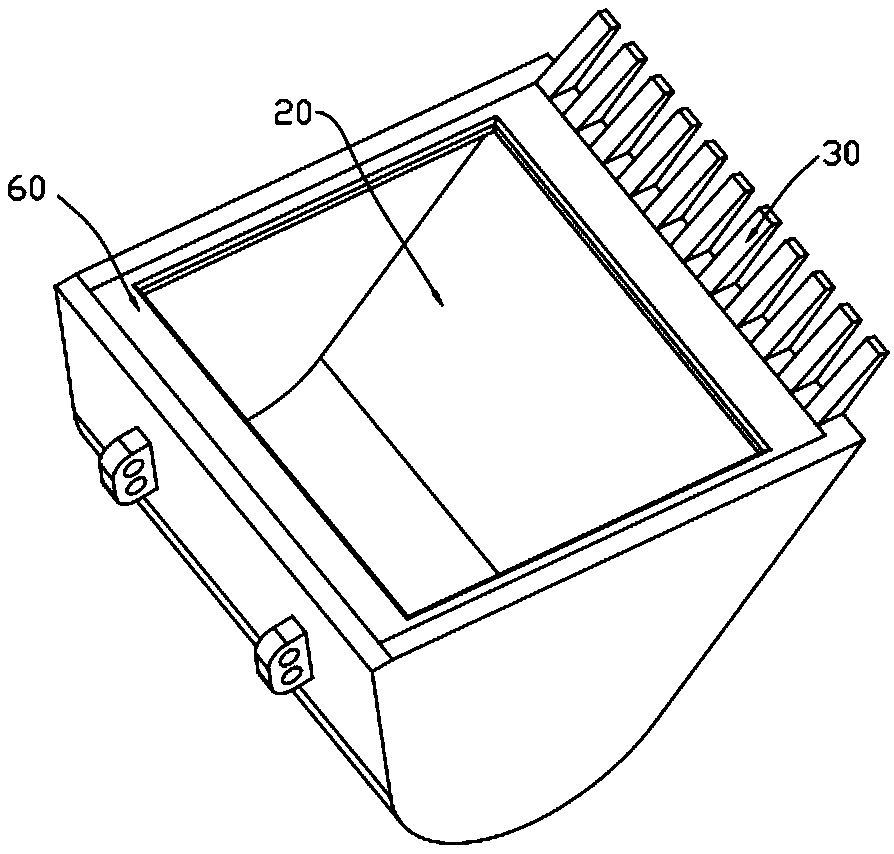

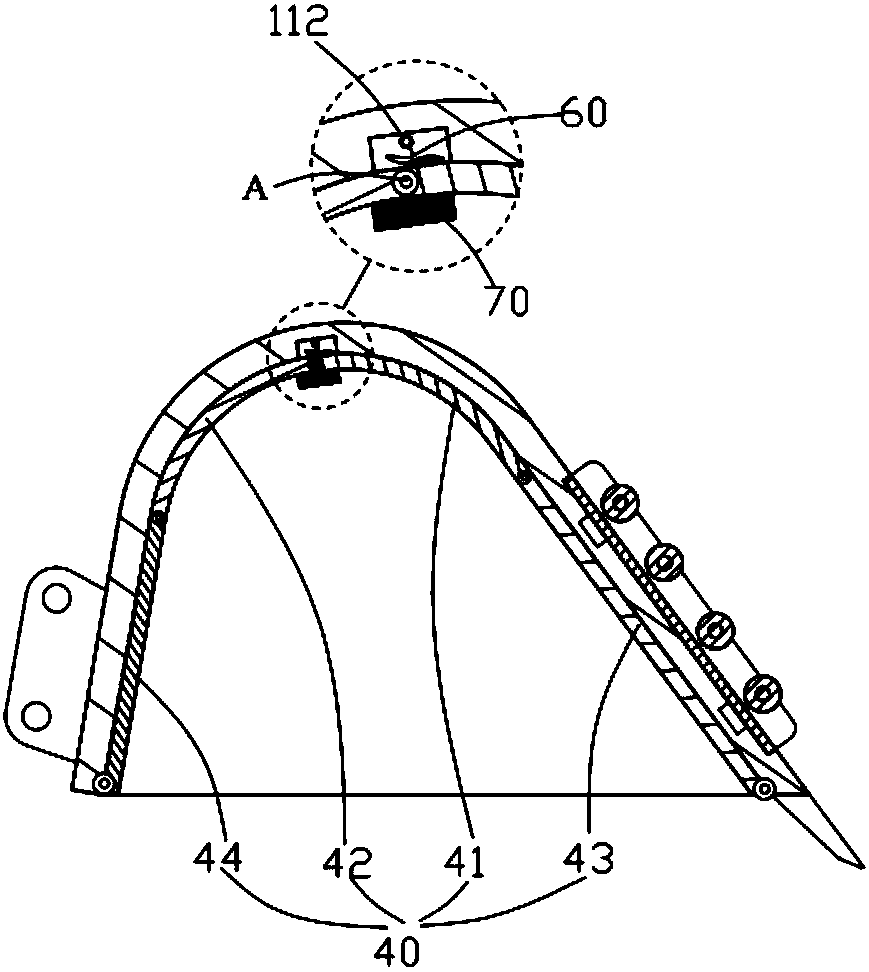

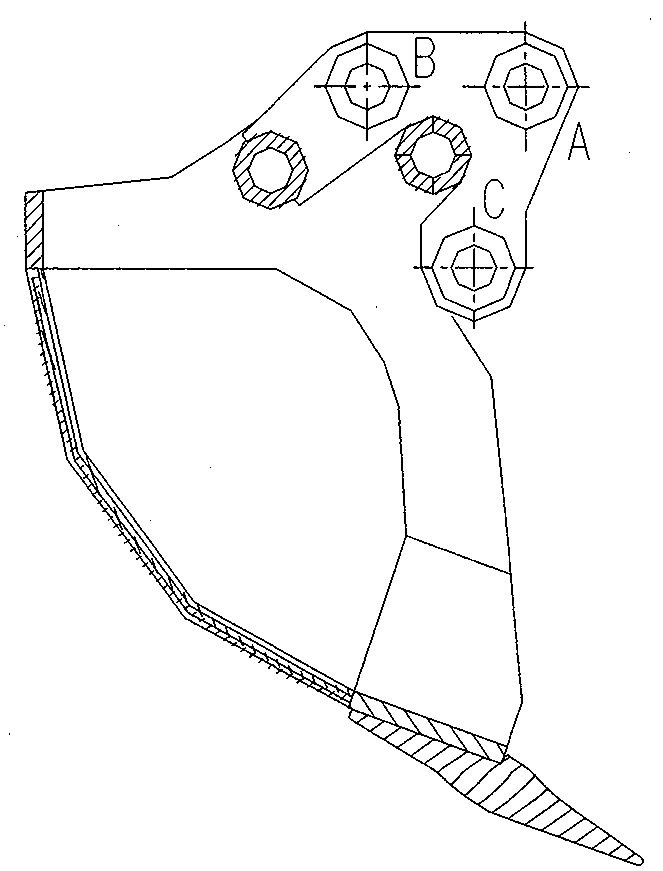

Bucket for excavator

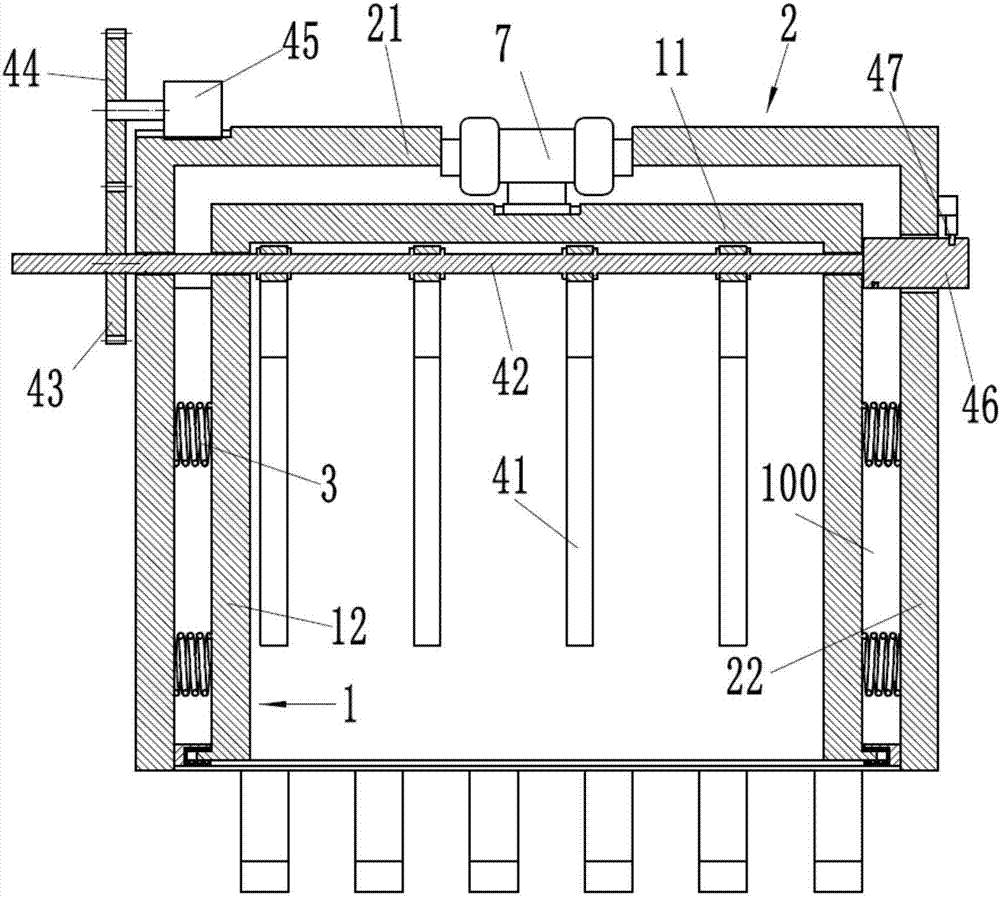

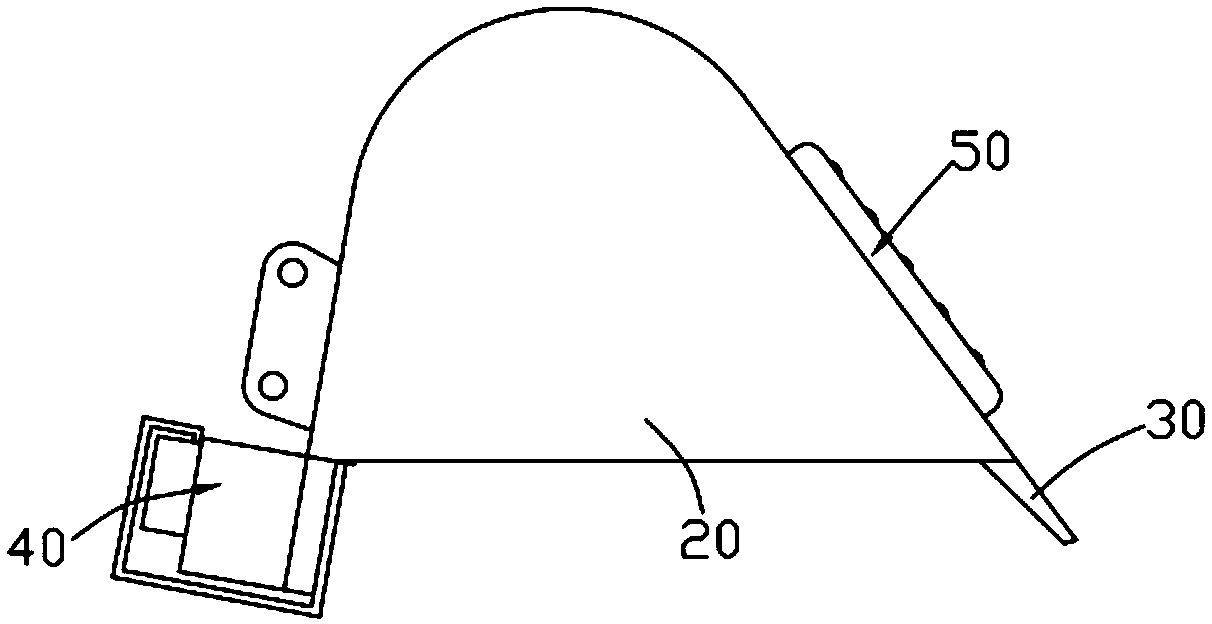

ActiveCN106759584AReduce job cycle timeIncrease effective bucket capacityMechanical machines/dredgersArchitectural engineeringExcavator

The invention discloses a bucket for an excavator. The bucket comprises a bucket plate, side plates symmetrically arranged on two sides of the bucket plate, bucket teeth arranged at one end of the bucket plate, and a scraper unit mounted at the other end of the bucket plate, wherein the scraper unit includes a base plate fixedly arranged at a free end of the bucket plate, a lead screw assembly mounted on the base plate, a motor assembly mounted at one end of the base plate for driving the lead screw assembly, a first cover for covering the motor assembly and the lead screw assembly, a second cover for covering an opening end of the first cover, a scraper arranged in an accommodating cavity defined by the bucket plate and the side plates for removing attached matters on the inner wall of the bucket plate, and a connecting rod for connecting the scraper with the lead screw assembly. The bucket for the excavator can effectively scrape off the attached matters on the inner wall of the bucket plate to improve the effective volume of the bucket.

Owner:临沂临工重托机械有限公司

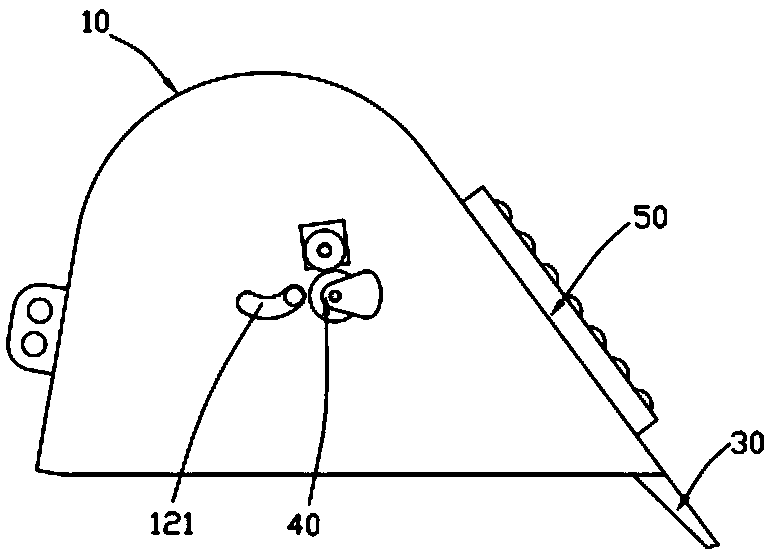

Excavator bucket capable of preventing soil adhesion

ActiveCN106836358ASimple structureReduce job cycle timeSoil-shifting machines/dredgersEngineeringCam

The invention discloses an excavator bucket capable of preventing soil adhesion. The excavator bucket comprises an external bucket body, a internal bucket body, a baffle ring and a cam unit. The internal bucket body is hinged inside the external bucket body; the baffle ring is mounted at the flared end of the external bucket body and used for guiding materials into the internal bucket body; and the cam unit is mounted on the external bucket body to make the internal bucket body swing back and forth inside the external bucket body. The excavator bucket capable of preventing soil adhesion can unload the soil in the bucket effectively, and shorten the working time of an excavator, and the effective bucket capacity of the excavator bucket is improved.

