Hybrid core driving device and forming machine

A driving device and hybrid technology, applied in the direction of core, mold composition, mold, etc., can solve the problems of difficulty in shortening the operation cycle time of the die-casting machine and the inability to open and close the fixed mold and the movable mold at the same time. The effect of shortening the work cycle time, simplifying the equipment, and suppressing the deterioration of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

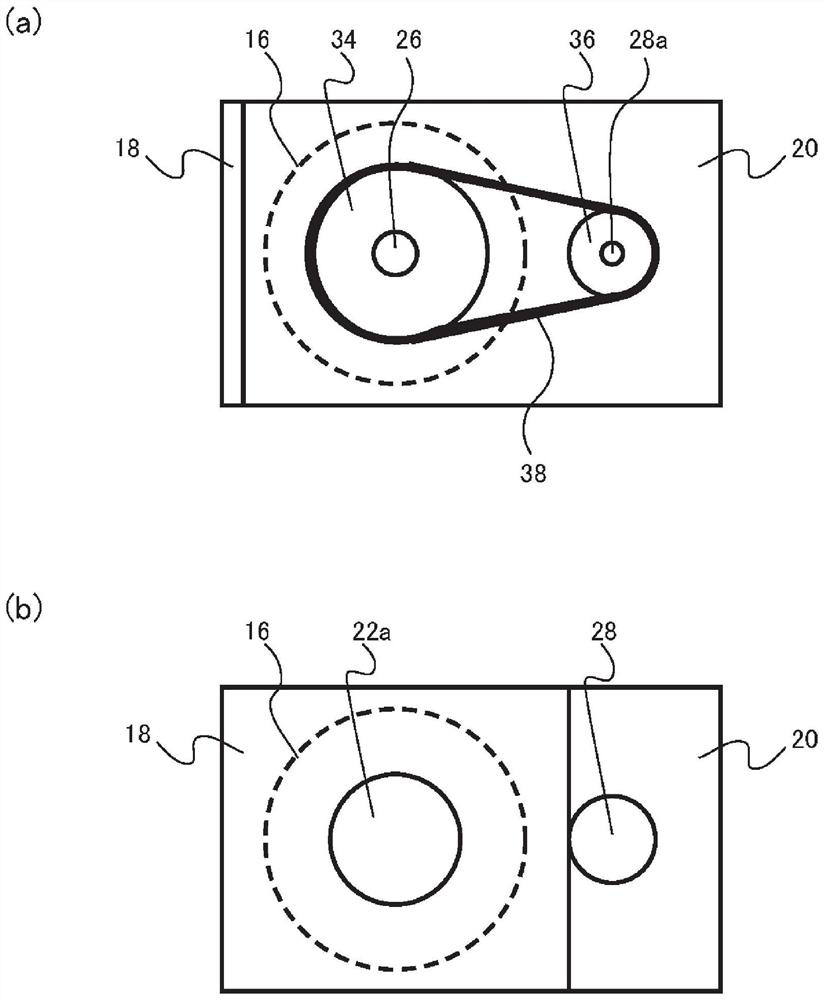

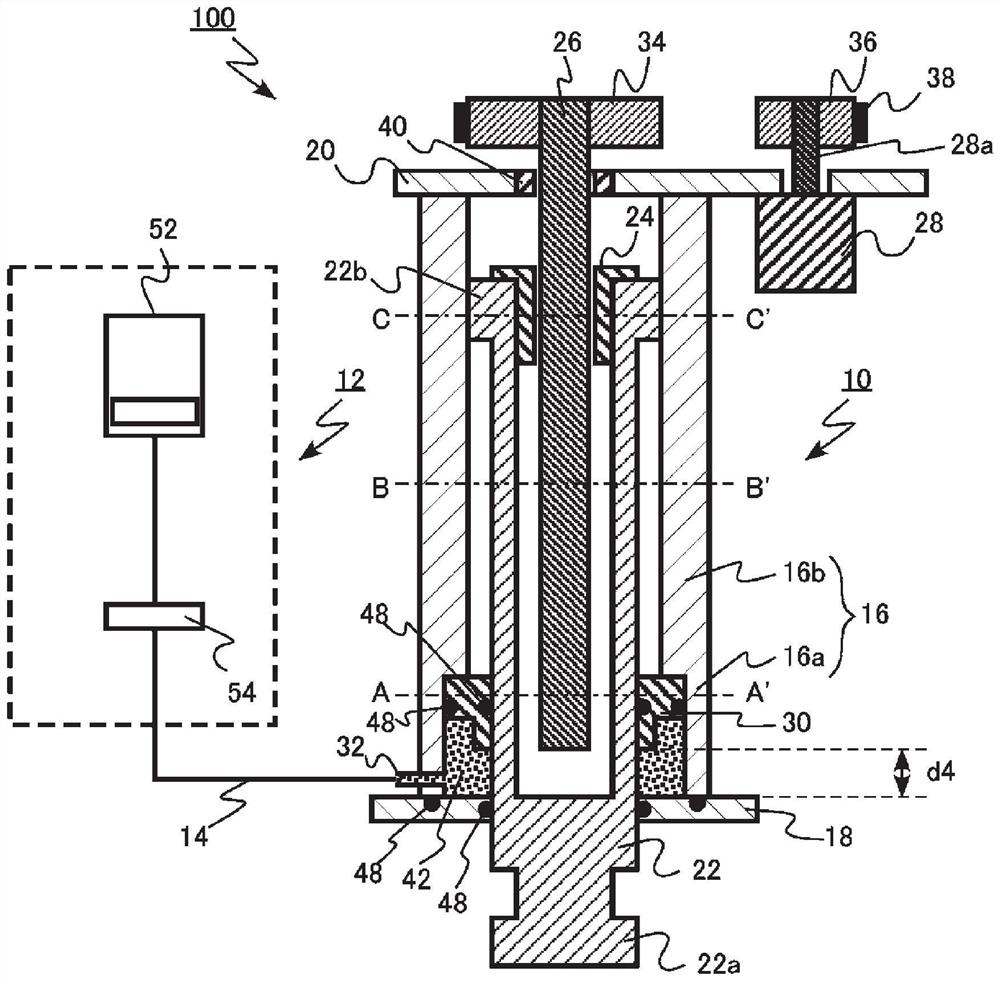

[0053] The hybrid core drive device according to the first embodiment includes a cylinder tube; a first cover member fixed to one end of the cylinder tube; a second cover member fixed to the other end of the cylinder tube; In the cylinder tube, the core can be connected at one end; the rod has an annular flange on the side of the second cover member rather than the connecting part, penetrates the first cover member, and can move linearly forward and backward relative to the cylinder tube; nut , fixed on the rod; the screw shaft, which penetrates the second cover member and the nut, is arranged to be inserted into the rod, and can rotate; the motor rotates the screw shaft; the annular piston is arranged in the cylinder, The rod penetrates the rod so