Patents

Literature

36results about How to "Improve oil immersion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

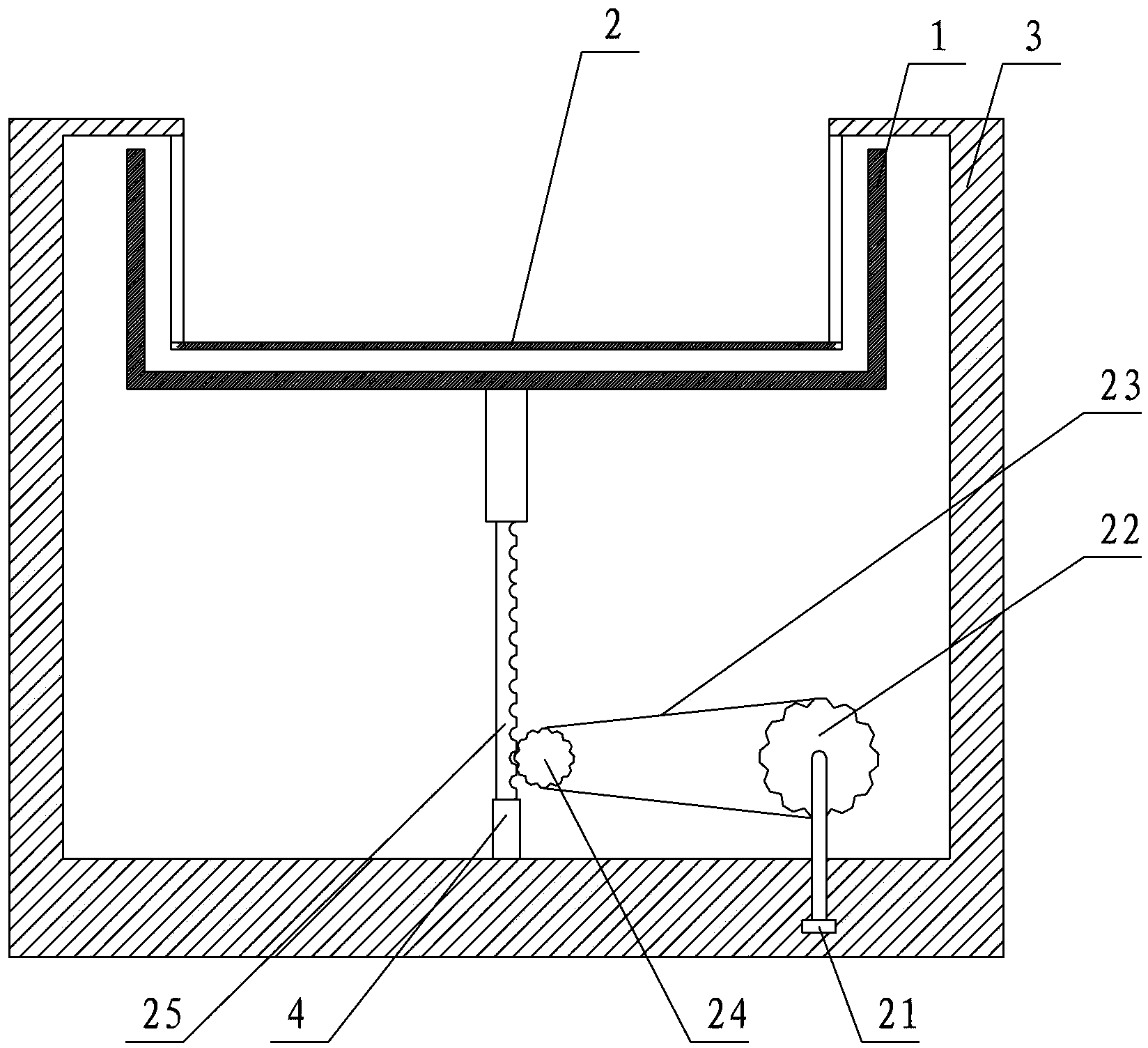

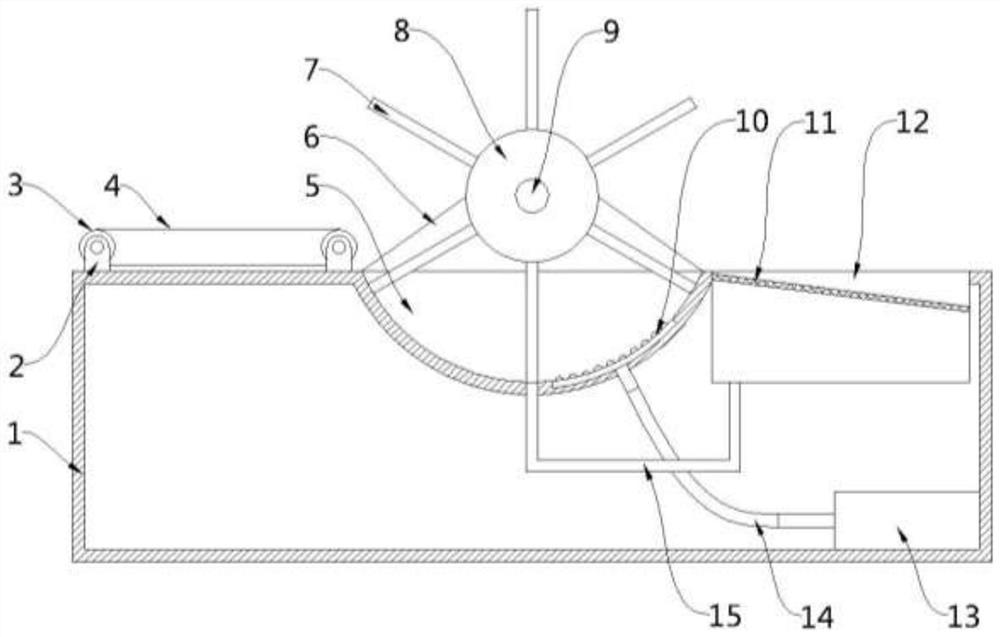