Owner:山东鲁宇重工机械制造有限公司

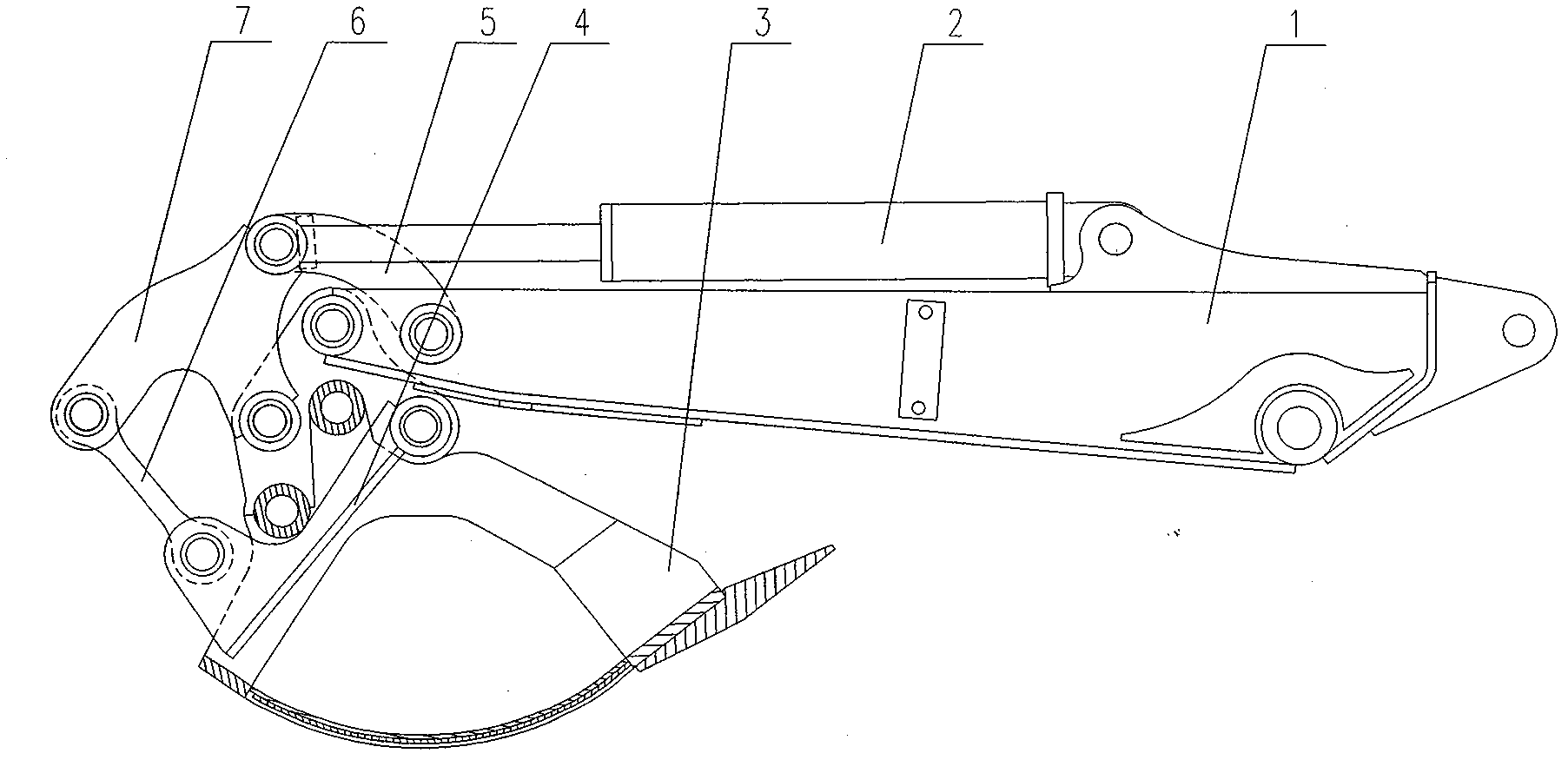

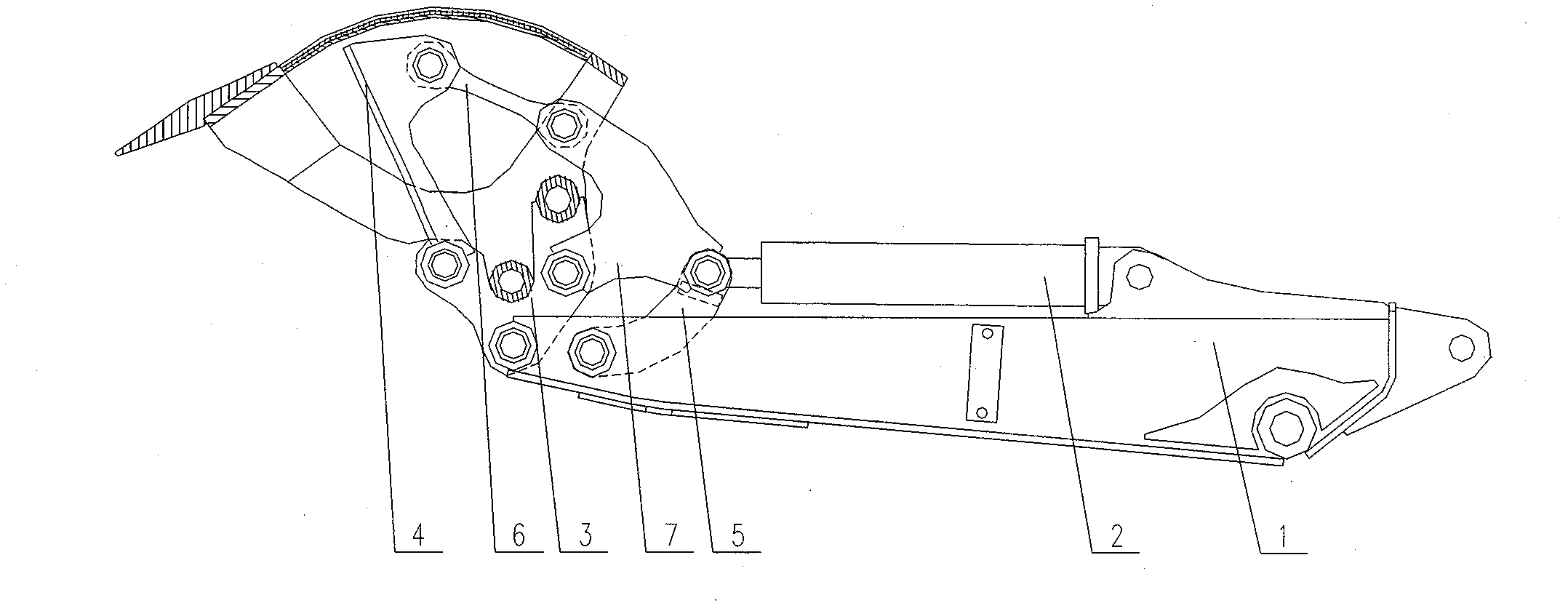

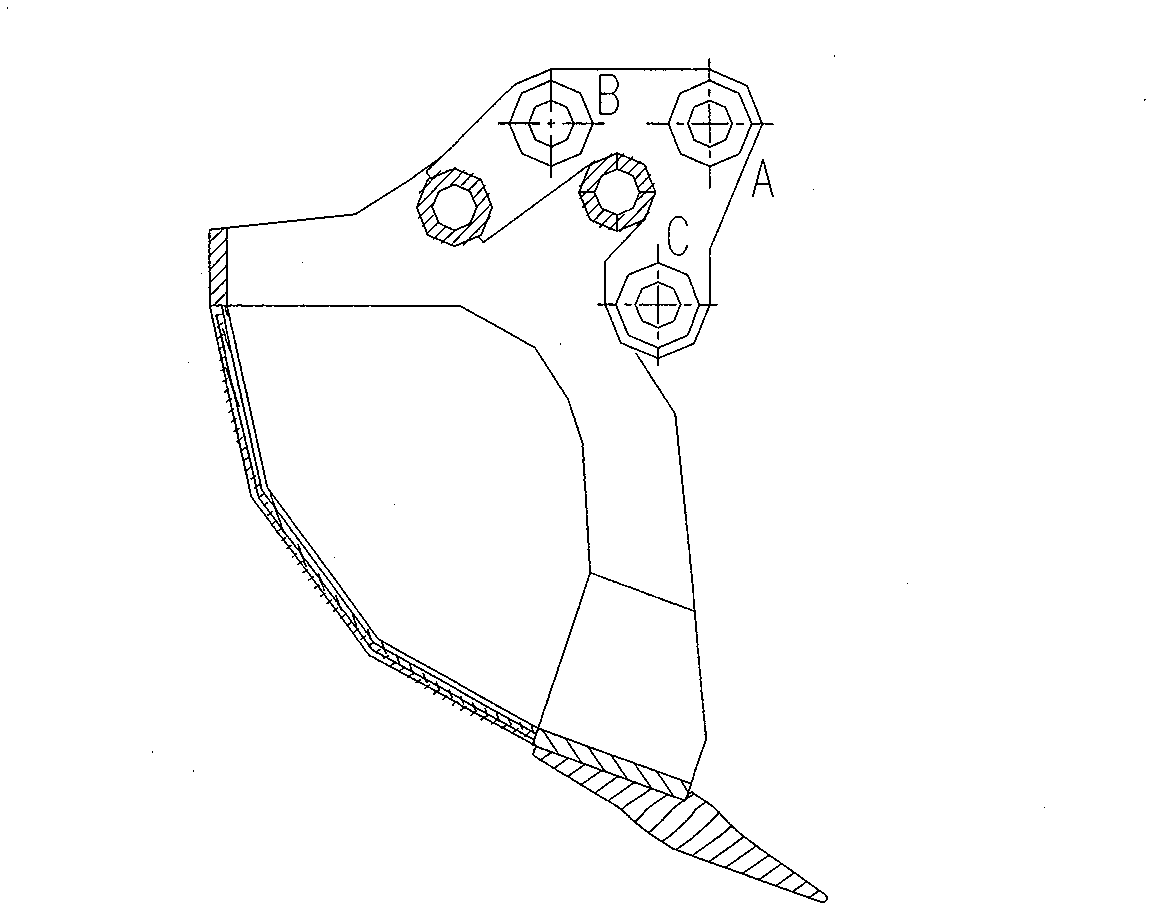

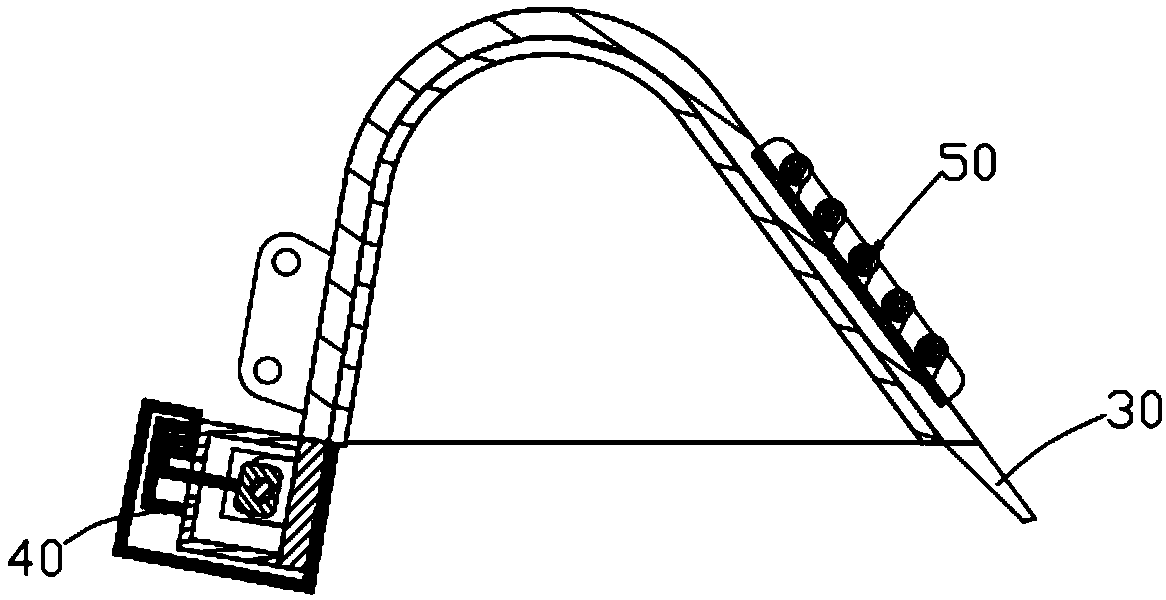

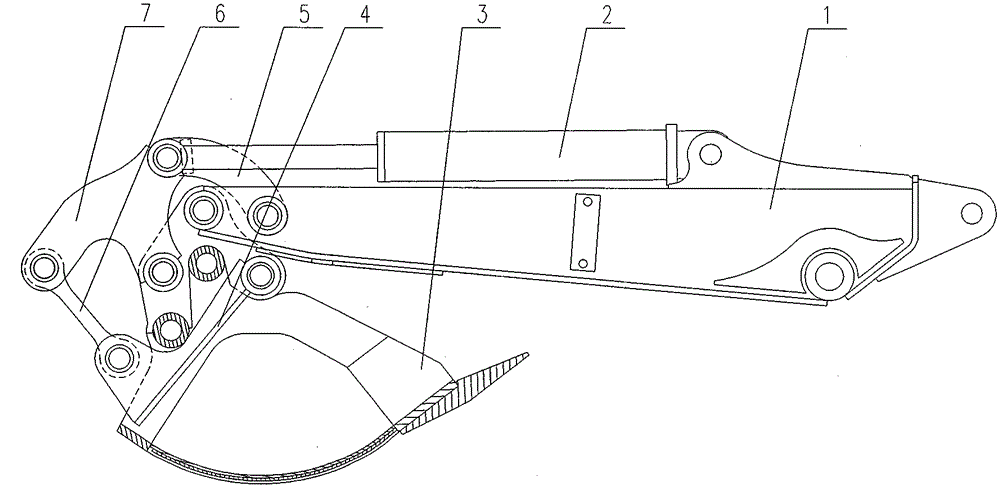

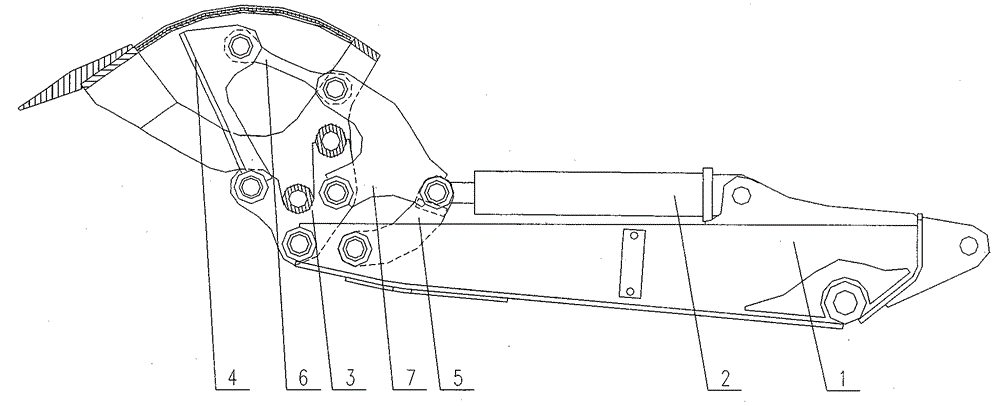

Digging bucket

ActiveCN103174181AReduce job cycle timeImprove effective bucket capacitySoil-shifting machines/dredgersEngineeringRocker arm

The invention discloses a digging bucket. Through operation of extension and constriction of a bucket cylinder, a four bar mechanism composed of a bucket rod, a bucket body, a rocking bar and a three-point rocker arm is driven; and then through a hinge point of the bucket body and the three-point rocker arm, the other set of four bar mechanism composed of a bucket body, a three-point rocker arm, a draw bar and a scraper plate is driven so that soil loading and forced soil unloading in the process of digging are achieved. According to the digging bucket, under the working condition of digging clay, the digging bucket has special advantages. And the digging bucket is high in efficiency, reliable in performance, simple in structure, convenient to manufacture and low in cost.

