Patents

Literature

143results about How to "Achieve jitter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

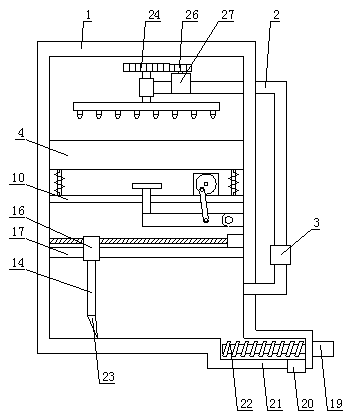

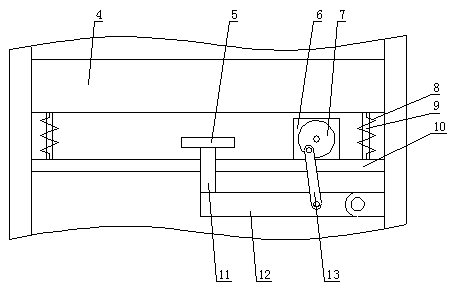

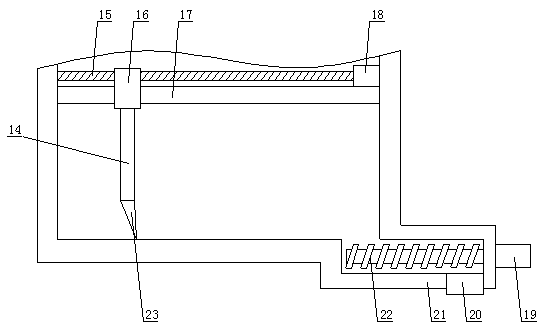

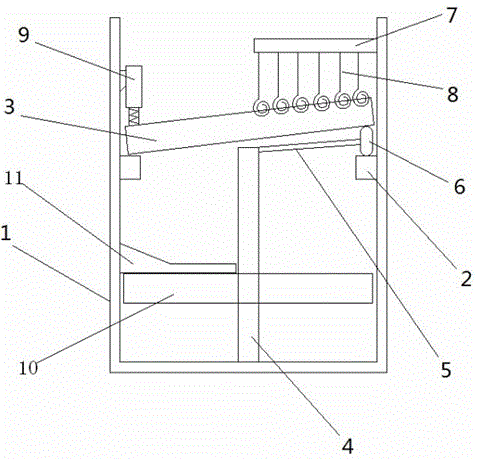

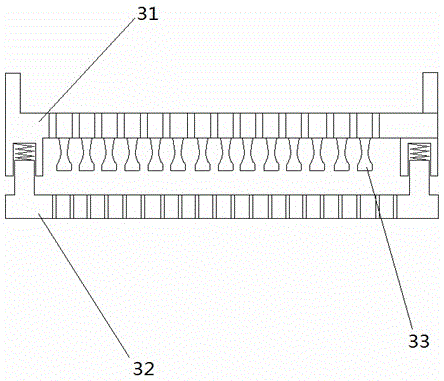

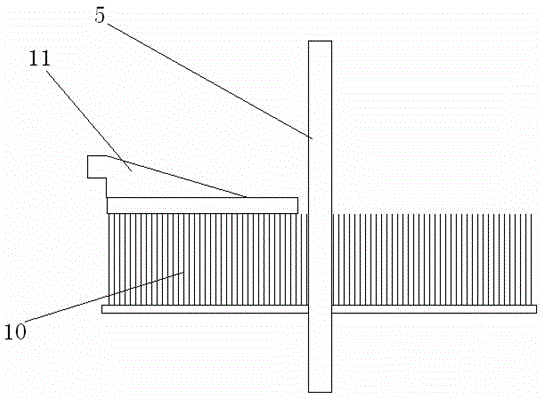

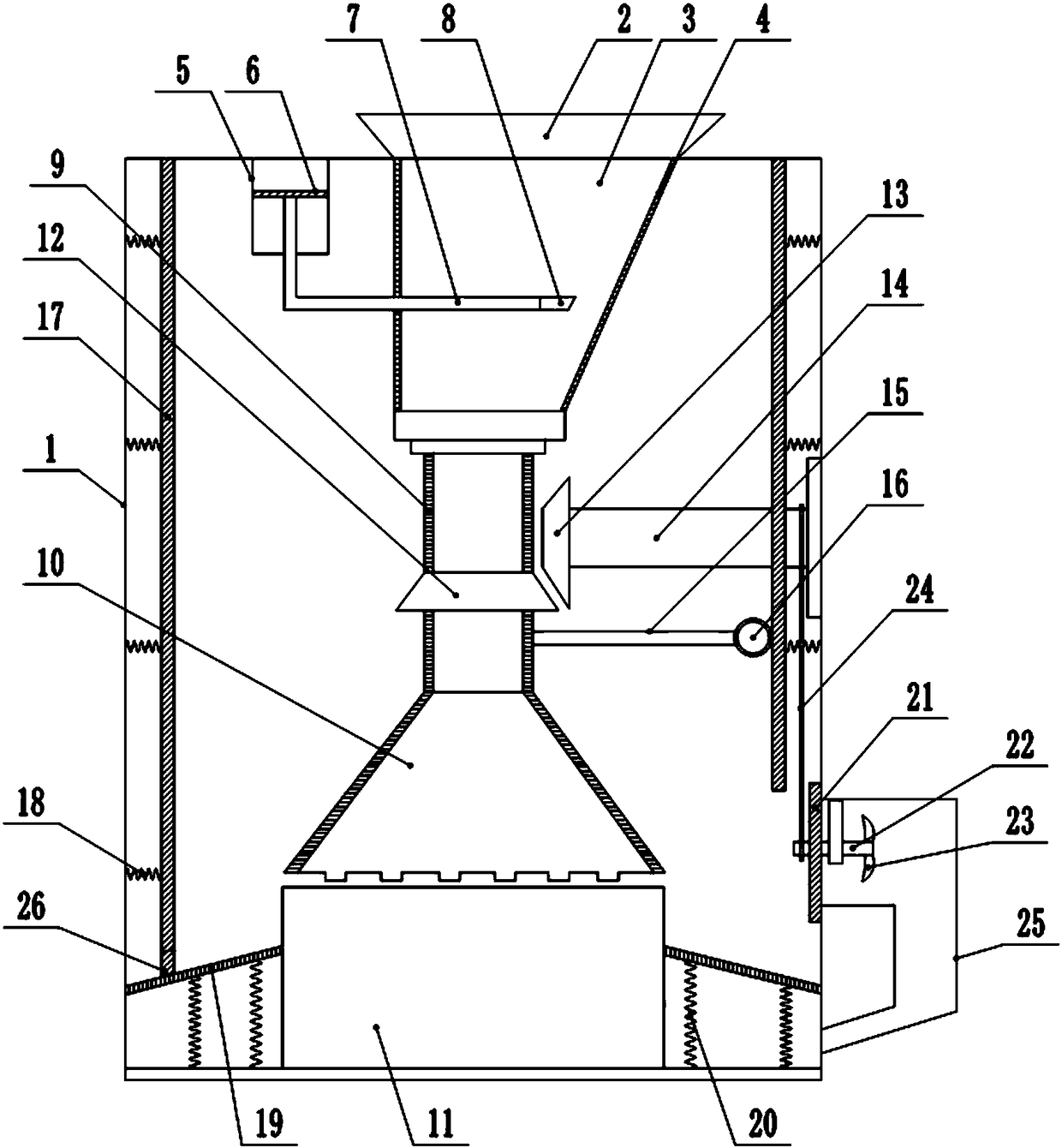

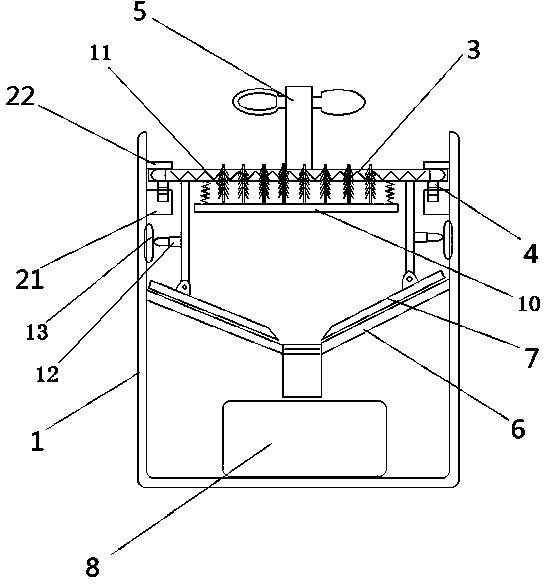

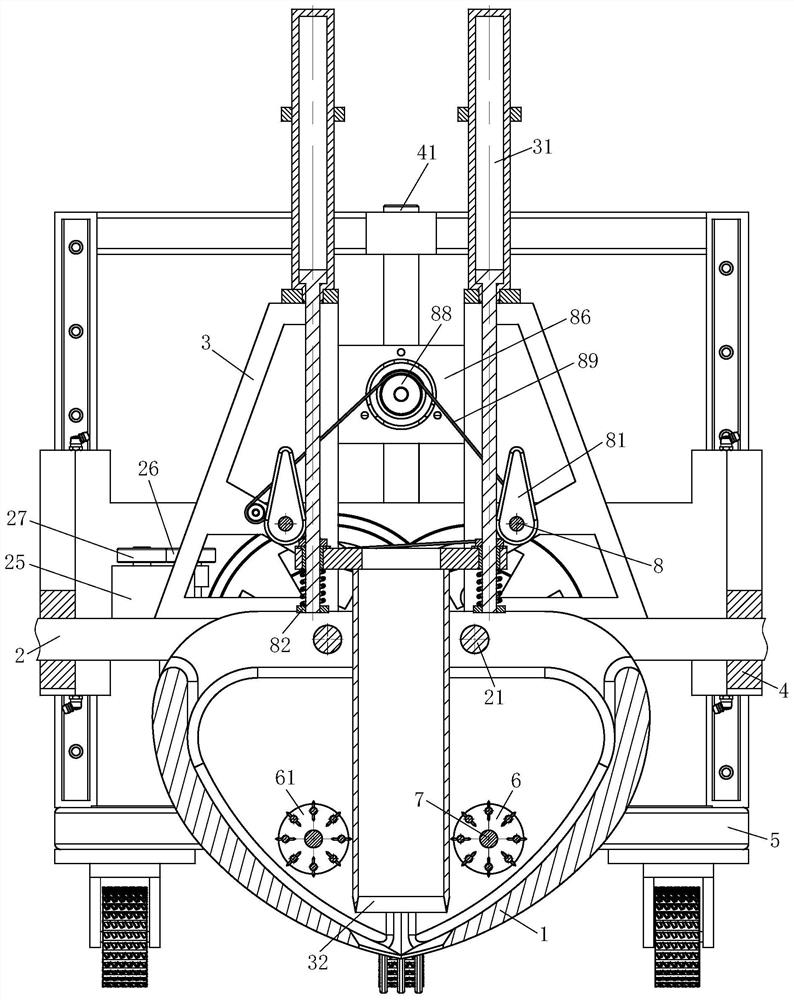

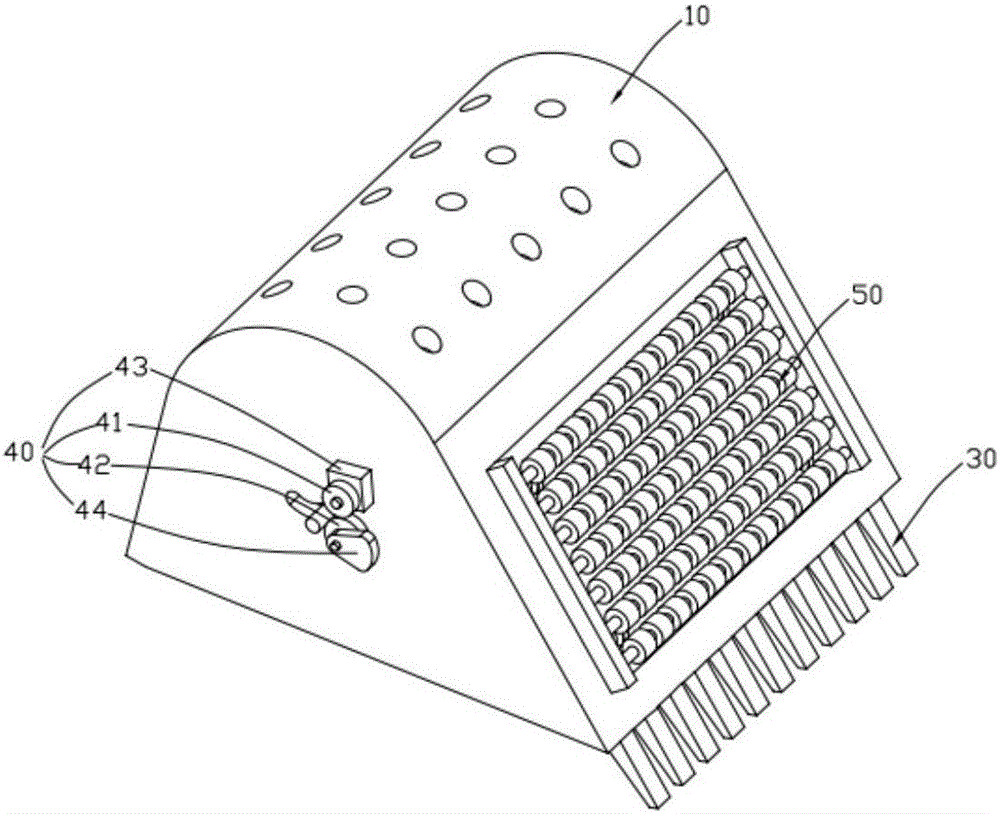

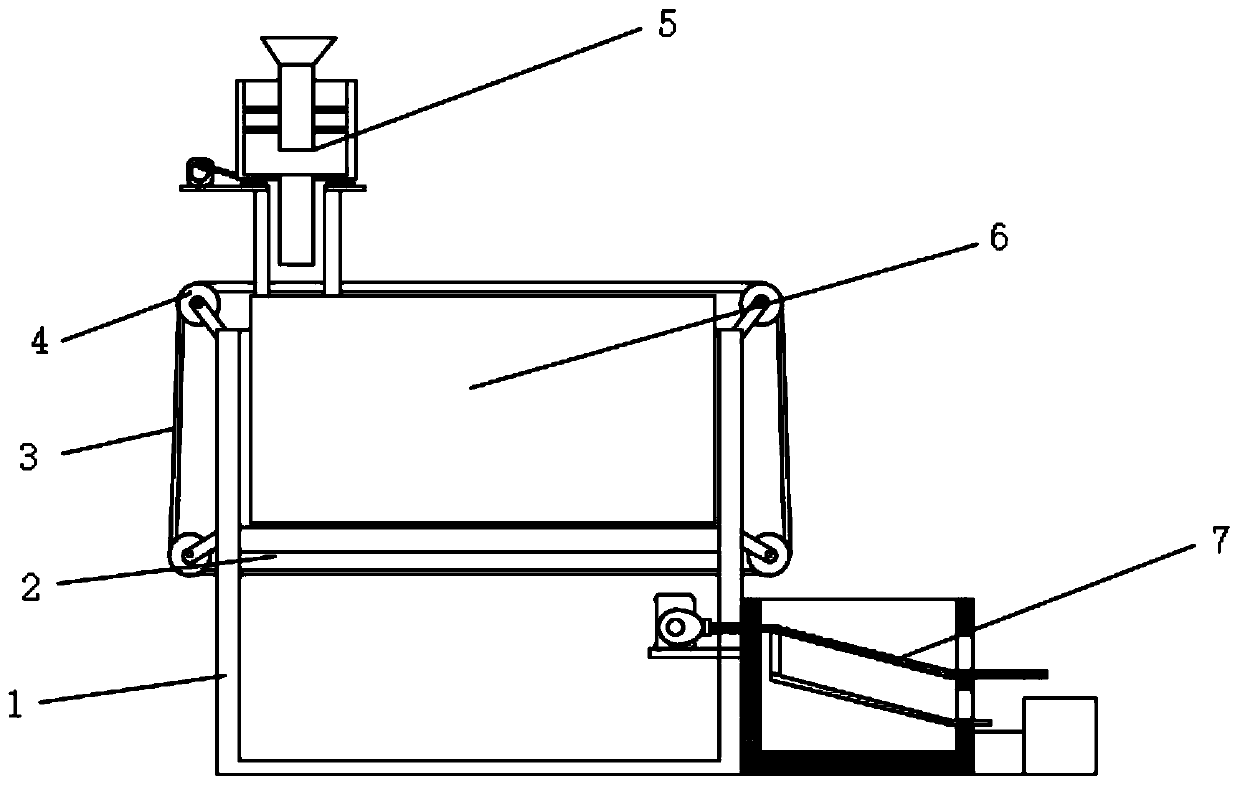

Spraying tower with function of cleaning filling layer

InactiveCN107812424AAchieve cleanupIn the spray tower of the cleaning function, it is realized by cleaningGas treatmentUsing liquid separation agentSludgeSewage outfall

The invention relates to a spray tower with the function of cleaning the packing layer, which includes a body, a water pipe, a packing layer and a water pump, and also includes a spraying mechanism, a cleaning mechanism and a sewage discharge mechanism. The cleaning mechanism includes a first support rod and a knocking block , a first transmission rod, a second transmission rod, a first drive assembly and two springs, the blowdown mechanism includes a second drive assembly, a second support rod, a moving block, a connecting rod, a scraper and a blowdown assembly, which has In the spray tower with packing layer cleaning function, the packing layer is beaten by the cleaning mechanism, and the dirt in the packing layer is cleaned out under the action of inertia, and the packing layer is sprayed by the spraying mechanism, thus realizing the cleaning of the packing layer. The cleaning of the packing layer can be kept clean, thereby improving the purification effect of the spray tower. Not only that, the sludge deposited in the spray tower is cleaned through the sewage discharge mechanism, which not only improves the efficiency of cleaning sludge in the spray tower, It also prevents sludge from clogging the sewage outlet.

Owner:南京市雨花台区创新创业法治宣传与法律服务中心

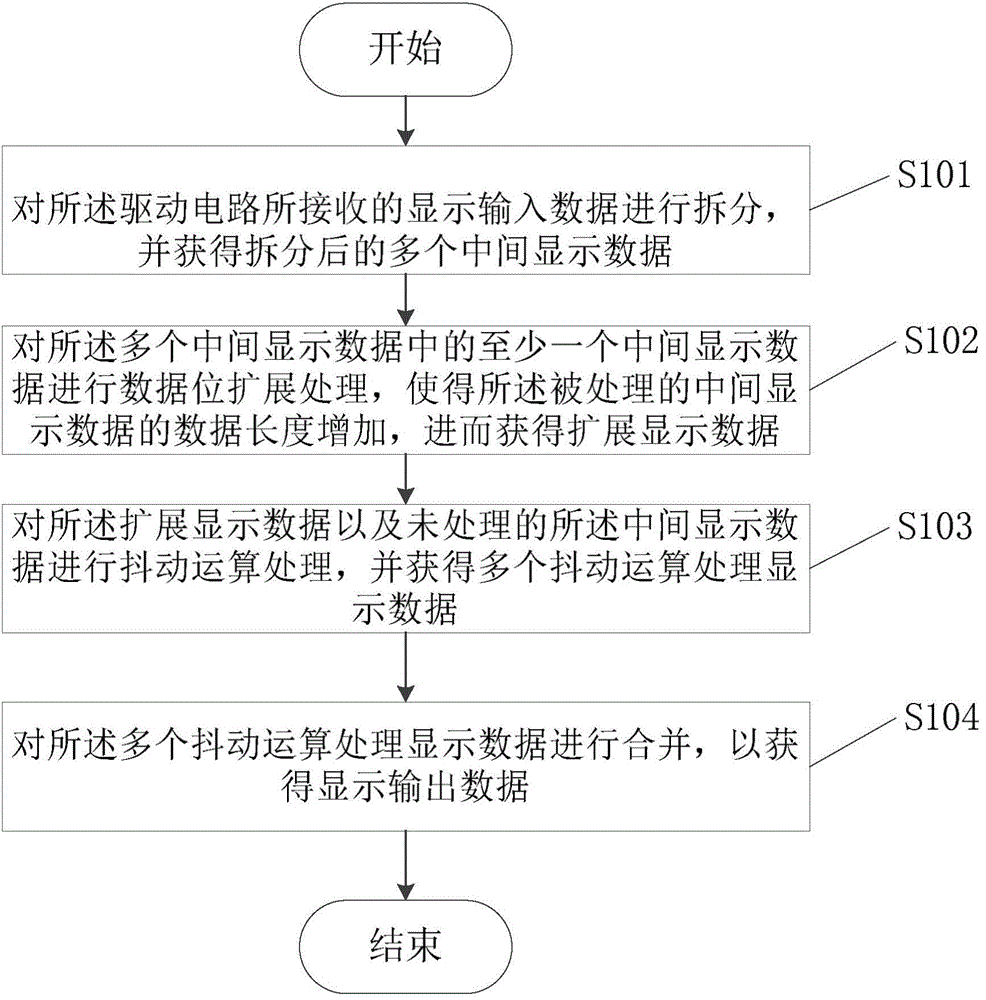

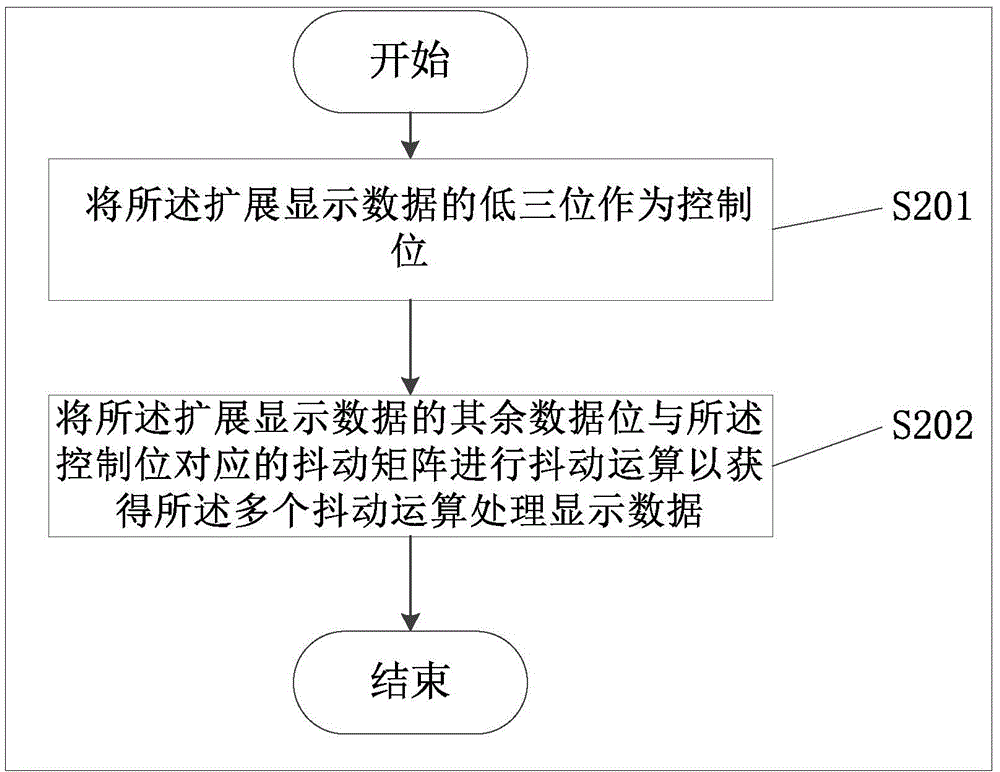

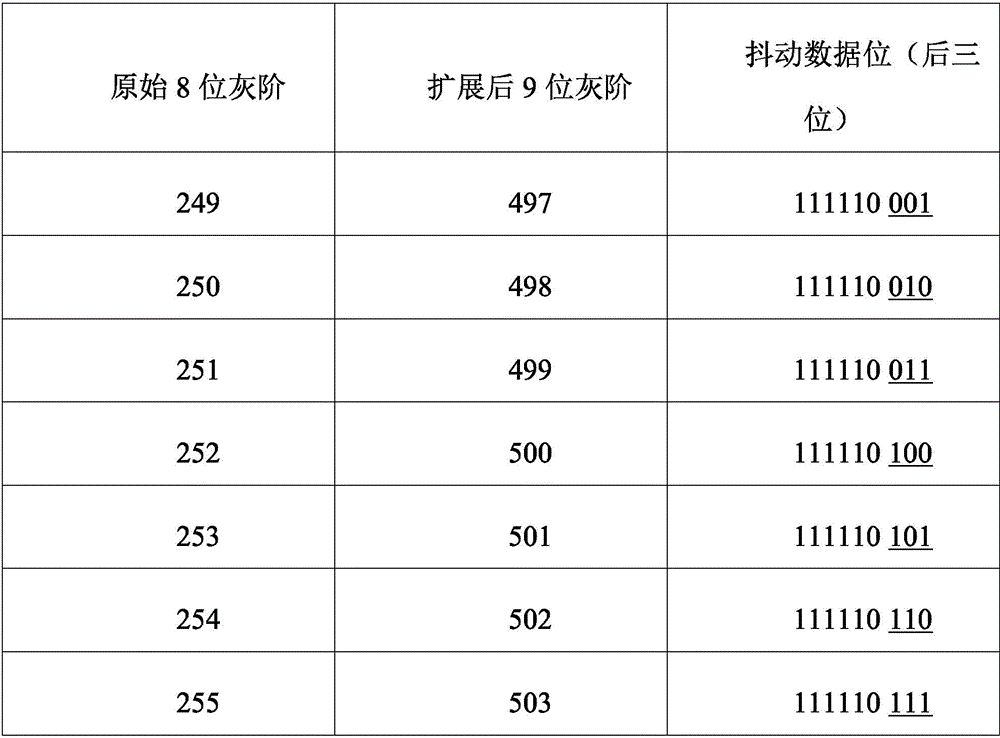

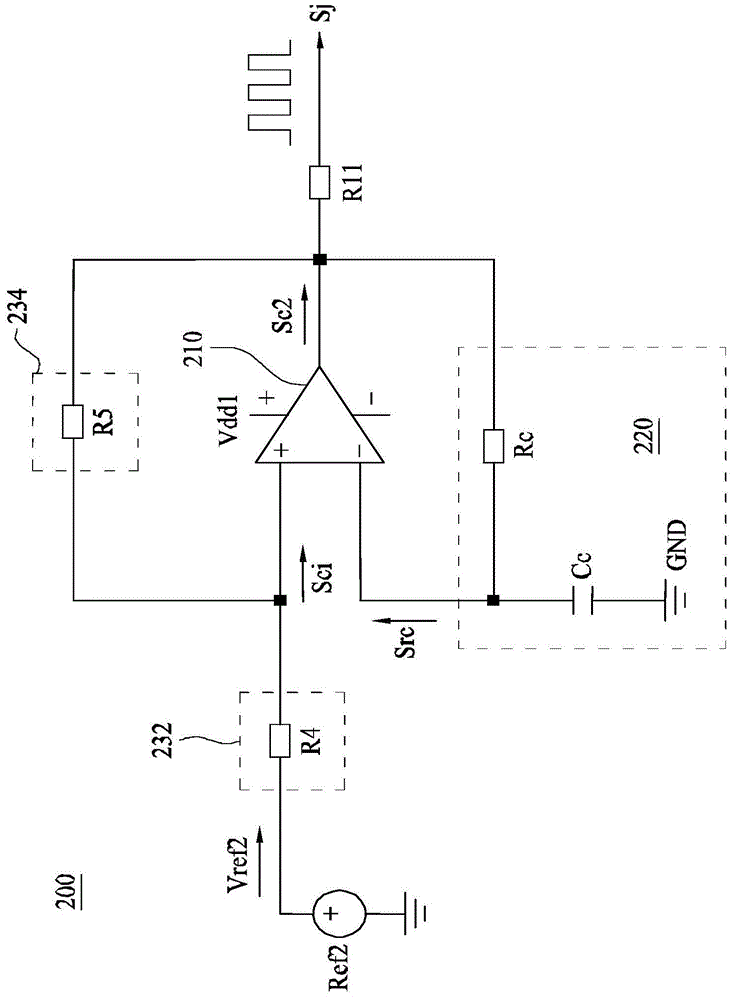

Color enhancement algorithm and control enhancement control device for expanding number of displayed gray scales

InactiveCN105632424AAchieve jitterCathode-ray tube indicatorsComputer graphics (images)Color enhancement

The invention provides a color enhancement algorithm for expanding number of displayed gray scales, wherein the color enhancement algorithm is used for adjusting the gray scales of displaying input data for obtaining displaying output data. The color enhancement algorithm comprises the steps of a, dividing the displaying input data which are received by a driving circuit, and obtaining a plurality of packets of intermediate displaying data after dividing; b, performing data bit expansion on at least one packet of intermediate displaying data in the plurality of packets of intermediate displaying data, so that the data length of the processed intermediate displaying data is increased and furthermore expanded displaying data are obtained; c, performing jitter processing on the expanded displaying data and the unprocessed intermediate displaying data and obtaining a plurality of packets of jitter-processed displaying data; and d, combining the plurality of packets of jitter-processed displaying data, thereby obtaining displaying output data.