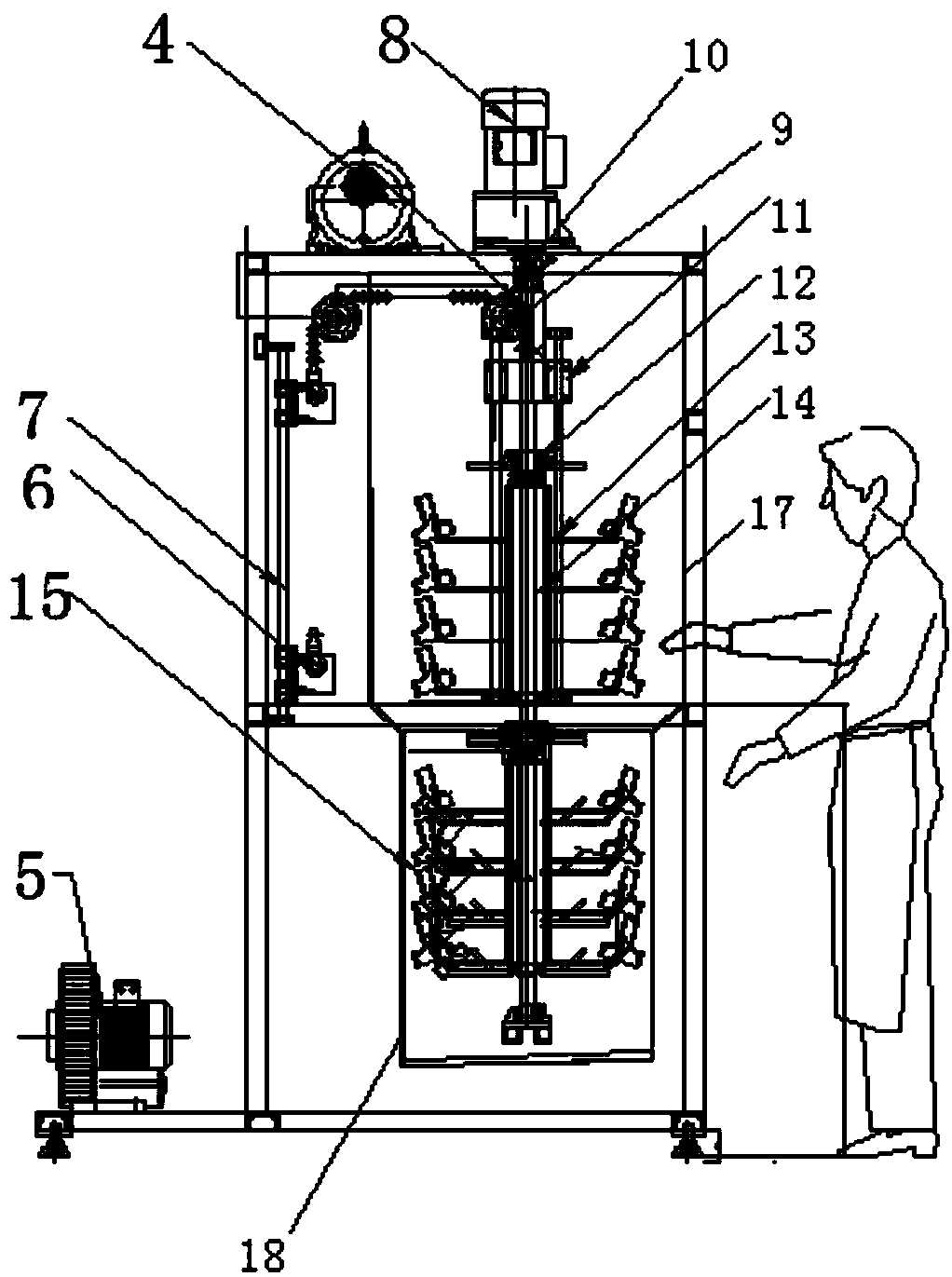

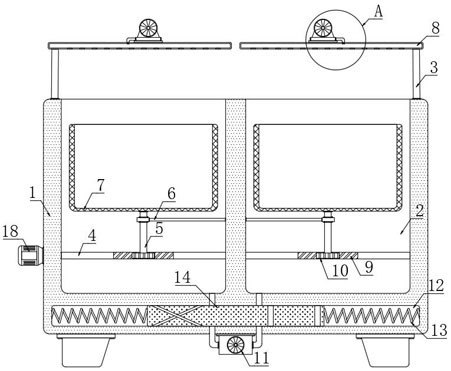

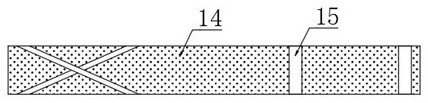

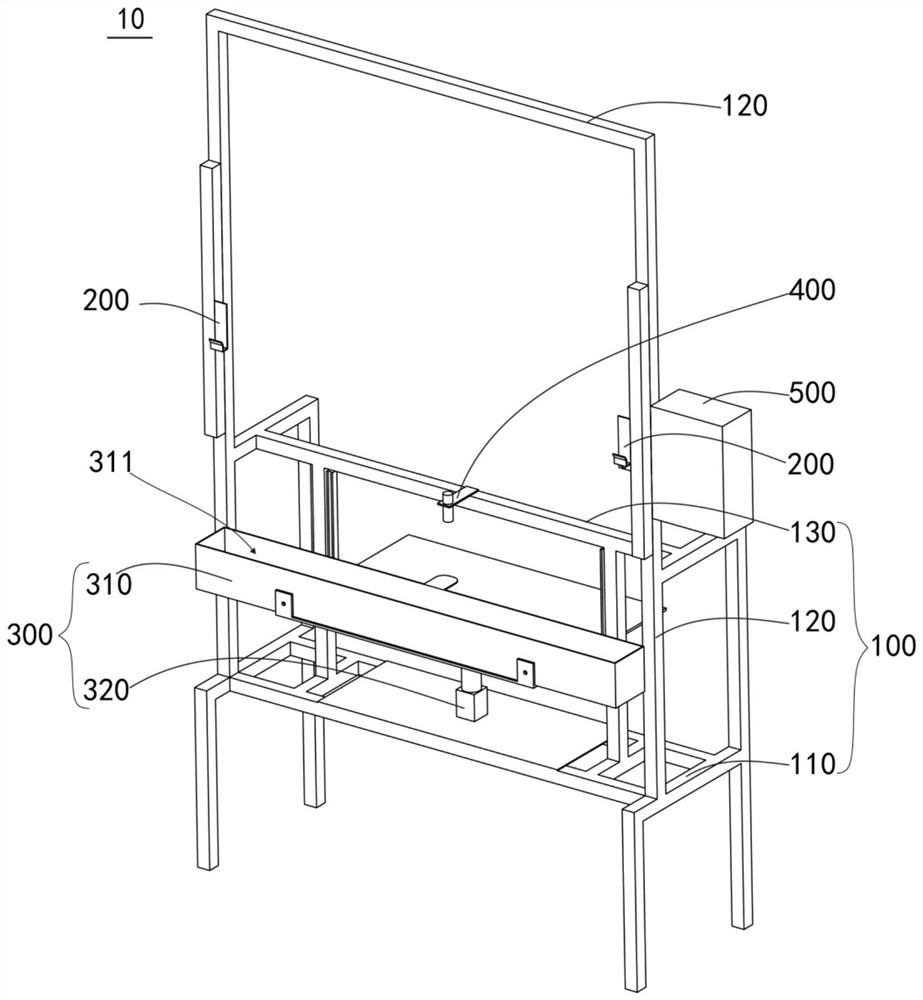

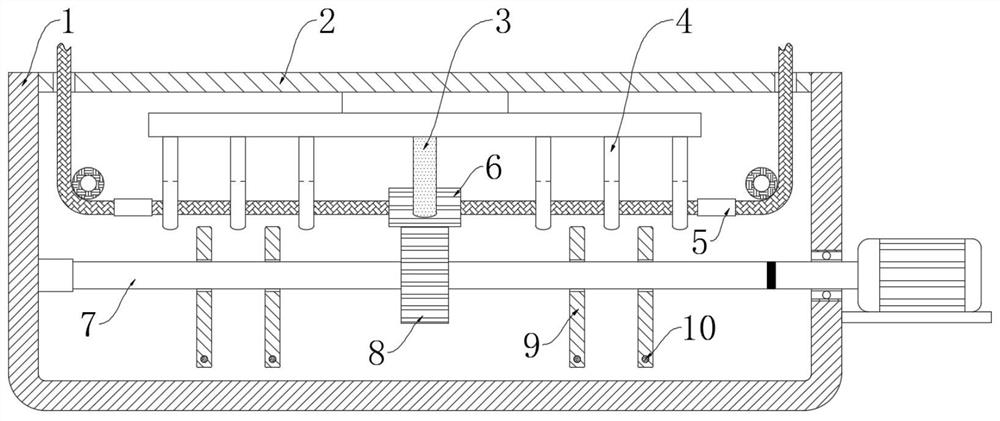

