Automatic oil immersion device for automobile part production

An auto parts, automatic technology, applied in the device and coating of the surface coating liquid, can solve the problem that the oil cannot cover all the areas of the auto parts, the oil immersion effect of the auto parts is not good, and the structure of the auto parts is complicated. , to achieve the effect of improving the oil immersion effect, comprehensive and uniform oil immersion, and good oil immersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

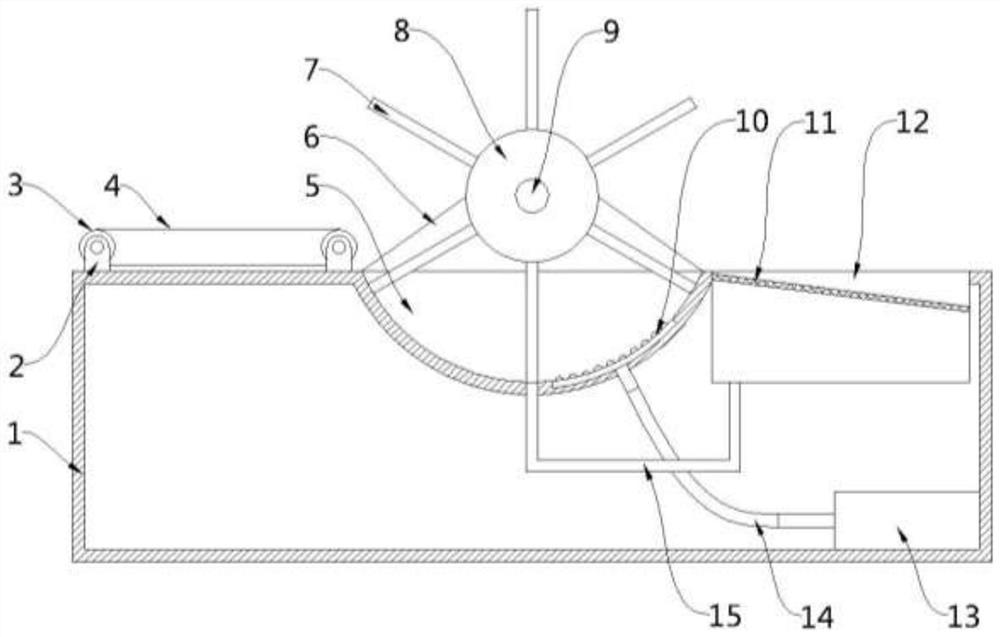

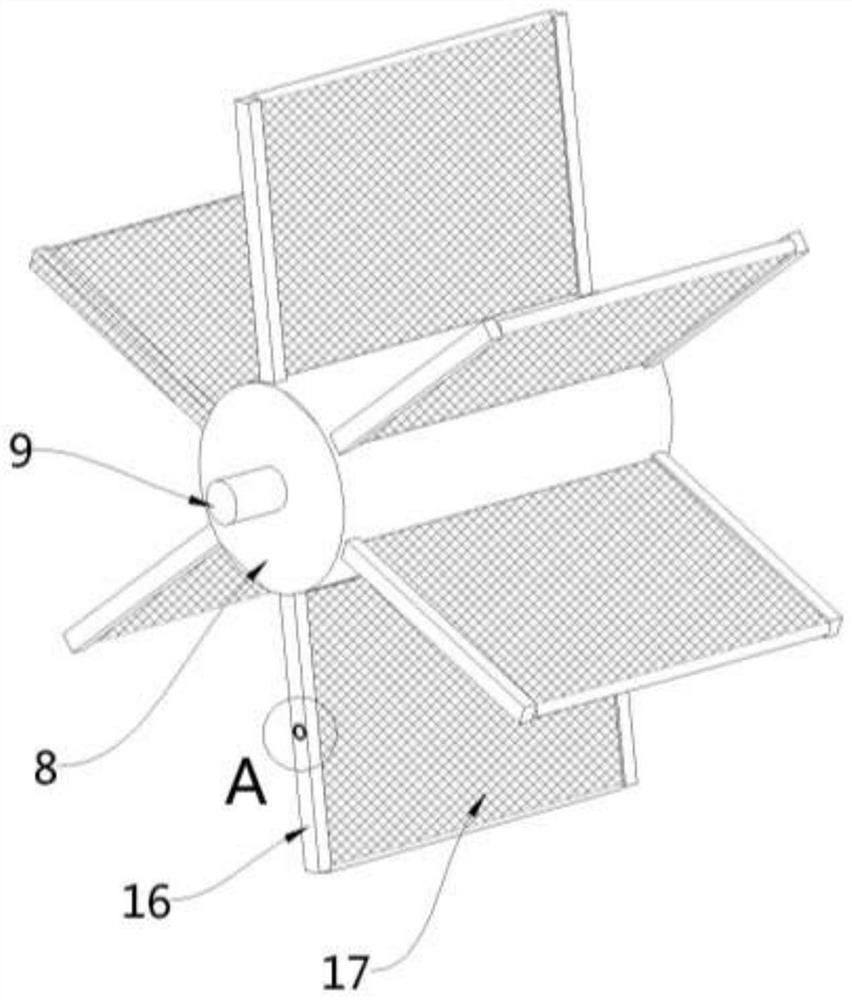

[0027] see Figure 1-4 , this embodiment provides an automatic oil immersion device for the production of auto parts, including a bottom box 1, an oil storage tank 5 and an oil filter tank 12 are opened on the upper part of the bottom box 1, and the upper part of the bottom box 1 is located far away from the oil storage tank 5. One side of the oil tank 12 is provided with a conveying assembly for transporting auto parts to the interior of the oil storage tank 5, and the upper part of the bottom box 1 is fixedly provided with a second bracket 6, and one side of the second bracket 6 is provided with a runner 8 through a rotating shaft 9. , the runner 8 is located above the oil storage tank 5, and the peripheral side wall of the runner 