Owner:NEW VISION MICROELECTRONICS INC

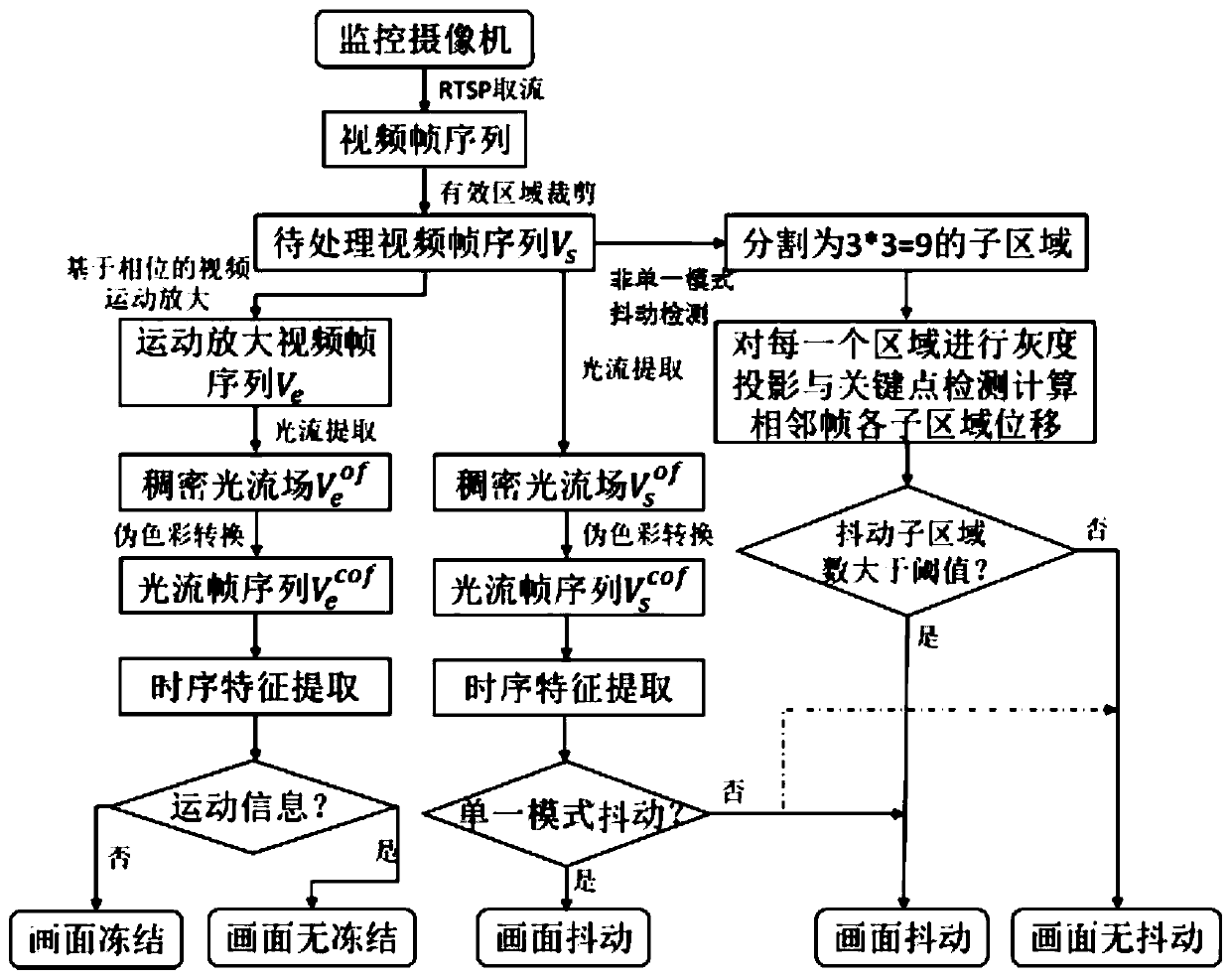

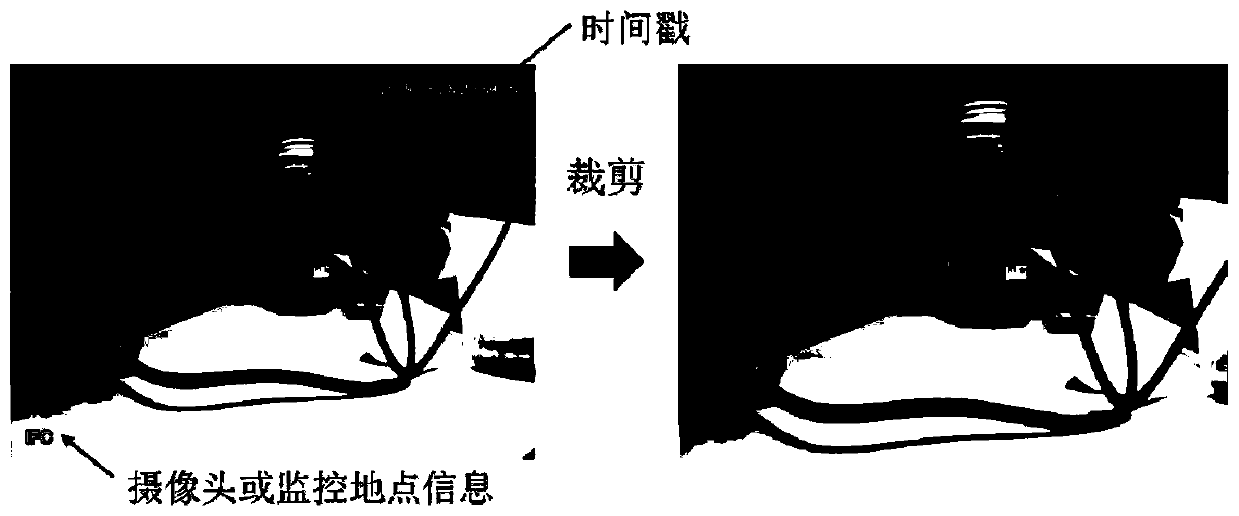

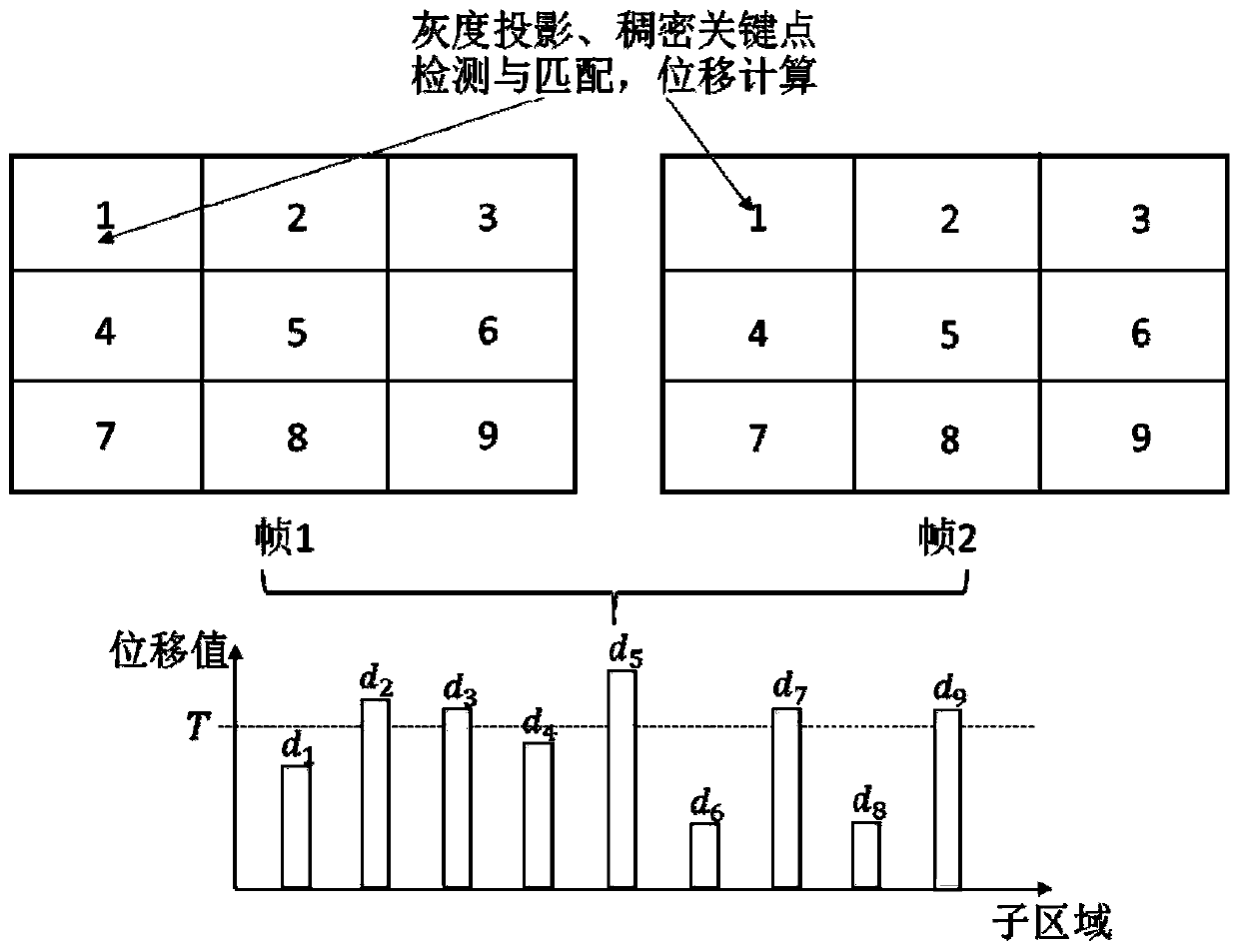

Video jitter and freezing detection method and device based on pixel time sequence motion analysis

ActiveCN110191320AEliminate false alarmsFalse alarm mitigationImage enhancementTelevision system detailsFrame sequenceOptical flow

The invention relates to a video jitter and freezing detection method based on pixel time sequence motion analysis. The method comprises the following steps: S1, obtaining a video frame sequence image; s2, cutting a video frame sequence image; s3, on the basis of the to-be-processed video frame sequence Vs, carrying out image non-single mode jitter detection; s4, obtaining a motion amplification video frame sequence Ve; s5, acquiring a dense optical flow field Vsof and a dense optical flow field Veof; s6, converting the dense optical flow field Vsof and the dense optical flow field Veof information into image information, and obtaining an optical flow frame sequence Vscof and an optical flow frame sequence Vecof; s7, respectively carrying out picture freezing and picture single-mode jitterdetection. The invention further discloses a video jitter and freezing detection device based on pixel time sequence motion analysis. The image freezing detection accuracy can reach 100%, the accuracy is improved through parallel processing of the two jitter detection methods, the detection speed is high, and image jitter and freezing detection are achieved at the same time in a unified algorithmframework.

Owner:HEFEI UNIV

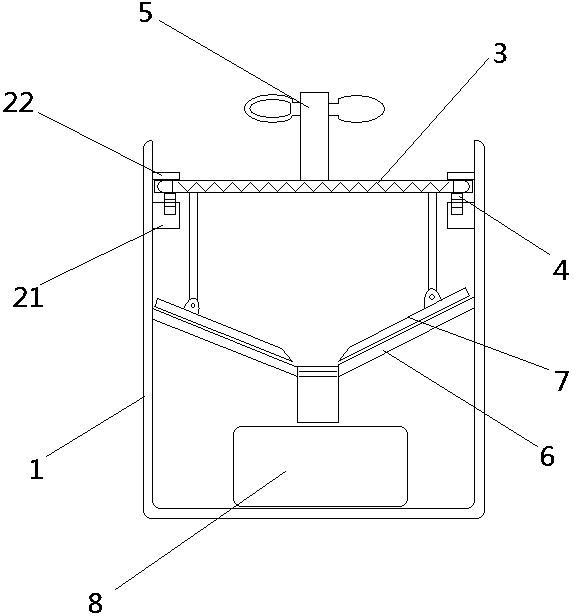

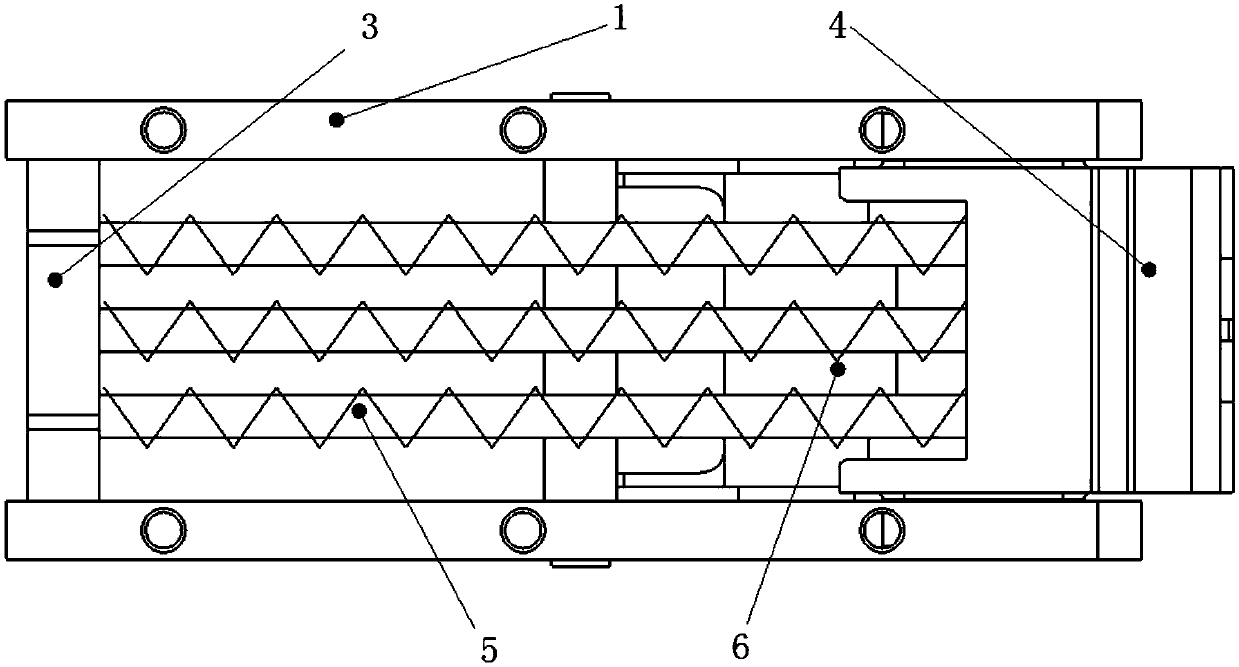

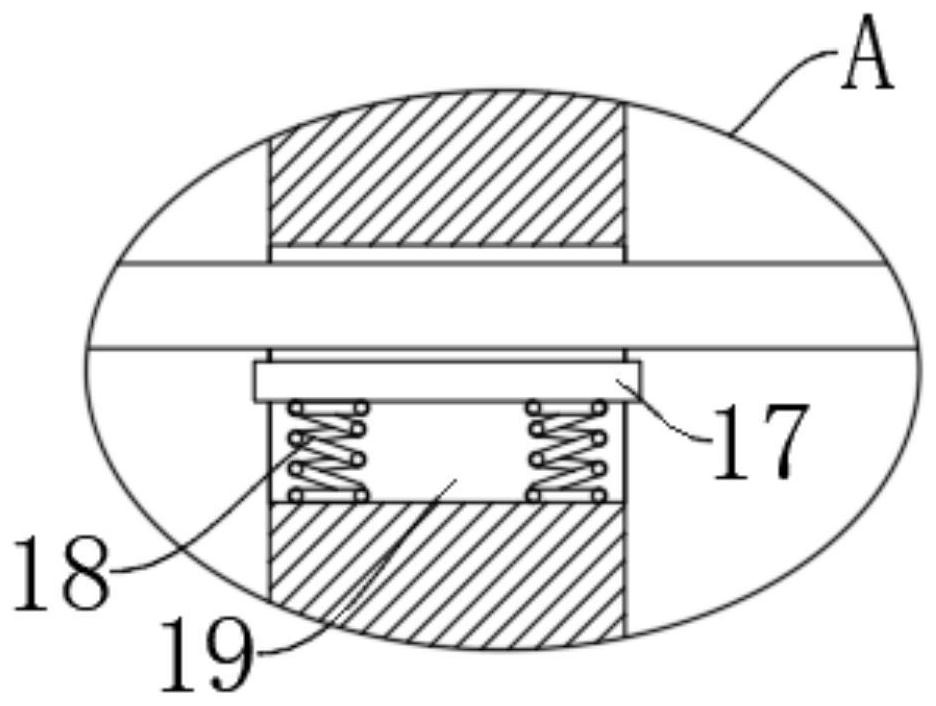

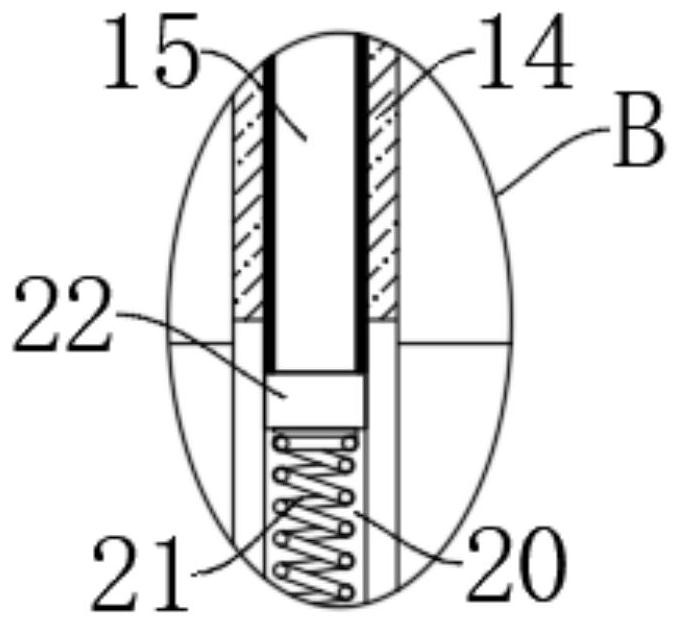

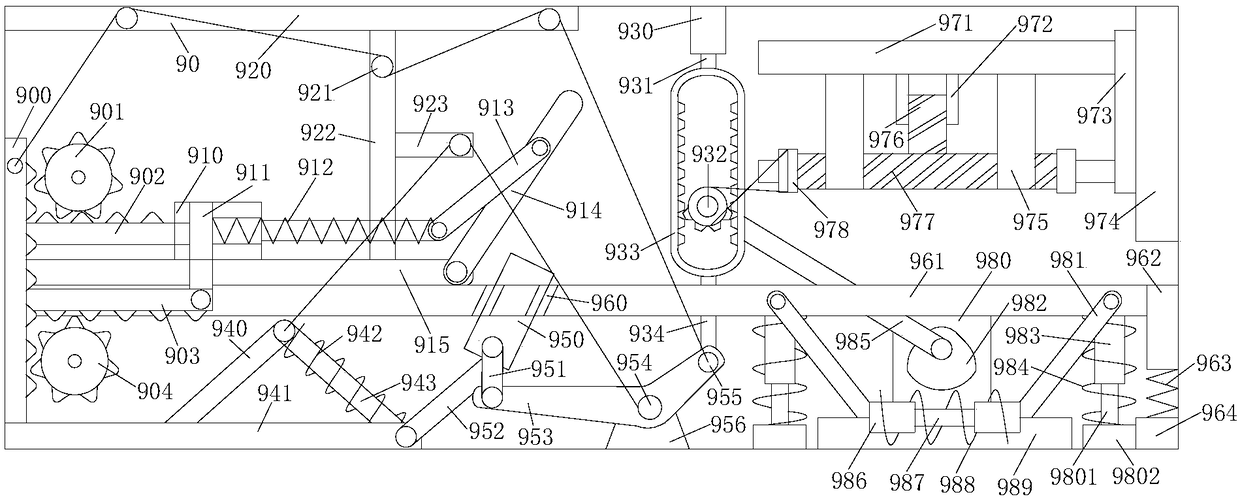

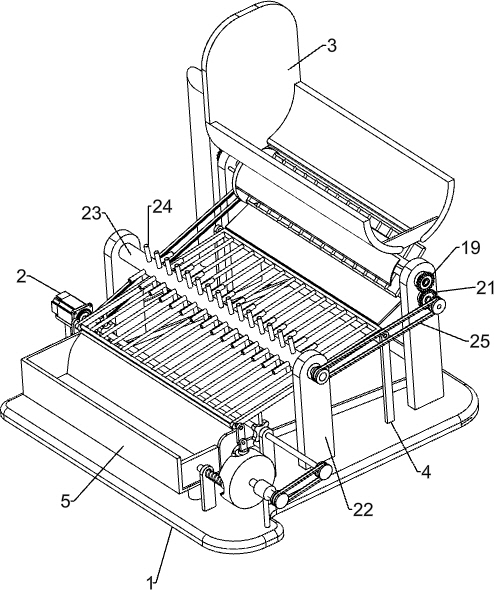

Screening and separating device for fine soil before soil improvement

ActiveCN105127106AAchieve vibrationAchieve jitterSievingScreeningClassical mechanicsStructural engineering

Owner:北京本农科技发展有限公司

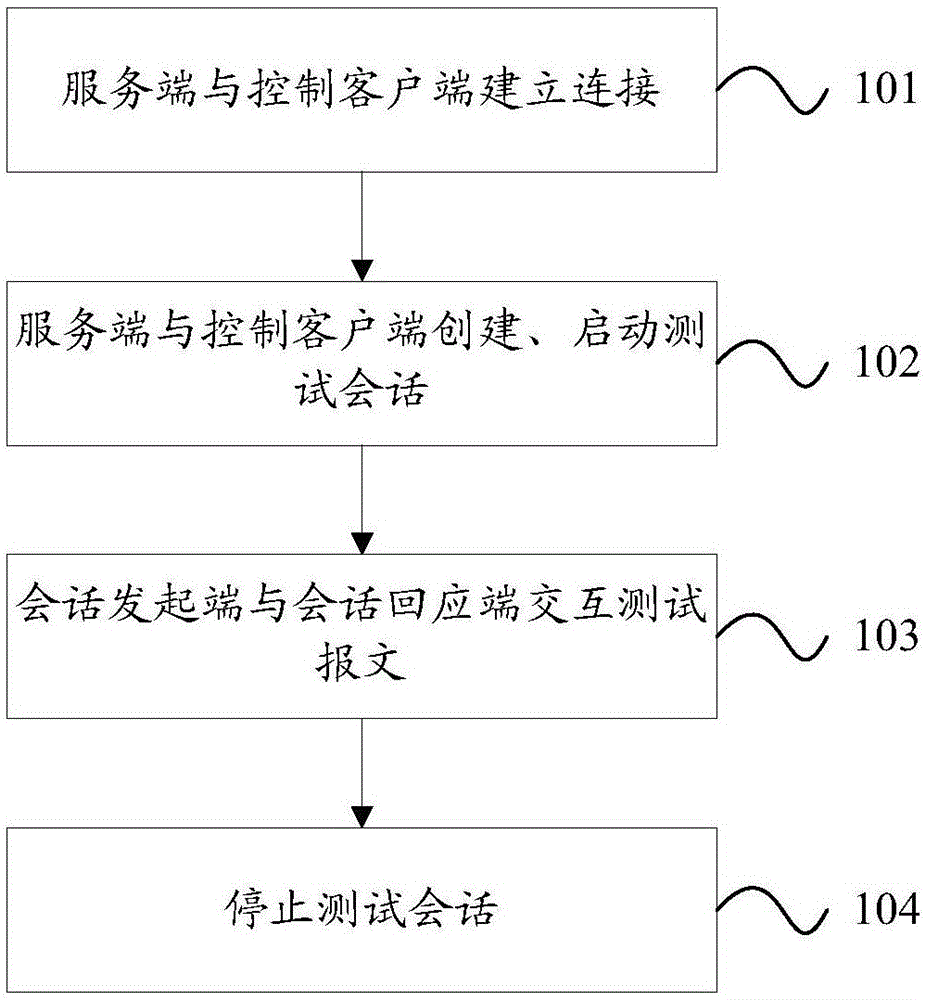

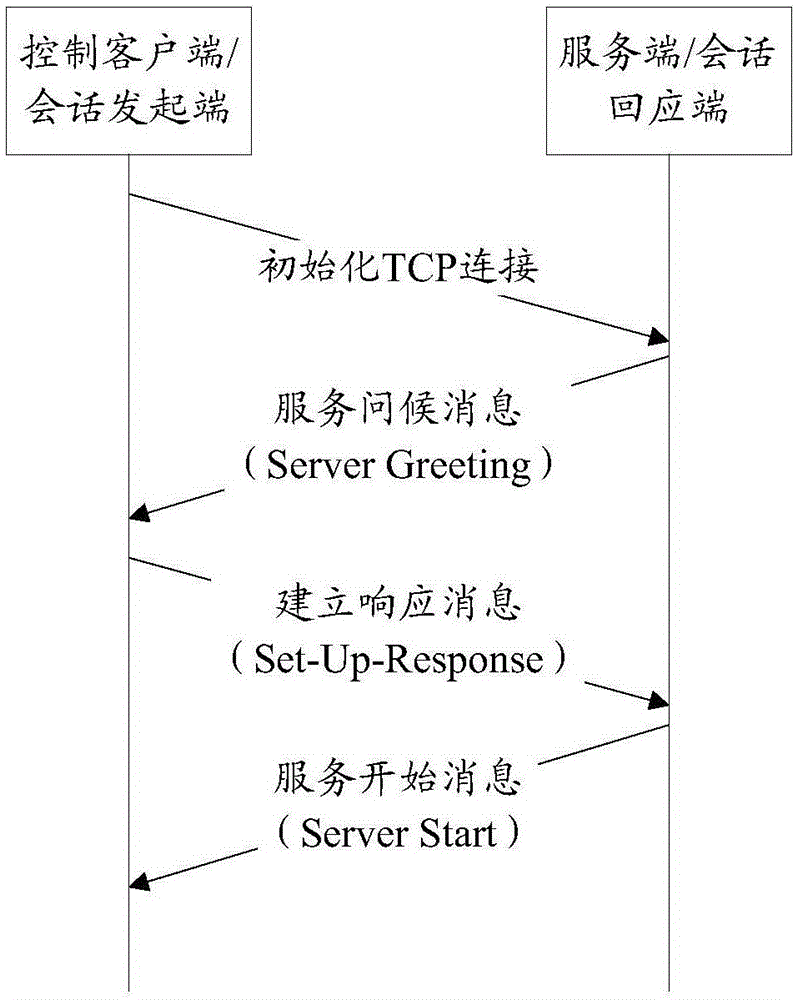

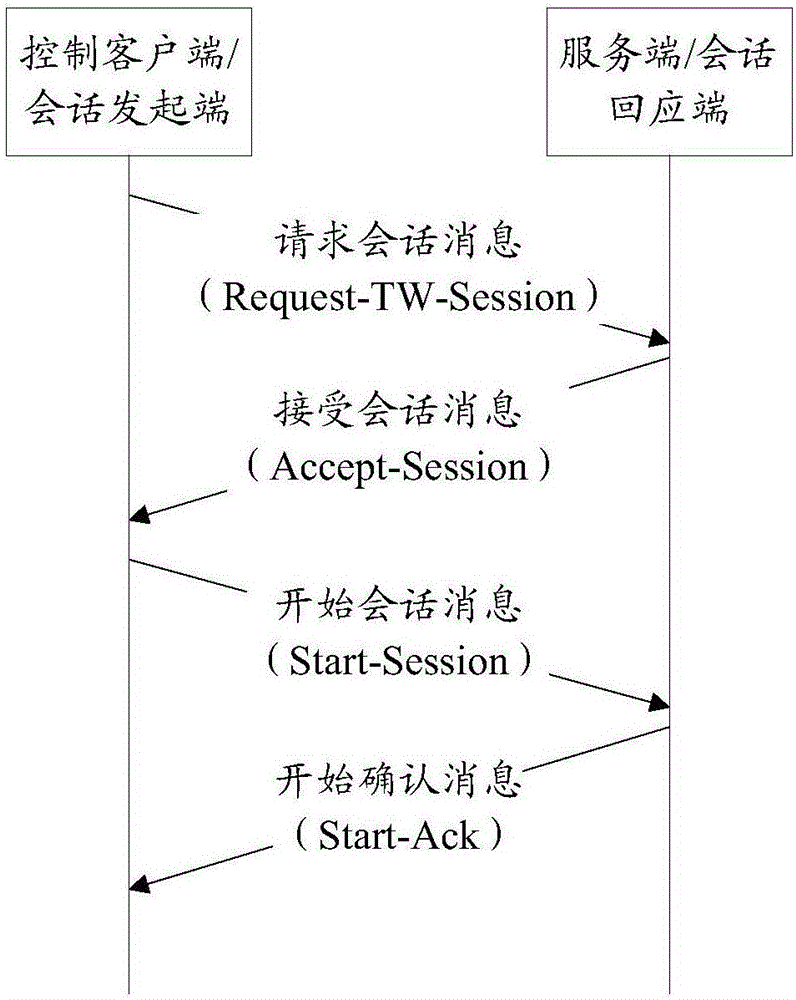

Network performance measuring method, apparatus and system

ActiveCN106603333ALarge measuring rangeImplement testData switching networksTelecommunications linkCommunication link