Owner:GUANGXI YUCHAI HEAVY IND

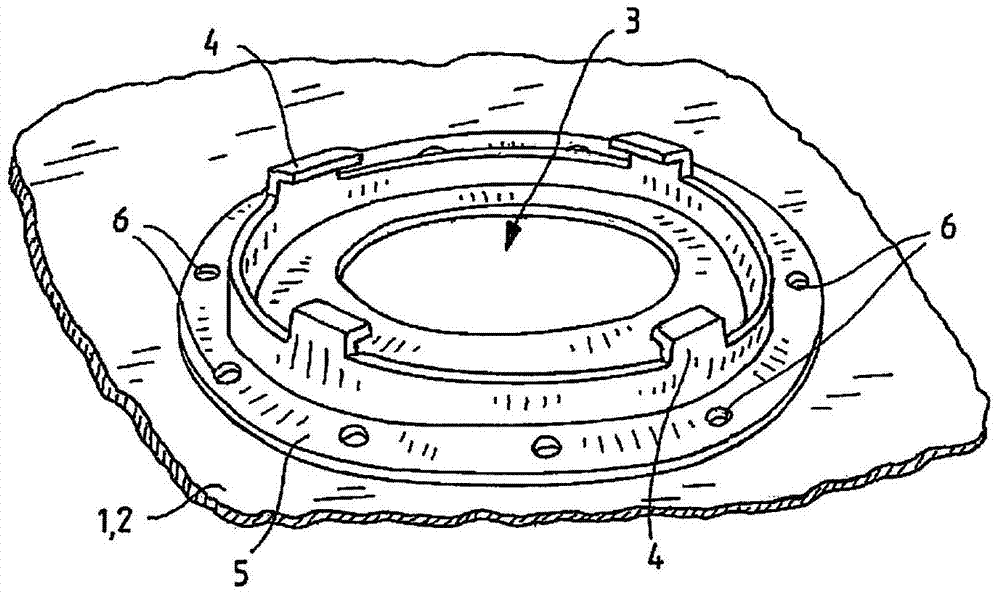

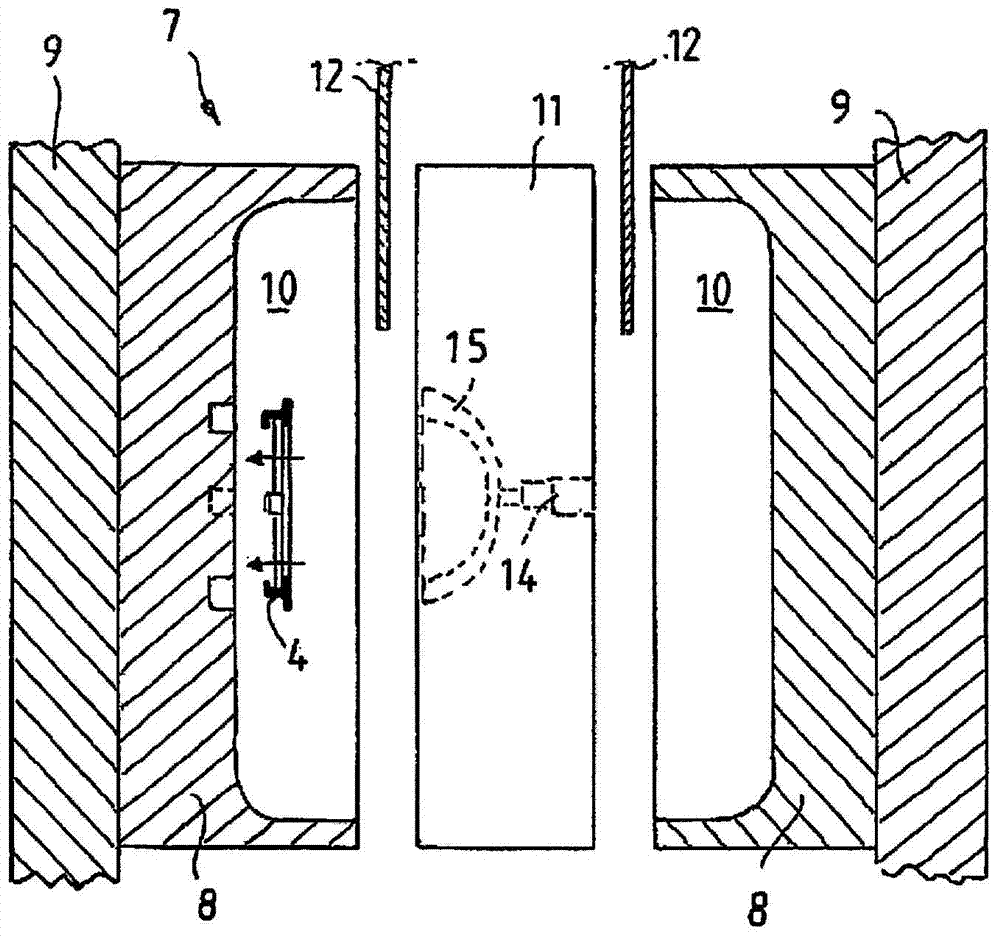

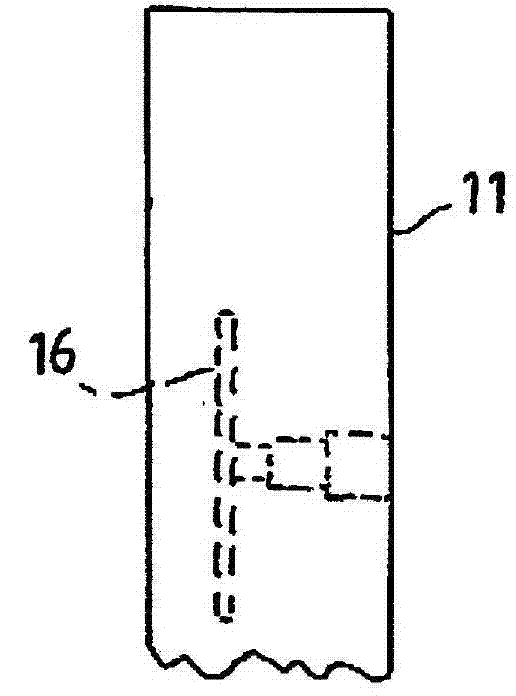

Method for producing a container made from thermoplastic material

ActiveCN104755248AReduce job cycle timeSmall surplusDomestic articlesHollow articlesEngineeringMechanical engineering

The invention relates to a method for producing a container (2) from a thermoplastic, having at least one surround (4), provided in the container wall (1), for a container opening. The surround (4) comprises a structure behind which parts of the container wall (1) extend and / or which is penetrated by said parts. The method is carried out using a multi-part blow mold that has at least two mold parts, each having at least one cavity, wherein the surround is placed as an insert in the cavity (10) of the blow mold (7). The method comprises pressing the preform that has been forced into the cavity (10) into the structure of the surround (4) by means of a tool which is brought to bear on the preform (12) on the side of the preform facing away from the cavity (10).

Owner:KAUTEX TEXTRON

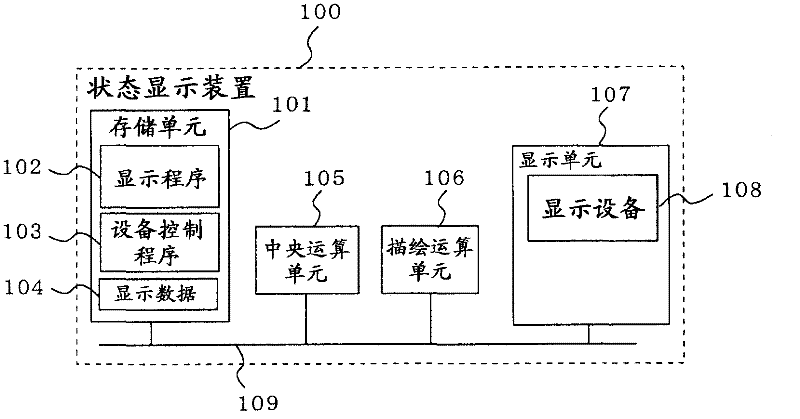

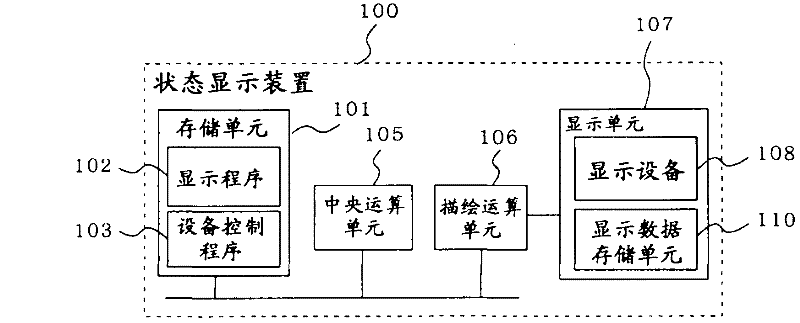

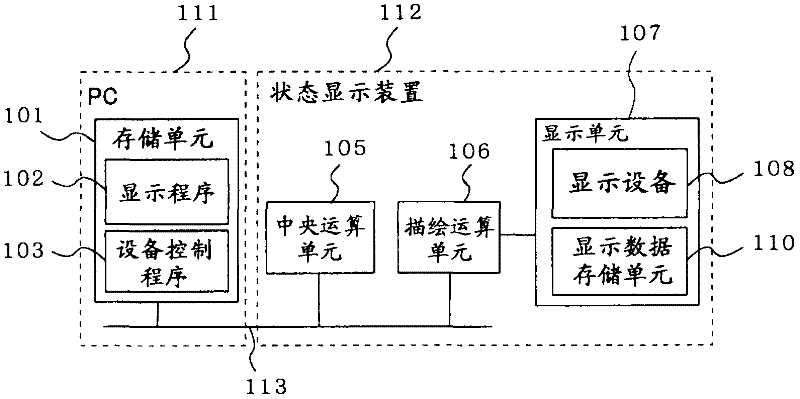

status display device

InactiveCN102301341AImprove work efficiencyEasy to verify performanceStatic indicating devicesError detection/correctionDisplay deviceCycle time

Owner:MITSUBISHI ELECTRIC CORP

A kind of ventilating system of underground tunnel

ActiveCN104481570BShort ventilation timeImprove efficiencyDust removalFire preventionDust explosionTunnel ventilation

The invention relates to a ventilation system, in particular to an underground blind tunnel ventilation system. Local ventilating fans of the system are arranged in a crossdrift, one inlet-outlet of the local ventilating fans is formed in a working face range of a blind tunnel through a drainage air barrel, the other inlet-outlet is connected to a branch barrel with an opening facing the wind direction and a branch barrel with an opening opposite to the wind direction in the crossdrift through a tee joint respectively, an air channel switching valve plate for opening and closing the two branch barrels is installed at the position of the tee joint, a smoke dust sensor is arranged at the rear end of the drainage air barrel, a smoke dust sensor is also arranged at the front end close to the drainage air barrel, of the blind tunnel, and the smoke dust sensors are connected with a fan control module through data lines. The problem that traditional system smoke dust air flows are in relatively-balanced low-efficiency state is solved, smoke dust close to the head-on position performs outwards diffuses and moves to an effective suction distance or effective range of the air barrel so as to effectively improve the smoke dust explosion efficiency in blind tunnel tunneling operation work.

