Excavator dust removal and debonding control system and method and excavator

A control system and control method technology, which is applied to mechanically driven excavators/dredgers, separation methods, earth movers/shovels, etc., can solve problems such as large dust and adhered materials, and achieve water saving, The effect of reducing the adhesion of materials and improving the construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

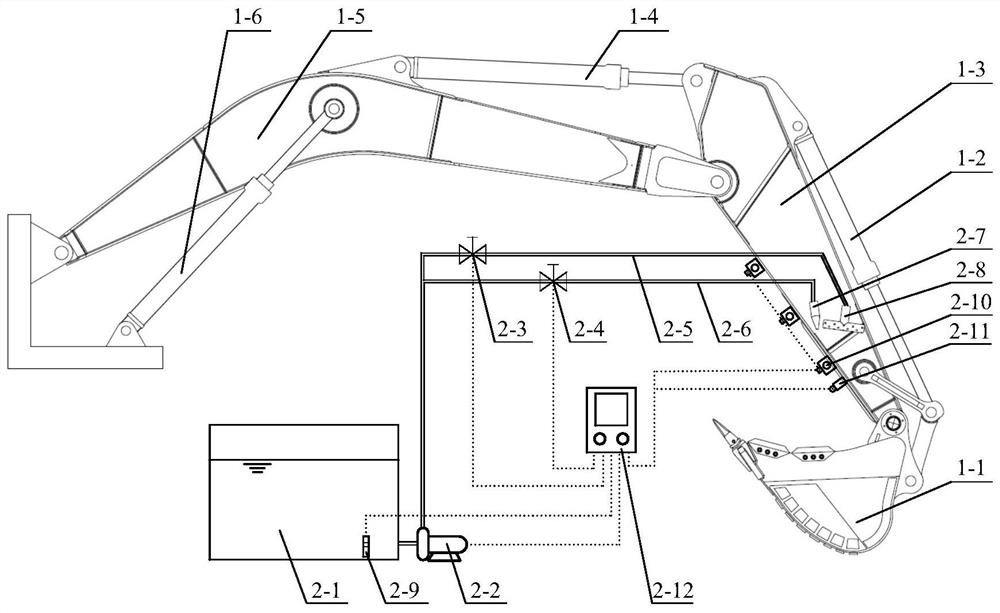

[0059] An embodiment of the present invention provides an excavator dust removal and debonding control system, see figure 1 , including: excavator working device, dust removal and debonding system and operation control system.

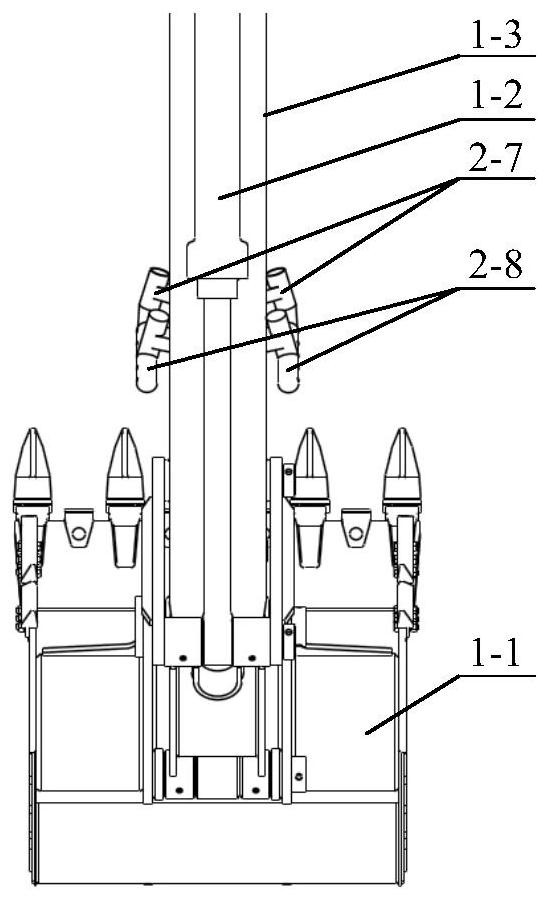

[0060] The working device of the excavator includes: a bucket 1-1 connected in sequence, an arm 1-3 and a boom 1-5, wherein the bucket 1-1 is connected to the bucket cylinder 1-2, and the arm 1-3 is connected to the bucket Rod oil cylinder 1-4, boom 1-5 are connected with boom oil cylinder 1-6.

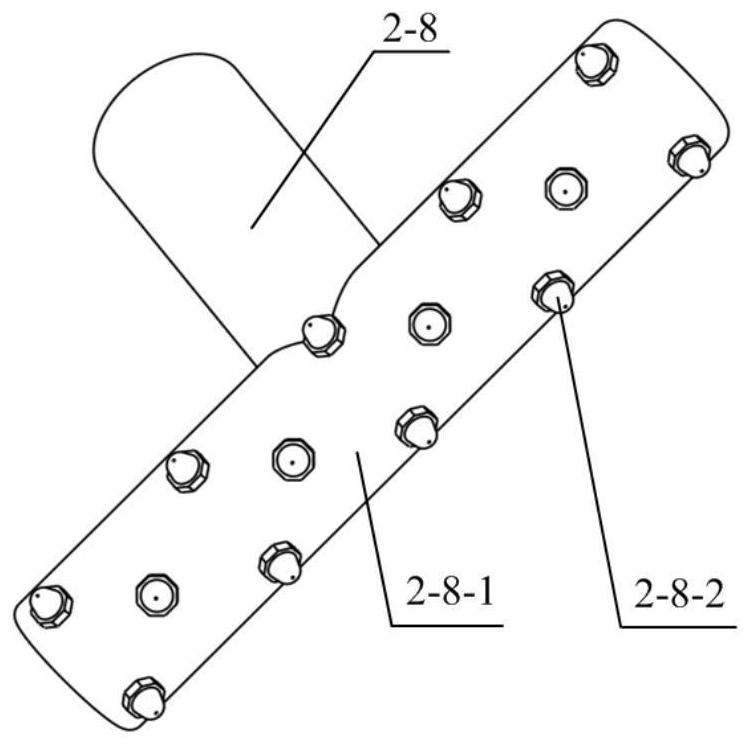

[0061] The dust removal and debonding system includes: water tank 2-1, water pump 2-2, dust removal solenoid valve 2-3, debonding solenoid valve 2-4, dust removal water pipe 2-5, debonding water pipe 2-6, high pressure wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com