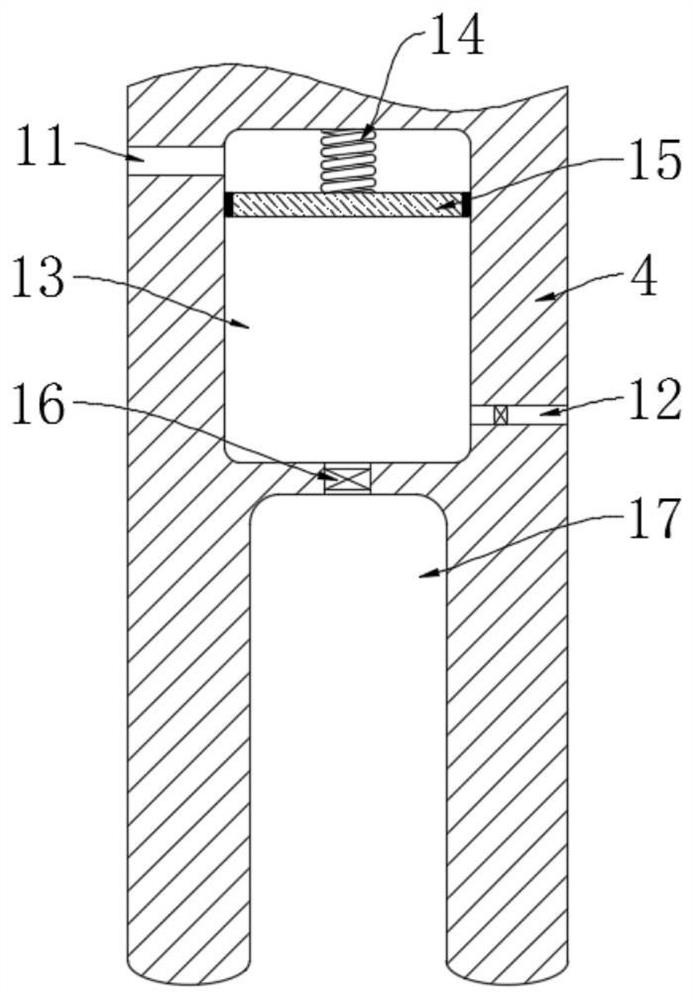

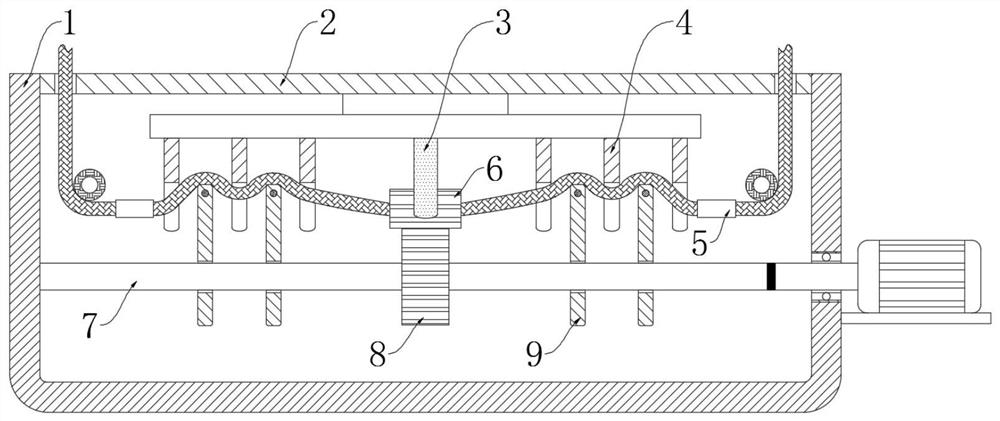

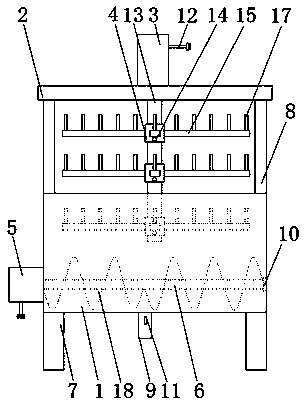

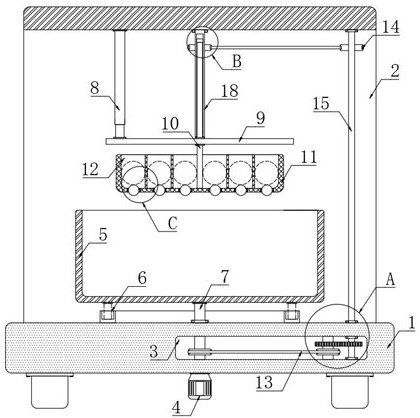

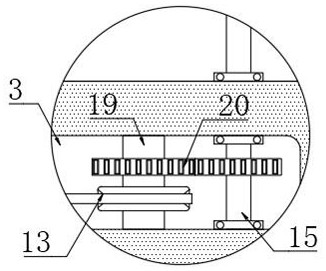