The invention discloses a network performance measuring method, apparatus and system. The method is used for measuring the network performance parameters of the communication link between a first device and a second device. The first device is configured to be a control client and a session initiating side to implement the TWAMP, and the second device is configured to a server and a session response side to implement the TWAMP. The network performance measuring method is applied to the first device and includes creating the TWAMP type SLA work after a work creation command is received; starting to schedule the TWAMP type SLA work after the starting work scheduling command is received; by scheduling the TWAMP type SLA work to realize the following operation: negotiating with the second device the UDP port number used in the interactive testing of messages; interactively testing the messages with the UDP port determined by the negotiation and the second device; and measuring the network performance parameters according to the interactive testing messages.

Owner:RAISECOM TECH

Blockage-proof open-air ombrometer

InactiveCN104375217ASpeed up the fallSpeed up fast focusRainfall/precipitation gaugesEngineeringStructural engineering

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

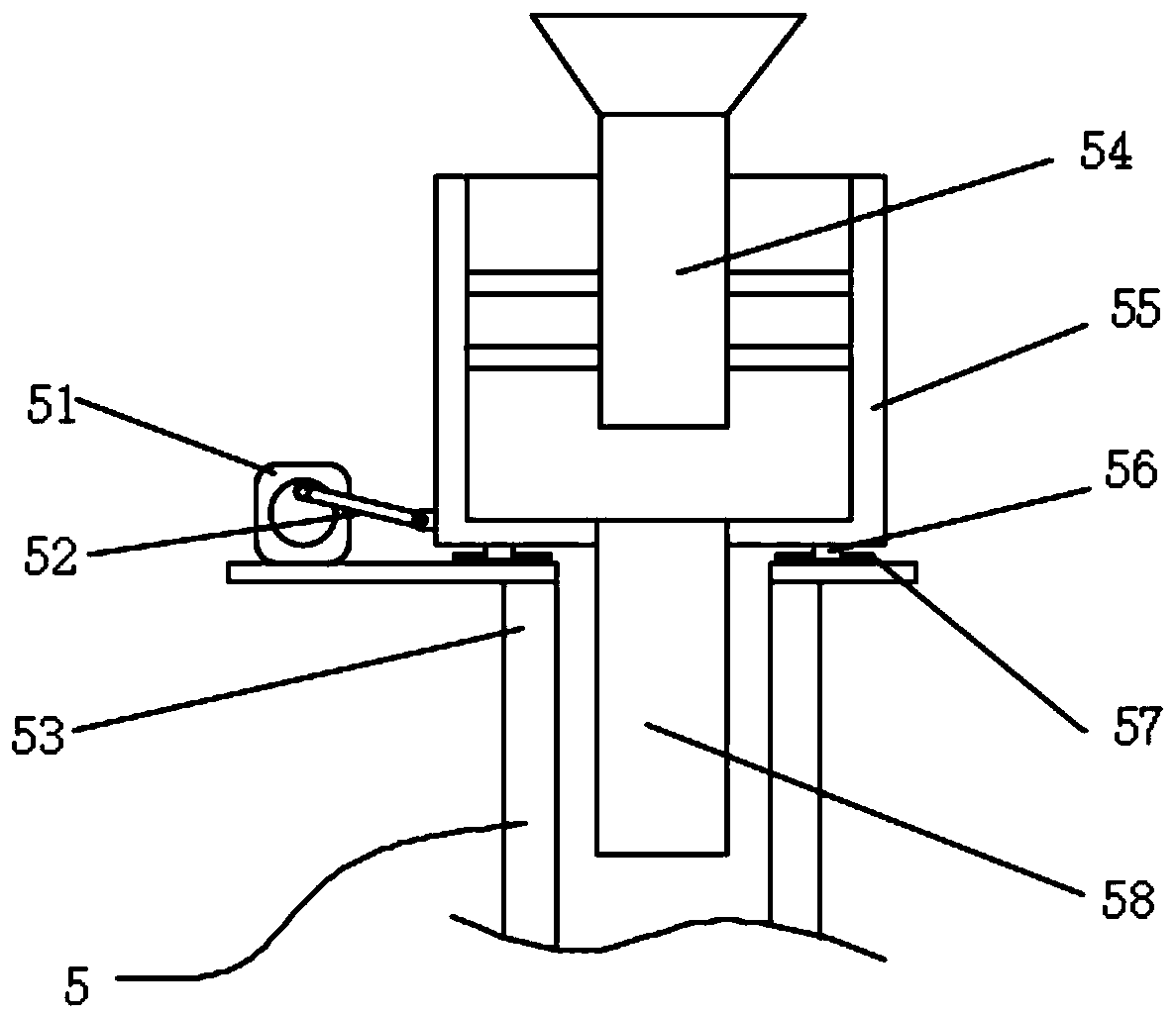

Circulating type feed crushing device

The invention discloses a circulating type feed crushing device, and belongs to the field of feed processing. The circulating type feed crushing device comprises a box body, two groups of crushing rollers, a filter screen and a material conveying box; the top of the box body is connected with a feeding port, the side wall of the box body is connected with a discharging port, two partition plates are fixedly connected into the box body and divide the box body into three mutually independent inner cavities, and the inner cavities comprise a power cavity between the two partition plates and crushing cavities between the two partition plates and the box body; the two groups of crushing rollers are rotationally connected into the two crushing cavities correspondingly; the filter screen is usedfor being connected into the two crushing cavities and located below the two sets of crushing rollers; and the material conveying box is fixedly connected to the side wall of the box body, a materialconveying component for conveying materials upwards is connected into the material conveying box, a filtering groove corresponding to the filter screen is further formed in the side wall of the box body, the filtering groove communicates with the material conveying box, and the top of the material conveying box communicates with the feeding port. According to the circulating type feed crushing device, dispersed feeding can be carried out, materials are filtered and then crushed secondarily, fine crushing is carried out, and the crushing effect is improved.

Owner:新余众望饲料科技有限公司

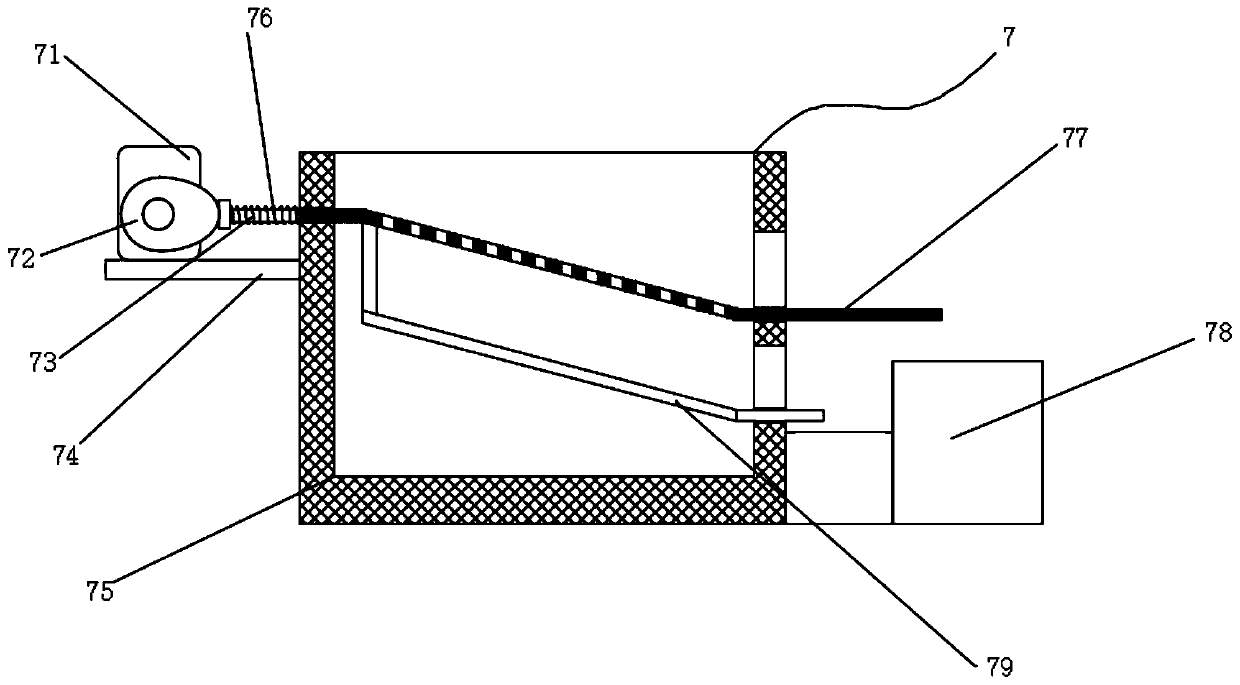

Powder coating grinding equipment

The invention relates to powder coating grinding equipment. The powder coating grinding equipment comprises a grinding box and a feed hopper; the feed hopper communicates with a feeding passage; the bottom of the feeding passage is rotationally connected with a discharging pipe; the bottom of the discharging pipe is fixedly connected with an upper grinding disc; the bottom of the upper grinding disc is provided with a discharging hole; a lower grinding disc is arranged below the upper grinding disc; the discharging pipe is coaxially and fixedly connected with a first bevel gear; the first bevel gear is engaged with a second bevel gear; the second bevel gear is coaxially and fixedly connected with a horizontal shaft; the two sides of the inner wall of the grinding box are each provided witha discharging plate; a plurality of shaking springs are fixedly arranged between the discharging plates and the sidewall of the grinding box; the discharging pipe is further fixedly connected with ahorizontally-arranged push rod; the free end of the push rod leans against the discharging plates; the outer wall of the lower grinding disc is vertically and slidably connected with an obliquely-arranged filter plate; the bottom of the filter plate is fixedly connected with a support spring; a discharging mechanism is arranged at one side of the grinding box; the discharging mechanism comprises adriving shaft; and a belt is connected between the driving shaft and the horizontal shaft. The powder coating grinding equipment solves the problem about adhesion of power coatings.

Owner:重庆阿罗科技有限公司

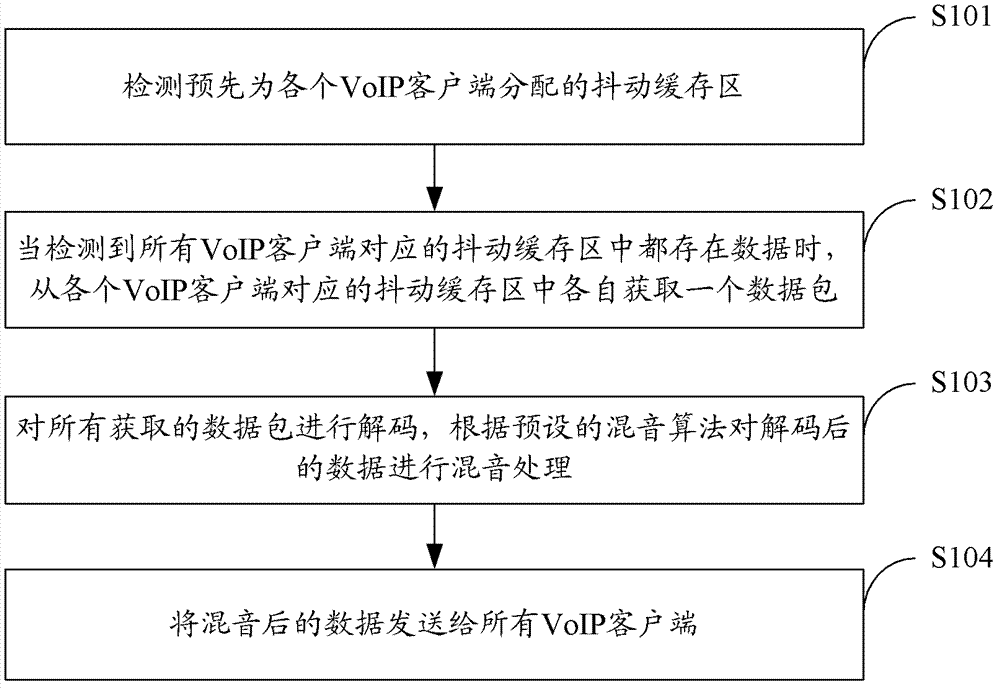

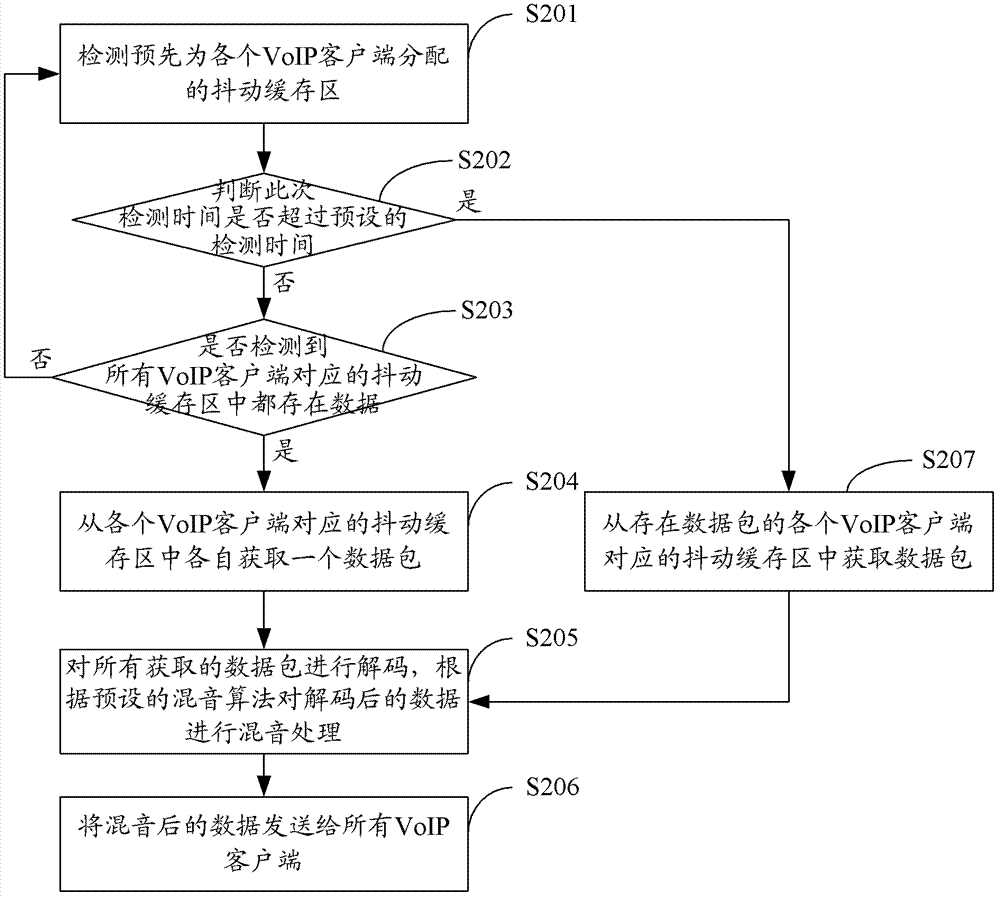

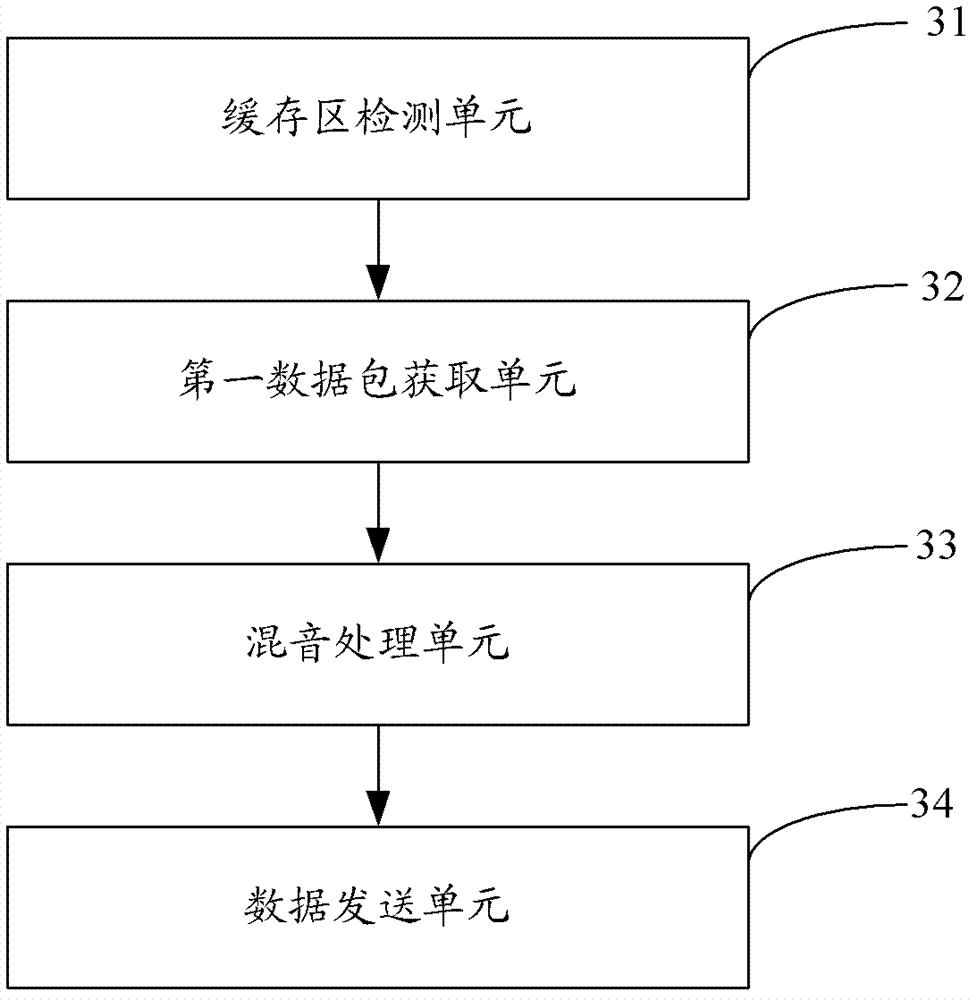

VoIP server synchronous sound mixing method and system

InactiveCN103248774AAchieve jitterEliminate jitterInterconnection arrangementsSpeech analysisComputer hardwareNetwork packet

The invention is applicable to the technical field of computers, and provides a VoIP (Voice Over Internet Protocol) server synchronous sound mixing method and system. The method comprises the following steps: detecting jiggle cache areas for distributing all VoIP client sides at advance; when data of all the VoIP client sides exits in the corresponding jiggle cache areas, acquiring data packages form the jiggle cache areas corresponding to all the VoIP client sides; decoding the data packages acquired, and carrying out the sound mixing processing on the decoded data according to the preset sound mixing algorithm; and sending the sound-mixed data to all the VoIP client sides. Through the arrangement of the jiggle cache areas, the data jiggle during the sound mixing process is eliminated effectively, and the sound mixing effect is improved, which increases the conversation experiment of VoIP users.

Owner:陈剑勇

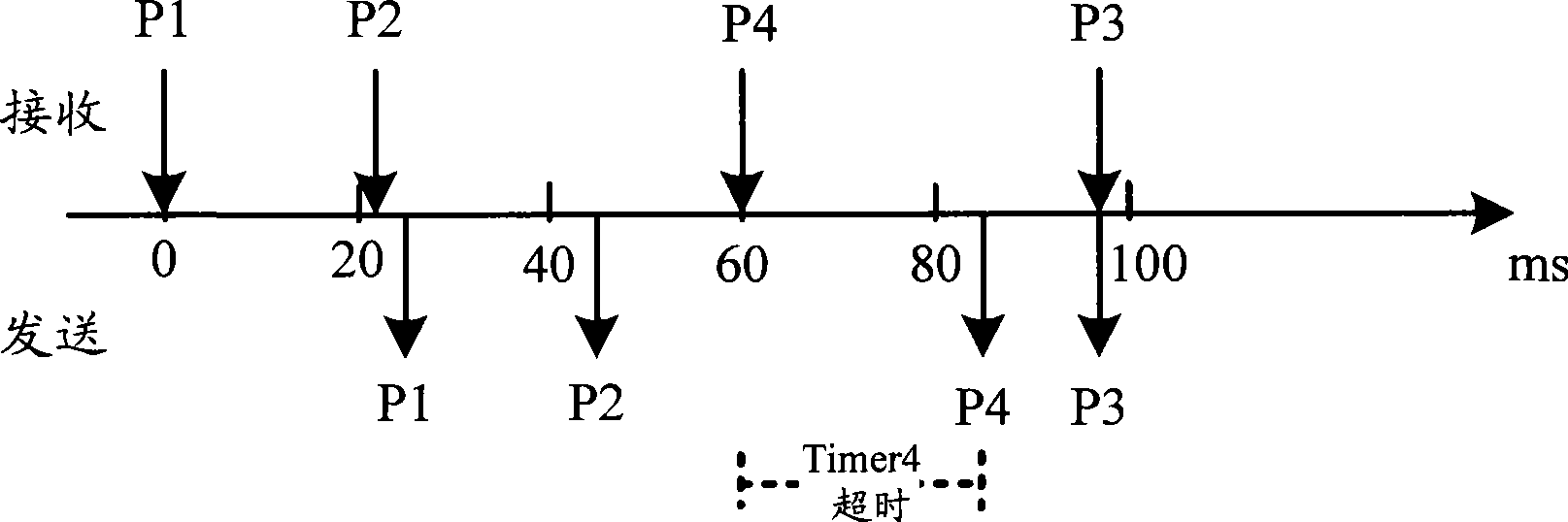

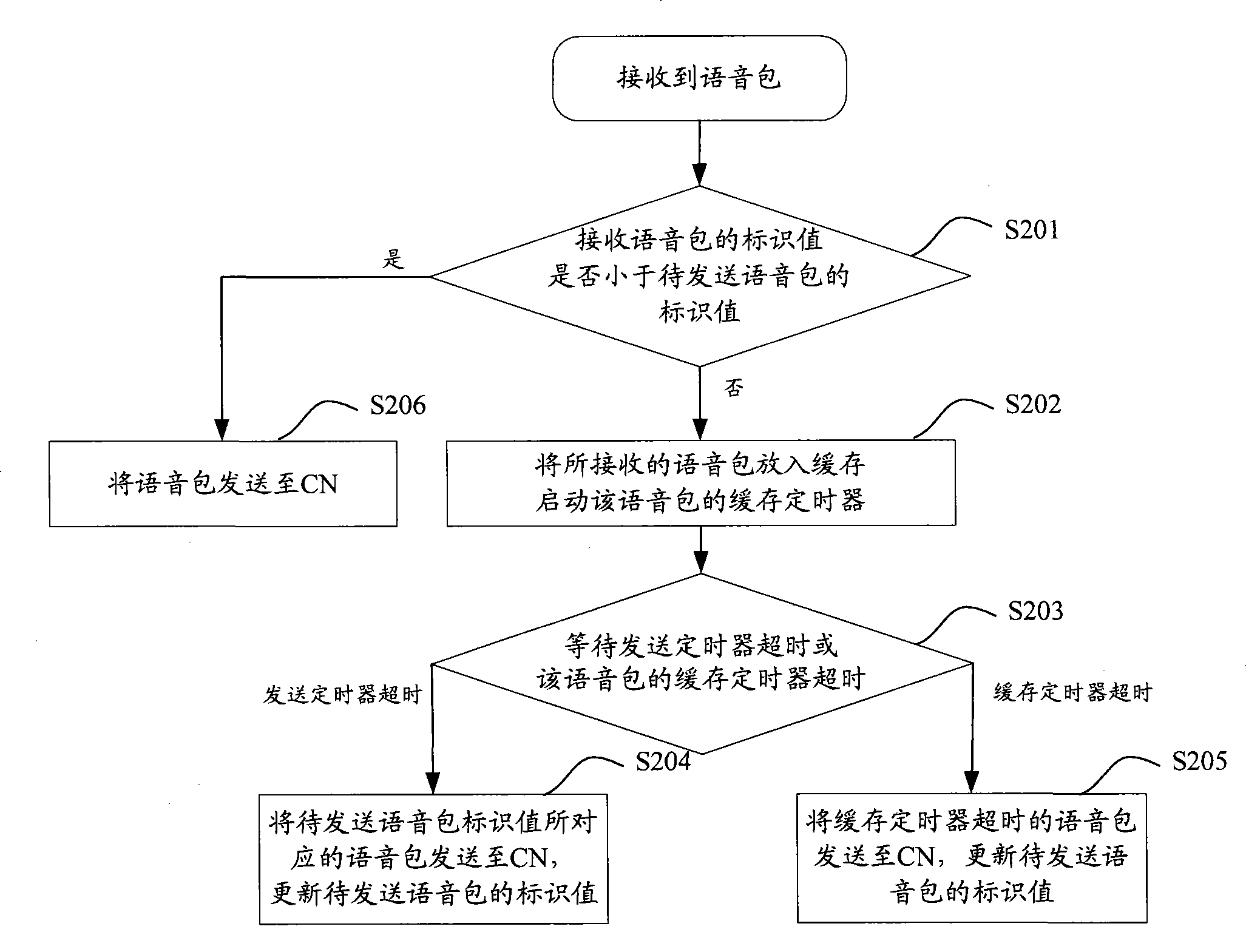

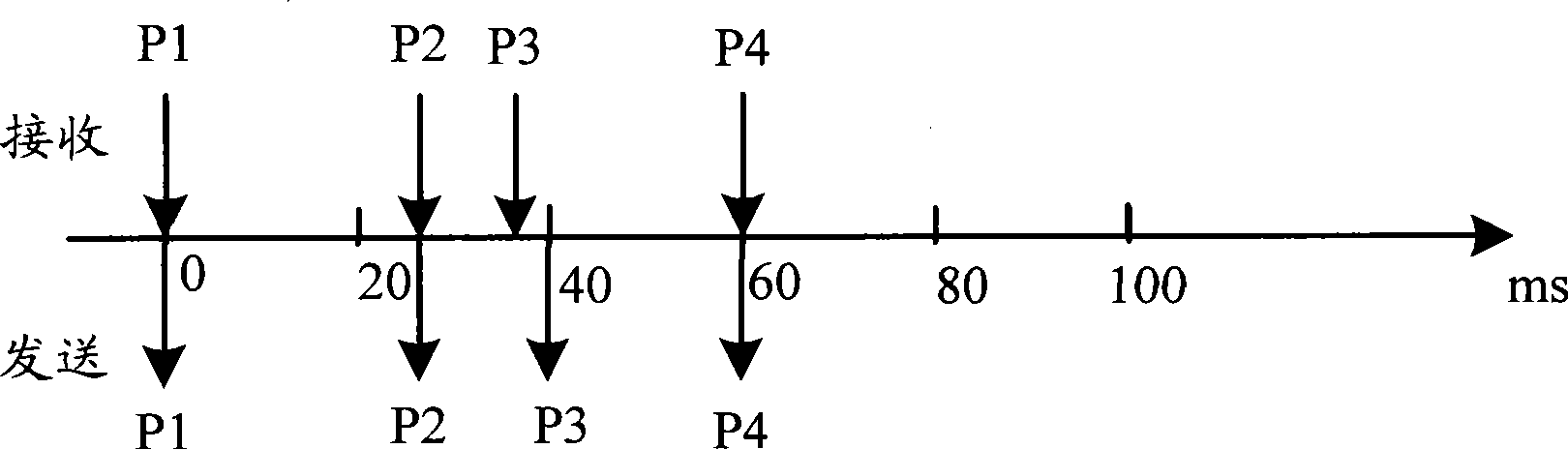

Voice packet sending method, apparatus and system

ActiveCN101426228AGuaranteed continuityAchieve jitterNetwork traffic/resource managementWireless network protocolsCommunication qualityComputer science