as to be slidable with respect to the cylinder tube and the rod, and a connecting portion is provided on the cylinder tube and can be connected to a pipe for supplying a working fluid for operating the piston to an area surrounded by...

no. 2 Embodiment approach

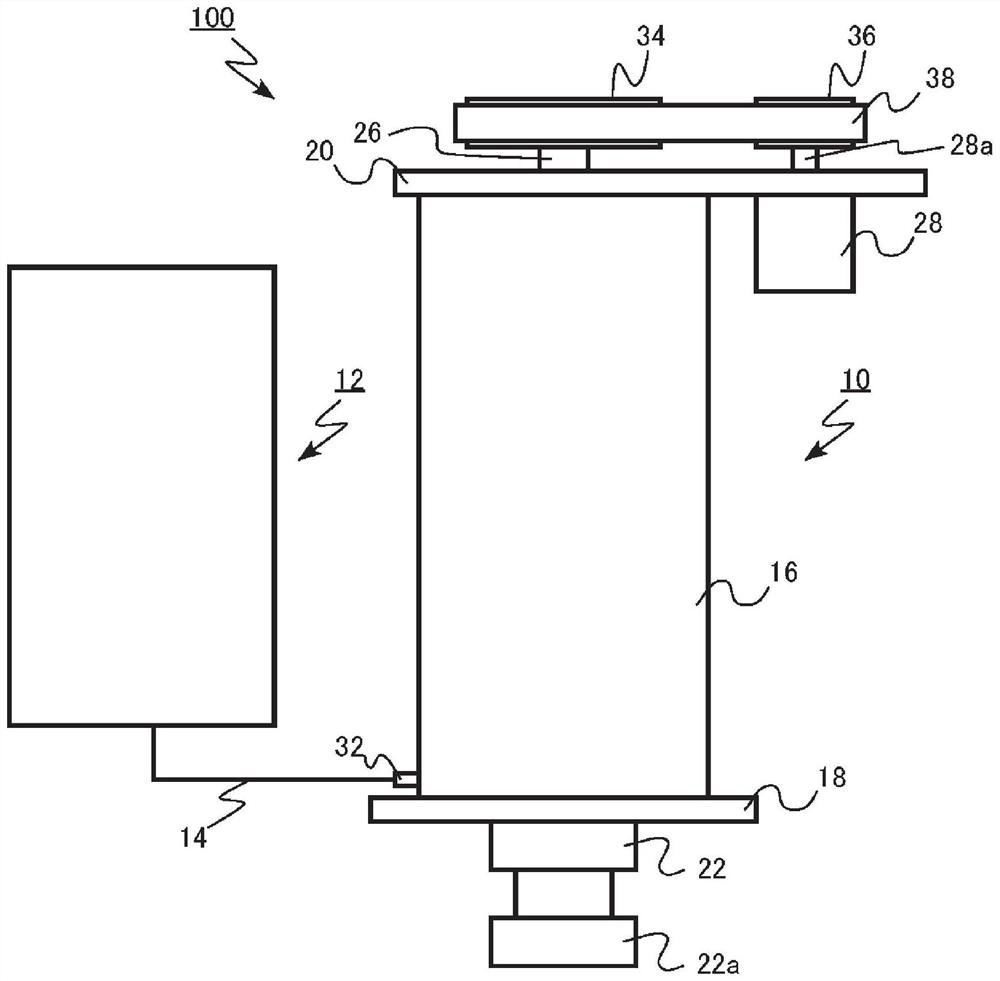

[0124] The molding machine according to the second embodiment includes: a base; a fixed die plate that is fixed on the base and holds the fixed die; and a movable die plate that is movably installed on the base in the die opening and closing direction, and aligns the movable die and the fixed die. Set and hold; Hybrid core drive device, drive the core combined with the fixed mold and movable mold; Clamping device, close the fixed mold and movable mold; Injection device, to the fixed mold, movable mold and mold The cavity formed by the core is filled with molten material; and the control unit controls the operation of the hybrid core drive device; the hybrid core drive device includes: a cylinder; a first cover member fixed to one end of the cylinder; a second The cover member is fixed to the other end of the cylinder tube; the rod, at least a part of which is provided in the cylinder tube, has a connecting portion at one end capable of connecting the core, and has an annular fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com