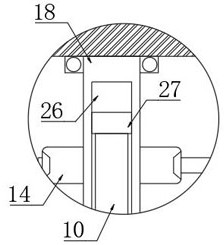

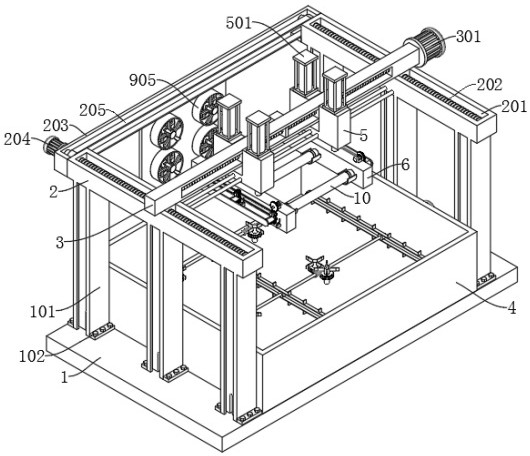

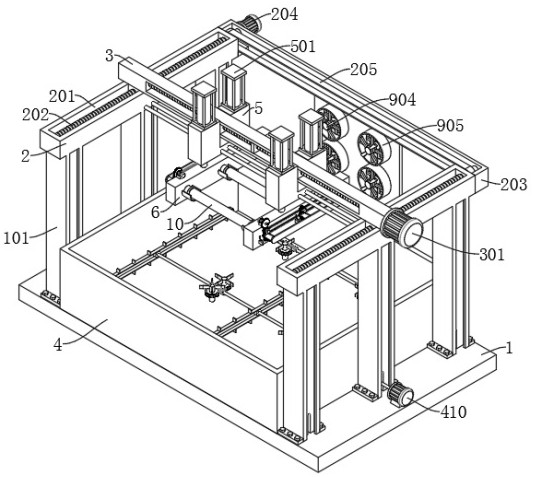

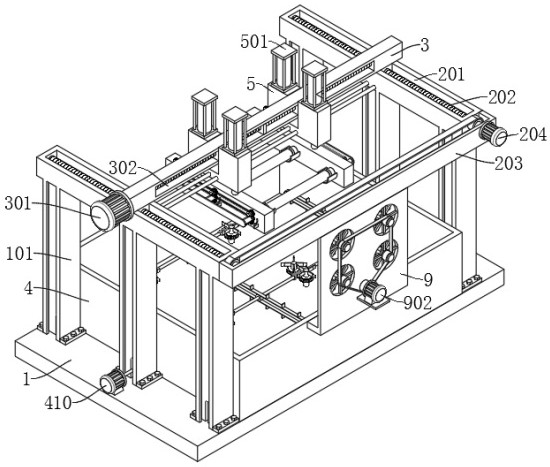

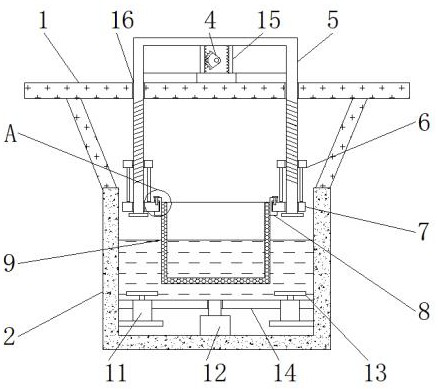