An embodiment of the invention discloses a method, a device and a system for transmitting sound package. The method for transmitting the sound package comprises the following procedures: receiving the sound package; caching the received sound package according to the identification of the received sound package; and transmitting the sound package in the cache to a core network a transmitting time which uses a sound package transmitting time period requested by the core network as a period is arrived. The technical scheme of embodiment of the invention can be applied to ascending service of CS over HSPA. Interference eliminating to the ascending sound package is realized through caching the sound package to guarantee that the sound package is transmitted to the core network through a fixed time interval requested by the core network thereby guaranteeing the continuity of sound and increasing the communication quality of sound.

Owner:SHANGHAI HUAWEI TECH CO LTD

Anti-condensation nivometer with self-accumulated-snow-removal function

InactiveCN104375214AAvoid blockingSpeed up the fallRainfall/precipitation gaugesSnow removalSnowpack

The invention discloses an anti-condensation nivometer with the self-accumulated-snow-removal function. The nivometer comprises an outer barrel body, a clamping piece is arranged on the outer barrel body, a filtering layer and a polygonal roller are arranged in the clamping piece, and a spoon-shaped fan is arranged on the upper portion of the filtering layer; a funnel body is arranged below the filtering layer, and a water scraper is attached to the funnel body and connected with the lower portion of the filtering layer; a collecting container is arranged below the funnel body, a net-shaped tray is arranged below the filtering layer, a snow removal device is arranged on the net-shaped tray, a spring piece is arranged between the filtering layer and the net-shaped tray, the water scraper is provided with a grinding and scraping part, and a quick lime layer is arranged on the inner wall of the outer barrel body. Compared with the prior art, because tree leaves and other impurities are blocked by the filtering layer, the tree leaves and other impurities are prevented from blocking the nivometer; because the filtering layer rotates and shakes on the polygonal roller, it can be avoided that snow water is accumulated in impurities falling onto the filtering layer, snow can enter the nivometer faster through the snow removal device, and condensation blocking is avoided; the grinding and scraping part can rub the quick lime layer when rotating along with the water scraper, broken dust of quick lime flies out and makes contact with water, heat is generated, and internal icing is prevented.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