8 is fixedly provided with a number of pusher assemblies 7, and one end of the rotating shaft 9 is connected to an external motor (not shown), specifically, the The pusher assembly 7 includes a number of side struts 16 fixedly arranged on the side ...

Embodiment 2

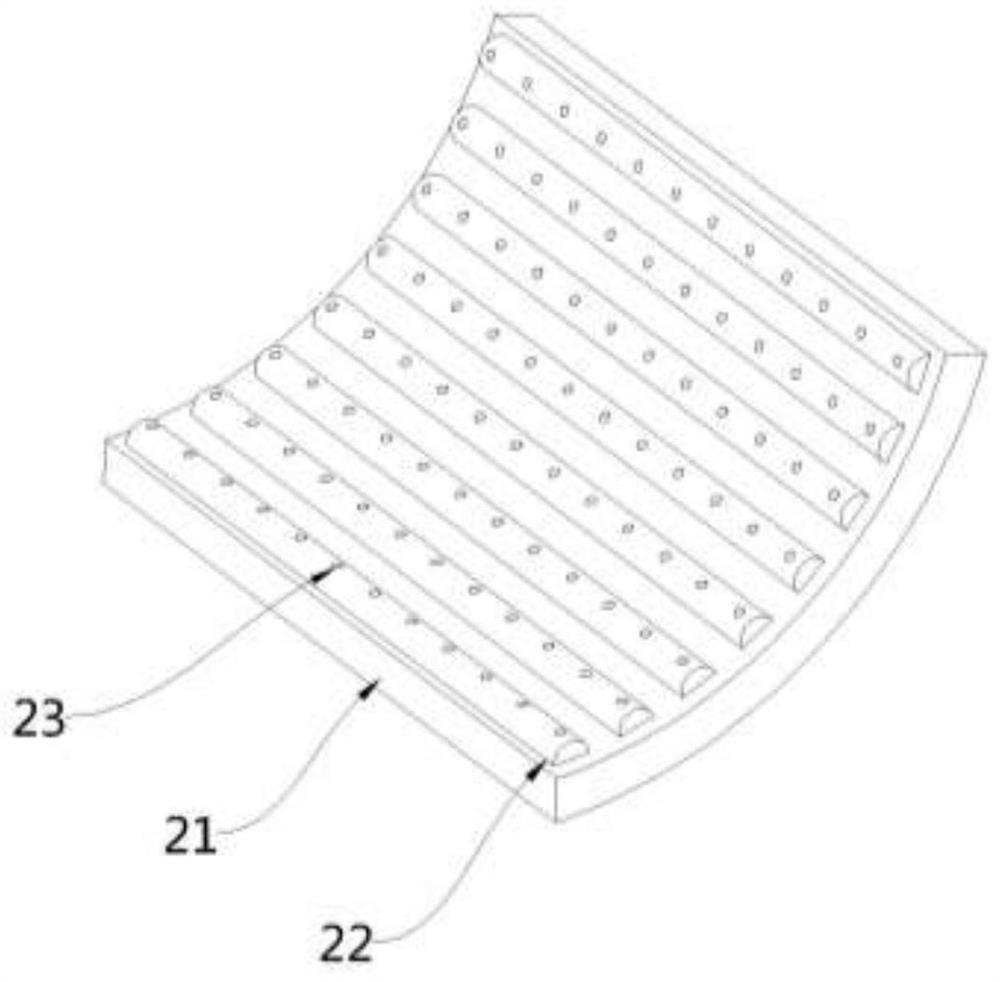

[0038] see figure 1 , an automatic oil immersion device for the production of auto parts. Compared with Embodiment 1, the present embodiment is fixed with a filter screen 11 inside the oil filter tank 11. Through the setting of the filter screen 11, the auto parts that have been soaked in oil can be Placed on the top of the filter screen 11, the excess oil in the auto parts can pass through the filter screen 11 and enter the bottom of the oil filter tank 12 to realize the draining of the auto parts.

[0039] Further, the end of the filter screen 11 away from the oil storage tank 5 is inclined downward, so that the auto parts located on the upper part of the filter screen 11 can slide downward by itself, so as to store more auto parts.

[0040]Further, the bottom of the oil filter tank 12 communicates with the oil storage tank 5 through a communication pipe 15, so that a communication structure is formed between the oil filter tank 12 and the oil storage tank 5, which facilitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com