an excavator bucket

A technology for excavators and buckets, which is applied in the field of excavators, can solve the problems that the clay in the bucket is not easy to unload, prolong the working cycle time of the excavator, and reduce the effective bucket capacity of the bucket, so as to reduce the working cycle time and achieve reliable performance , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

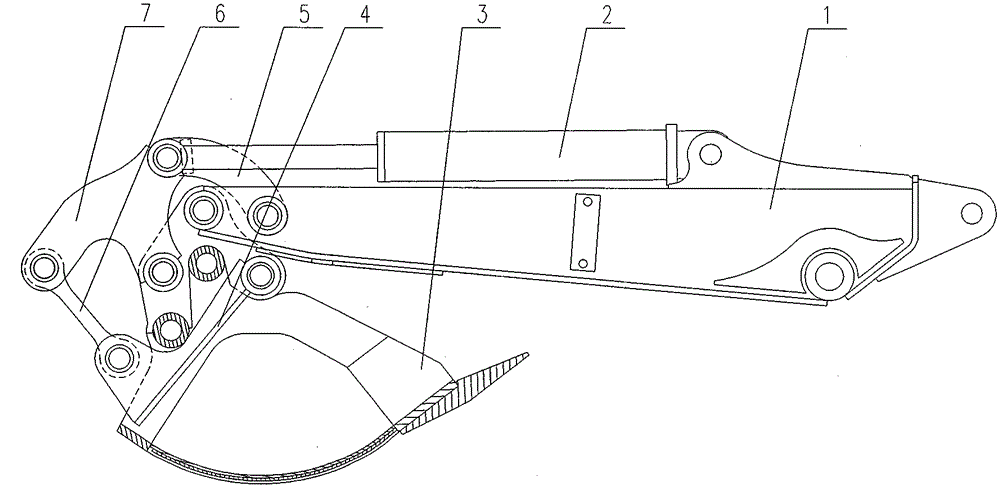

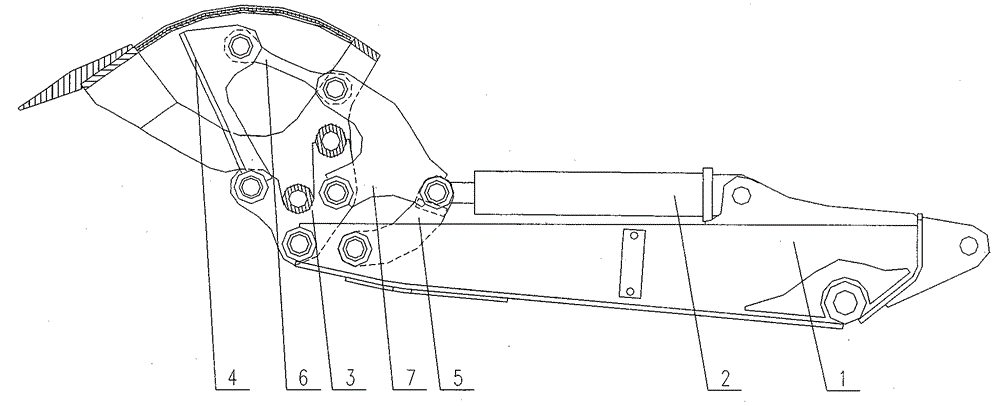

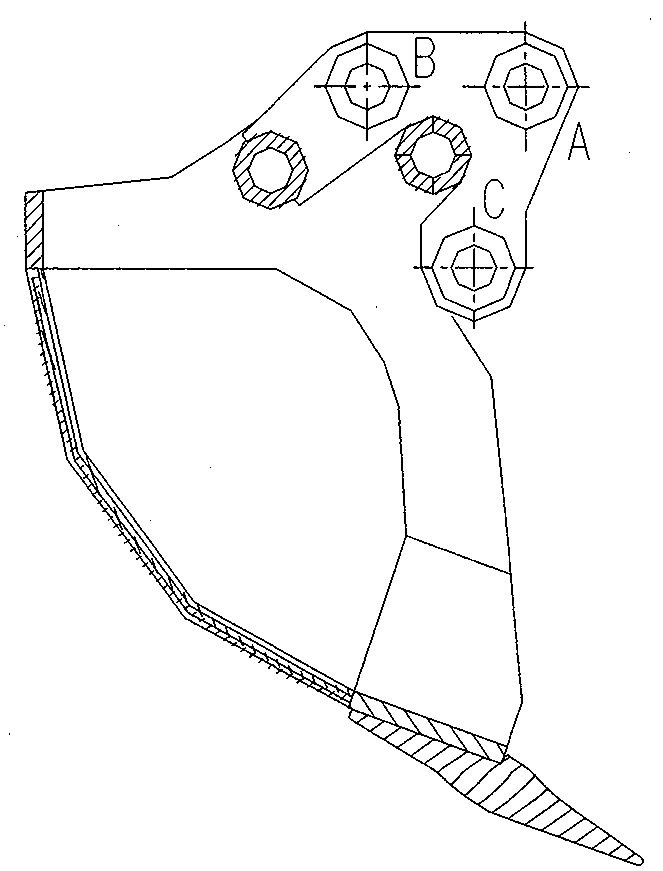

[0020] Example 1, see Figure 1 to Figure 6 , an excavator bucket with a forced soil unloading mechanism mainly includes a bucket rod, a rocker, a bucket cylinder, a bucket, a scraper, a tie rod, and a three-point rocker. The stick is respectively hinged with the rocker, the bucket cylinder and the bucket according to the traditional installation method of the excavator, and the traditional connecting rod is replaced by the three-point rocker ; The other end of the rocking bar is hinged to the other end of the bucket oil cylinder and one end of the three-point rocker arm; the three-point rocker arm has three hinge points in total, and the other Two hinge points, one end is hinged on the second end of the bucket, the other end is hinged on the pull rod; the other end of the pull rod is hinged on the scraper; the other end of the scraper is hinged on the The third end of the bucket; the bucket has three hinge points in total, and does not have a rear wall; by operating the expa...

Embodiment 2

[0022] Embodiment 2, said arm (1) is respectively hinged with bucket (3) wherein one end is A end, rocking bar (5), bucket oil cylinder (2) according to the traditional installation method of excavator, and traditional The connecting rod is replaced by a three-point rocker arm (7); the other end of the rocker bar (5) is hinged to the other end of the bucket oil cylinder (2) and one end of the three-point rocker arm (7) at the same time. end; the three-point rocker arm (7) has three hinge points in total, and the other two hinge points, one of which is end E is hinged at the second end of the bucket (3), namely end B, The other end, namely the F end, is hinged on the pull rod (6); the other end of the pull rod (6) is hinged on the scraper (4); the other end of the scraper (4) is hinged on the The third end of the bucket (3) is the C end.

[0023] see figure 1 , when the bucket (4) is excavating clay, it pushes a set of stick (1), bucket (3), rocker (5), three-point The four-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com