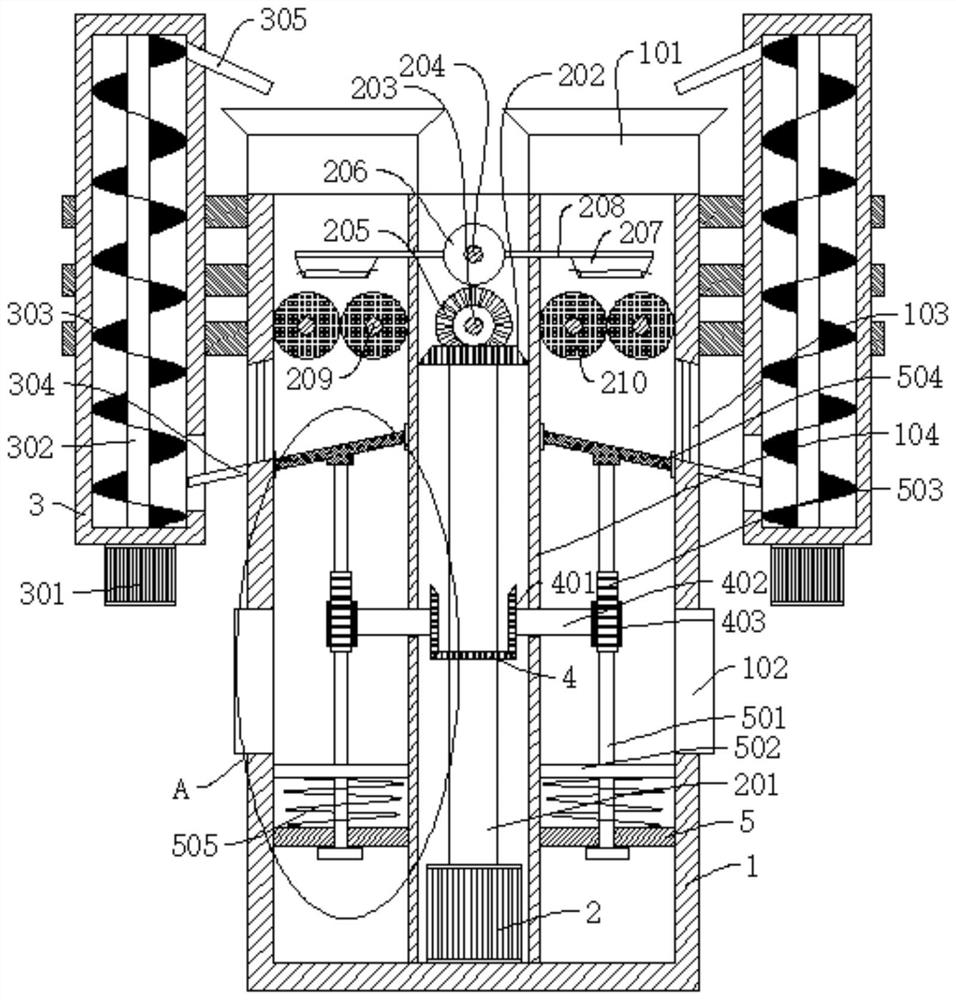

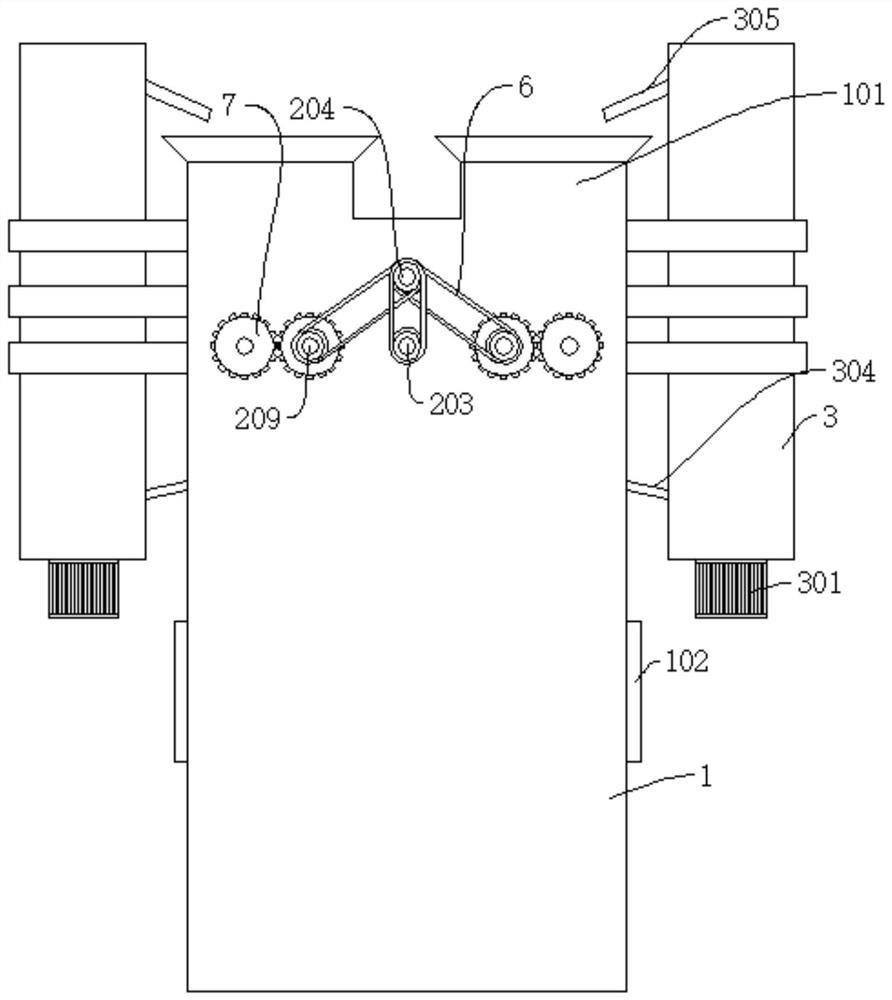

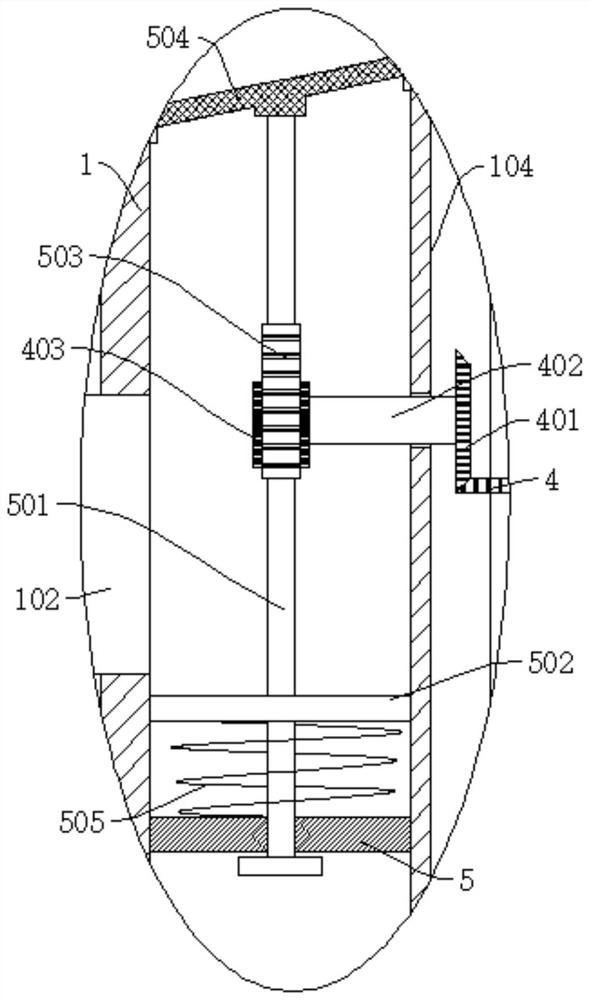

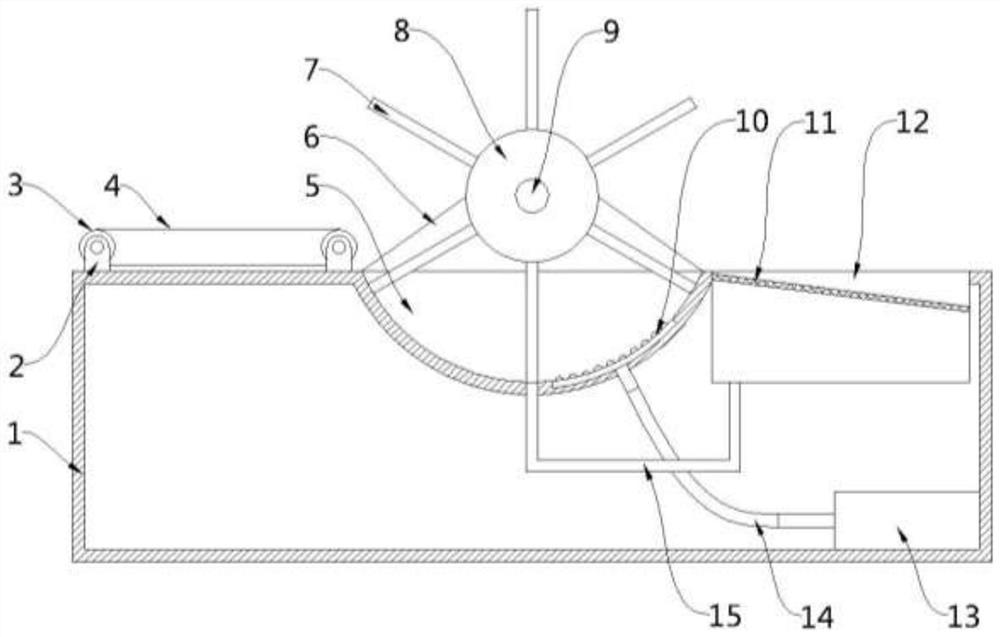

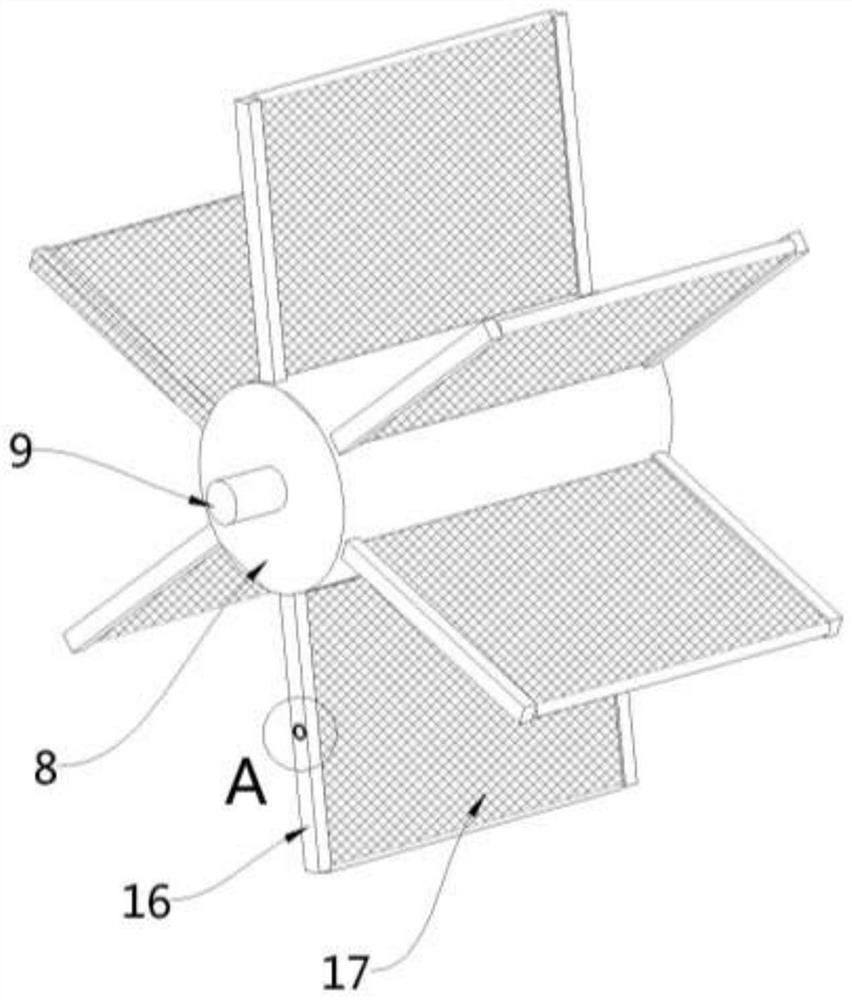

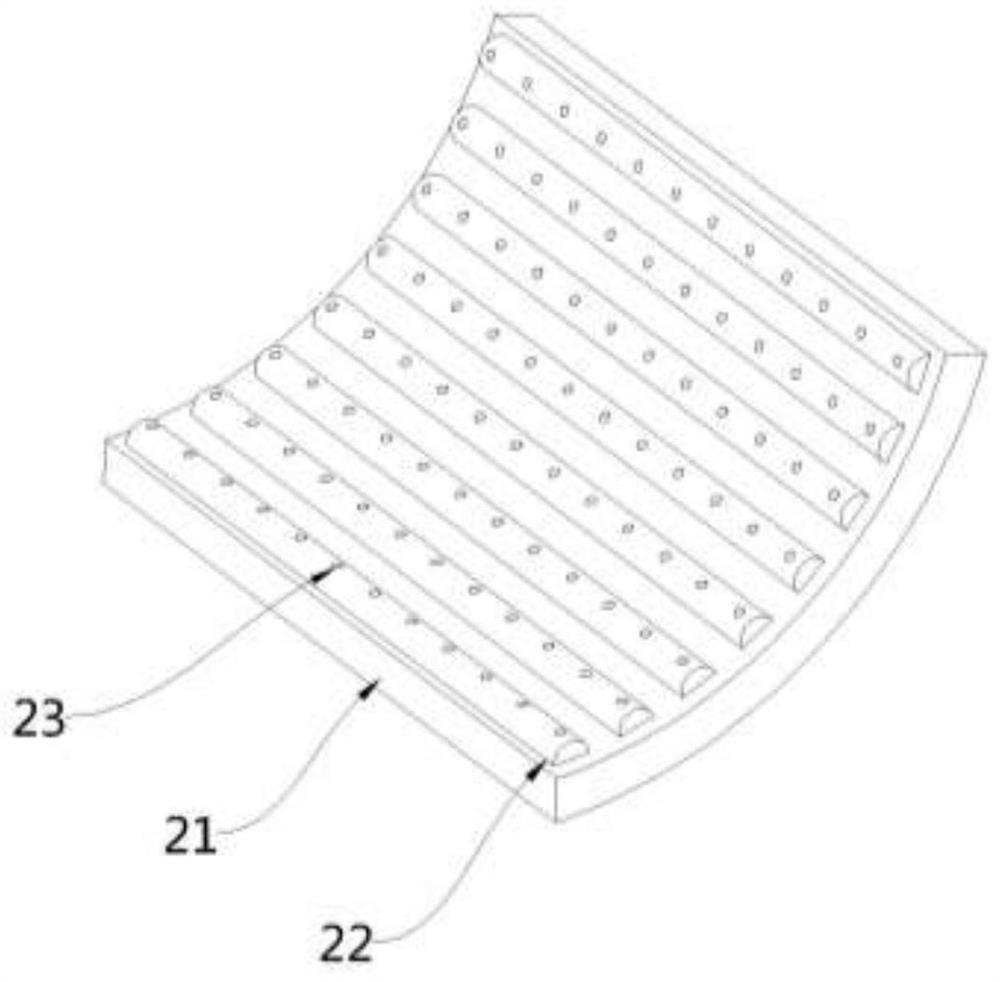

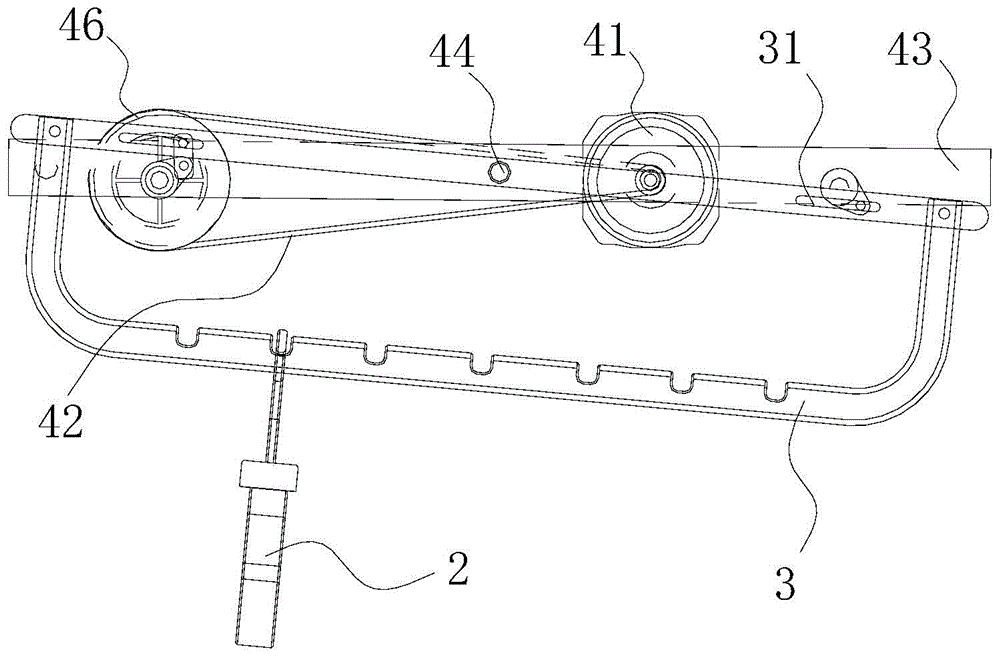

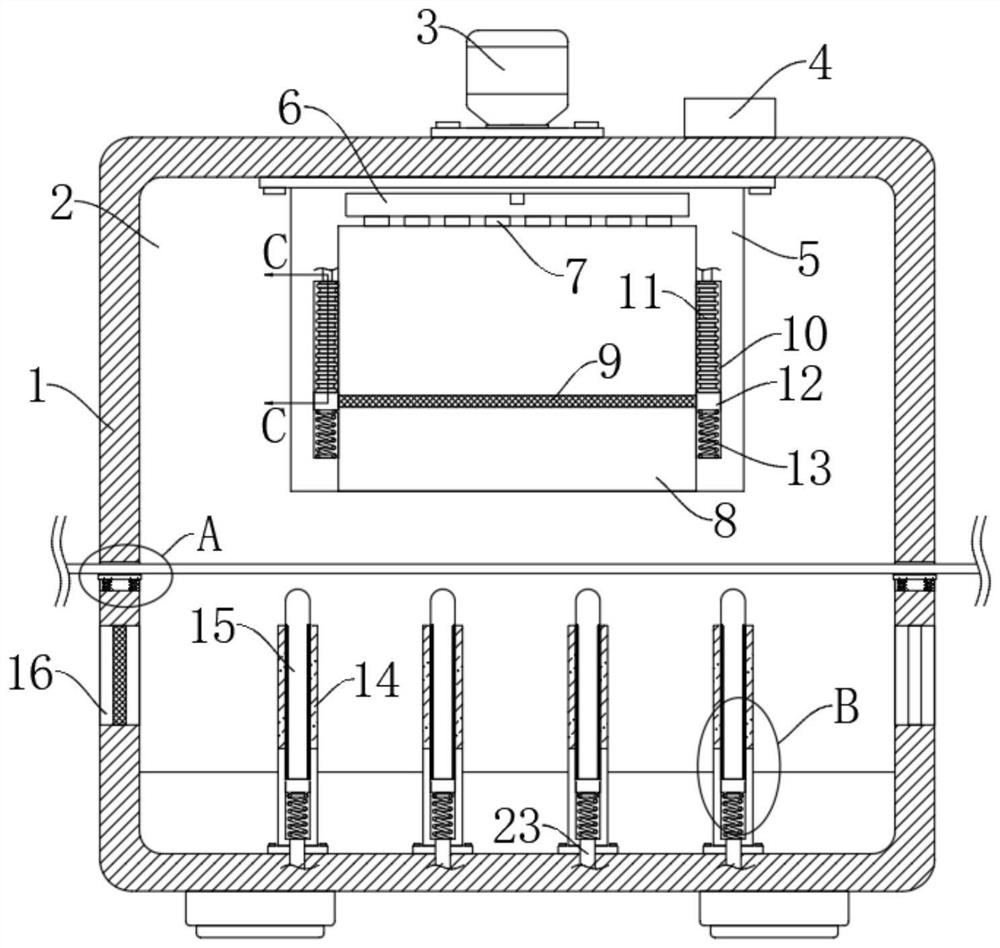

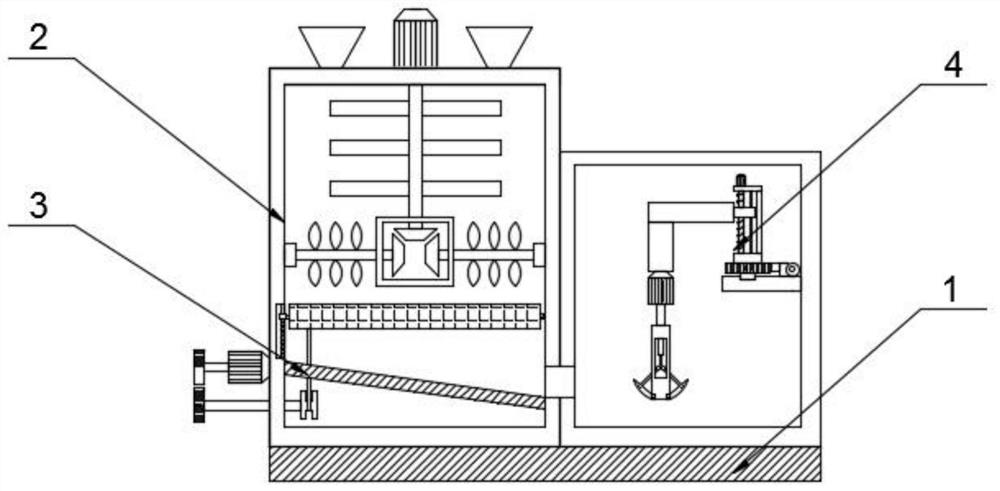

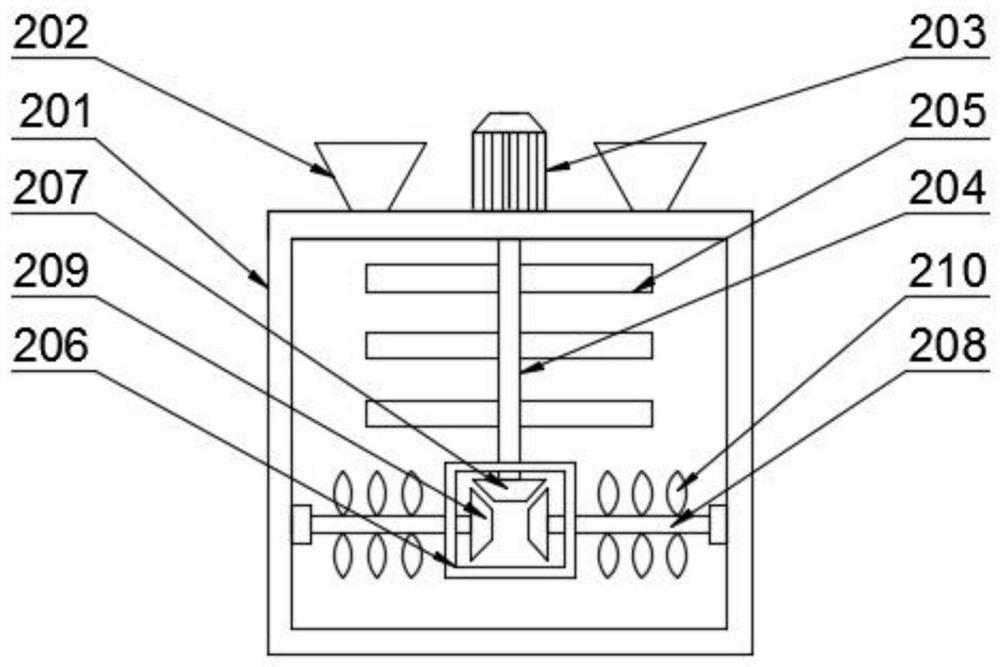

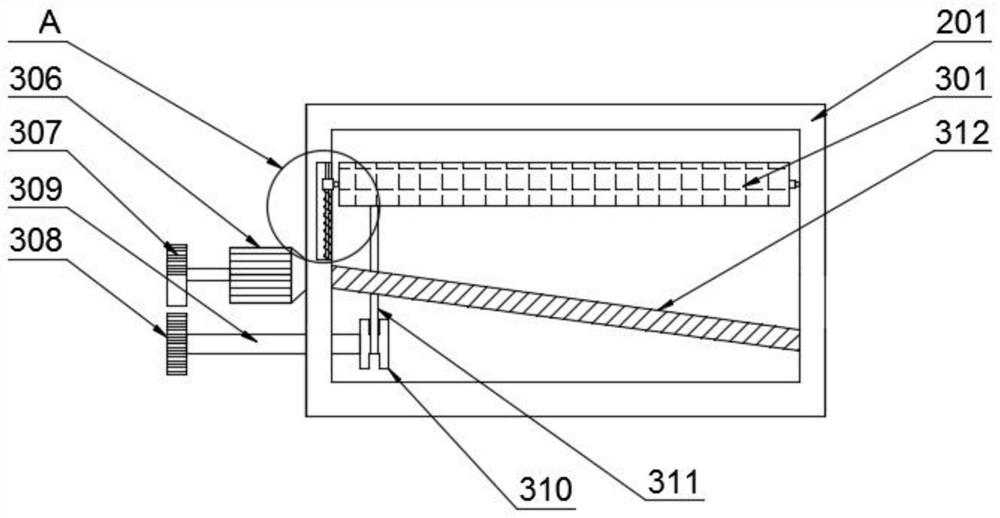

Automatic oil immersion device for automobile part production

InactiveCN112827742AImprove oil immersion effectAchieve jitterLiquid surface applicatorsCoatingsElectric machineryOil filter

The invention provides an automatic oil immersion device for automobile part production, and belongs to the technical field of automobile part production. The automatic oil immersion device comprises a bottom box, an oil storage tank and an oil filtering tank are formed in the upper part of the bottom box, and a conveying assembly for conveying automobile parts into the oil storage tank is arranged on the side, away from the oil filtering tank, of the oil storage tank on the upper part of the bottom box; a second support is fixedly arranged on the upper portion of the bottom box, a rotating wheel is rotationally arranged on one side of the second support through a rotating shaft and located above the oil storage tank, and a plurality of pushing assemblies are fixedly arranged on the circumferential side wall of the rotating wheel; and one end of the rotating shaft is connected to an external motor. The automatic oil immersion device has the advantages of being simple in structure, convenient to use and good in oil immersion effect; a screen plate is driven to rotate through a partition assembly, shaking of the screen plate is achieved in cooperation with a reset assembly, then automobile parts located in oil liquid are driven to be dispersed, so that the automobile parts make full contact with the oil liquid, the oil immersion effect of the automobile parts is improved, and comprehensive and uniform oil immersion of the automobile parts is realized.

Owner:范小伟

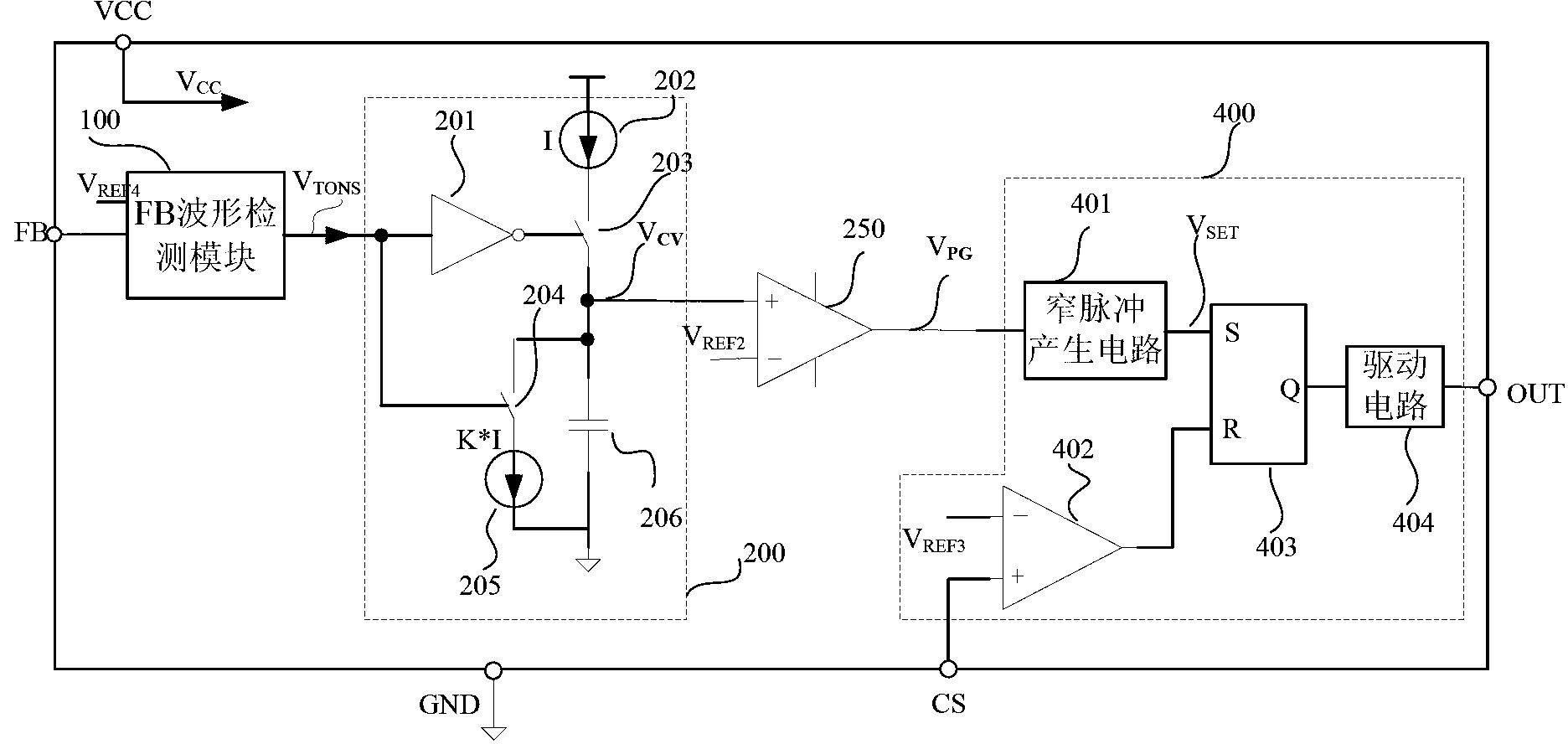

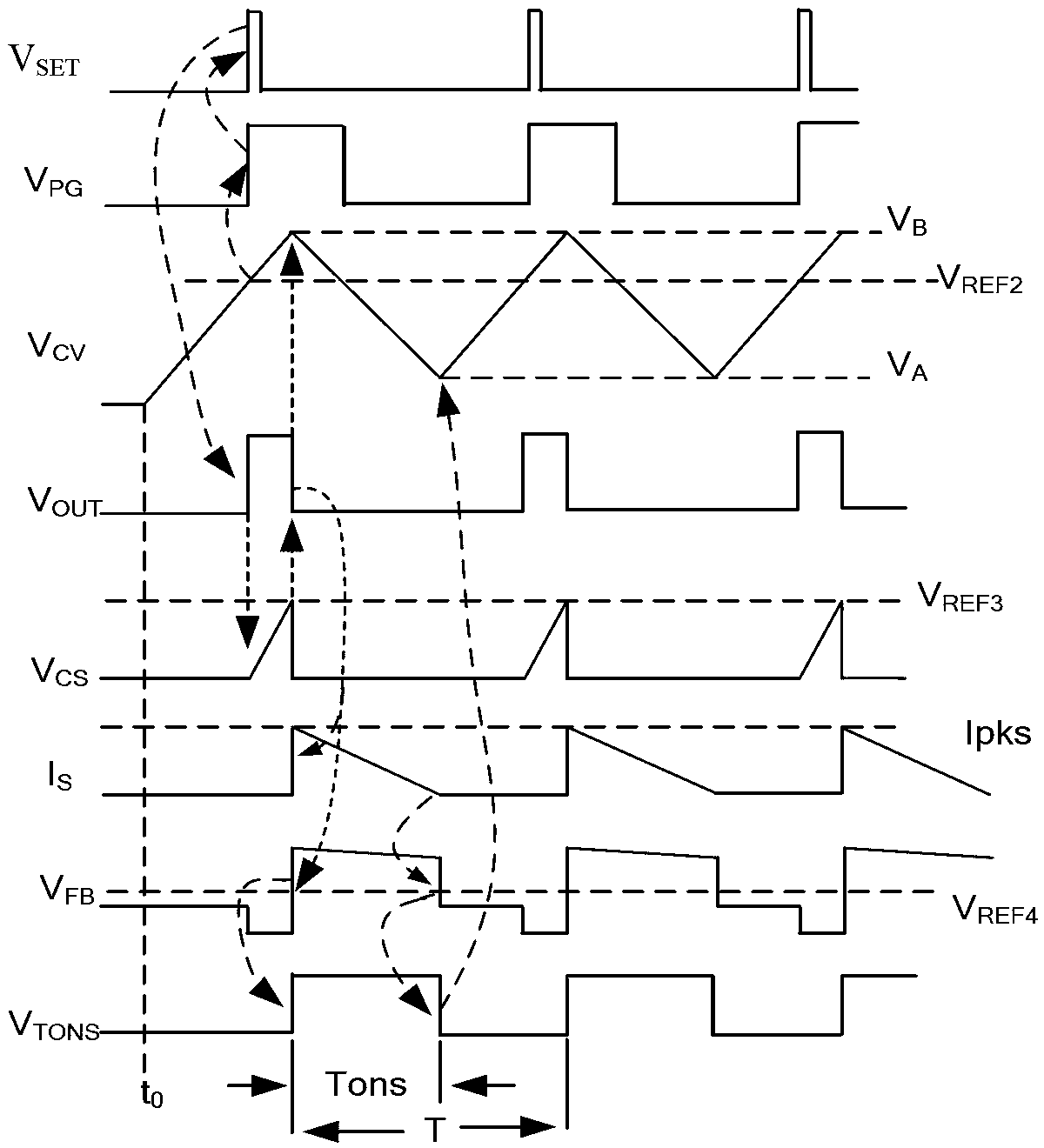

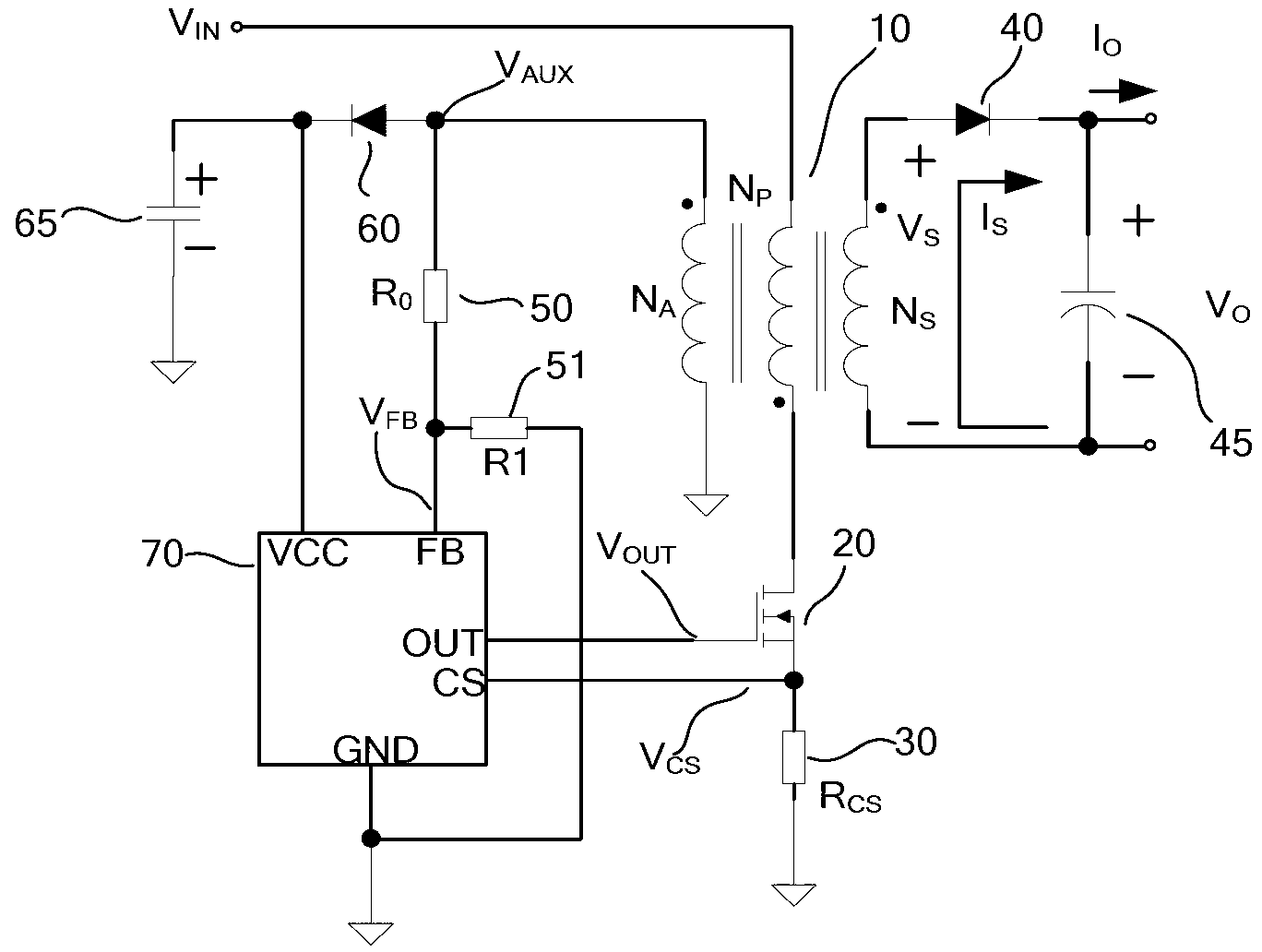

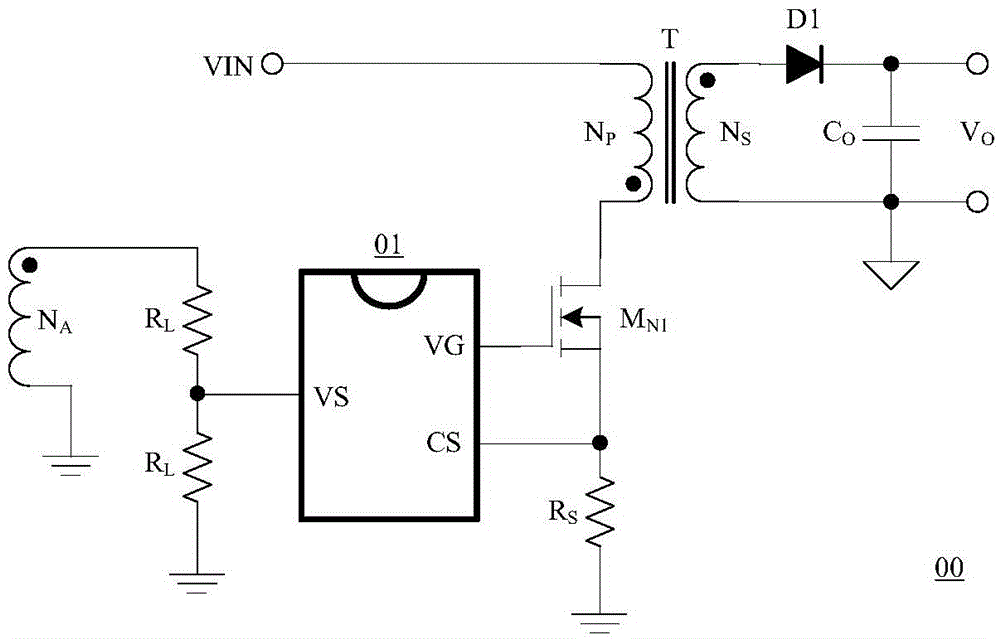

Constant current switching power supply and constant current controller thereof

ActiveCN103259415AAchieve jitterReduce peak levelDc-dc conversionElectric variable regulationTransformerControl signal

The invention relates to a constant current switching power supply and a constant current controller of the constant current switching power supply. The constant current controller comprises a FB waveform detecting module, a triangular wave generating module, a waveform control module and an output module, wherein the FB waveform detecting module, the triangular wave generating module, the waveform control module and the output module are connected in sequence. The waveform control module is used for receiving triangular waves output by the triangular wave generating module and for controlling output voltage waveforms of the output module according to triangular wave output control signals, so that the output voltage waveforms of the output module have periodic variation, moreover each period comprises a plurality of pulses, and the interval between any two adjacent pulses is unequal to others. The constant current switching power supply comprises a transformer, a voltage division circuit, a main switch tube, an output circuit and the constant current controller. The constant current switching power supply and the constant current controller can achieve switch frequency jittering, are conducive to reduction of the peak level of electromagnetic interference and to reduction of design cost of a system EMI filter, and meanwhile maintain high-precision constant current output.

Owner:FREMONT MICRO DEVICES SHENZHEN LTD

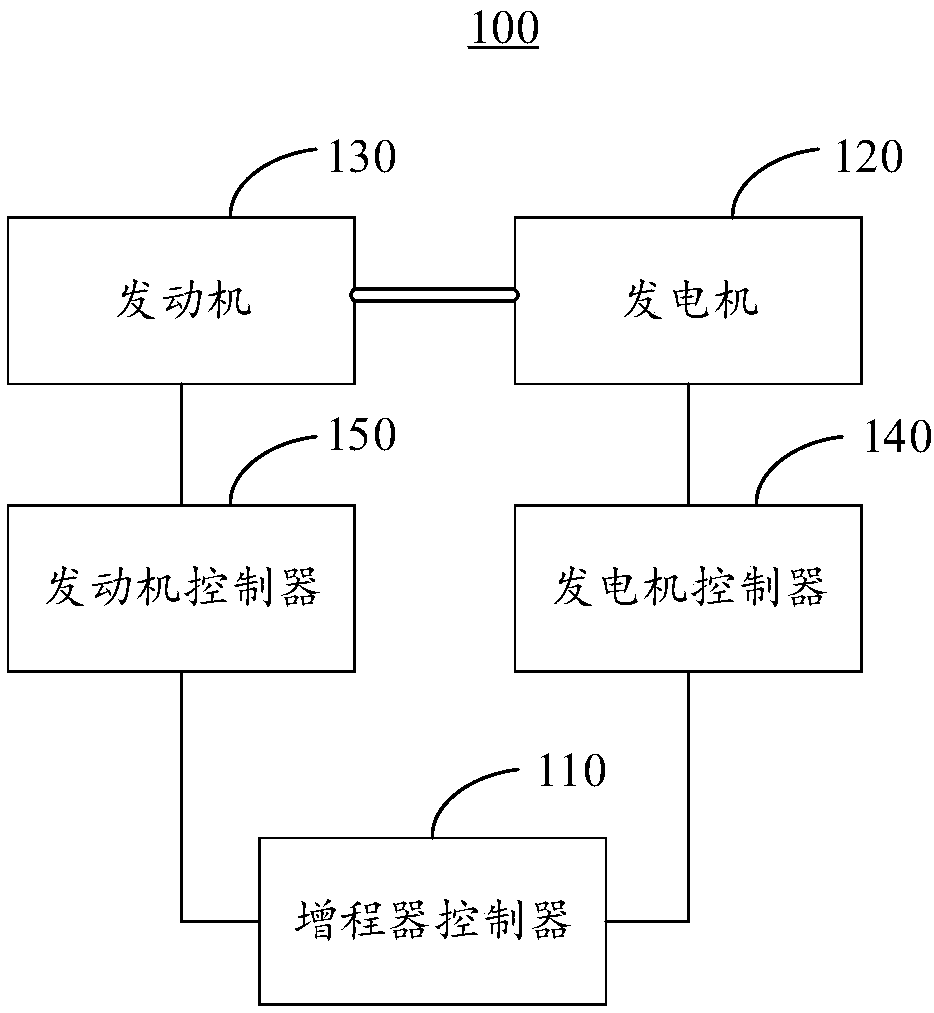

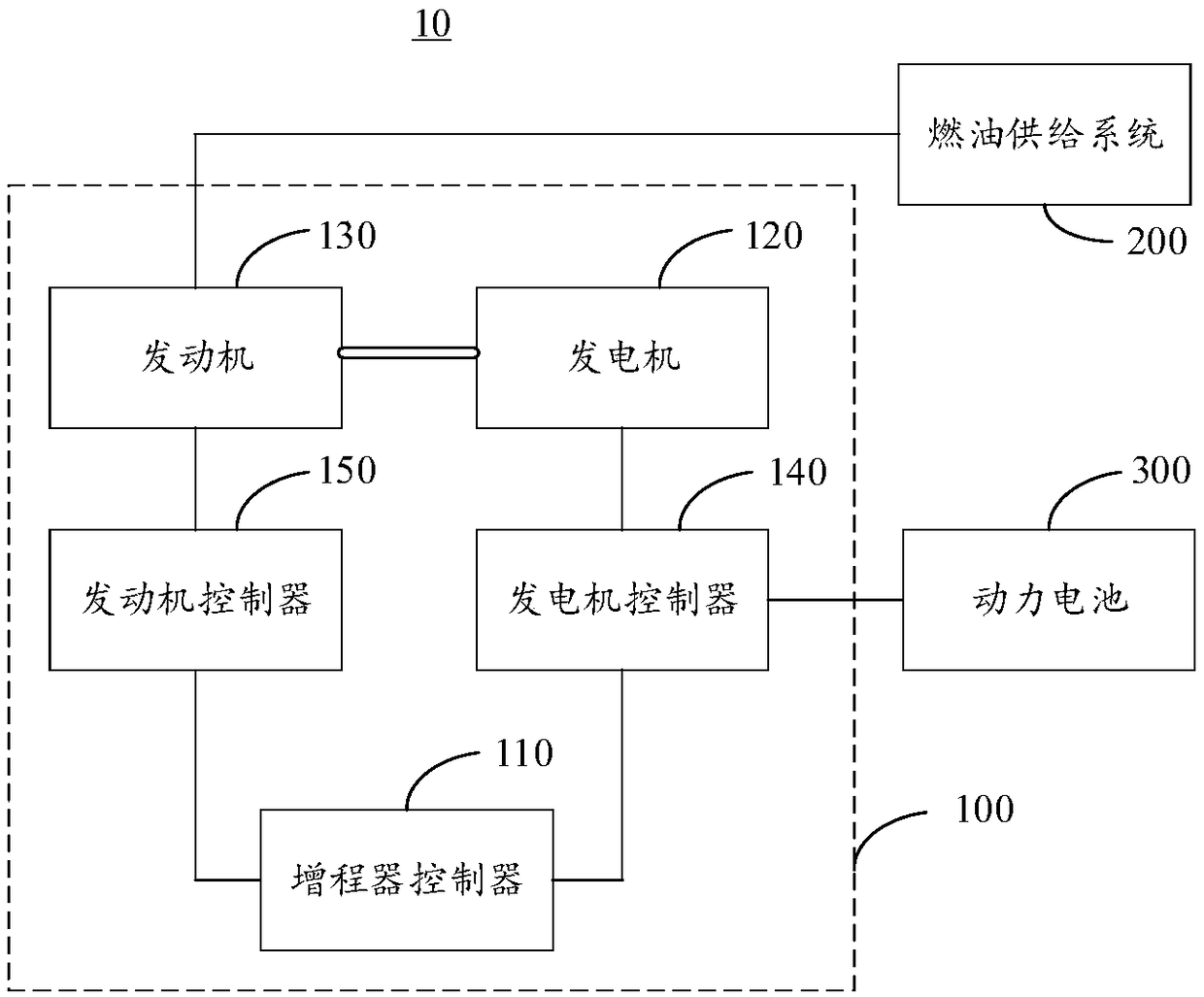

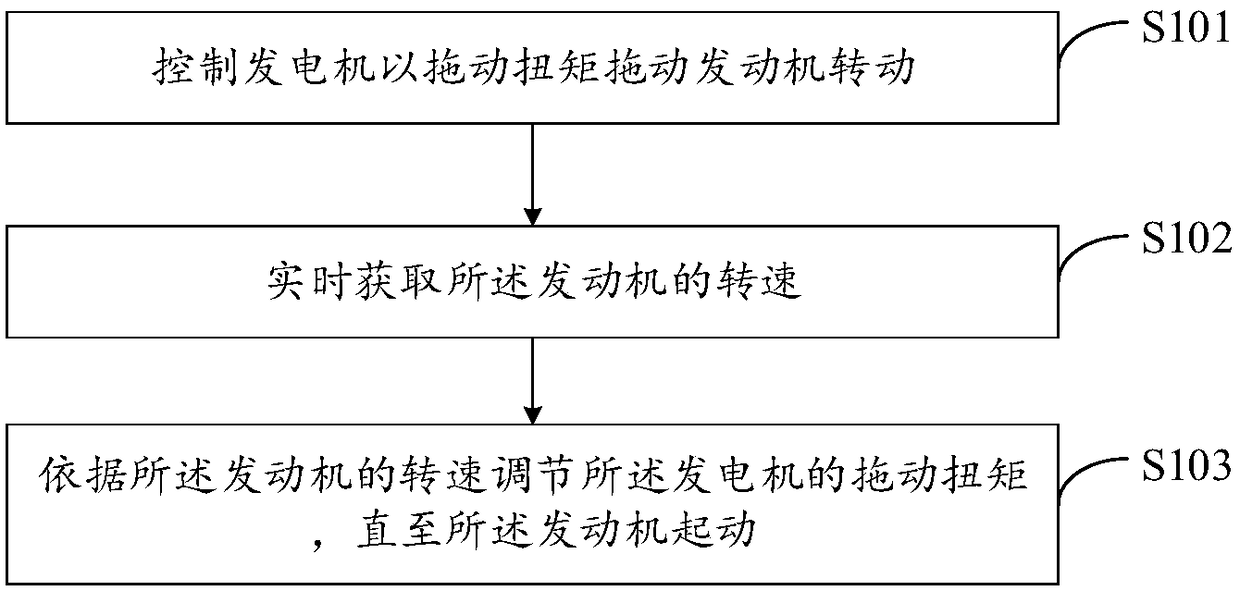

Range extender starting control method, range extender and electric vehicle

InactiveCN108608872AImprove noiseImprove vibrationHybrid vehiclesPropulsion using engine-driven generatorsElectric vehicleControl theory

