Auxiliary discharging device for mountain incense manufacturing

A technology that assists in material cutting and mountain incense, which is applied in the direction of transportation and packaging, conveyor objects, solid separation, etc., can solve problems such as manual removal, and achieve the effect of convenient removal and collection of mountain incense waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

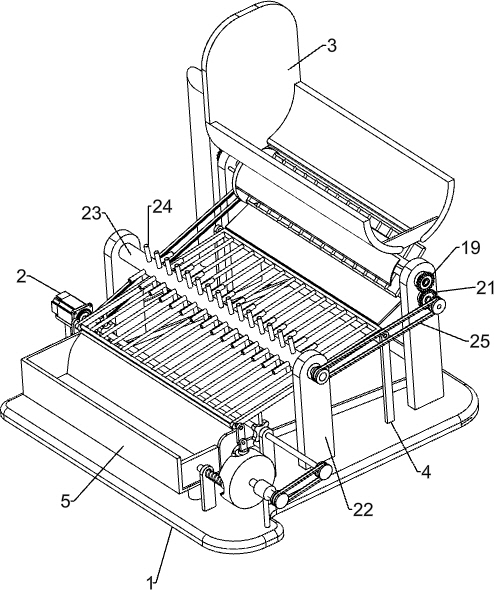

[0027] A kind of mountain incense making auxiliary feeding device, such as figure 1 As shown, it includes a base 1, a servo motor 2, a sequential unloading mechanism 3, a shaking mechanism 4 and a collection frame 5. The left side of the top of the base 1 is provided with a servo motor 2, and the rear side of the top of the base 1 is provided with a sequential unloading mechanism 3. The blanking mechanism 3 is connected with the output shaft of the servo motor 2 successively, and the shaking mechanism 4 is arranged in the middle of the base 1 top, and the shaking mechanism 4 is connected with the output shaft of the servo motor 2, and the front side of the base 1 top is provided with a collecting frame 5.

[0028] When people need to unload the yam, the yam starts to fall into the parts of the sequential feeding mechanism 3. People first start the servo motor 2, and the rotation of the output shaft of the servo motor 2 drives the parts of the sequential feeding mechanism 3 to r...

Embodiment 2

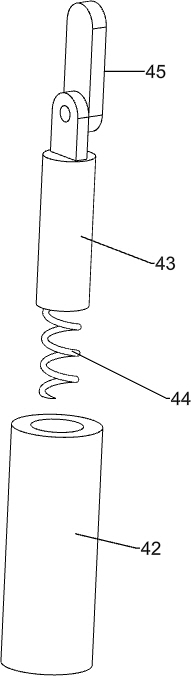

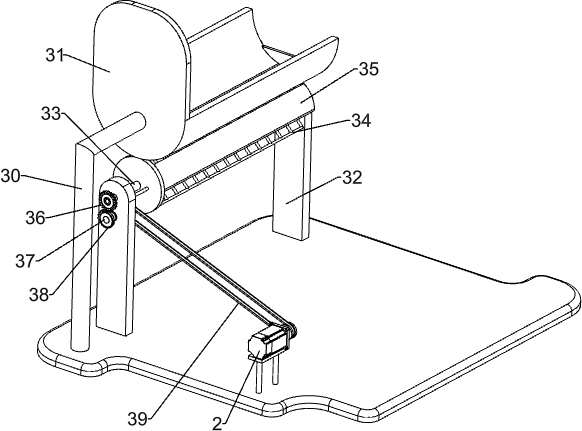

[0030] On the basis of Example 1, such as Figure 2-8 As shown, the blanking mechanism 3 includes a fixed rod 30, a material retaining frame 31, a first mounting seat 32, a first rotating shaft 33, a material retaining frame 34, an arc baffle 35, a first gear 36, and a first rotating shaft in sequence. 37. Missing gear 38 and the first belt transmission assembly 39, the top rear side of the base 1 is provided with a fixed rod 30, the top right side of the fixed rod 30 is provided with a retaining frame 31, and the top rear side of the base 1 is symmetrically provided with a first mounting seat 32, the first rotating shaft 33 is rotatably connected between the upper parts of the first mounting seats 32 on both sides, and the upper part of the first mounting seat 32 on the left is provided with an arc-shaped baffle 35, and the first rotating shaft 33 and the arc-shaped baffle 35 are rotatable connection, the first rotating shaft 33 is provided with retaining frames 34 at interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com