Bucket special for excavator

A technology for excavators and buckets, applied in the field of excavators, can solve the problems of reducing the effective bucket capacity of the bucket, the soil in the bucket is not easy to unload clean, and prolonging the operation cycle time of the excavator, so as to reduce the operation cycle time and improve the efficiency. Bucket capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

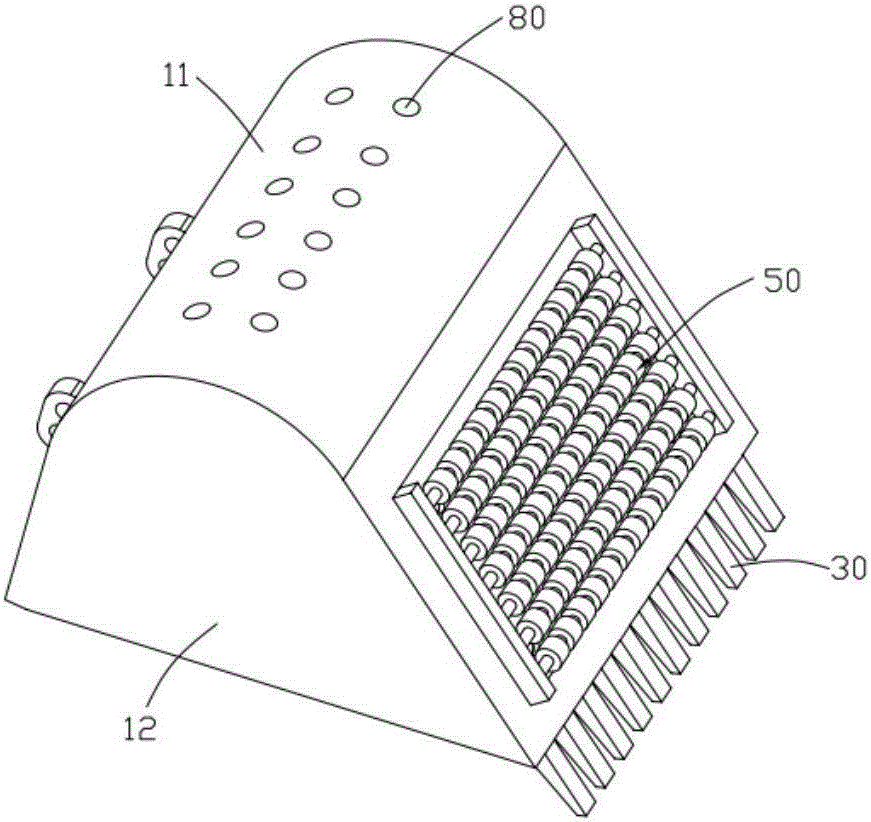

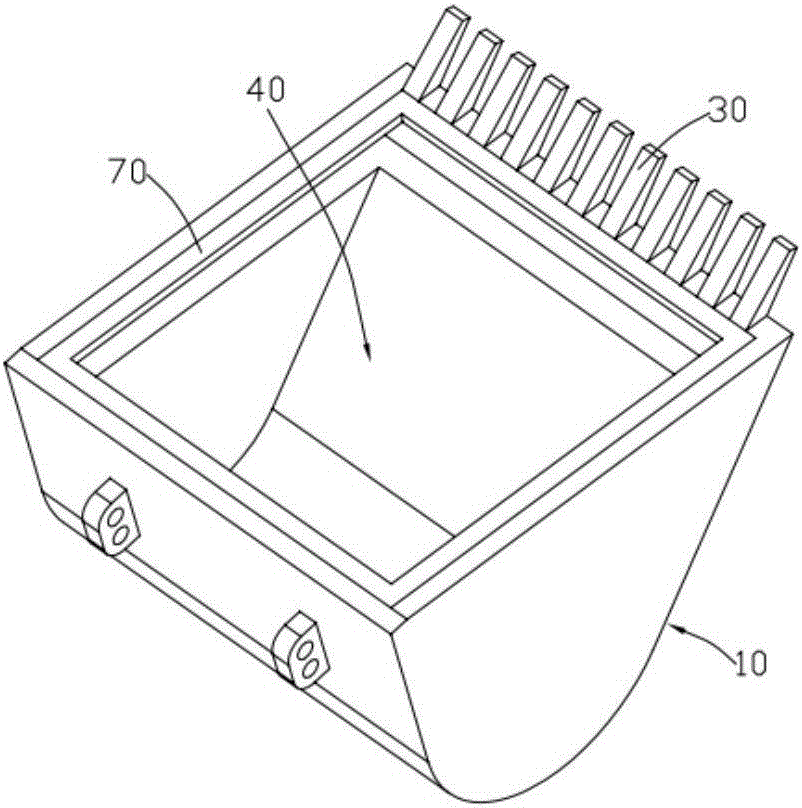

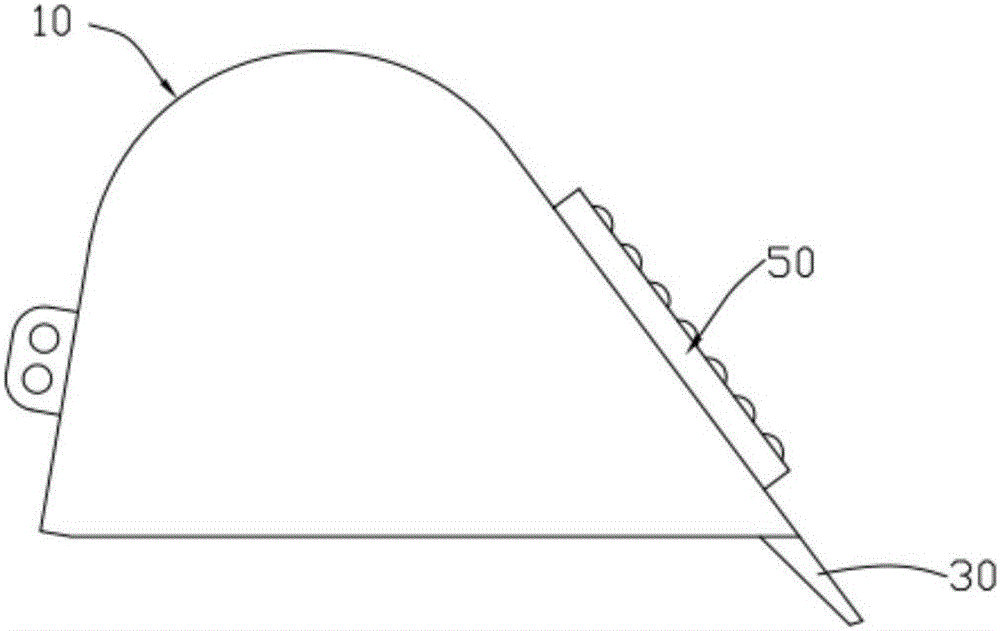

[0026] See Figure 1 to Figure 4 As shown, a special bucket for an excavator includes: an external bucket 10 , and a built-in bucket 40 installed in the external bucket 10 through a compression spring 20 . In the present invention, the structure of the bucket is set in the form of an external bucket 10 and a built-in bucket 40 , and the connection between the external bucket 10 and the built-in bucket 40 is realized through a compression spring 20 . When the built-in bucket 40 is not loaded with material, the compression spring 20 is in the initial state; when the built-in bucket 40 is loaded with material, the weight of the material acts on the compression spring 20 evenly, and at this moment, the compression spring 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com