A control method for reducing overflow protection time in hydraulic system

A technology of hydraulic system and control method, which is applied in the directions of fluid pressure actuating system components, fluid pressure actuating devices, servo motors, etc. Efficiency, reduction of useless power and heat generation, effect of lowering oil temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

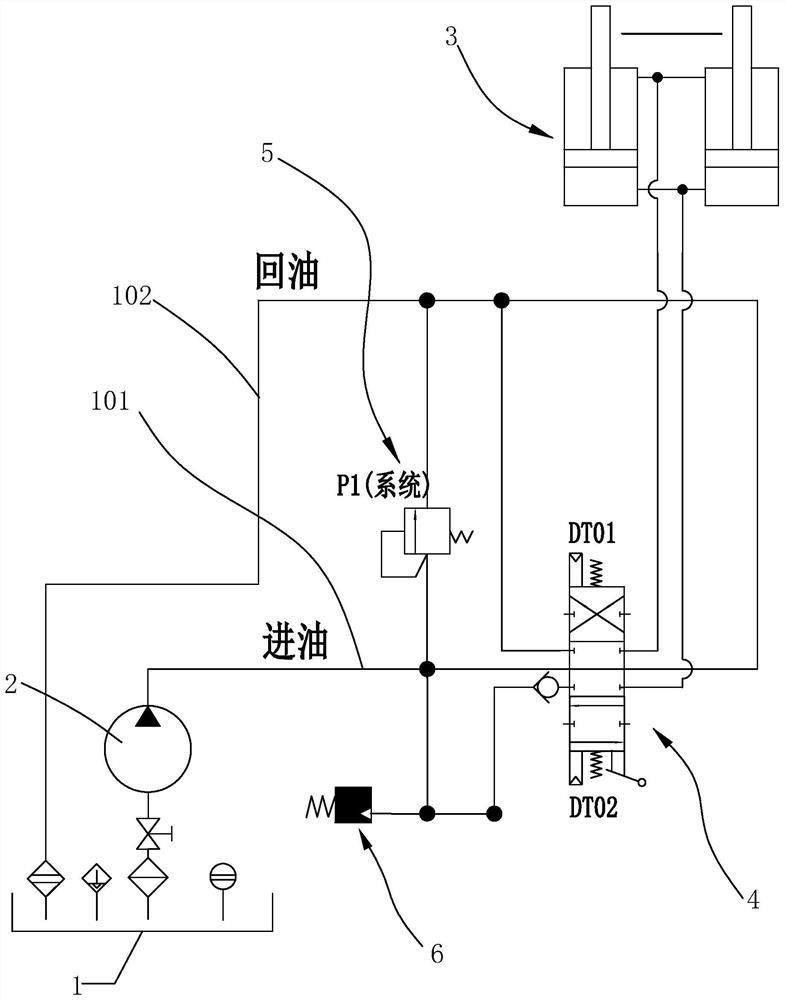

[0056] Such as figure 1 As shown, a control method for reducing the overflow protection time of a hydraulic system in this embodiment, the hydraulic system includes a fuel tank 1, a hydraulic pump 2 connected to the fuel tank 1, and a main oil inlet circuit connected to the hydraulic pump 2 101. The main oil return circuit 102 connected to the oil tank 1, the operating oil cylinder 3, the solenoid valve 4 for controlling the reversing of the operating oil cylinder 3, and the PLC electronic control unit. The operating oil cylinder 3 is connected to the main oil inlet circuit through the electromagnetic valve 4 101 and the main oil return circuit 102, the solenoid valve 4 includes an electromagnet DT01 for controlling the extension of the piston rod of the operating cylinder 3 and an electromagnet DT02 for controlling the retraction of the piston rod of the operating cylinder 3, so The above-mentioned main oil inlet circuit 101 and the main oil return circuit 102 are connected ...