The invention discloses a range extender starting control method, a range extender and an electric vehicle and relates to the technical field of electric vehicles. After controlling a power generatorto pull an engine to rotate at a pulling torque, a range extender controller adjusts the pulling torque of the power generator according to an engine rotation speed obtained in real time till the engine is started. In the range extender starting process, the torque of the power generator is controlled on the basis of the range extender controller, different pulling torques are given for differentengine rotation speeds so that the pulling torque of the power generator to the engine is reduced with the increasing of the engine rotation speed to realize smooth starting of the engine; and therefore, shaking and noises caused by large rotation speed change in the starting process are avoided, the NVH performance of the electric vehicle is improved, and the prolonging of the service life of theengine is significant.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

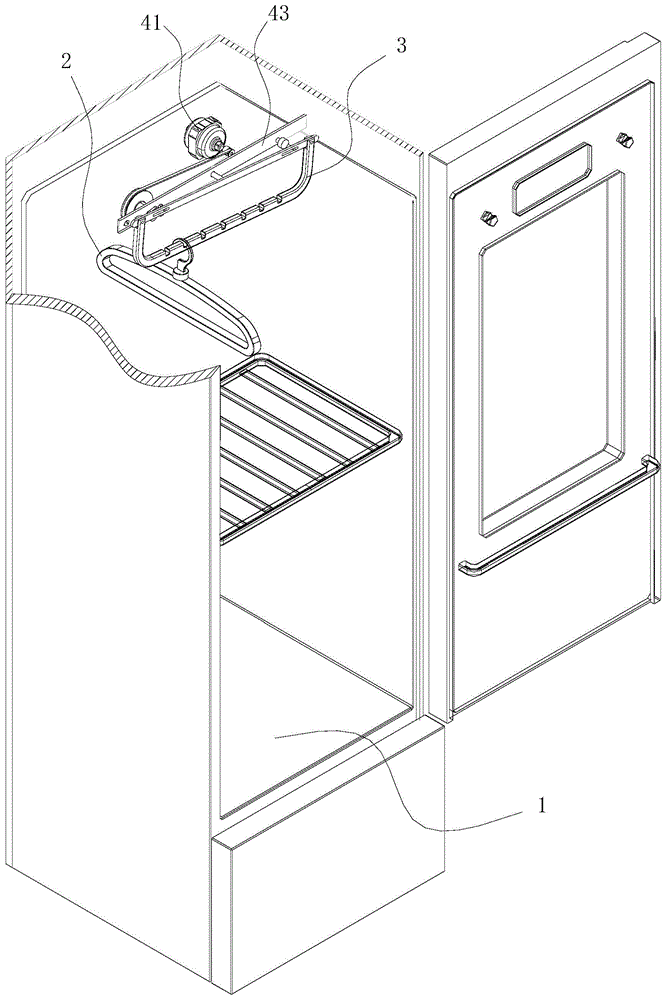

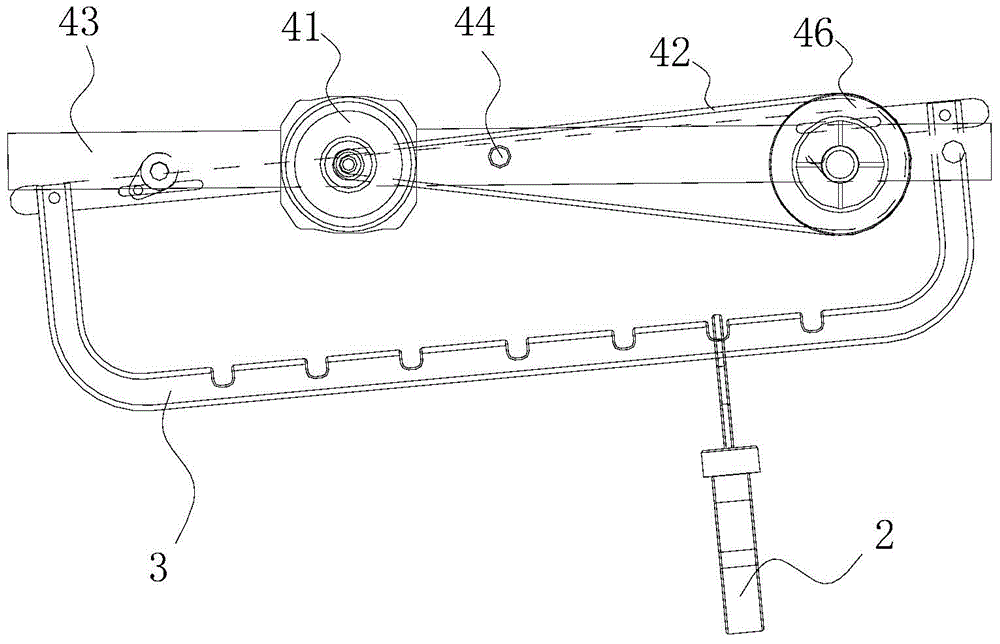

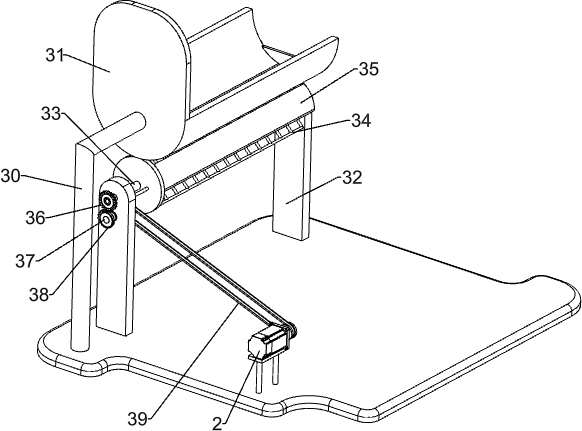

Cabinet type clothes dryer control method and cabinet type clothes dryer

ActiveCN106283570AAchieve jitterGood dry clothesTextiles and paperLaundry driersState of artReciprocating motion

The invention discloses a cabinet type clothes dryer control method and a cabinet type clothes dryer, belongs to the field of clothes drying devices and control methods thereof, and aims to solve the problems of poor wrinkle removing effects of objects to be dried and the like in the prior art. The cabinet type clothes dryer control method includes the steps: applying vertical force to the objects to be dried; enabling the objects to be dried to vertically reciprocate; shaking the objects to be dried to accelerate drying and remove wrinkles of the objects to be dried. The cabinet type clothes dryer comprises a hollow cabinet body, a supporting rod is used for placing hangers is arranged in the hollow cabinet body, and a driving device is connected on the supporting rod and can drive the supporting rod to vertically reciprocate. According to the cabinet type clothes dryer control method and the cabinet type clothes dryer, the objects to be dried are shaken, drying hot air is burbled, a certain acceleration is applied to the objects to be dried, inertia force is used for stretching the objects to be dried and removing the wrinkles, and drying is accelerated.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

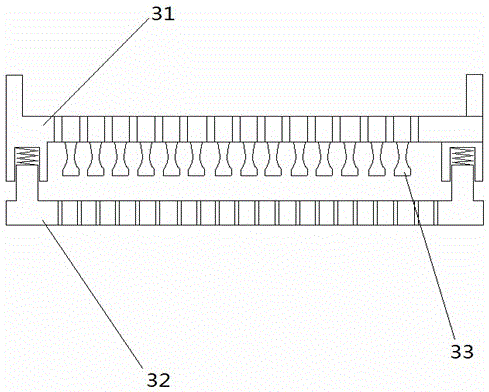

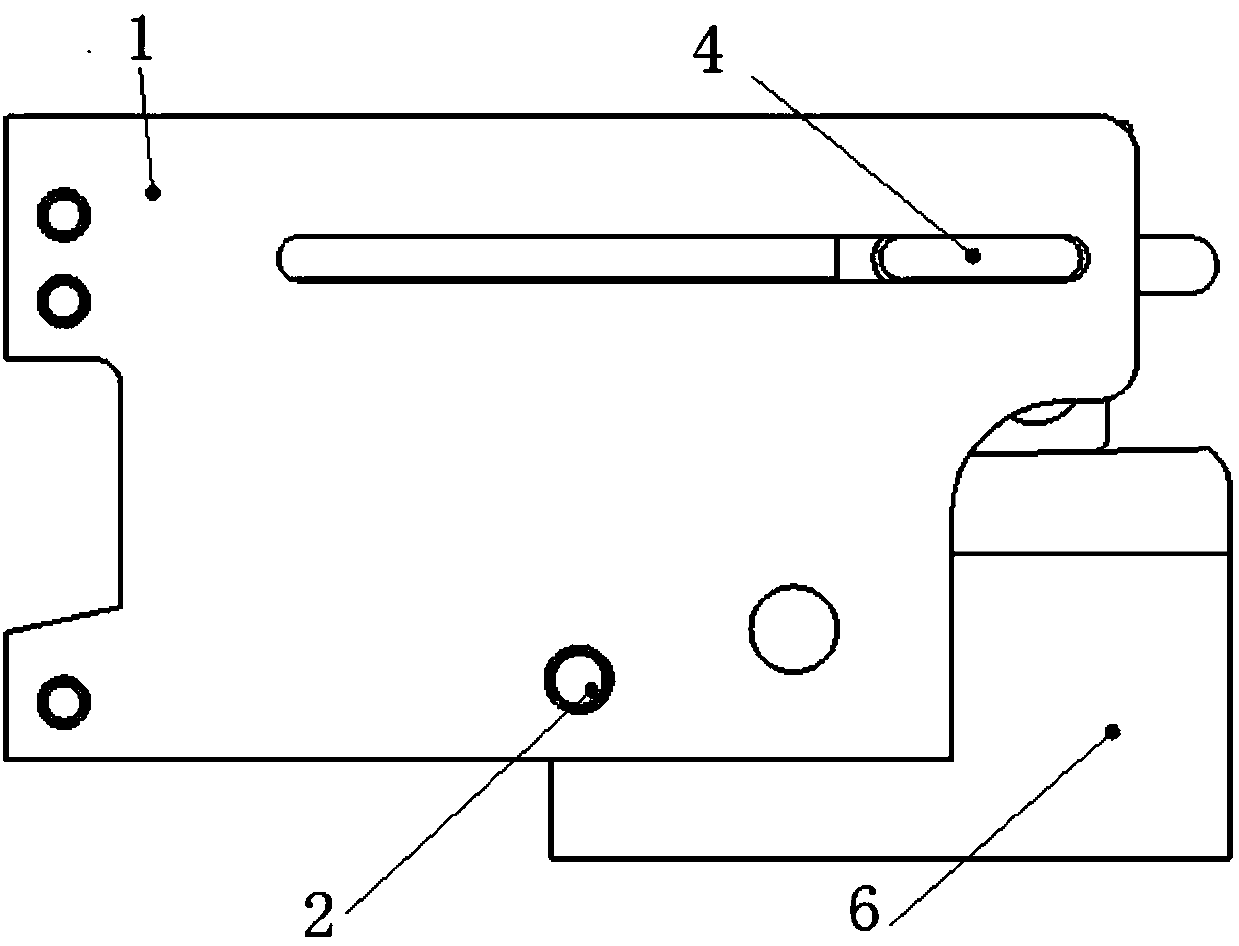

Drying and screening device used before soil improvement

ActiveCN105057197AEfficient separationVibration frequencySievingScreeningAgricultural engineeringStructural engineering

The invention discloses a drying and screening device used before soil improvement. The device comprises a tube structure, and a circle of annular step surrounds the inner wall of the tube structure. A round filtering screen is arranged on the annular step. A drive rotary rod and a driven rotary rod are arranged in the tube structure. One end of the drive rotary rod is connected with and perpendicular to one end of the driven rotary rod. The other end of the drive rotary rod is connected with the center position of the bottom in the tube structure. An oval joggling roller is arranged at the other end of the driven rotary rod and located between the annular step and the filtering screen. An air blower flue is arranged on the tube structure. Compared with the prior art, the drive rotary rod rotates in the radial direction to drive the driven rotary rod to convolute, so that the joggling roller is driven to roll between the annular step and the filtering screen, vibration and joggling are achieved, soil blocks placed on the filtering screen crack under strong vibration, and then soil is screened.

Owner:SHENZHEN BINLU GARDEN

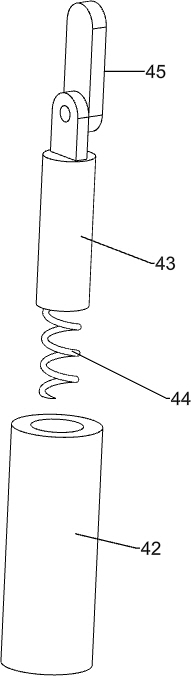

Arm folding system of multi-rotor unmanned aerial vehicle

PendingCN107933877AAvoid bumpingNot easy to shakeFuselagesAir-flow influencersUncrewed vehicleStructural engineering

The invention belongs to the technical field of unmanned aerial vehicles and discloses an arm folding system of a multi-rotor unmanned aerial vehicle. The arm folding system of the multi-rotor unmanned aerial vehicle is provided with arms; the arms are positioned in holes of tube sleeves; one end of a guide column is fixed on a stopping slide block, and the other end of the guide column is arranged in a limiting block; a spring is positioned on the guide column; and the stopping slide block is placed in a slide groove of a side stop block. The arms of the arm folding system can be automatically unfolded, thereby solving the problem of too large wingspan of the unmanned aerial vehicle, reducing the transport volume and being convenient for transporting; and after the arms are unfolded, thearms are automatically locked, the structure of the folded part is stable, and the arms can not shake when being subjected to upward or downward force.

Owner:智灵飞(北京)科技有限公司

Textile cloth fluff removing device for textile production

ActiveCN112391825AAchieve jitterLarge jitterMechanical cleaningPressure cleaningPolymer scienceEngineering

The invention discloses a textile cloth fluff removing device for textile production. The device comprises a shell, wherein a fluff removing chamber is arranged in the shell, through openings are formed in the two sides of the fluff removing chamber, a mounting block is mounted at the inner top of the fluff removing chamber, an air blowing groove is formed in the lower end of the mounting block, atransverse cavity is formed in the mounting block, an air outlet is formed in the inner wall of the left side of the fluff removing chamber, and a filter screen is mounted in the air outlet; supporting mechanisms are arranged in the two through openings; a pulse air blowing mechanism is arranged in the transverse cavity and is used for carrying out primary fluff removal on cloth; and a shaking mechanism matched with the pulse air blowing mechanism is arranged in the air blowing groove. The fluff removing device is high in fluff removing efficiency, fluff can be rapidly removed through cooperation of the pulse air blowing mechanism and a plurality of abutting rods, an electrostatic air suction mechanism is further arranged, the removed fluff can be adsorbed, and the fluff is effectively prevented from adhering to the cloth for the second time.

Owner:湖北省亚丹纺织实业有限公司

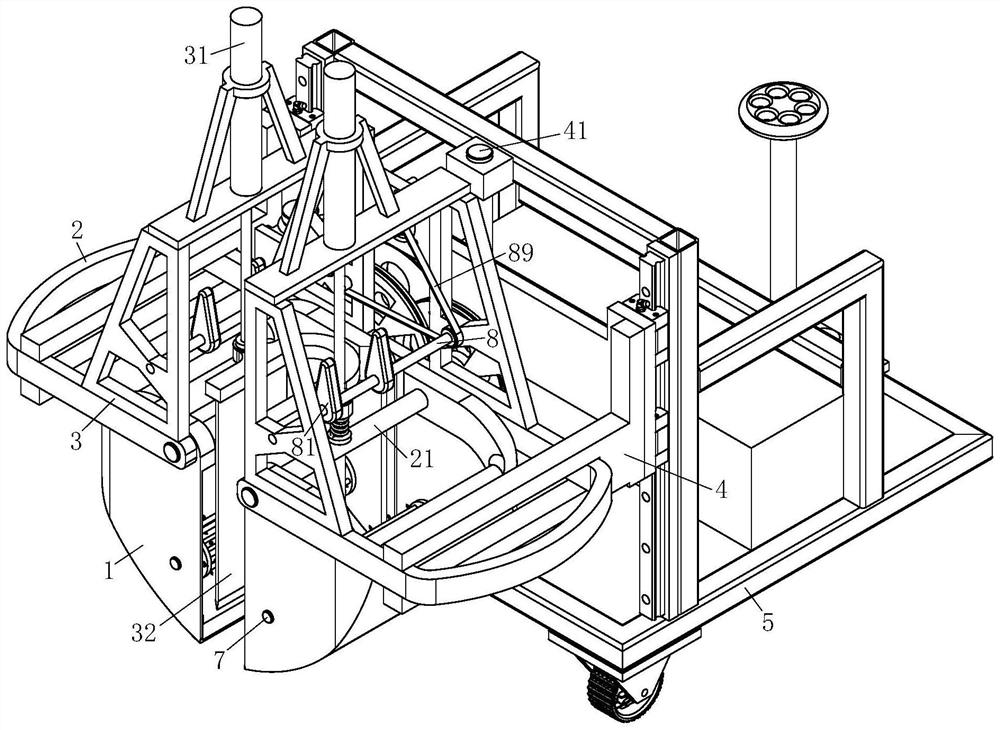

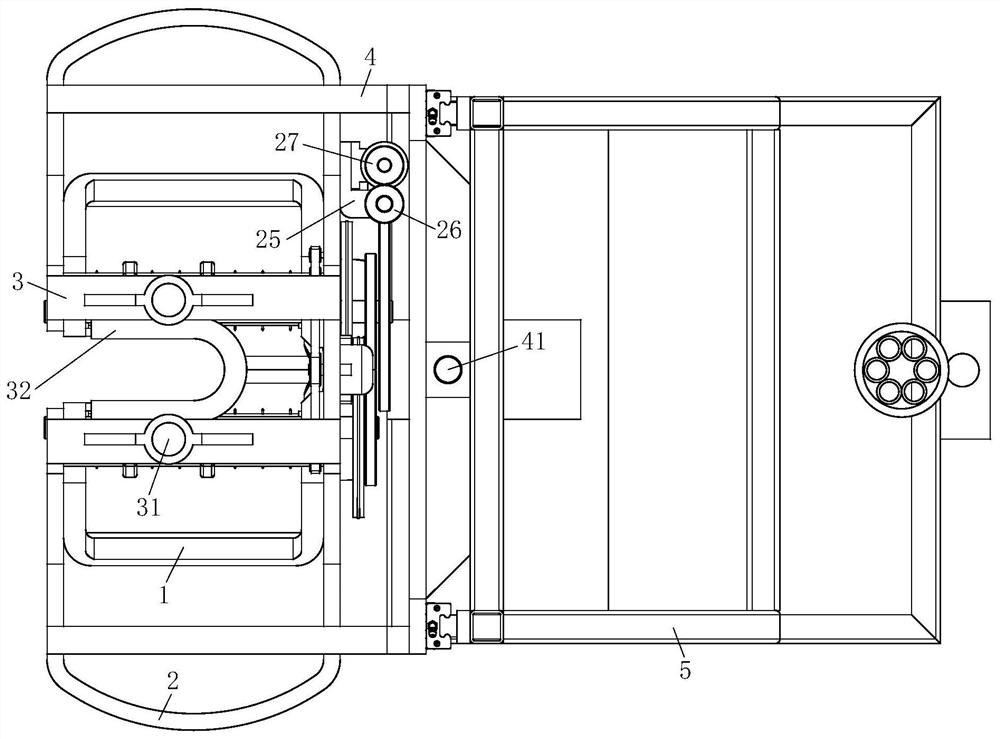

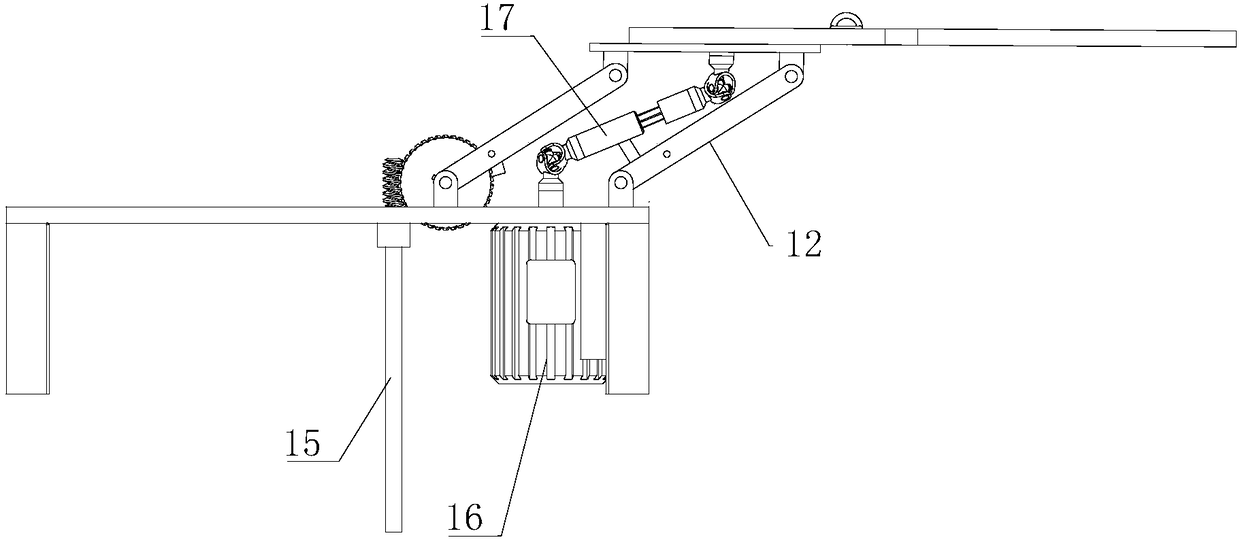

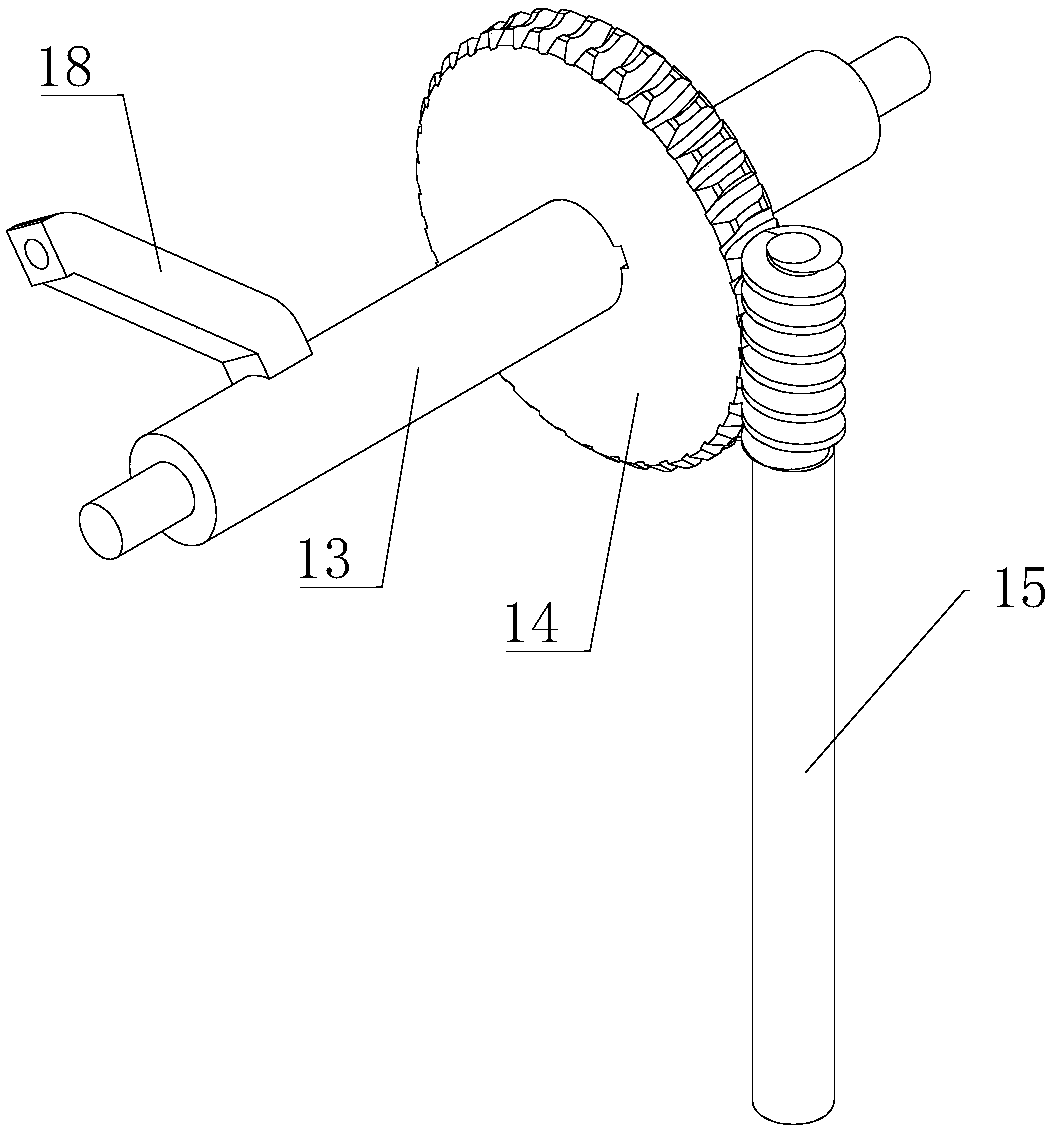

Integrated pit digging machine for seedling planting

ActiveCN112690062AAchieve plantingEasy to put inPlantingFurrow making/coveringElectric machineryAgricultural engineering

The invention belongs to the technical field of pit digging equipment, and particularly relates to an integrated pit digging machine for seedling planting. The integrated pit digging machine comprises an excavator bucket, a fixing frame, a first rotating shaft, a first gear, a first worm wheel, a first worm, a supporting base, a second gear, a third gear, a first motor, a supporting frame, an electric push rod, a baffle, a lifting frame, a lead screw, a second worm wheel, a second worm, a second motor and a tractor. By controlling cooperation of the first motor, the second motor, the electric push rod and the third motor, opening and closing of the excavator bucket are controlled, ascending and descending of the excavator bucket, ascending and descending of the baffle and shaking of the baffle are controlled, and then pit digging, seedling placing and soil backfilling of the pit digging machine are achieved; and therefore, semi-automation or automation of seedling planting is achieved, the seedling planting time is shortened, the seedling planting speed is increased, and meanwhile the labor intensity of workers during seedling planting is relieved.