Owner:YILIANG CHIHONG MINING IND

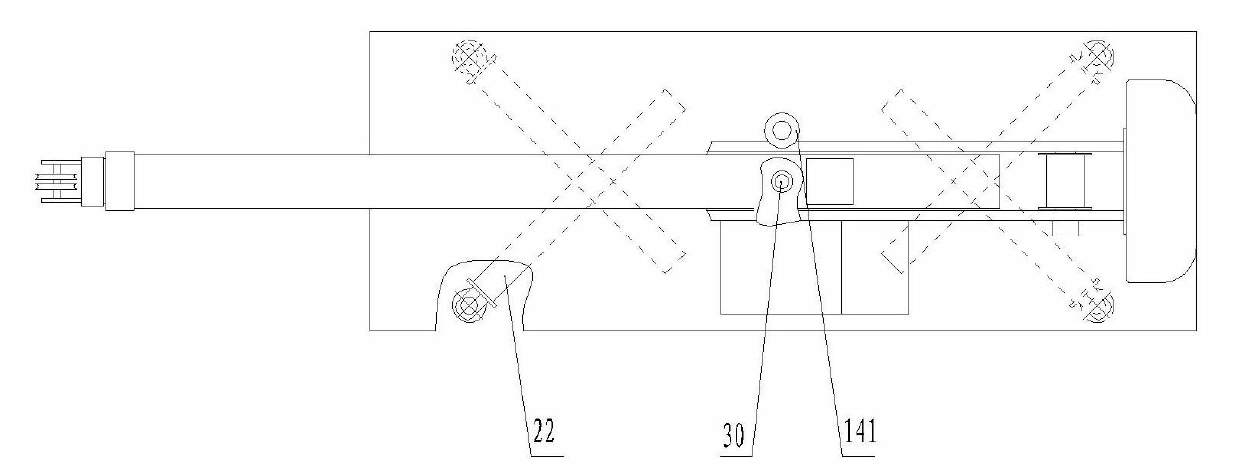

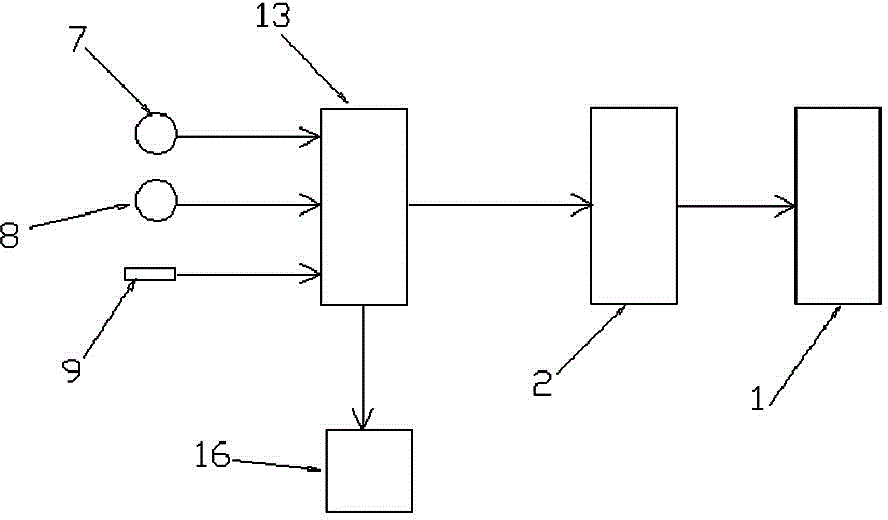

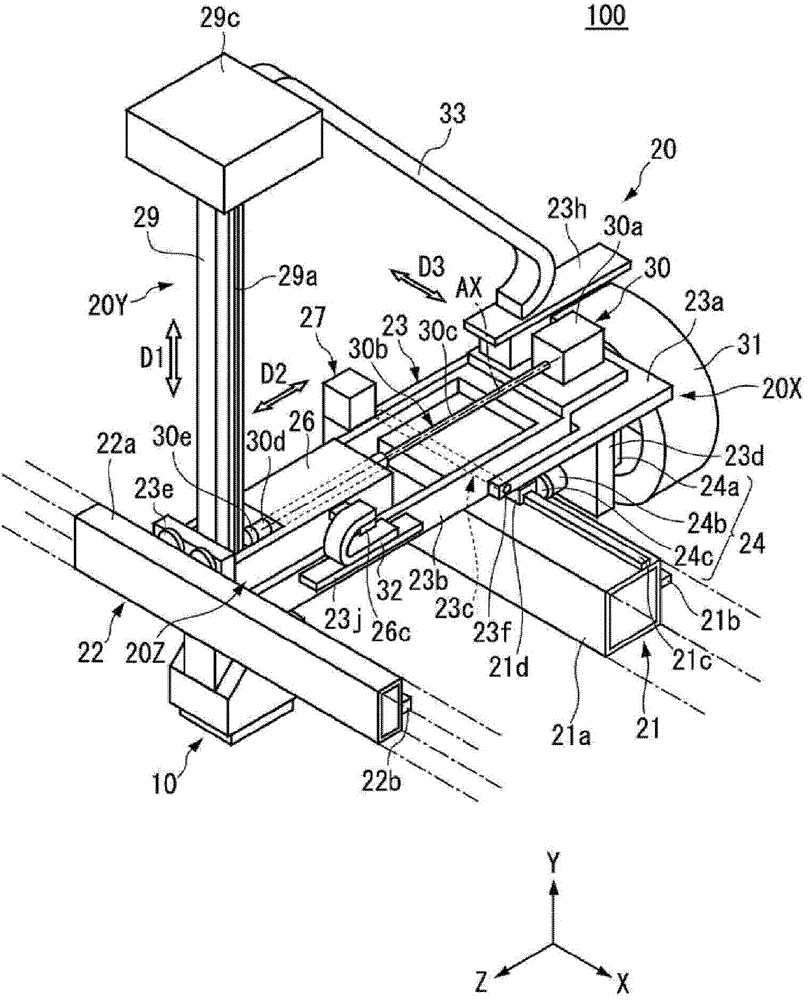

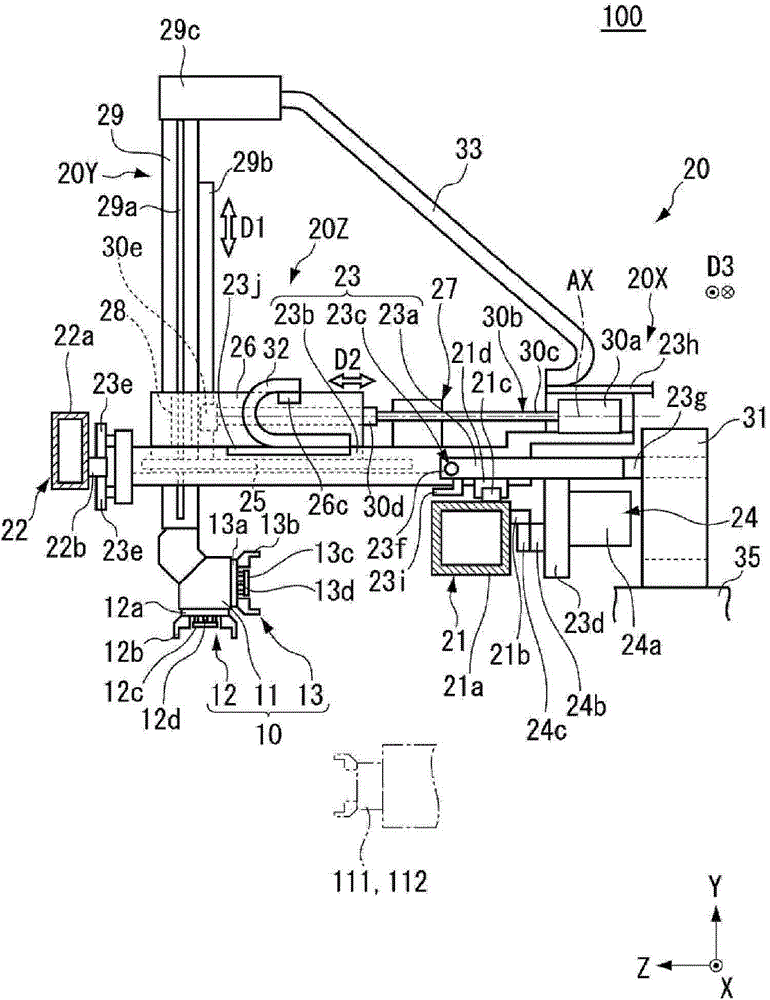

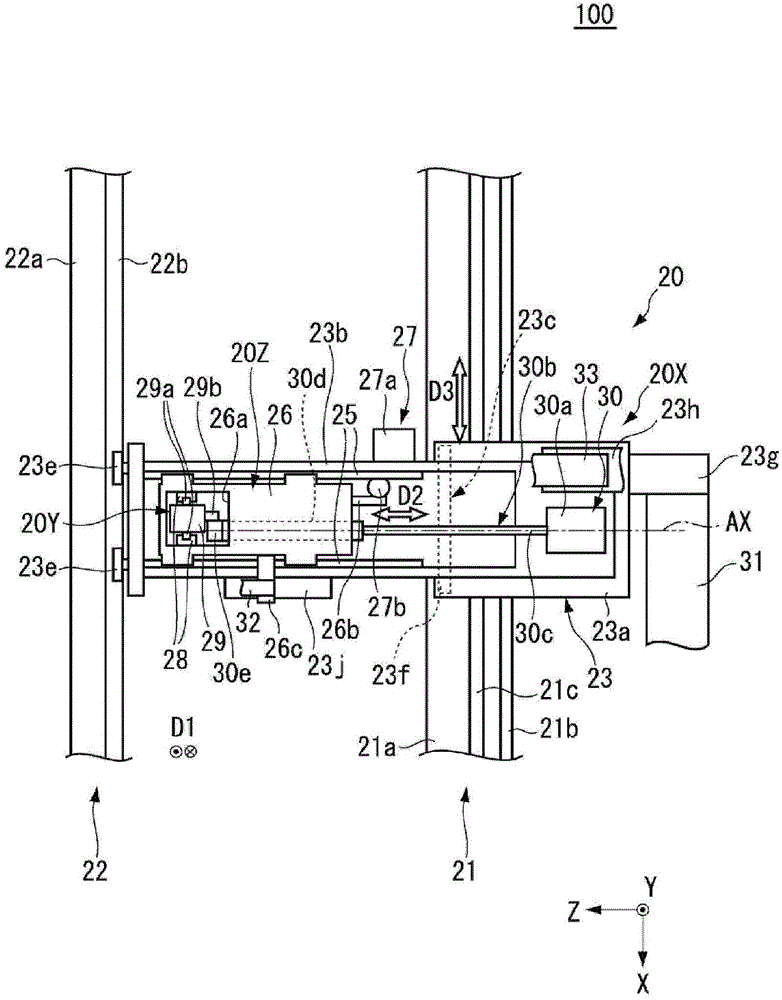

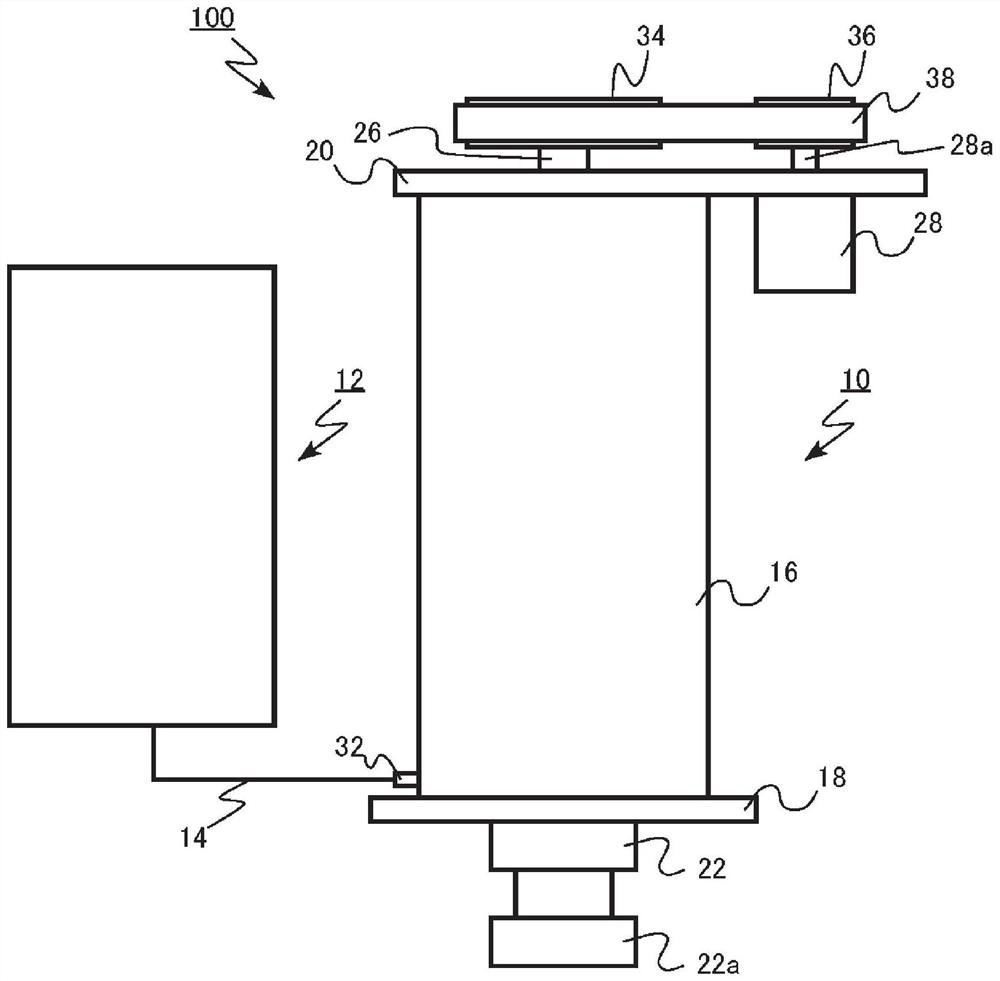

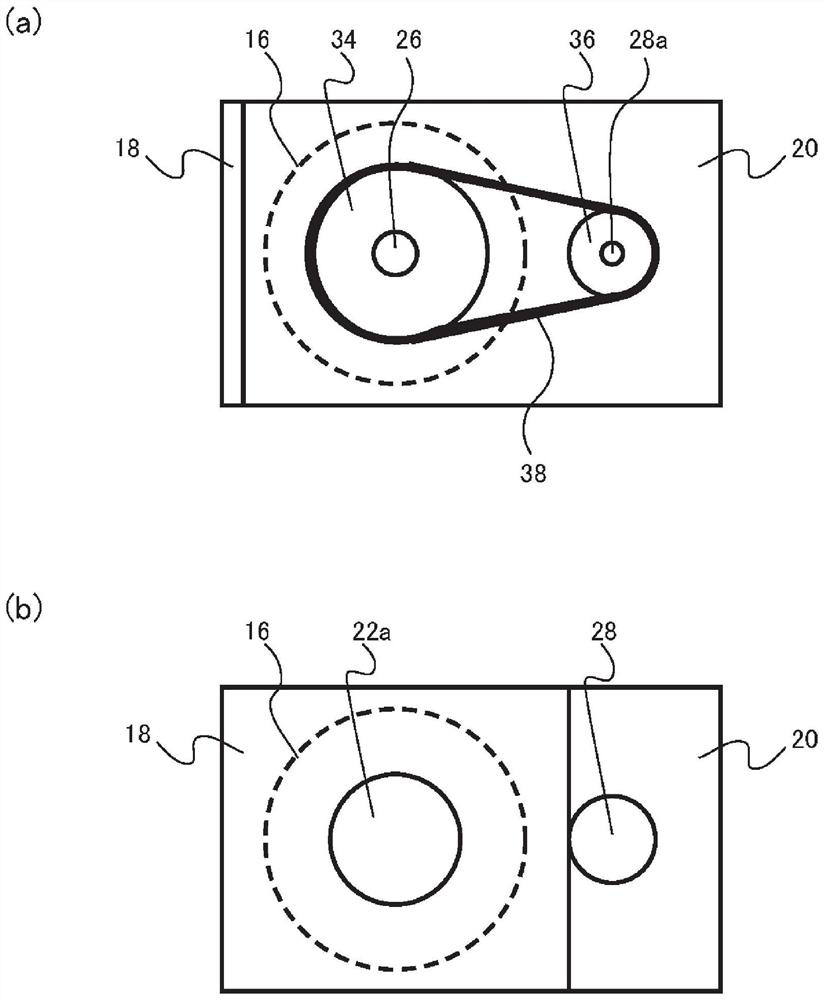

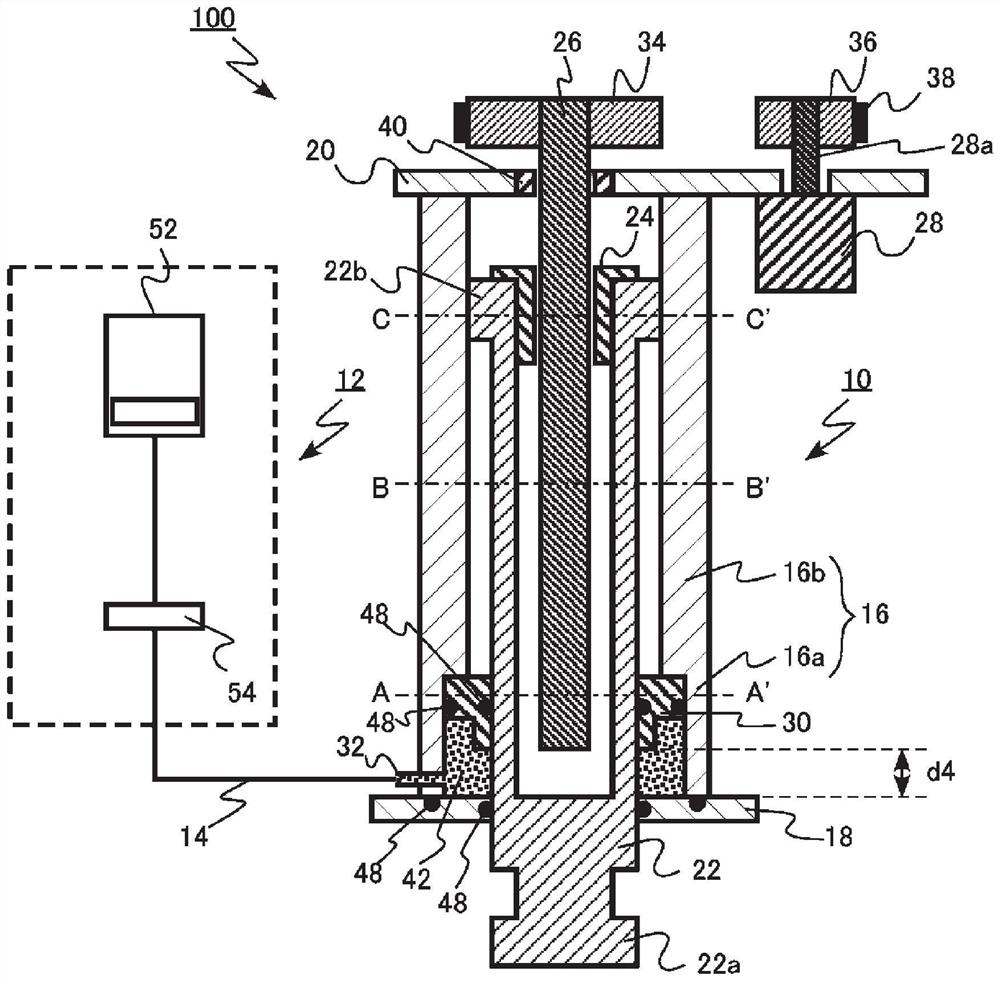

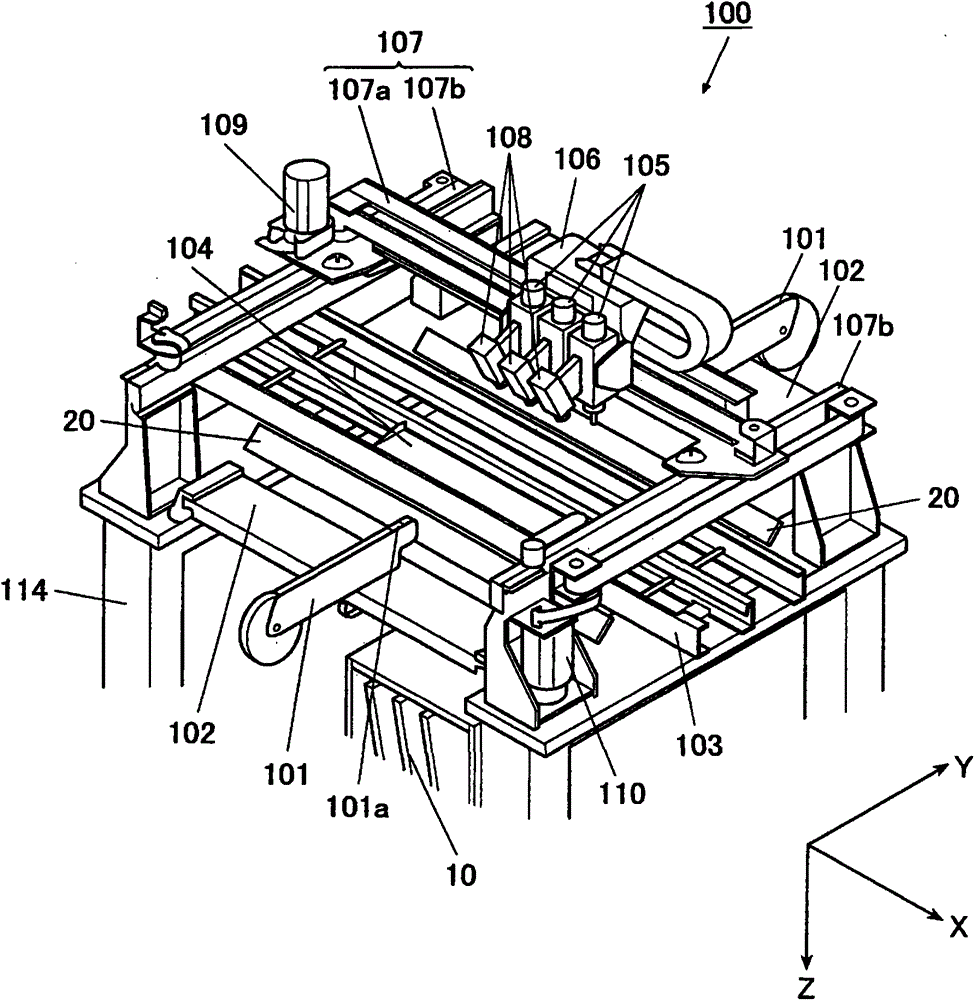

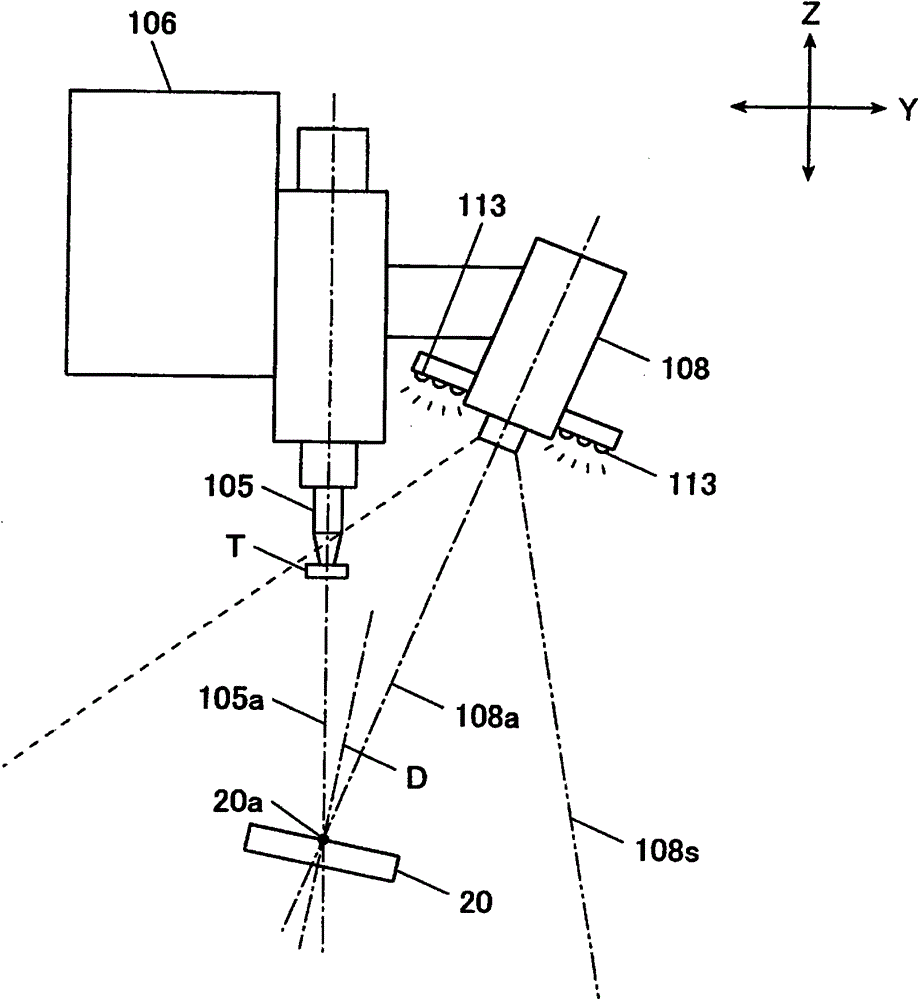

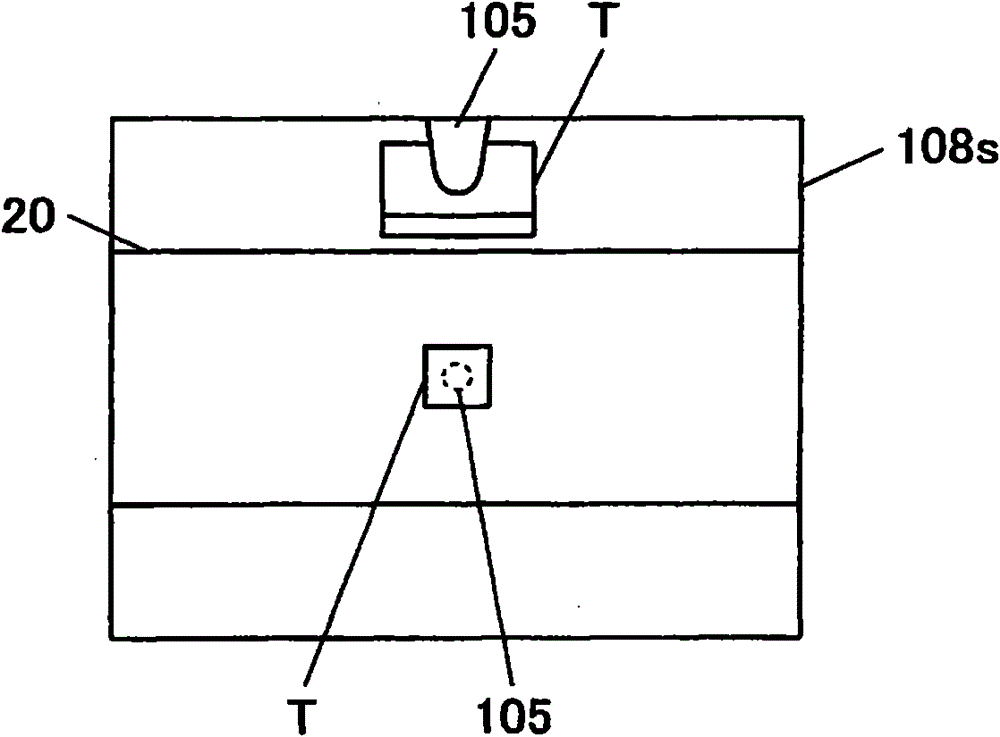

Workpiece conveying device and machine tool

InactiveCN105328497AShorten movement timeQuick upgradeProgramme-controlled manipulatorLarge fixed membersMachine toolEngineering

Provided are a workpiece conveying device (100) and a machine tool that can reduce time required to convey a workpiece. The workpiece conveying device (100) includes an elevating section (29) that includes a chuck (12, 13) for holding the workpiece, a slider (26) that supports the elevating section (29) such that the elevating section (29) is movable in a first direction (D1), the slider (26) being movable in a second direction (D2) different from the first direction (D1), and a driving section (30) that drives the elevating section (29), wherein the driving section (30) includes a driving source (30a) disposed away from the elevating section (29) and the slider (26), and a transmitting section (30b) that transmits a driving force of the driving source (30a) to the elevating section (29).

Owner:MURATA MASCH LTD

Excavator special bucket

ActiveCN106836329BIncrease effective bucket capacityAchieve jitterMechanical machines/dredgersEngineeringCycle time

The invention discloses a bucket special for an excavator. The bucket comprises an outer bucket body and an inner bucket body mounted in the outer bucket body through a compressed spring; an outward-extending convex edge is formed on the flaring end of the inner bucket body, the outer bucket body comprises an outer bucket plate and a pair of outer side plates arranged on the two sides of the outer bucket plate, the inner bucket body comprises an inner bucket plate corresponding to the outer bucket plate and a pair of inner side plates corresponding to the outer side plates, the outer bucket plate comprises an outer arc plate, a first outer straight plate and a second outer straight plate, the first outer straight plate and the second outer straight plate are located at the two ends of the outer arc plate, and are tangent to the outer arc plate, and a plurality of through holes are formed in the outer arc plate. Surface adhesive materials in the bucket can be effectively unloaded thoroughly, the work circulation time of the excavator is reduced, and the effective capacity of the bucket is improved.

Owner:徐州贝峰机械制造有限公司

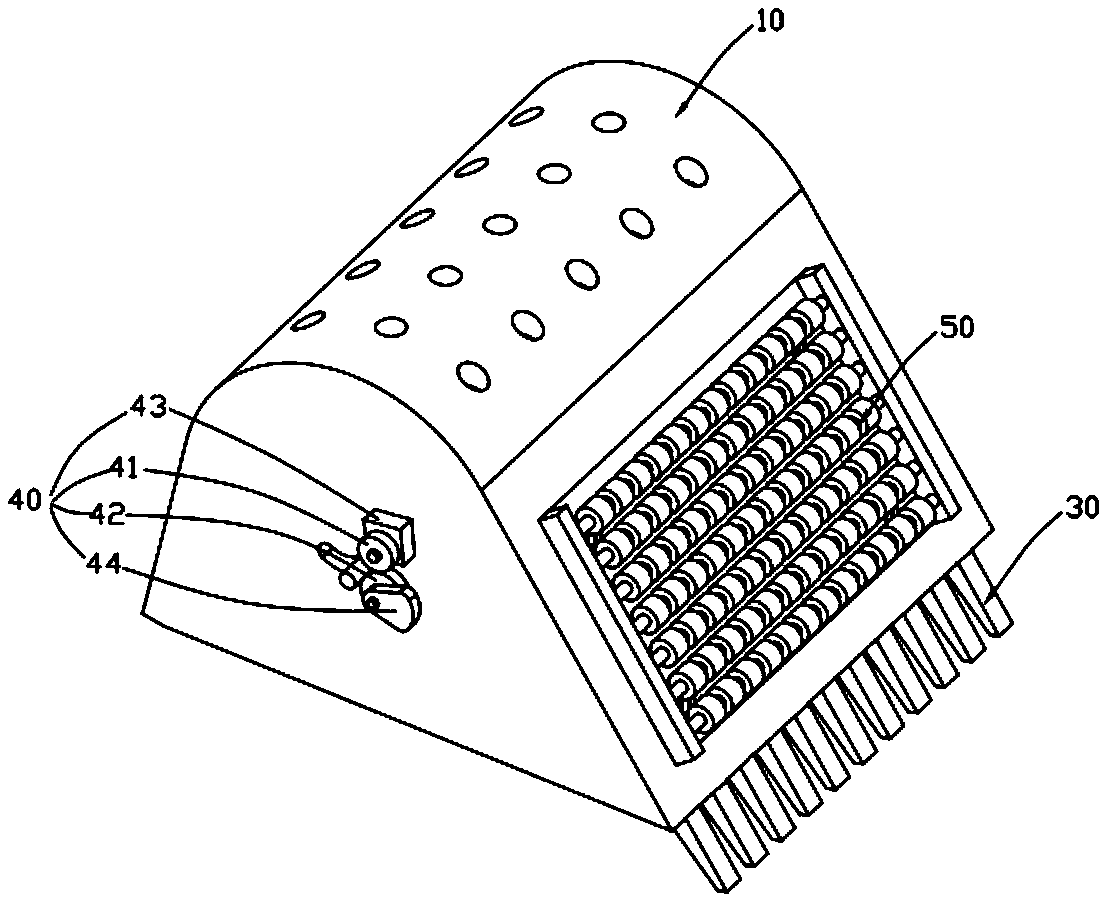

Bucket special for excavator

ActiveCN106836329AIncrease effective bucket capacityAchieve jitterMechanical machines/dredgersEngineeringExcavator

The invention discloses a bucket special for an excavator. The bucket comprises an outer bucket body and an inner bucket body mounted in the outer bucket body through a compressed spring; an outward-extending convex edge is formed on the flaring end of the inner bucket body, the outer bucket body comprises an outer bucket plate and a pair of outer side plates arranged on the two sides of the outer bucket plate, the inner bucket body comprises an inner bucket plate corresponding to the outer bucket plate and a pair of inner side plates corresponding to the outer side plates, the outer bucket plate comprises an outer arc plate, a first outer straight plate and a second outer straight plate, the first outer straight plate and the second outer straight plate are located at the two ends of the outer arc plate, and are tangent to the outer arc plate, and a plurality of through holes are formed in the outer arc plate. Surface adhesive materials in the bucket can be effectively unloaded thoroughly, the work circulation time of the excavator is reduced, and the effective capacity of the bucket is improved.