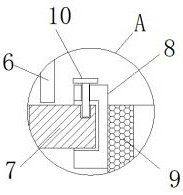

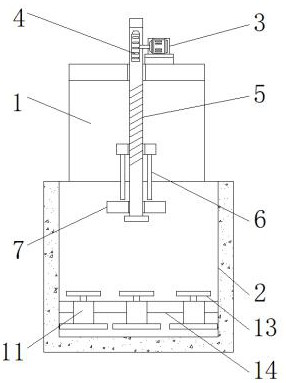

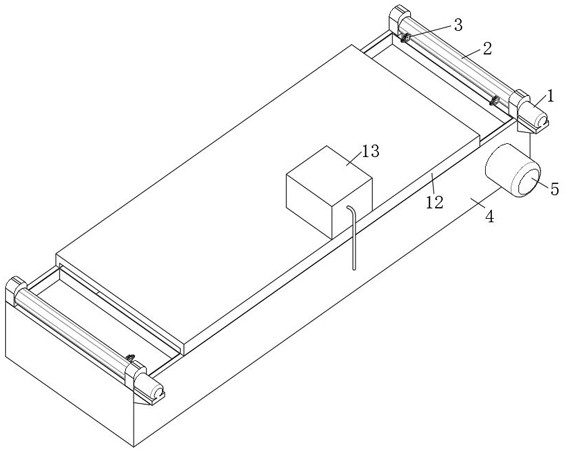

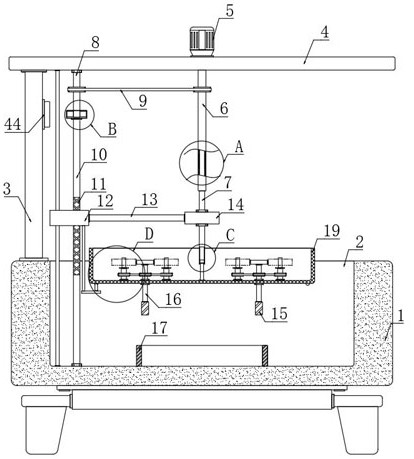

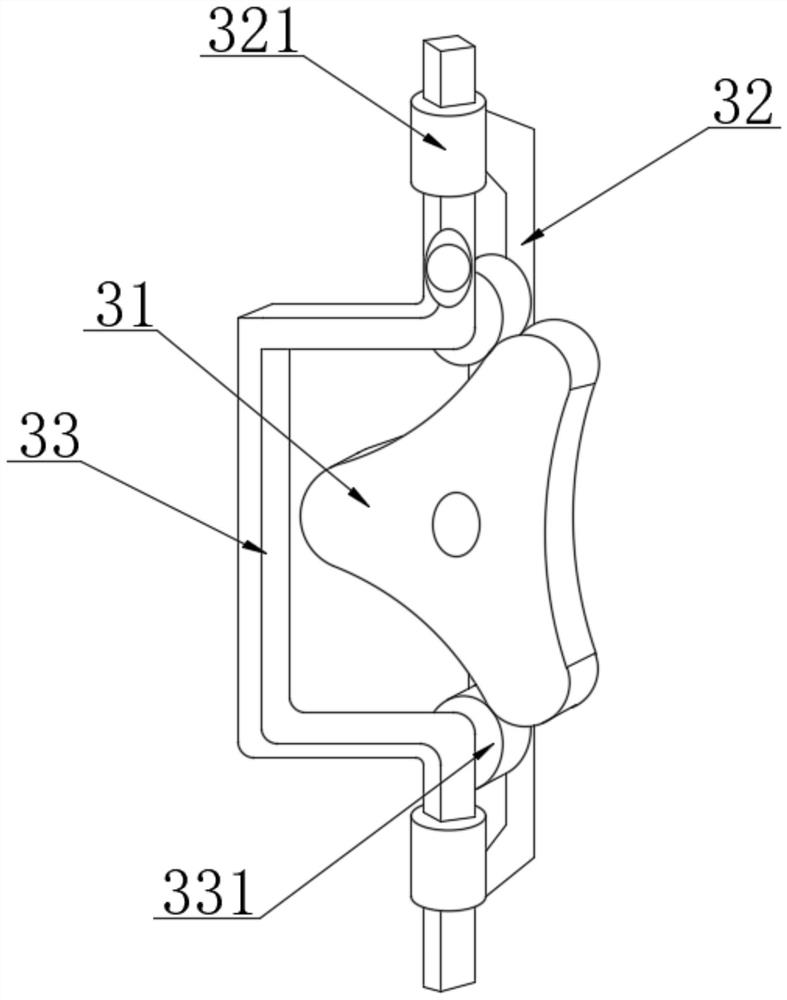

Oil immersion device for transformers

InactiveCN103350053AWon't stickImprove oil immersion effectLiquid surface applicatorsInductances/transformers/magnets manufactureTransformerOil immersion