Owner:泰安市晨祥市政建设工程有限公司

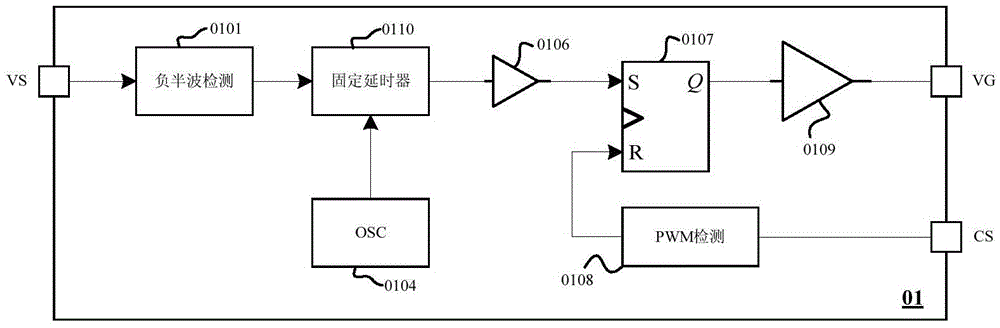

Wave trough breakover control circuit and control method thereof

ActiveCN105577004AAchieve valley conductionAchieve jitterEfficient power electronics conversionAc-dc conversionMultiplexingControl system

The invention provides a novel frequency jitter wave trough breakover control system. The system has a wave trough breakover function and also has a frequency jitter function in a full input voltage range and a full load range. The energy of the electromagnetic interferences is dispersed in the frequency bands in a whole frequency jitter range; therefore the influence resulted from the electromagnetic interferences is controlled to the lowest level; the integral performance of the controller is improved; circuit multiplexing can be carried out through the control of the two techniques; a large portion of wafers can be saved; and the application rate is improved.

Owner:SHENZHEN NANYUN MICROELECTRONICS CO LTD

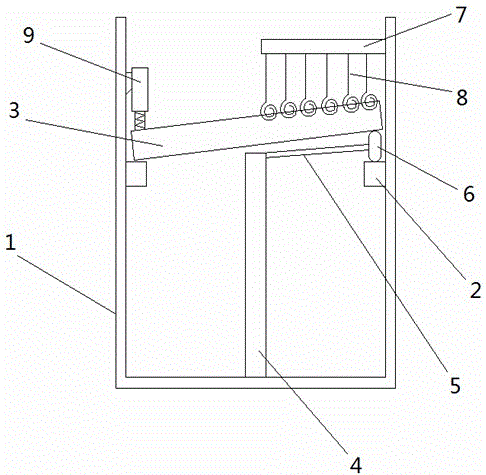

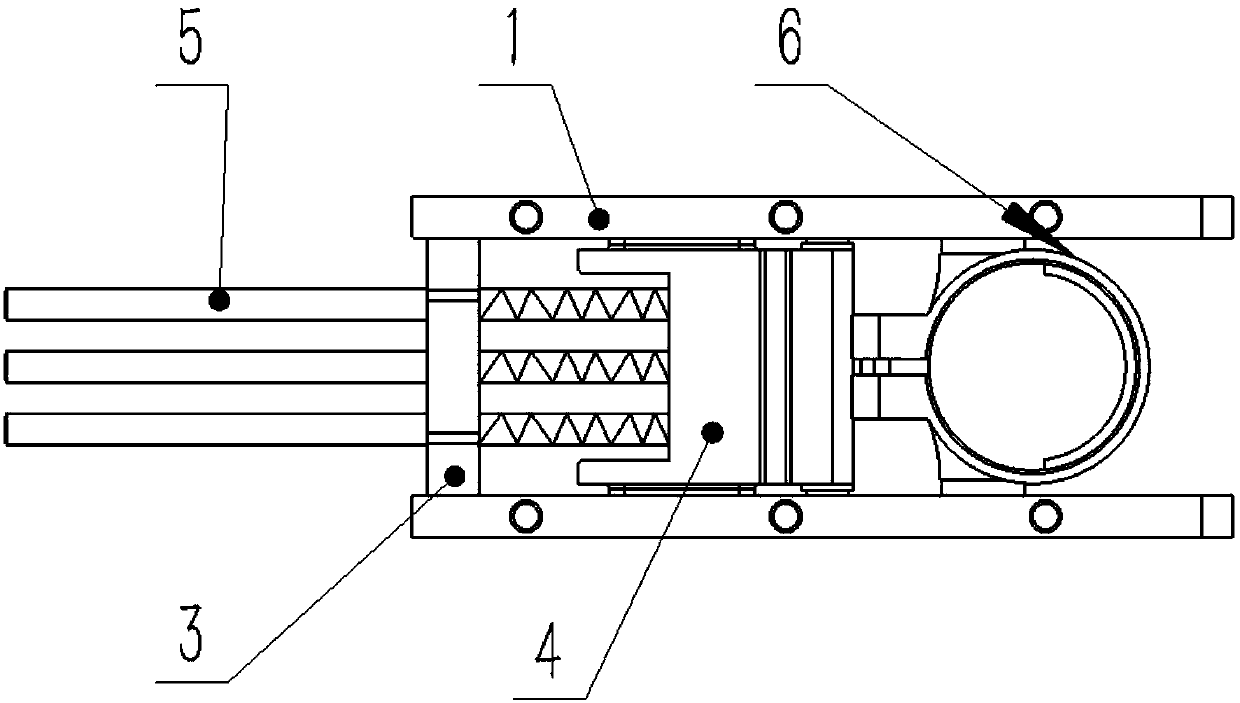

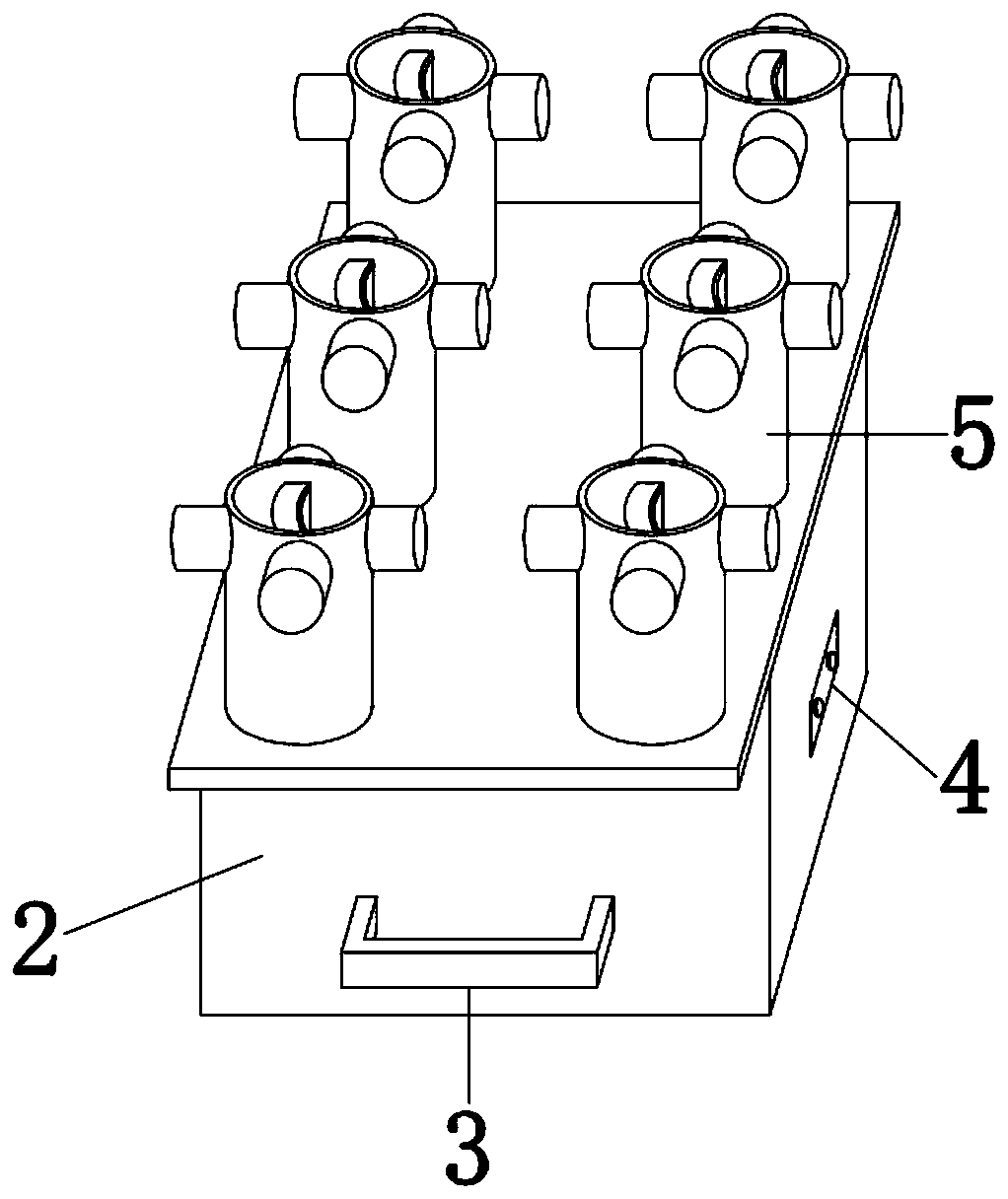

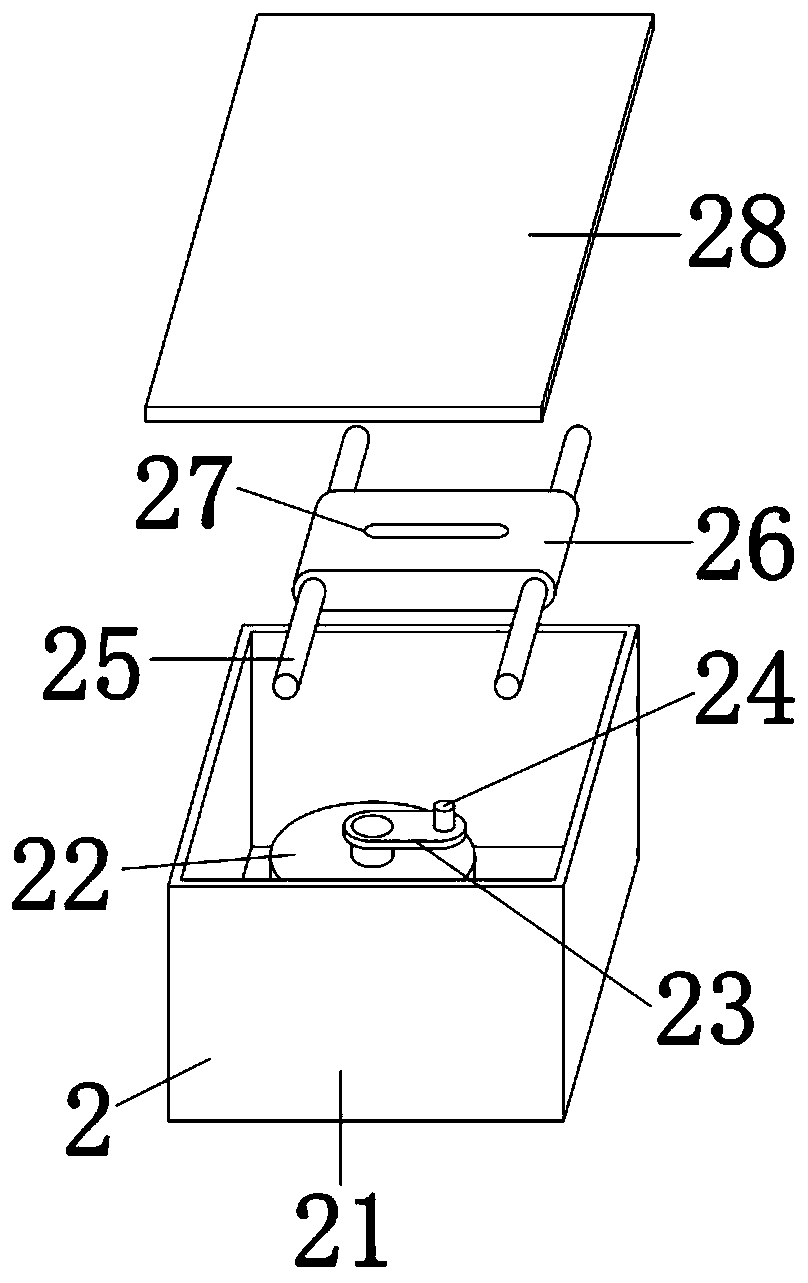

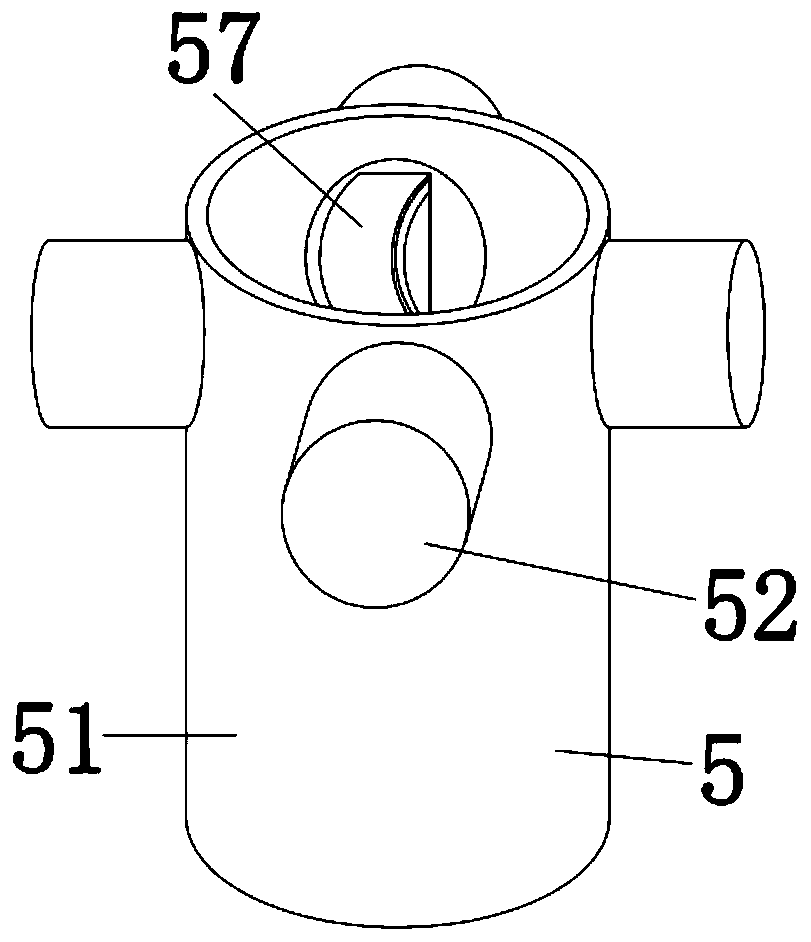

Test tube oscillation equipment for medical examination

InactiveCN111282491AAchieve jitterRealize mechanical shockShaking/oscillating/vibrating mixersTransportation and packagingPhysical therapyMedical testing

The invention relates to the technical field of medical examination, and discloses test tube oscillation equipment for medical examination, wherein the test tube oscillation equipment comprises a shaking mechanism, handles, a button and positioning mechanisms; the two handles are detachably arranged on the front side and the rear side of the shaking mechanism correspondingly; the button is detachably arranged on the right side of the shaking mechanism; the multiple positioning mechanisms are detachably arranged at the top of the shaking mechanism from front to back. The test tube vibration device can realize mechanical vibration of test tubes, saves time and labor, can position a plurality of test tubes of different models, meets the requirement of simultaneous vibration of a plurality oftest tubes, is high in vibration efficiency, and greatly meets the requirement of medical examination.

Owner:蒋婵婵

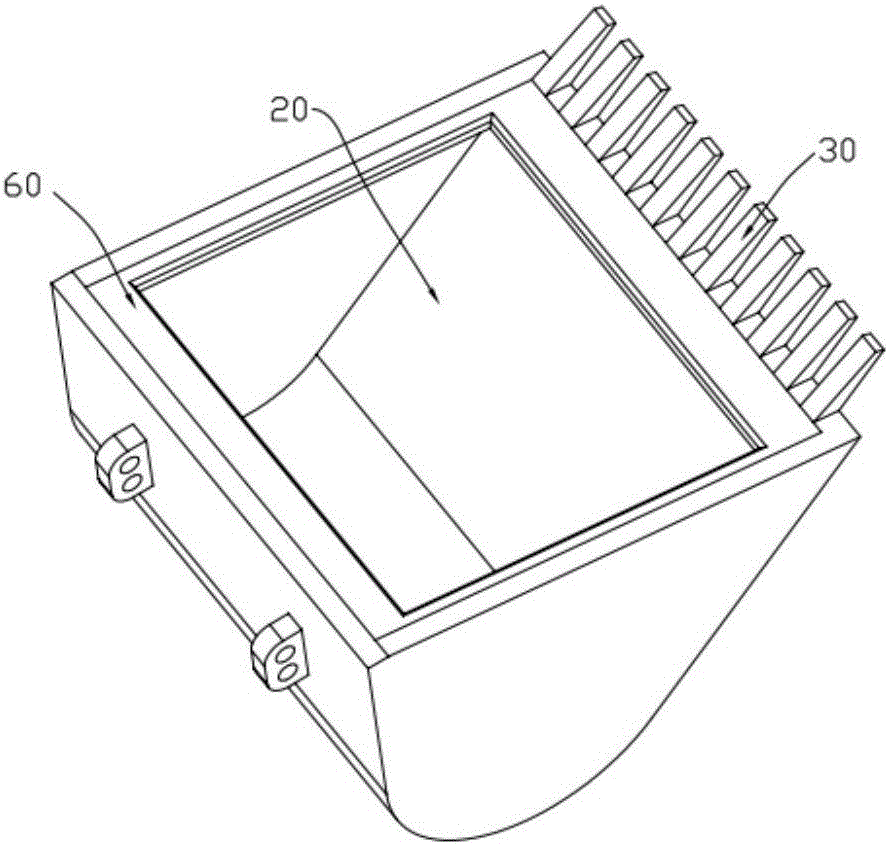

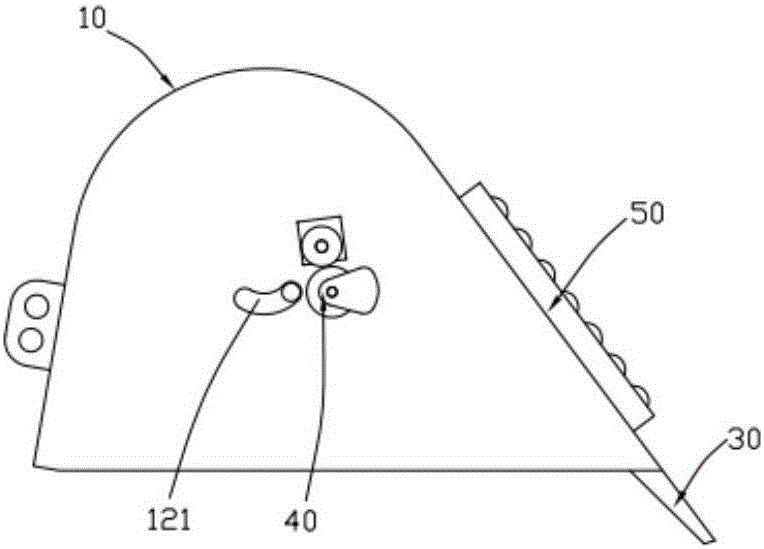

Excavator bucket capable of preventing soil adhesion

ActiveCN106836358ASimple structureReduce job cycle timeSoil-shifting machines/dredgersEngineeringCam

The invention discloses an excavator bucket capable of preventing soil adhesion. The excavator bucket comprises an external bucket body, a internal bucket body, a baffle ring and a cam unit. The internal bucket body is hinged inside the external bucket body; the baffle ring is mounted at the flared end of the external bucket body and used for guiding materials into the internal bucket body; and the cam unit is mounted on the external bucket body to make the internal bucket body swing back and forth inside the external bucket body. The excavator bucket capable of preventing soil adhesion can unload the soil in the bucket effectively, and shorten the working time of an excavator, and the effective bucket capacity of the excavator bucket is improved.

Owner:山东鲁宇重工机械制造有限公司

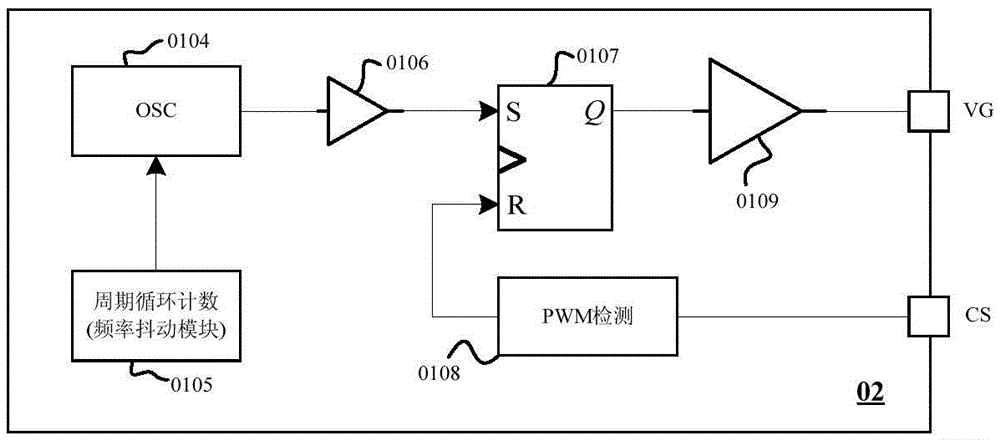

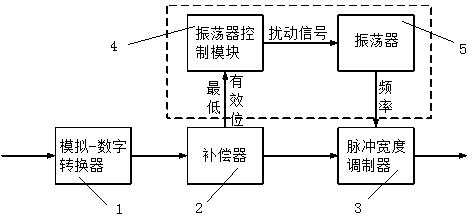

Signal dither system and method based on switching period changes

InactiveCN103731024AHigh resolutionGood circuit stabilityDc-dc conversionElectric variable regulationVIT signalsDisturbance voltage

The invention discloses a signal dither system and method based on switching period changes. The signal dither system comprises a signal dither circuit. When a DC-DC switching power circuit is connected with the signal dither circuit, the input end of an oscillator control module in the signal dither circuit is connected with the output end of a compensator in the DC-DC switching power circuit, the output end of an oscillator in the signal dither circuit is connected with the input end of a pulse width modulator in the DC-DC switching power circuit, a noise signal is added to the oscillator control module by judging the infinitesimal disturbance of the least significant bit of an output signal of the compensator in the switching frequency, a disturbance voltage is generated, switching frequency is generated by the oscillator according to the disturbance voltage, dither of the signal is achieved, the resolution ratio of the signal is obviously improved, the low-resolution-ratio pulse width modulator can be applied to the DC-DC switching power circuit, chip area can be effectively reduced, the signal resolution ratio can be obviously improved, and good application prospects can be achieved.