Embodiment 2

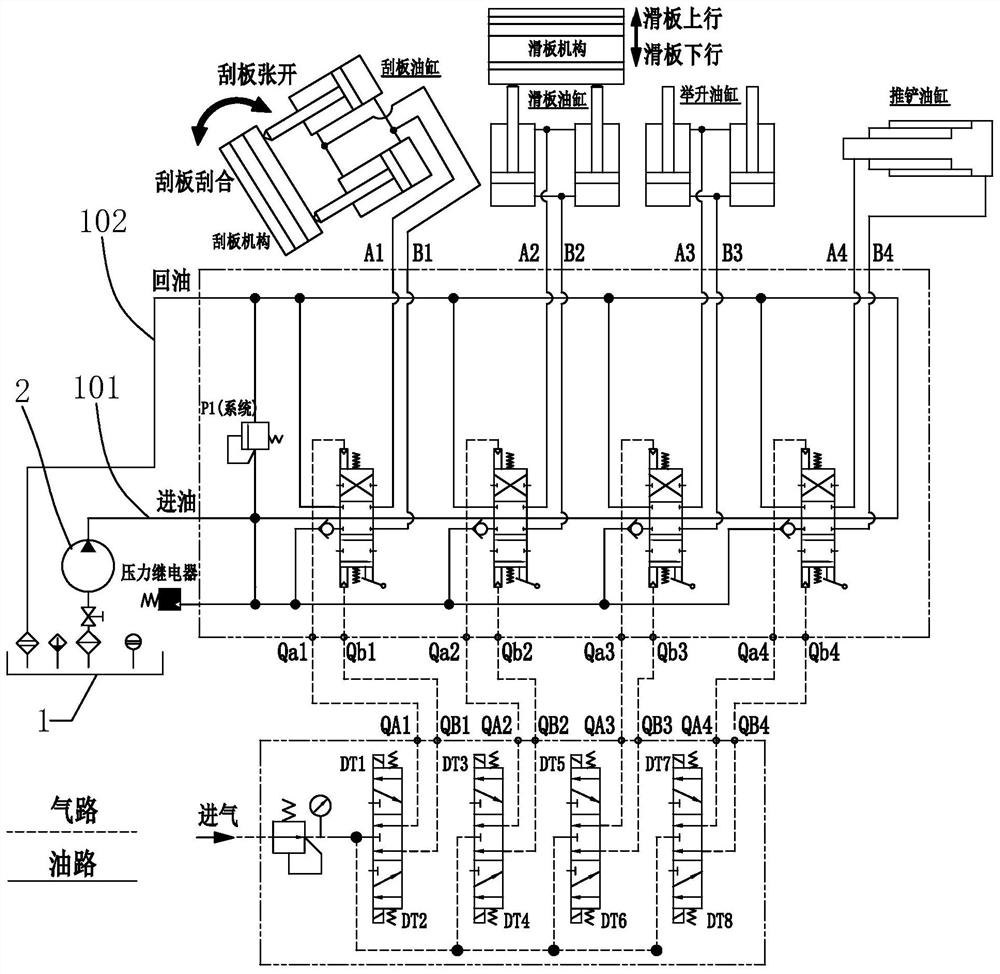

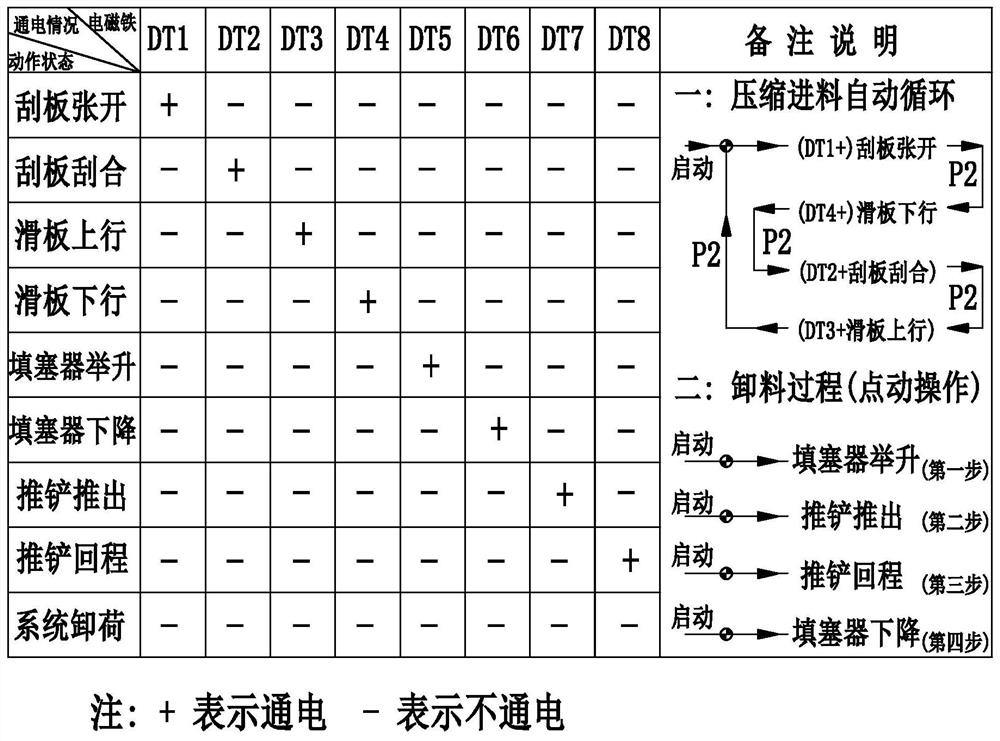

[0070] Such as Figure 2 to Figure 6 As shown, the hydraulic system control method of the compression mechanism of the rear-mounted compression garbage truck of this embodiment, the hydraulic system of the compression mechanism of the rear-mounted compression garbage truck includes a fuel tank 1, a hydraulic pump 2 connected to the fuel tank 1, The main oil inlet circuit 101 connected to the hydraulic pump 2, the main oil return circuit 102 connected to the oil tank 1, the scraper cylinder 31 to control the opening or closing of the scraper, the slider cylinder 32 to control the upward or downward movement of the slider, and the scraper cylinder to control 31 reversing solenoid valve A41, solenoid valve B42 controlling the reversing of the slide cylinder 32, and PLC electronic control unit, the scraper cylinder 31 is connected between the main oil inlet circuit 101 and the main return oil circuit 102 through the solenoid valve A41 During the period, the solenoid valve A41 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com