Method for producing a container made from thermoplastic material

A thermoplastic material and container technology, which is applied to household appliances, hollow objects, and other household appliances, can solve the problem of time-consuming production cycle and achieve the effect of reducing the operation cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

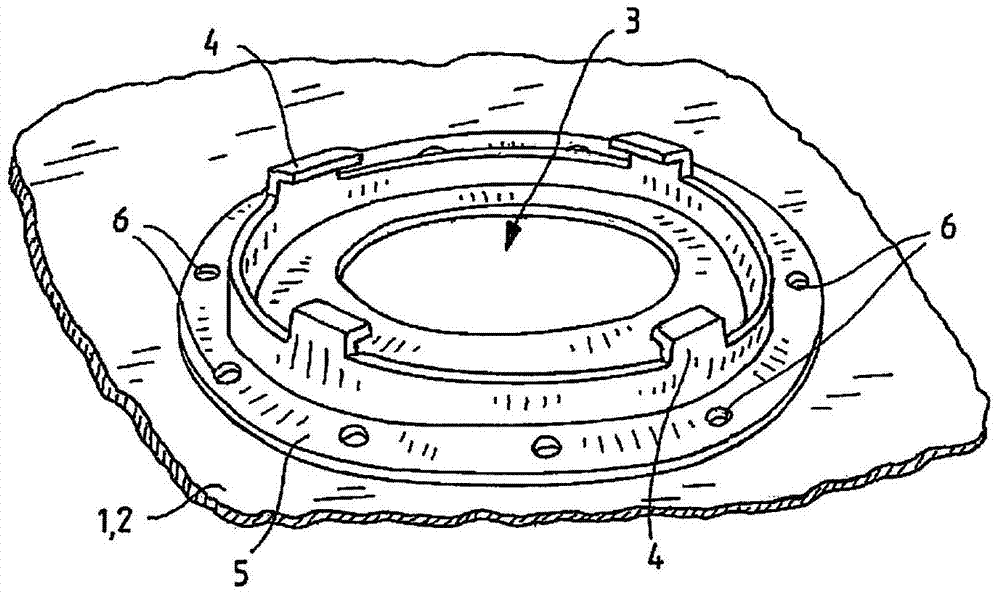

[0041] first reference figure 1 , shows a part of the container wall 1 of the container 2 made of thermoplastic material in the region of the opening 3 of the container 2 . The opening 3 can be designed, for example, as an inspection hole which can be sealed with a cover. The opening 3 comprises a metal rim 4 designed as a flange ring or bayonet ring. The frame 4 can alternatively be designed as a sleeve for the leads. An annular edge 5 with holes is arranged on the frame 4, and a plurality of holes 6 are arranged on the circumference of the annular edge 5 for the thermoplastic material of the container wall 1 to pass through. The container wall 1 is produced, for example, from a single-layer or multi-layer extrusion based on HDPE. The frame can be made of steel or aluminum. As described below, the border is formed in the container wall 1 during the production of the container 2 and the opening 3 is cut out or machined by a circular machine after the container 2 is removed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com