Owner:徐州贝峰机械制造有限公司

Single-pump hydraulic control loop of key drilling action of cutting drill rig

ActiveCN102747950BPrevent slippingImprove auto-adaptabilityServomotor componentsServomotorsFuel tankEngineering

A single-pump hydraulic control loop of a key drilling action of a cutting drill rig comprises a load-sensitive variable pump, a load-sensitive multi-way valve, a rotary motor, a propulsion oil tank, a drilling logic control block, a rotation guide handle, a propulsion guide handle, and a hydraulic oil tank. An oil inlet of the load-sensitive variable pump is connected with the hydraulic oil tank. An oil outlet and a load-sensitive opening of the load-sensitive variable pump are connected with an oil inlet and a load-sensitive opening of the load-sensitive multi-way valve respectively. Each valve pressure difference compensator of the load-sensitive multi-way valve is provided with an external control opening. The external control openings are connected with the drilling logic control block. The rotation guide handle and the propulsion guide handle are connected with the drilling logic control block or a guide control opening of the load-sensitive multi-way valve. The double-pump hydraulic control loop has the advantages that power head rotation-proportion-controlled propulsion is achieved, high-speed rotating with propulsion prior to rotation is achieved, fast rod lifting while retaining certain rotation speed is achieved, and the like.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

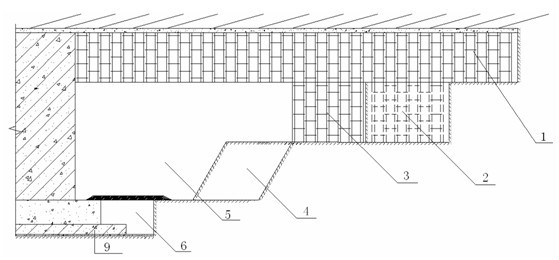

A mining method for broken and inclined medium-thick ore bodies with surrounding rocks on the hanging wall

InactiveCN108612530BSolve potential safety hazardsReduce depletionUnderground miningSurface miningDrift miningRock cutting

The invention discloses a mining method for a hanging wall surrounding rock broken inclined medium thick orebody. Stope division is carried out on the orebody along the orebody trend, broken ores aretransported in stages, subsections are divided within the stages, sublevel drift mining method is adopted in advance for stoping and filling of the orebody close to the hanging wall, the drift too plates of at one ends of all sublevel mining drifts close to a heading wall are interconnected to form a slope, thus making preparations for trench ore-drawing and enabling trench ore-drawing at all subsections, then a bottom-up stoping sequence is employed for stoping and filling of each subsection orebody, thereby effectively solving the problem of potential safety hazard when a carry scraper enters a stope for a long time. In addition, implementation of downward fan-shaped medium-deep holes improves the rock drilling efficiency and safety, all construction guarantees no destruction to the hanging wall broken surrounding rock, also a rock drilling gallery is employed as the air-return way, and the problem of difficult ventilation is effectively solved. The method provided by the invention generally shows significant security measures in ore drawing, rock drilling and ventilation of middle-low grade hanging wall surrounding rock broken inclined medium thick stable orebodies.