Owner:SUZHOU YINENG MICROELECTRONICS TECH

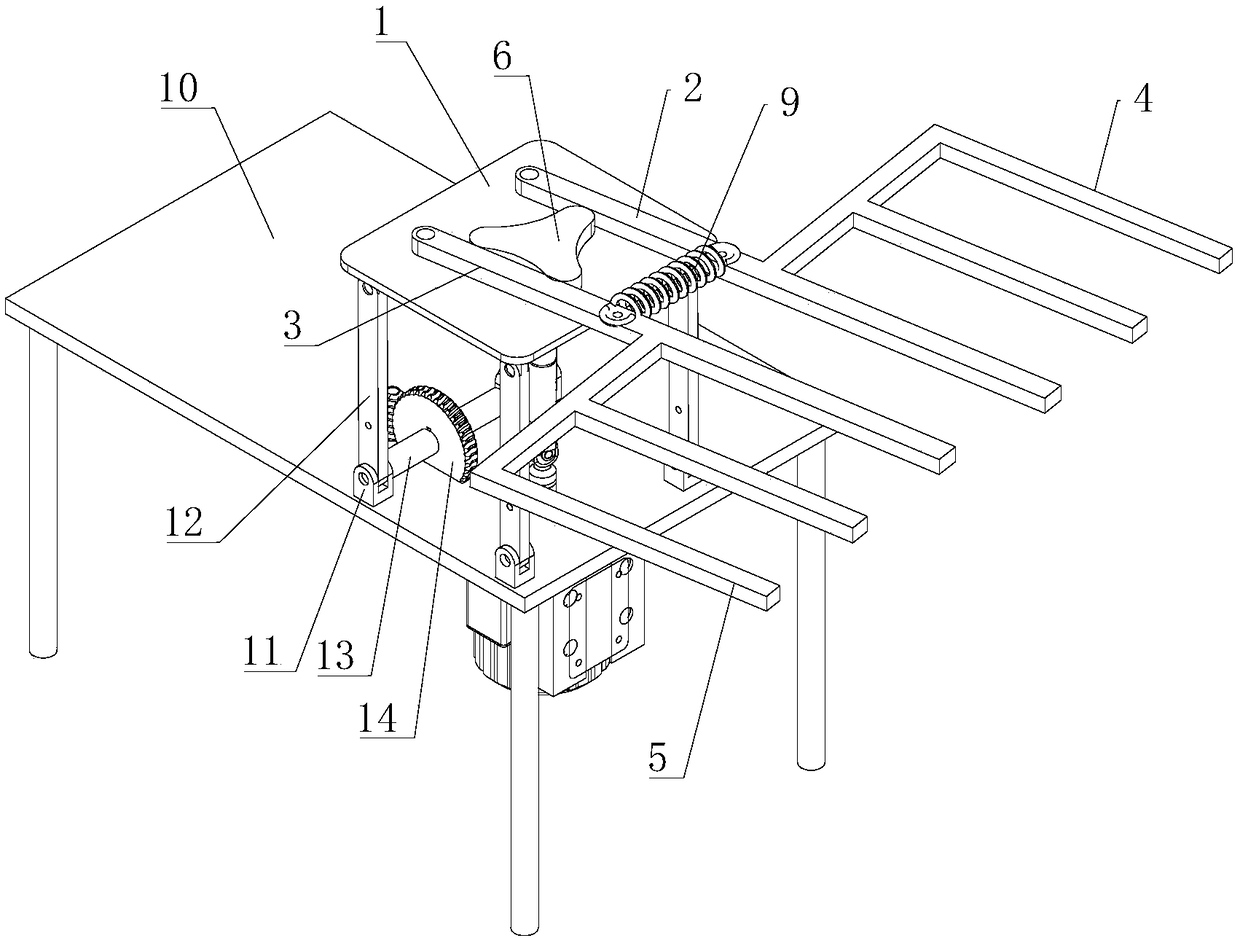

Fruit shaking-off device

The invention provides a fruit shaking-off device. The problem in the prior art that the fruit picking efficiency is low is solved. The fruit shaking-off device comprises a horizontal supporting plate, two swinging rods are arranged on the upper surface of the supporting plate, the ends of the swinging rods are both hinged to the supporting plate and can swing back and forth in the horizontal plane, and wide teeth used for being inserted into fruit branches are further fixed to the swinging rods; the supporting plate is further provided with a cam which is located between the swinging rods, wherein the cam is in contact with the portion between the swinging rods, is driven by a power mechanism to rotate in the horizontal plane, and drives the swinging rods to move. The fruit shaking-off device is simple in structure and convenient to use, can effectively shake off fruits and improve the picking efficiency of the fruits, and has high practicability.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

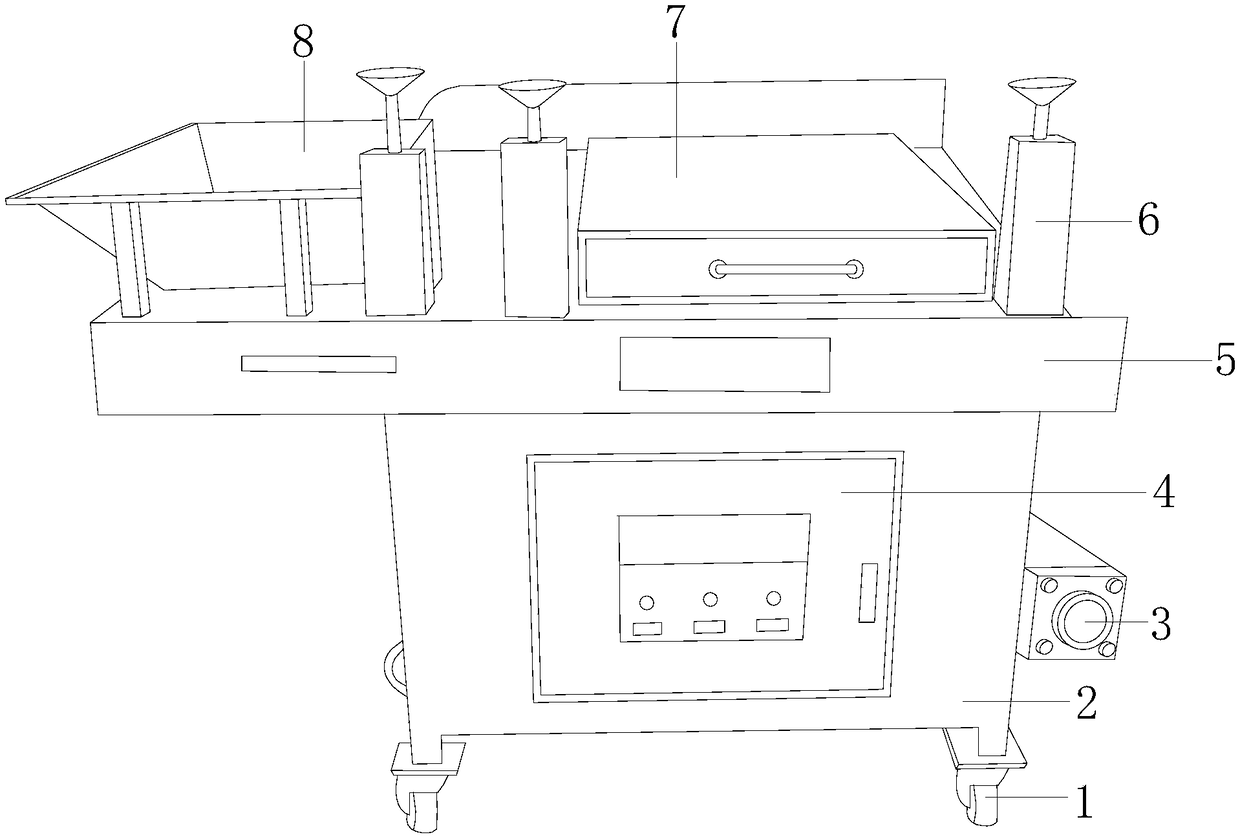

Novel package press shaping machine

The invention discloses a novel package press shaping machine which structurally comprises moving wheels, a shaping machine body, a conveyor, an intelligent control door plate, a machine body upper table, a rotary adjuster, a turnover drawer, a feed inlet and a package shaping mechanism. The moving wheels are locked to the bottom of the shaping machine body, the intelligent control door plate is movably connected to the front end face of the shaping machine body, the conveyor is installed in the middle of the side, away from the feed inlet, of the shaping machine body, the machine body upper table is located above the shaping machine body, the machine body upper table and the shaping machine body form an integrated structure, the rotary adjuster is installed above the machine body upper table, and the turnover drawer is movably connected to the top of the machine body upper table through a hinge. Manual package press shaping is not needed, time and labor are saved, the efficiency is high, bag packages are buffered through damping after falling down during equipment package press shaping, the damage rate of equipment is reduced, the bag packages are damped again after being turned over to achieve secondary buffer, the equipment is further maintained, the bag packages are shaken in an assisted mode when flattened, and shaping is more uniform.

Owner:惠安闽神石材加工设备开发有限公司

Thermal insulation plastic and production process thereof

The invention discloses thermal insulation plastic and a production process thereof. The thermal insulation plastic comprises the following raw materials in parts by weight: 50-65 parts of cellulose,8-15 parts of polyethylene, 1-5 parts of polymethyl phenolic aldehyde, 1-5 parts of quartz, 12-15 parts of polysiloxane, 12-15 parts of polyesterimide, 7-12 parts of mineral oil, 7-12 parts of polyethylene, 7-10 parts of ethylene glycol and 3-5 parts of a high-temperature-resistant matrix. A first motor is started to drive a first rotating shaft to rotate, so first crushing blades are driven to rotate so as to crush a mixture; and meanwhile, the first rotating shaft drives a first bevel gear to rotate so as to drive a second bevel gear engaged with the first bevel gear to rotate, and the second bevel gear drives a second rotating shaft to rotate so as to drive second crushing blades to rotate, so the mixture is further crushed, and crushing efficiency is improved.

Owner:亳州丰色信息科技有限公司

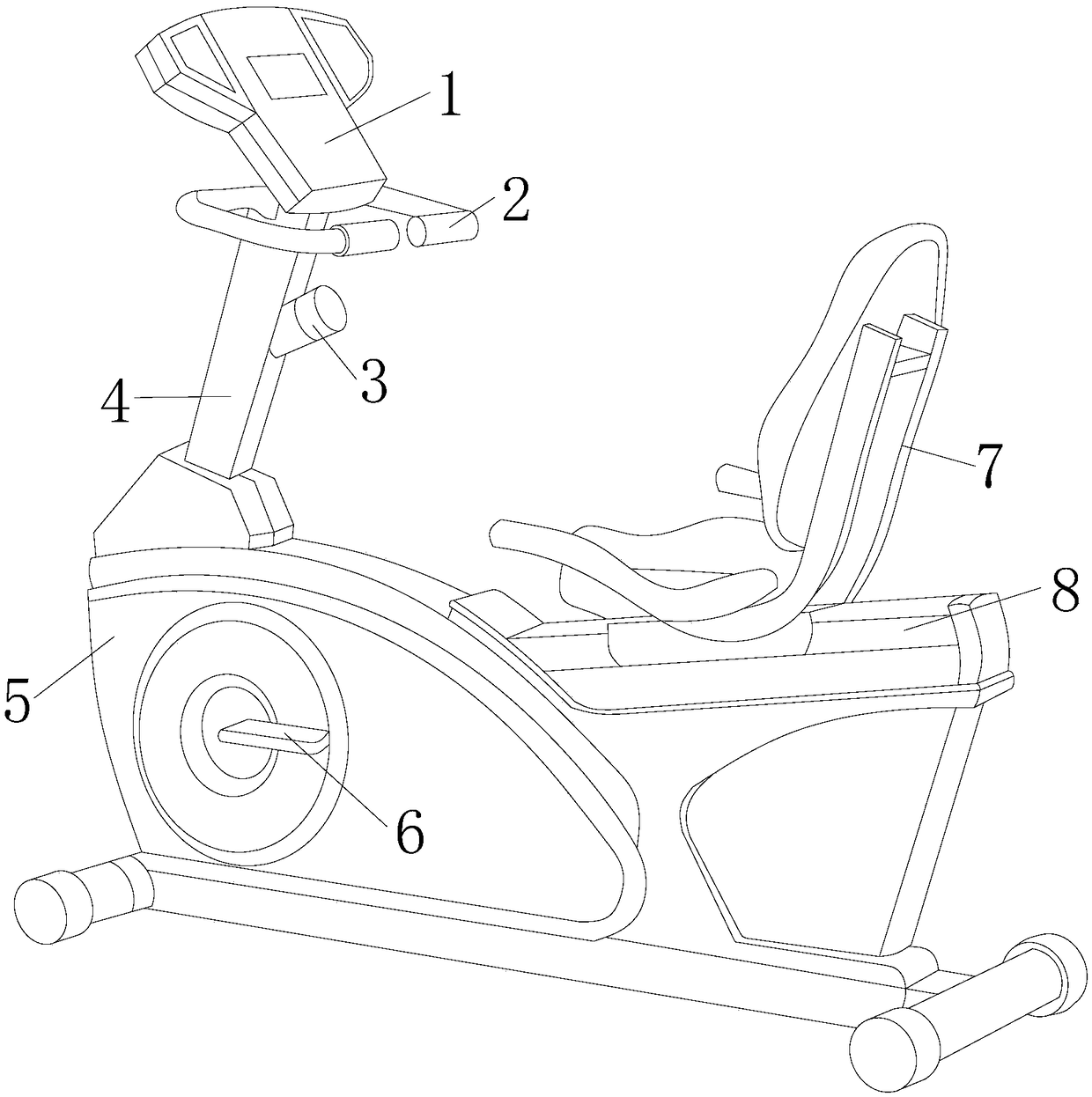

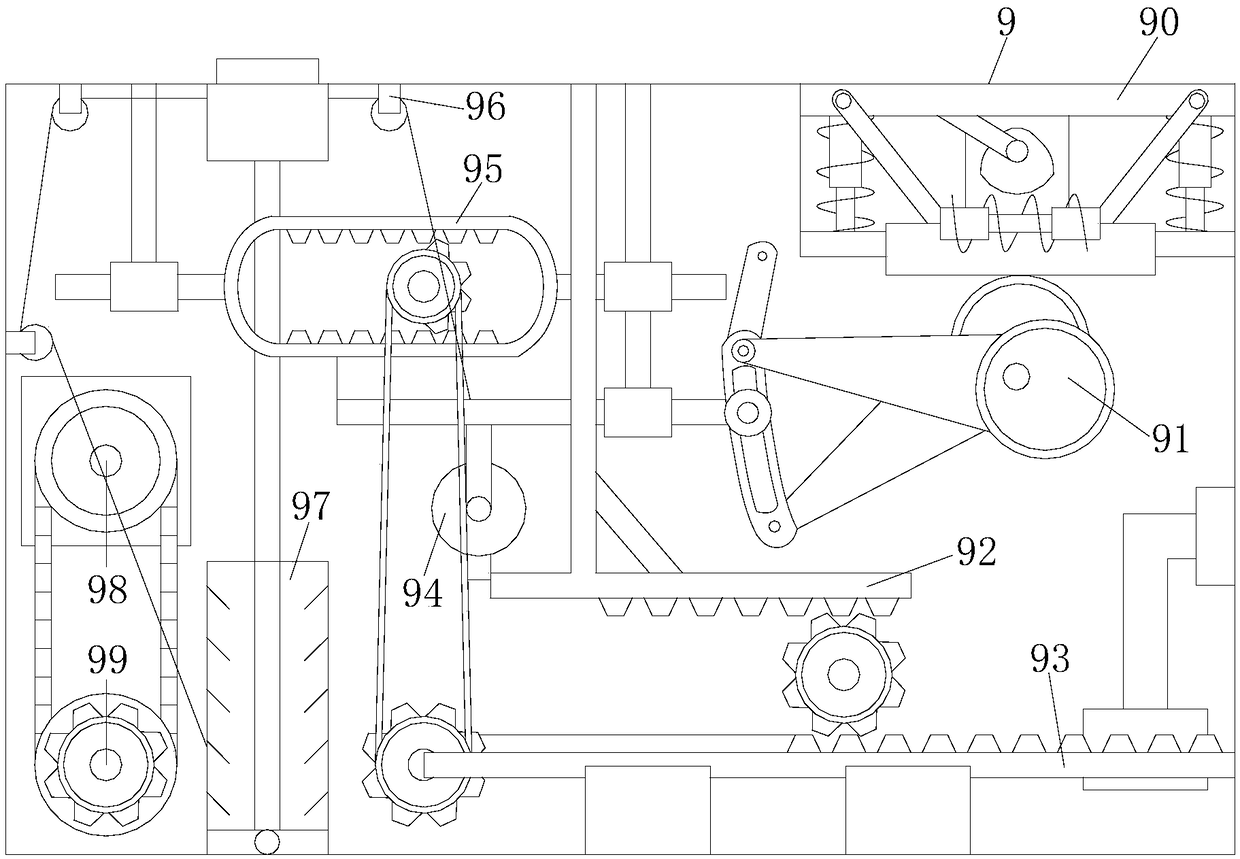

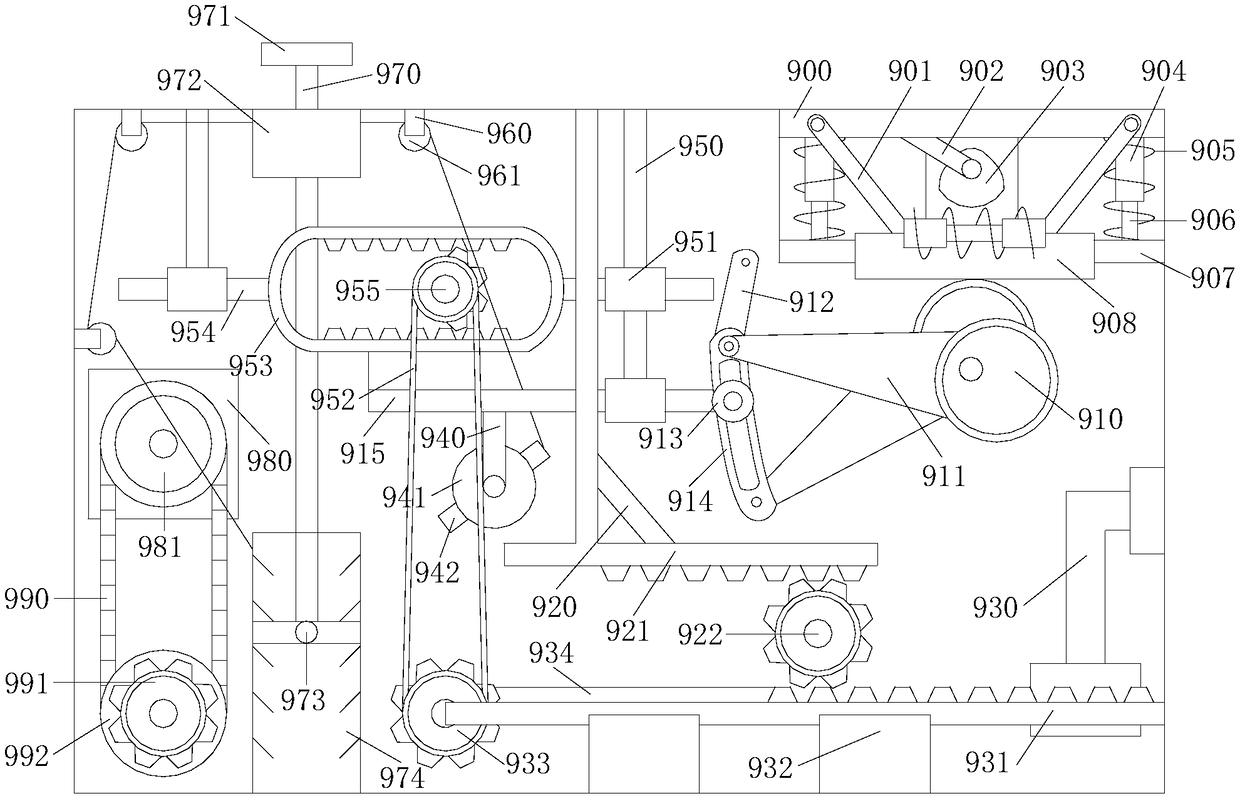

Self-generating exercise bike

InactiveCN108126308ARise achievedAchieve jitterFrom muscle energyChiropractic devicesEngineeringYounger people

The invention discloses a self-generating exercise bike which structurally comprises an intelligent control board, a grab handle, a knob, a support, an exercise bike body, pedals, a fitness seat, a fitness seat carriage and an internal state regulation device, wherein the intelligent control board is mounted at the upper end of the support; the grab handle is locked at the upper end of the support; the support is connected with the knob; the knob is positioned at one side, which is close to the fitness seat, of the support. According to the invention, the pedals rotate to drive a motor to run,so as to implement energy saving, and on the basis of energy saving, by regulating a position of the fitness seat, different exercise modes are implemented; when the seat is fixed in the middle of the fitness seat carriage, the self-generating exercise bike can be used for conventional exercise and applicable for old people to exercise; when the seat is adjusted forwards, the seat can be risen tomake the body to change different stretching forms so as to carry out pedaling exercise; when the seat is adjusted backwards, shaking of the seat can be implemented, so that the self-generating exercise bike implements weight lose when implementing bodybuilding, and is applicable for young people to exercise.

Owner:谢淑萍

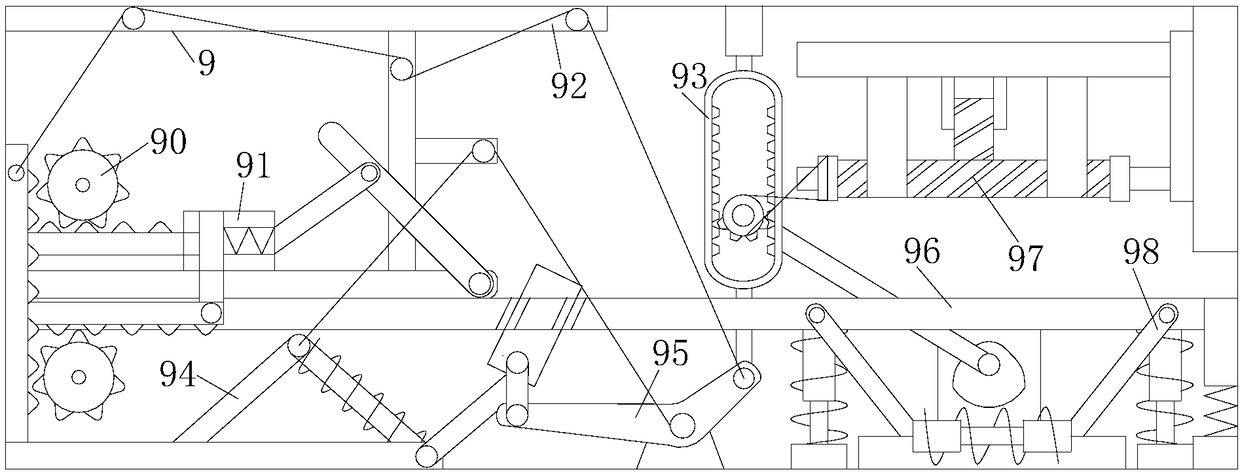

Magnetic polishing machine assembly line

InactiveCN111168479AFast polishingAchieve jitterEdge grinding machinesPolishing machinesPolishingElectric machinery

The invention discloses a magnetic polishing machine assembly line. The magnetic polishing machine assembly line includes a mounting frame, a mounting beam, a conveyor belt, circulating rollers, a feeding structure, a magnetic box and a screening structure. When polishing operation is performed, workpieces are placed in a workpiece feeding cylinder, polishing needles are put into a magnetic needlebox, at this time, a shaking motor operates, and the magnetic needle box is pulled by the shaking motor to realize the shaking of the magnetic needle box. Mixing and delivery are performed by a discharge cylinder, and at this time, the conveyor belt rotates under the matching of the circulating rollers to move the workpieces to the top side of the magnetic box. Through magnetic operation, the purposes of grinding and polishing are achieved. After polishing, the workpieces and the polishing needles fall onto a screening plate, at this time, a screening motor operates to drive a cam to rotate,a return spring is pushed, and with the cooperation of a push rod, the shaking of the screening plate and the separation of the workpieces from the polishing needles are realized. The workpieces slidedown along the screening plate, the polishing needles slide down along a bearing plate, in this way, the workpieces can be quickly polished in batch, and the polishing efficiency is greatly improved.

Owner:苏州圣亚精密机械有限公司

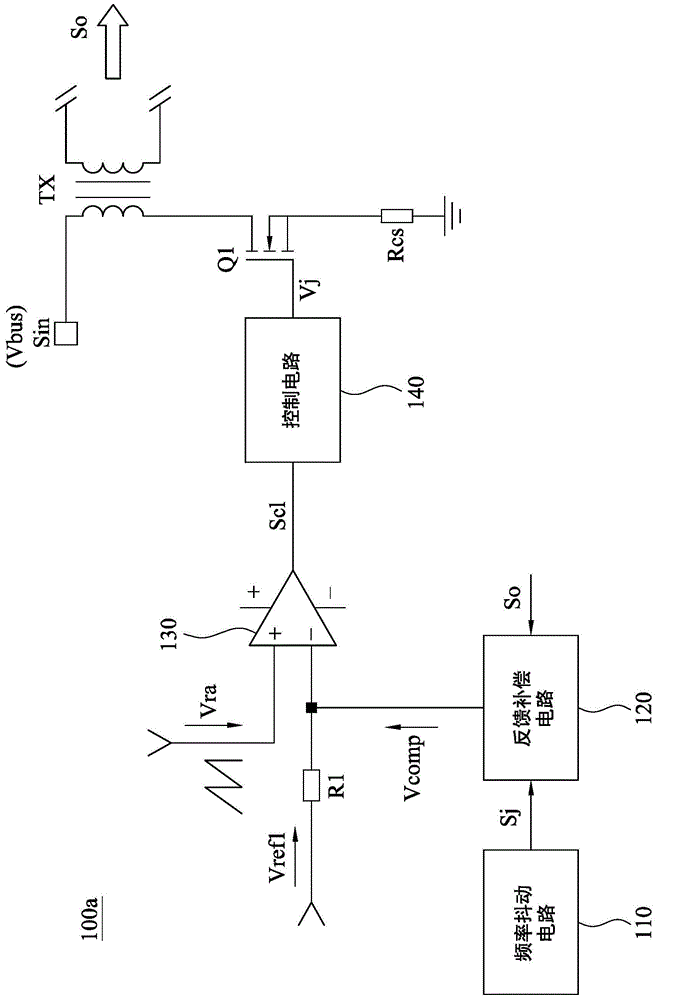

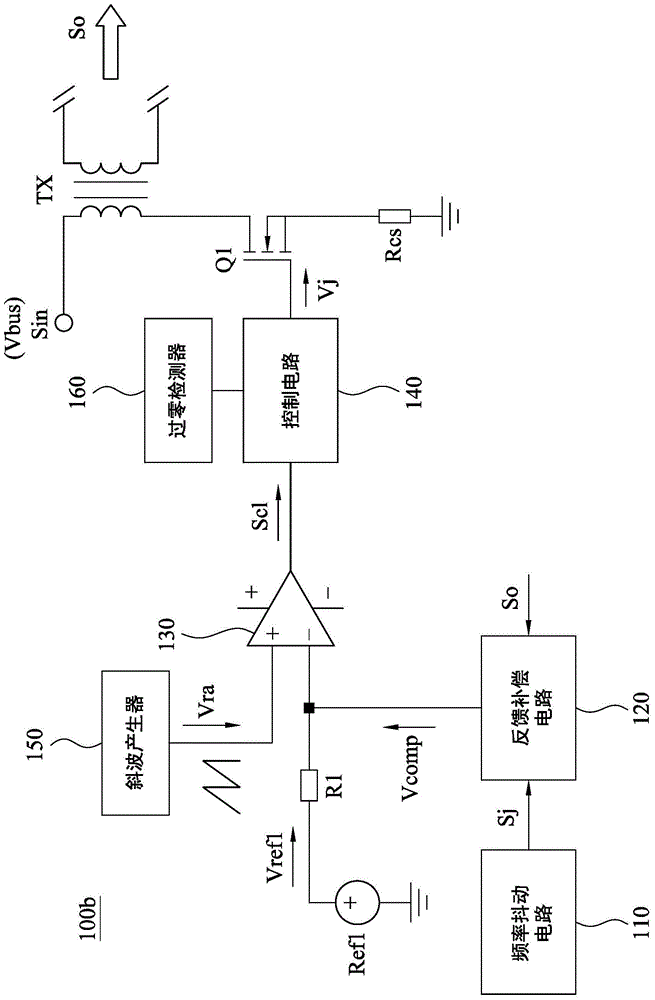

Frequency jittering control circuit and method

ActiveCN105099164AAchieve jitterImprove EMI characteristicsDc-dc conversionOutput compareControl signal

A frequency jittering control circuit includes a frequency jittering circuit, a feedback compensation circuit, a comparator and a control circuit. The frequency jittering circuit generates a frequency jittering signal. The feedback compensation circuit generates a feedback compensation signal in response to the frequency jittering signal and an output signal. The comparator outputs a comparison output signal according to the feedback compensation signal and an oscillation signal. The control circuit outputs a frequency jittering control signal for switching a main switch in a power supply apparatus, according to the comparison output signal, such that the power supply apparatus correspondingly generates the output signal.

Owner:DELTA ELECTRONICS (SHANGHAI) CO LTD

Auxiliary discharging device for mountain incense manufacturing

PendingCN112090738AEasy to collectRealize the effect of shaking off and screeningSievingScreeningEnvironmental engineeringMechanical engineering

The invention relates to an auxiliary discharging device, in particular to an auxiliary discharging device for mountain incense manufacturing. According to the auxiliary discharging device for mountain incense manufacturing, mountain incense can be discharged in batches, waste in the mountain incense is shaken off and screened out, the mountain incense is aligned, and mountain incense waste can becollected conveniently. The auxiliary discharging device for mountain incense manufacturing comprises: a base and a servo motor, wherein the servo motor is arranged on the front side of the top of the base; a sequential discharging mechanism, wherein the sequential discharging mechanism is arranged on the side, away from the servo motor, of the top of the base, and the sequential discharging mechanism is connected with an output shaft of the servo motor; a shaking mechanism, wherein the shaking mechanism is arranged in the middle of the top of the base, and the shaking mechanism is connectedwith the output shaft of the servo motor; and a collecting frame, wherein the collecting frame is arranged on the side, close to the servo motor, of the top of the base. According to the device, the mountain incense can be discharged in sequence, the mountain incense waste is shaken off and screened out, the high-quality mountain incense in the collecting frame is aligned, the mountain incense waste is shaken off, and people can conveniently take out and collect the mountain incense waste.

Owner:曾云婷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com