Owner:CENT SOUTH UNIV

bucket for excavator

ActiveCN106759584BReduce job cycle timeIncrease effective bucket capacityMechanical machines/dredgersArchitectural engineeringEngineering

The invention discloses a bucket for an excavator. The bucket comprises a bucket plate, side plates symmetrically arranged on two sides of the bucket plate, bucket teeth arranged at one end of the bucket plate, and a scraper unit mounted at the other end of the bucket plate, wherein the scraper unit includes a base plate fixedly arranged at a free end of the bucket plate, a lead screw assembly mounted on the base plate, a motor assembly mounted at one end of the base plate for driving the lead screw assembly, a first cover for covering the motor assembly and the lead screw assembly, a second cover for covering an opening end of the first cover, a scraper arranged in an accommodating cavity defined by the bucket plate and the side plates for removing attached matters on the inner wall of the bucket plate, and a connecting rod for connecting the scraper with the lead screw assembly. The bucket for the excavator can effectively scrape off the attached matters on the inner wall of the bucket plate to improve the effective volume of the bucket.

Owner:临沂临工重托机械有限公司

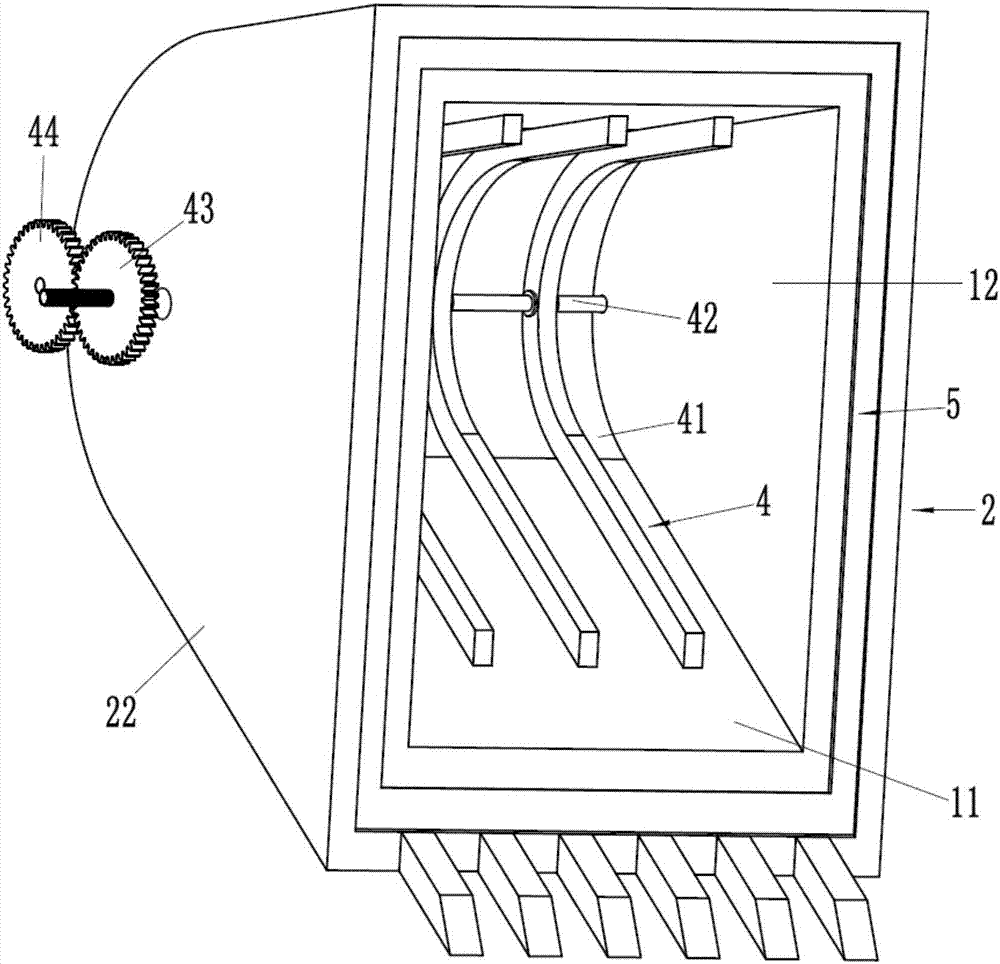

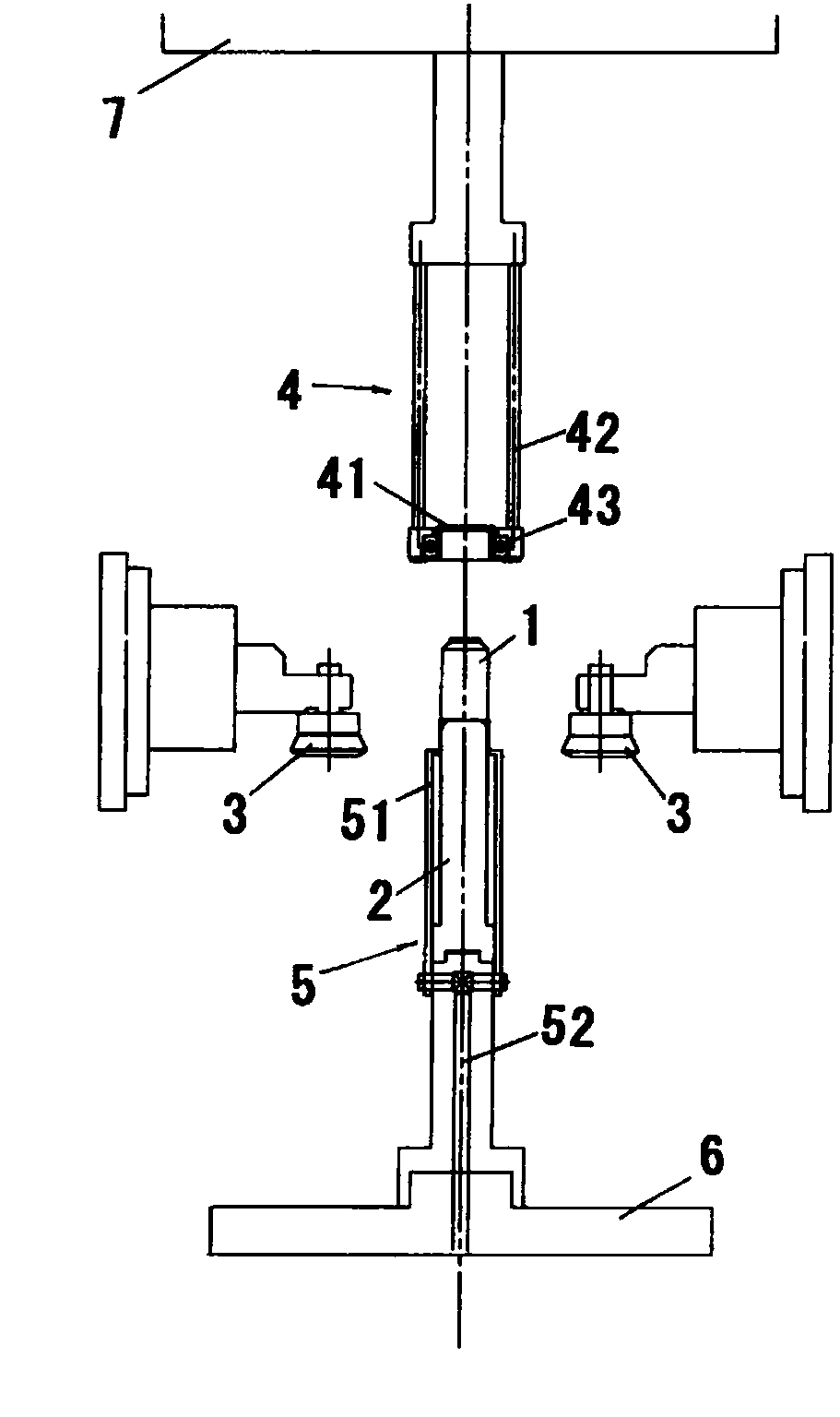

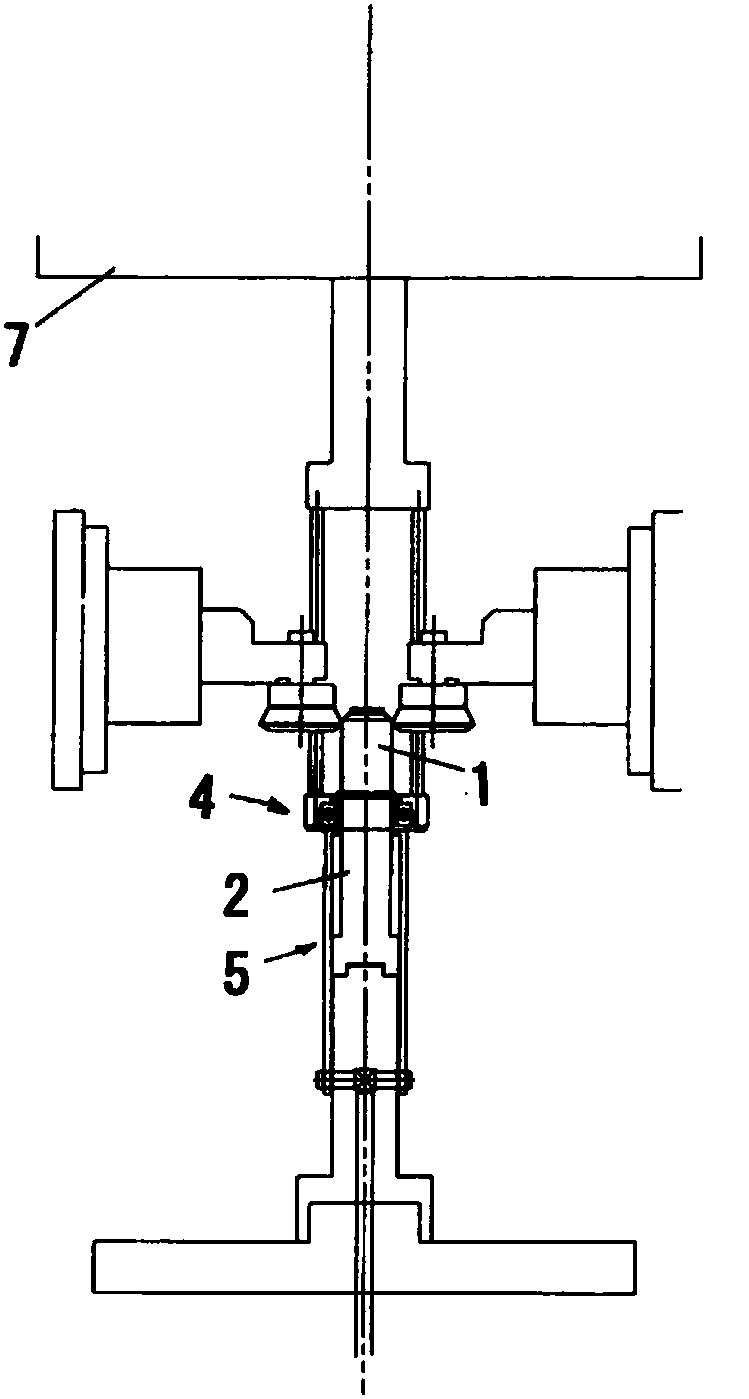

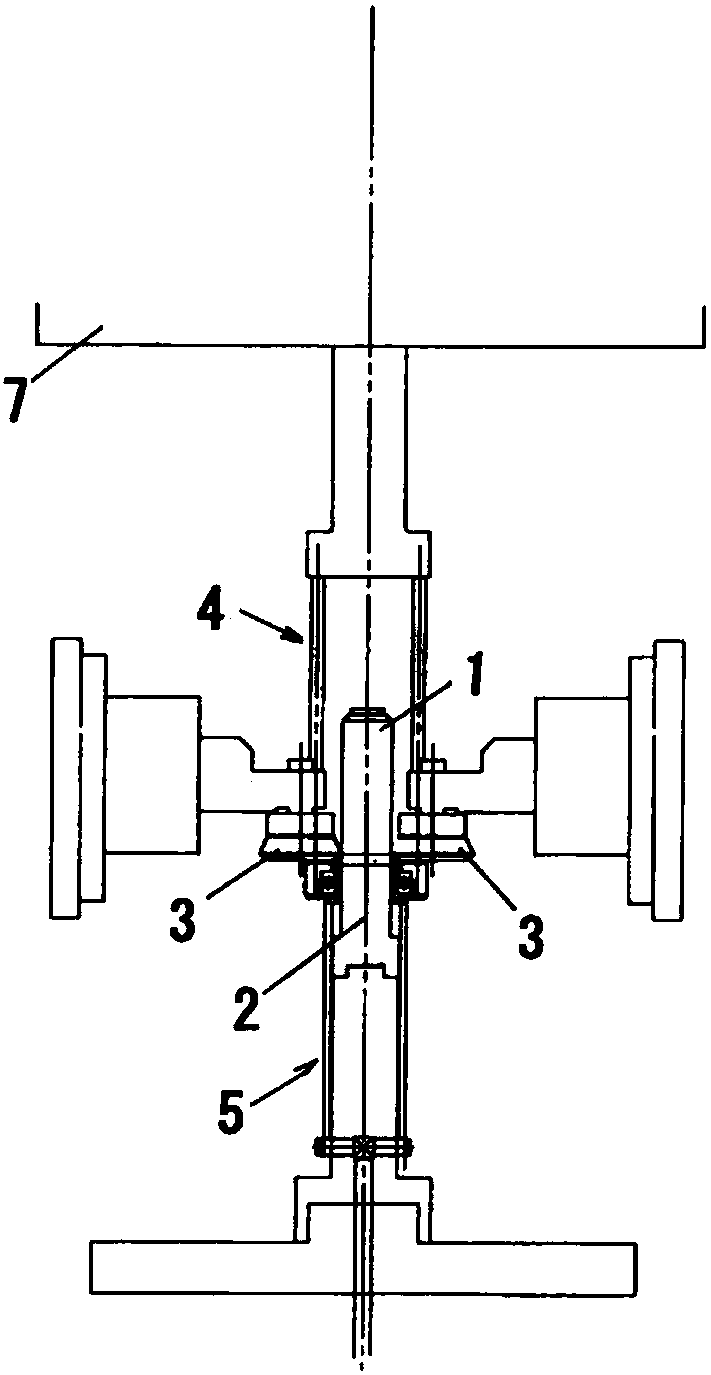

Spinning device and spinning molding method for cylindrical material

The present invention provides a cylindrical material spinning device which is formed at a cylindrical material protruding edge portion and will not deform and fall off from a tension giving mechanism even a larger tension is put in an axial direction of the cylindrical material and a spinning method. The spinning device has the tension giving mechanism (4) which applies the tension to the axial direction of the cylindrical material (1) through the protruding edge portion (11) formed at an opening end portion of the cylindrical material (1); and a supporting mechanism (5), wherein the protruding edge portion (11) of the cylindrical material (1) is clamped between the supporting mechanism and the tension giving mechanism (4), and ironing is performed while the tension is applied to the axial direction of the cylindrical material (1) when the protruding edge portion (11) of the cylindrical material (1) is clamped between the tension giving mechanism (4) and the supporting mechanism (5).

Owner:NIHON SPINDLE MFG CO LTD

An excavator bucket against clay

ActiveCN106836358BIncrease effective bucket capacityAchieve jitterSoil-shifting machines/dredgersEngineeringCam

Owner:山东鲁宇重工机械制造有限公司

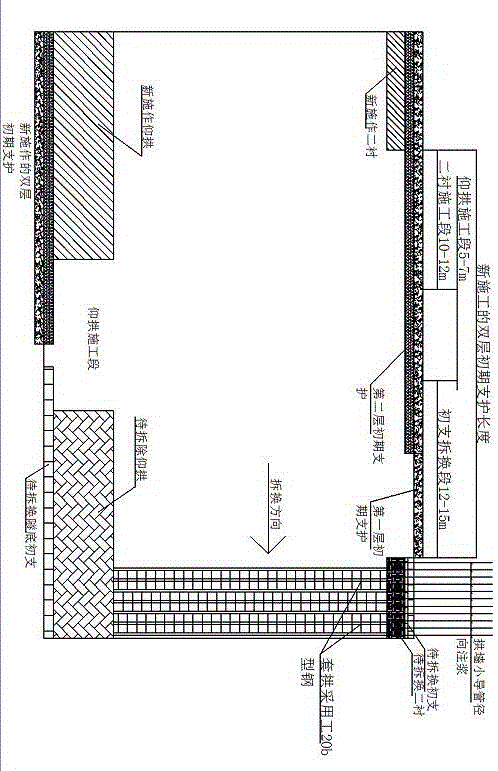

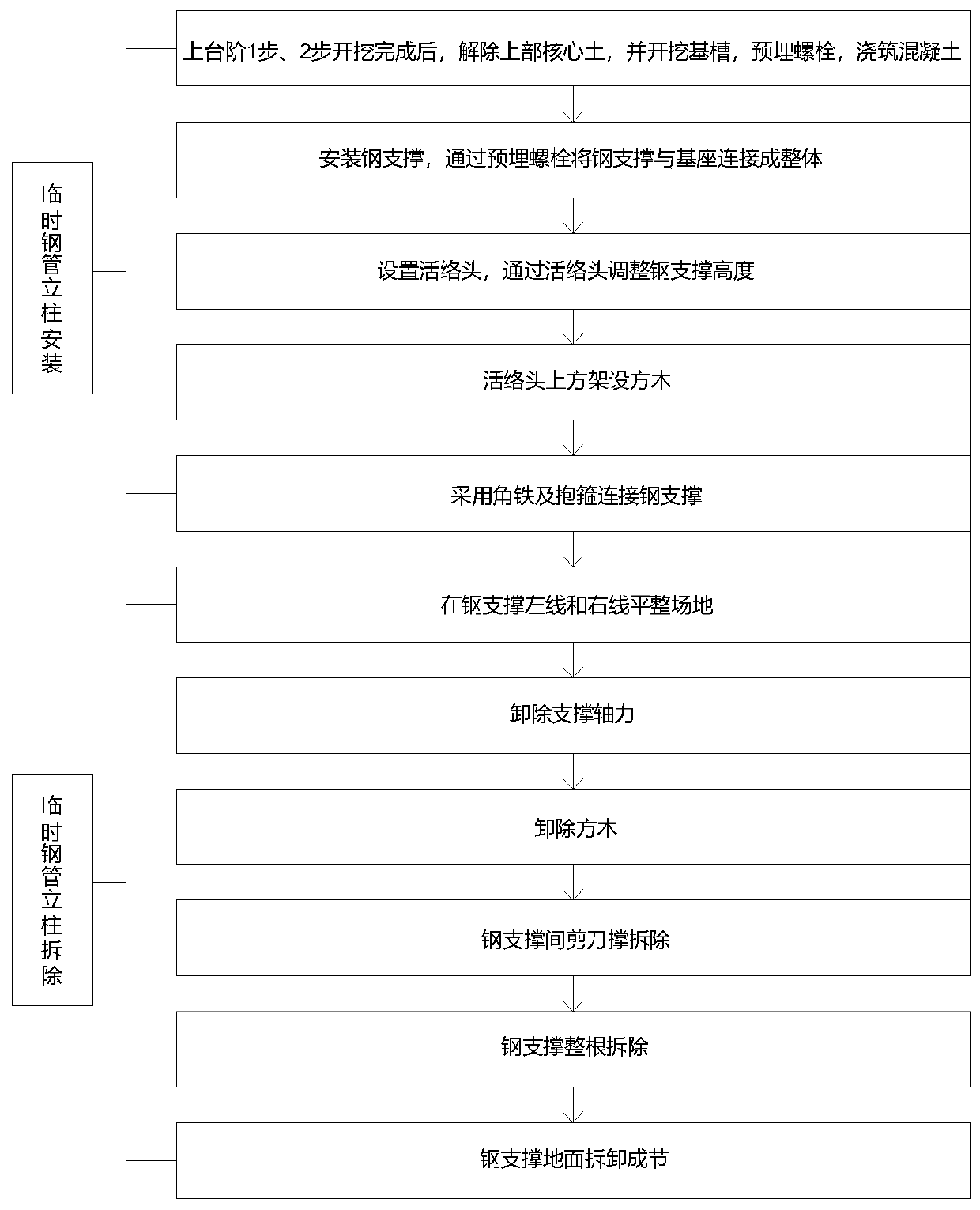

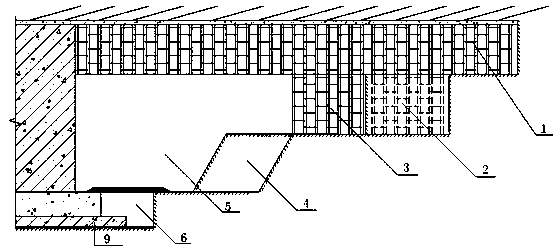

Method for excavating subway station through middle steel pipe vertical columns

ActiveCN110242320AIncrease the speed of excavationReduce the impact of disturbanceUnderground chambersTunnel liningReinforced concreteSubway station

The invention relates to the technical field of construction engineering, and discloses a method for excavating a subway station through middle steel pipe vertical columns. The method comprises the steps that after an upper step 1 and an upper step 2 are excavated, upper core soil is removed, reinforced concrete is poured on a foundation, bolts are pre-buried, steel supports are erected, the steel supports are connected with the foundation, movable heads are arranged, a square timber is erected above the movable heads, the steel supports are connected through angle iron, and after deformation is stable, the temporary steel supports are removed. The influence of perturbation on surrounding rock during blasting excavation is reduced, stress of the surrounding rock is released advantageously, construction processes are more optimized, deformation of the surrounding rock is better controlled, the defects that by adopting a traditional method, in rock column removing, the high-altitude operation safety risk exists, the construction difficulty is large, and the technology is complex are overcome, meanwhile, an upper step excavating process operation platform is fully utilized, thus the construction difficulty is lowered, construction operation is facilitated, segmented timely support is achieved, the operation circulation time is shortened, the tunnel excavating speed is effectively increased while safety is ensured, and the construction processes are reduced.

Owner:CHINA CONSTR COMM ENG GRP UNITED +2

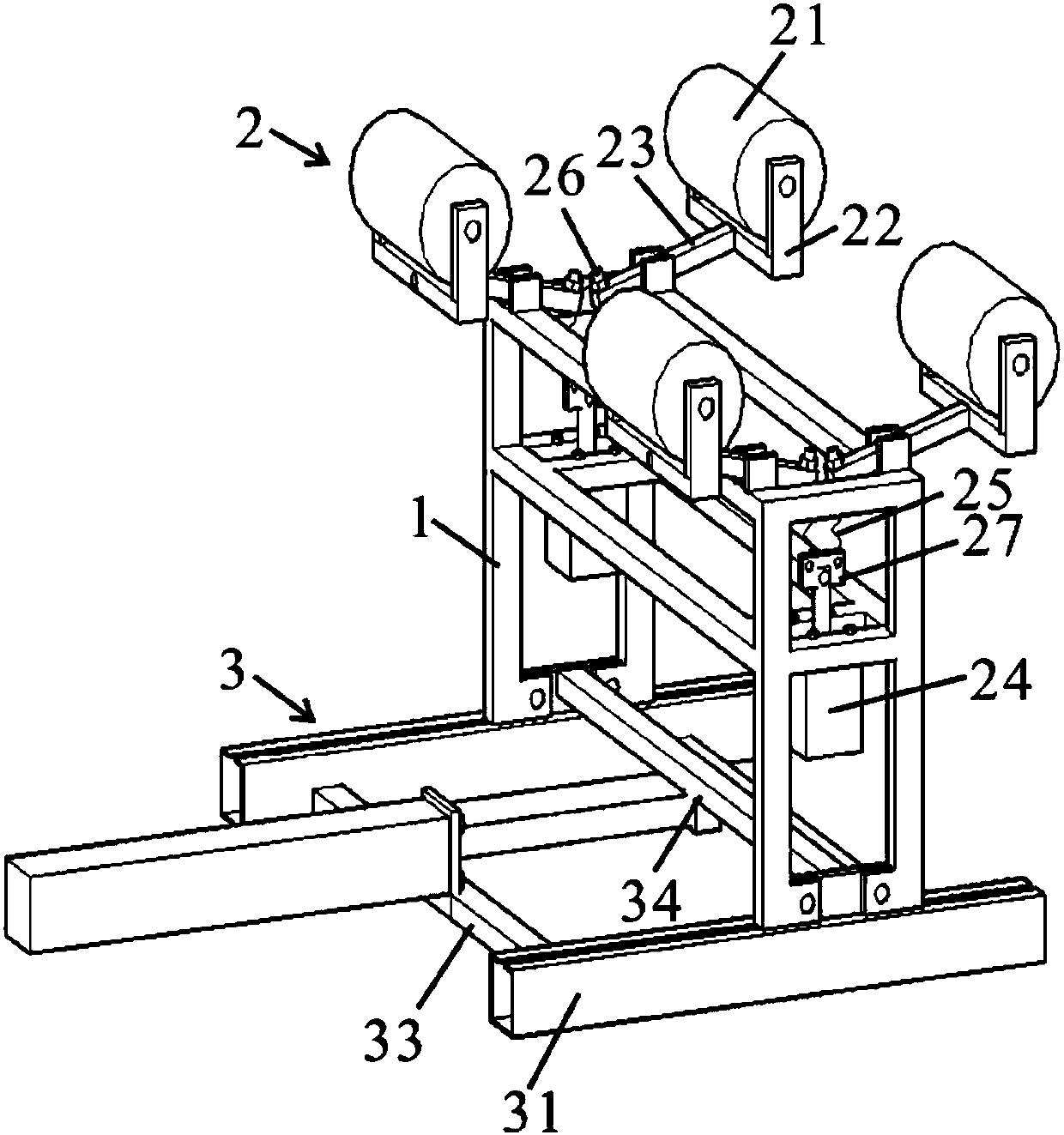

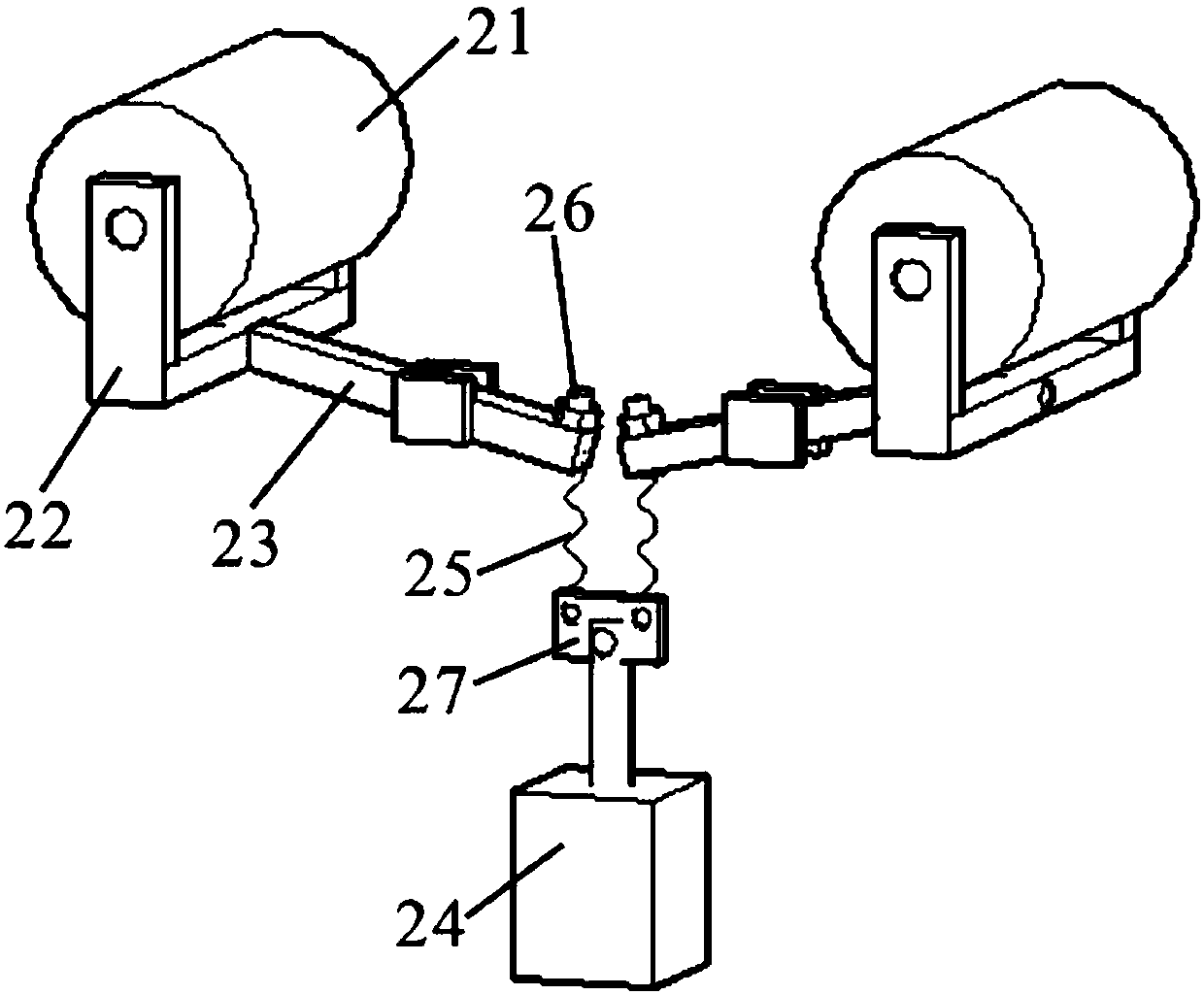

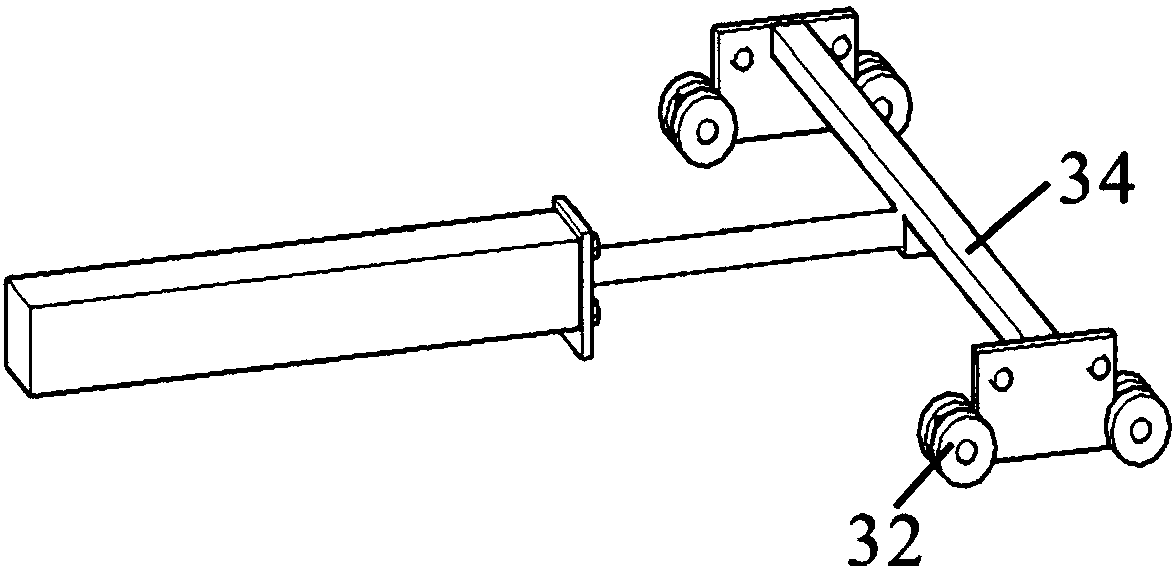

Full-automatic rolling device for vehicle roof panel films

PendingCN109958688AReduce drop frequencyReduce the frequency of landing and reduce the cost of reworkMaterial gluingMan machineEngineering

The invention discloses a full-automatic rolling device for vehicle roof panel films. The full-automatic rolling device for the vehicle roof panel films comprises a main body frame, a rolling mechanism and a sliding mechanism, wherein the rolling mechanism is movably connected on the main body frame in a liftable mode, and the bottom of the main body frame is in reciprocating sliding connection with the sliding mechanism. According to the full-automatic rolling device for the vehicle roof panel films, the problem that the man-machine labor intensity at stations is large is solved, the production efficiency is improved, the films are rolled evenly, the accuracy of the rolling positions is improved, the rolling quality stability is improved, the falling frequency of the films is reduced, andthe repair cost is reduced.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Double-pump hydraulic control loop of key drilling action of cutting drill rig

ActiveCN102747948BAvoid stuck drillPrevent slippingServomotor componentsServomotorsFuel tankPressure difference

A double-pump hydraulic control loop of a key drilling action of a cutting drill rig comprises a double linkage load-sensitive variable pump set, a double oil intake linkage load-sensitive multi-way valve, a rotary motor, a propulsion motor, a drilling logic control block, a rotation guide handle, a propulsion guide handle, and a hydraulic oil tank. An oil inlet of the double linkage load-sensitive variable pump set is connected with the hydraulic oil tank. An oil outlet and a load-sensitive opening are connected with an oil inlet and a load-sensitive opening of the double oil intake linkage load-sensitive multi-way valve respectively. Each valve pressure difference compensator of the load-sensitive multi-way valve is provided with an external control opening. The external control openings are connected with the drilling logic control block. The rotation guide handle and the propulsion guide handle are connected with the drilling logic control block or a guide control opening of the load-sensitive multi-way valve. The double-pump hydraulic control loop has the advantages that power head rotation-proportion-controlled propulsion is achieved, independent load-sensitive control of rotation and propulsion is achieved, propulsion speed is increased, and the like.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

an excavator bucket

ActiveCN106836330BIncrease effective bucket capacityEffective uninstallMechanical machines/dredgersArchitectural engineeringCycle time

The invention discloses an excavator bucket. The excavator bucket comprises a bucket plate, side plates formed on both sides of the bucket plate, and a bucket tooth mounted on the bucket plate. The bucket plate comprises an arc plate, a first straight plate and a second straight plate; the first straight plate and the second straight plate are located at the two ends of the arc plate correspondingly and are both tangent to the arc plate; the bucket tooth is mounted at the free end of the first straight plate; and a forced soil unloading unit is arranged in an accommodating chamber defined by the bucket plate and the side plate. The excavator bucket can unload soil in the bucket effectively, and shorten the working time of an excavator, and the effective bucket capacity of the excavator bucket is improved.

Owner:徐州天骋智能科技有限公司

Large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method

ActiveCN102562075BMeet the requirements for enhanced controlsSpeed up early closure timesUnderground chambersTunnel liningShortest distanceRock tunnel

The invention discloses a large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method, which comprises the steps as follows: (1) annularly excavating an upper step of an upper part arc pilot tunnel, transferring excavated earthwork of the upper step to a lower step; (2) excavating a left part of a middle step about 4.5-5 meters behind the upper step, and transferring excavated earthwork to the lower step; (3) excavating a right part of the middle step about 3-4 meters behind the left part of the middle step, and transferring excavated earthwork to the lower step;(4) excavating a left part of the lower step about 6-8 meters behind the left part of the middle step or about 3-4 meters behind the right part of the middle step, and conveying excavated earthwork of the left part of the lower step out of the tunnel; (5) excavating a right part of the lower step about 3-4 meters behind the left part of the lower step, and conveying excavated earthwork of the lower step out of the tunnel; and (6) excavating the rest part of the tunnel bottom about 20-25 meters behind the right part of the lower step, excavating continuously according to the steps in a circulating and interlacing manner, and finally realizing tunnel excavating construction. The method can be used for building a large cross-section tunnel in a safe, rapid and economic manner.

Owner:CCCC SECOND HIGHWAY ENG CO LTD +1

Hybrid core driving device and forming machine

ActiveCN114555261AInhibit deteriorationReduce job cycle timeFoundry mouldsFoundry coresEngineeringPiston

A hybrid core drive device according to an embodiment is provided with: a cylinder tube; a first cover member at one end of the cylinder tube; a second cover member at the other end; a rod which has a connection part to which the core is connected at one end of the cylinder tube, has an annular flange on the second cover member side, and penetrates the first cover member; the nut is fixed on the rod; a screw shaft penetrating the second cover member and the nut and provided so as to be insertable into the rod; a motor that rotates the screw shaft; a piston which is provided in the cylinder tube, through which the rod passes, and which is capable of sliding relative to the cylinder tube and the rod; and a connection part capable of connecting a pipe for supplying the operating fluid to a region surrounded by the cylinder tube, the first cover member, and the piston.

Owner:SHIBAURA MASCH CO LTD

an excavator bucket

ActiveCN103174181BReduce job cycle timeImprove effective bucket capacitySoil-shifting machines/dredgersEngineeringExcavator

The invention discloses a digging bucket. Through operation of extension and constriction of a bucket cylinder, a four bar mechanism composed of a bucket rod, a bucket body, a rocking bar and a three-point rocker arm is driven; and then through a hinge point of the bucket body and the three-point rocker arm, the other set of four bar mechanism composed of a bucket body, a three-point rocker arm, a draw bar and a scraper plate is driven so that soil loading and forced soil unloading in the process of digging are achieved. According to the digging bucket, under the working condition of digging clay, the digging bucket has special advantages. And the digging bucket is high in efficiency, reliable in performance, simple in structure, convenient to manufacture and low in cost.

Owner:GUANGXI YUCHAI HEAVY IND

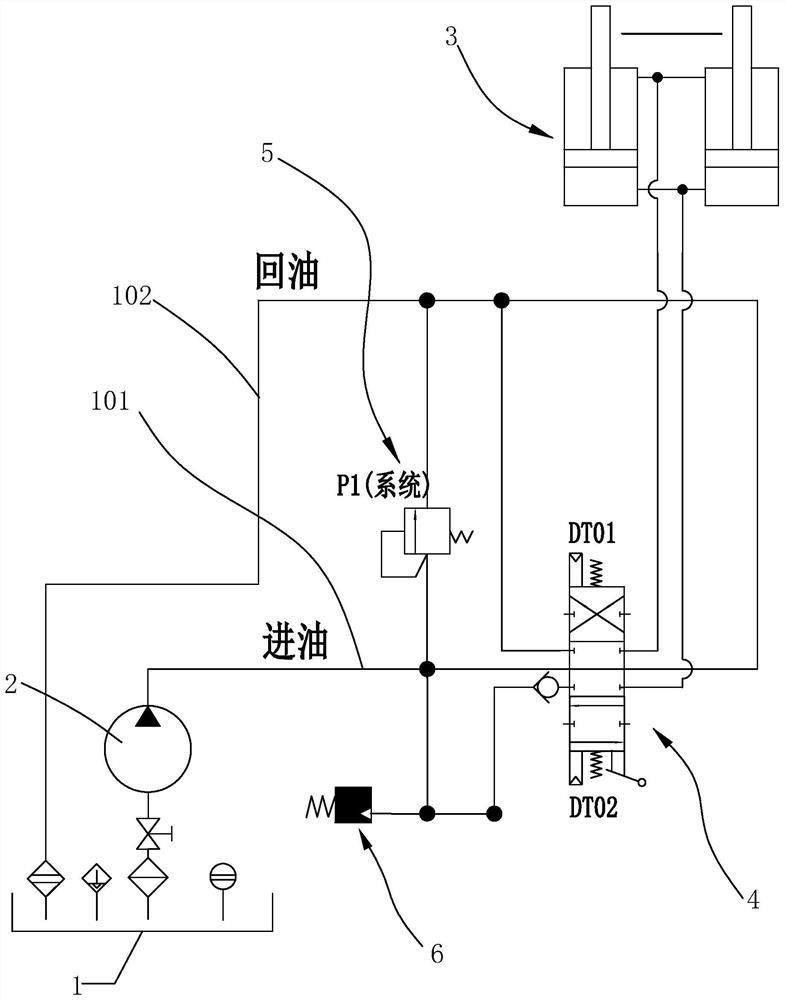

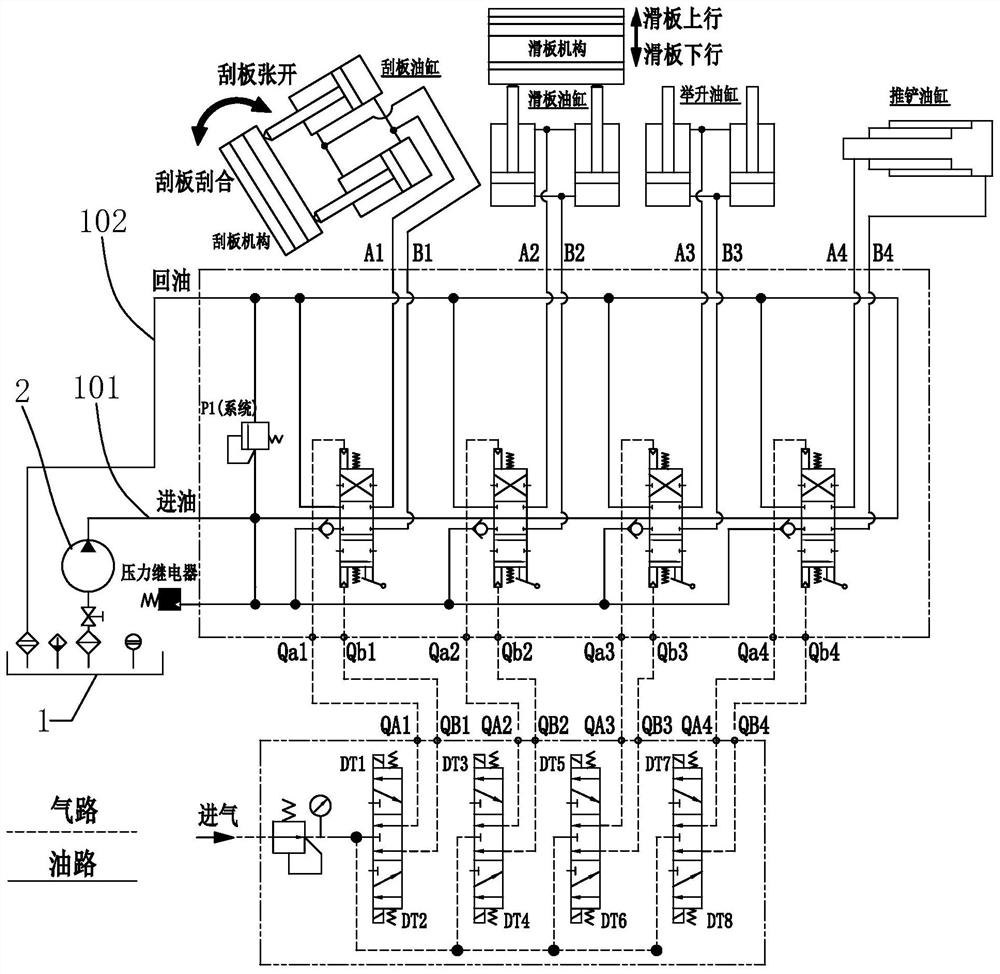

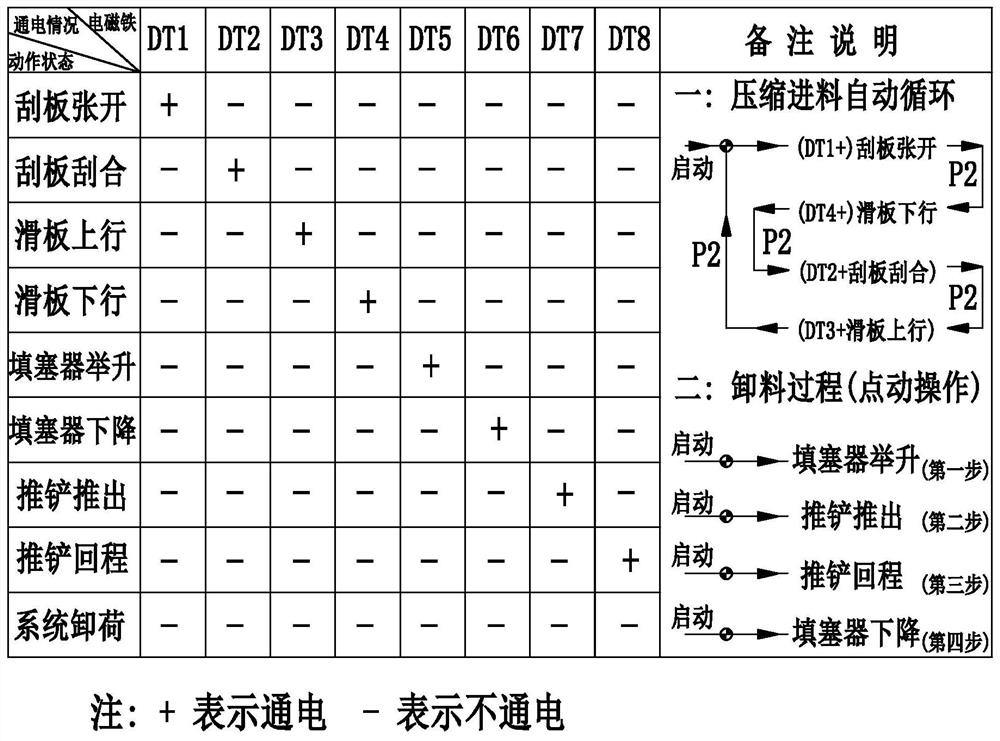

A control method for reducing overflow protection time in hydraulic system

ActiveCN110388342BImprove efficiencyReduce high pressure relief timeServomotorsFluid-pressure actuator componentsHydraulic cylinderControl manner

The invention discloses a control method for reducing the overflow protection time of a hydraulic system. In a working stroke of a hydraulic cylinder, when the system pressure value is greater than the set value P2, the PLC electric control unit calculates the instantaneous time of the system pressure value Pt Change rate Kt, when the instantaneous change rate Kt is less than the set value A0, that is, the system pressure rises slowly, it is determined that the hydraulic cylinder moves to the maximum stroke position, and the PLC electronic control unit issues an instruction to de-energize the corresponding electromagnet and stop the power supply. Oil, using this control method, no matter how the load changes, it can always make the piston rod move in place, and at the same time reduce the high pressure overflow time, reduce useless power and heat, improve the efficiency of the hydraulic system, reduce the oil temperature, reduce the operating cycle time, and improve the operating efficiency. Beats, improve work efficiency.

Owner:深圳东风汽车有限公司

Electronic parts installation apparatus

ActiveCN101902902BEasy to installImprove production efficiencyElectrical componentsImaging processingEngineering

The present invention provides an electronic parts installation apparatus, capable of stably and accurately recognizing hold mode of the electronic parts. The apparatus includes a substrate holding part; a member supply part for supplying the electronic parts; a loading head having an adsorption nozzle; a loading head shifting mechanism capable of locating the loading head arbitrarily; a filming unit arranged on the loading head to film the electronic part absorbed by the adsorption nozzle; a filming reflection mirror extended between the member supply part and the substrate holding part and having only one reflecting plane; and an image processing device for judging the position and angle of the absorbed electronic part relative to the absorption nozzle according to the filming image of the electronic part obtained through reflection of the filming reflection mirror, wherein the reflecting plane of the filming reflection mirror is an inclined plane which adopts a bisecting line between a central line of the adsorption nozzle and the line of sight of the filming unit as its perpendicular line.

Owner:JUKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com