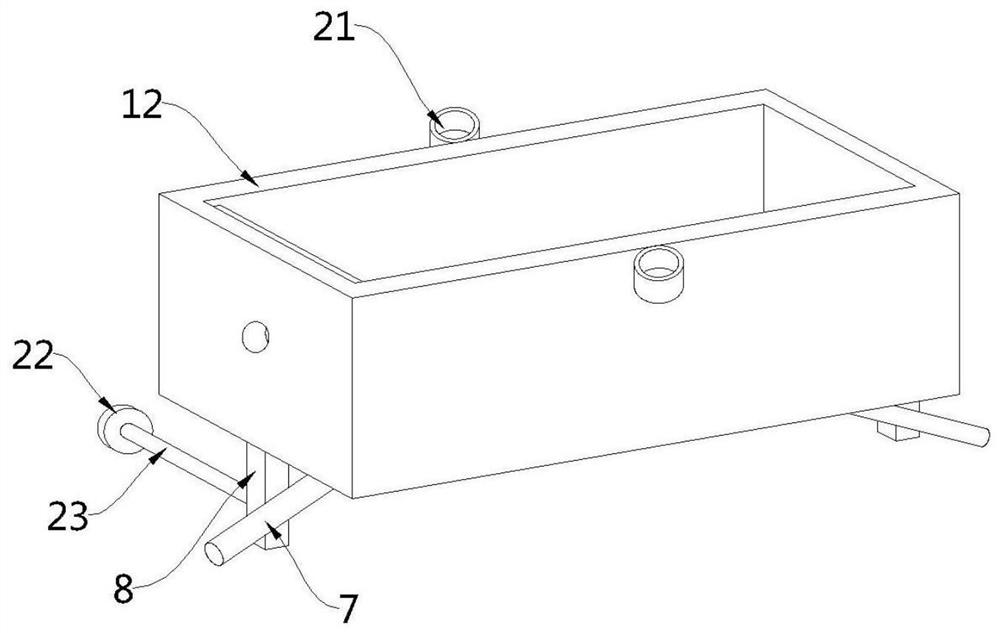

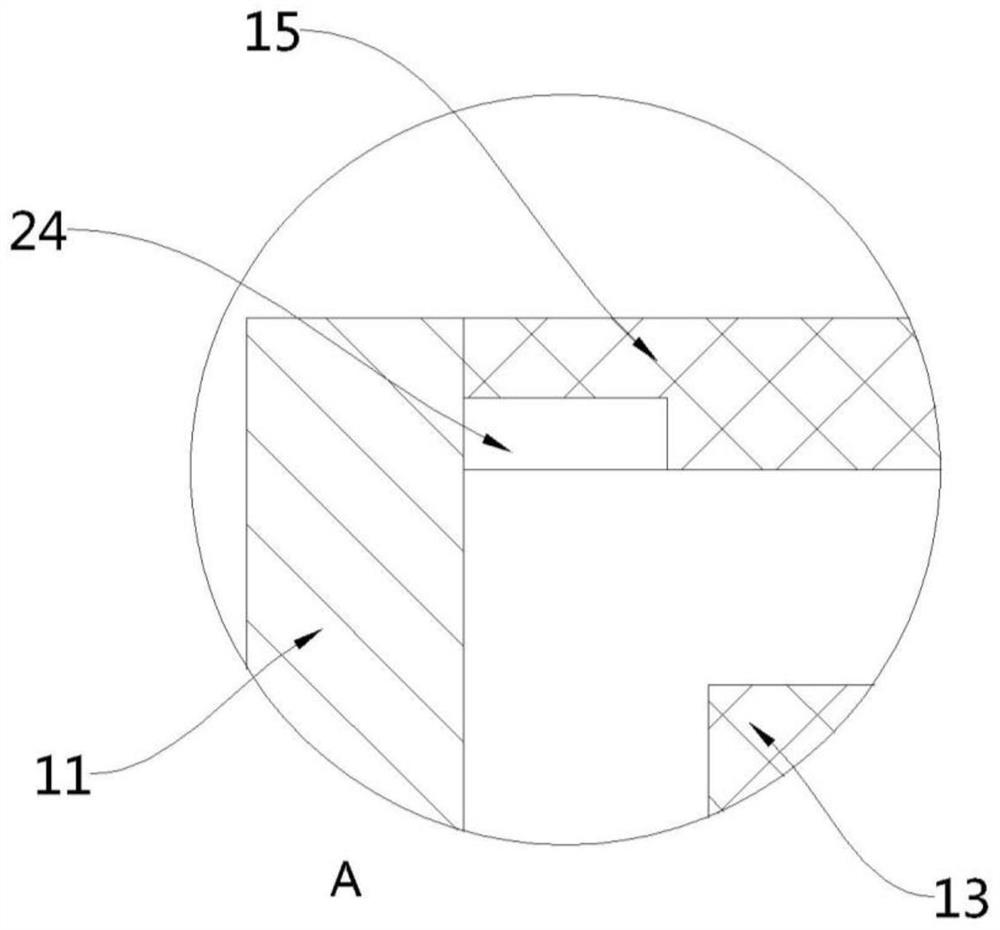

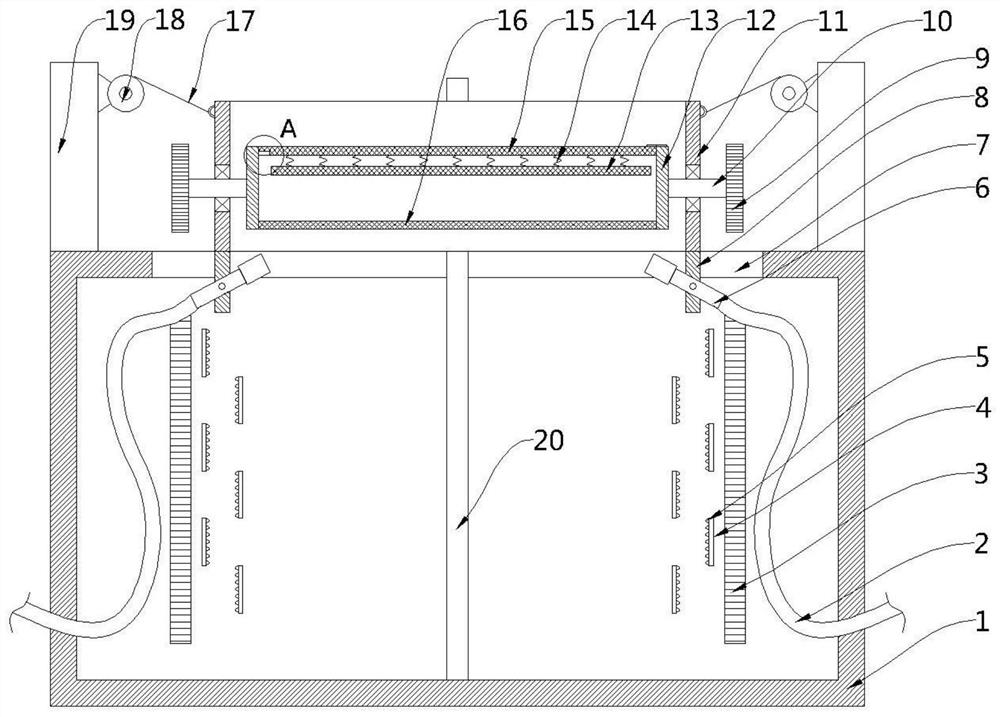

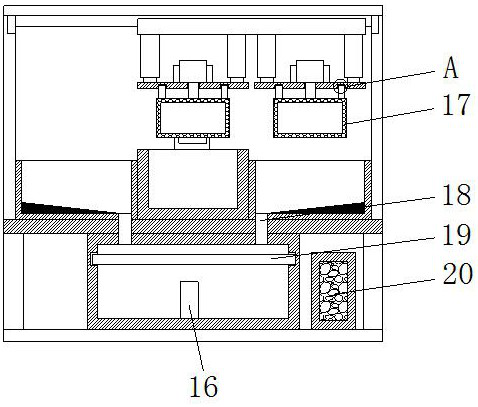

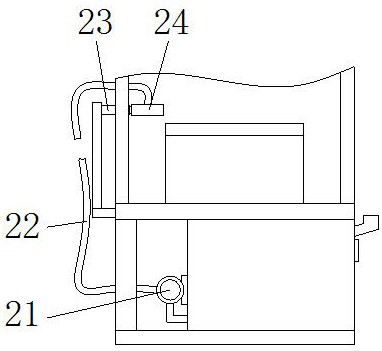

The invention discloses an oil immersion device for transformers, which includes an oil immersion container, an operating panel, a machine frame and a driving mechanism, wherein the oil immersion container is used for accommodating insulating oil; an operating panel is used for allowing a transformer to be placed thereon; the oil immersion container is mounted on the machine frame and can move vertically relative to the machine frame; the operating panel is fixed on the machine frame and positioned in the oil immersion container; a driving mechanism includes a driving component, a first gear, a chain, a second gear and racks; the driving component is in transmission connection with the first gear; the chain is in transmission connection with the first gear and the second gear; the racks are in transmission connection with the second gear, and are vertically arranged and fixed on the oil immersion container; the driving mechanism is used for driving the oil immersion container to move vertically, so that the transformer on the operating panel is immersed with oil. According to the invention, the driving mechanism controls the oil immersion container to vertically move, so that the transformer placed on the operating panel is immersed with oil and pins of the transformer are not contacted with insulating oil, as a result, the oil immersion effect is excellent, the product percent of pass is high, and the treatment efficiency of the device is high.

Owner:安徽润诚机电有限公司

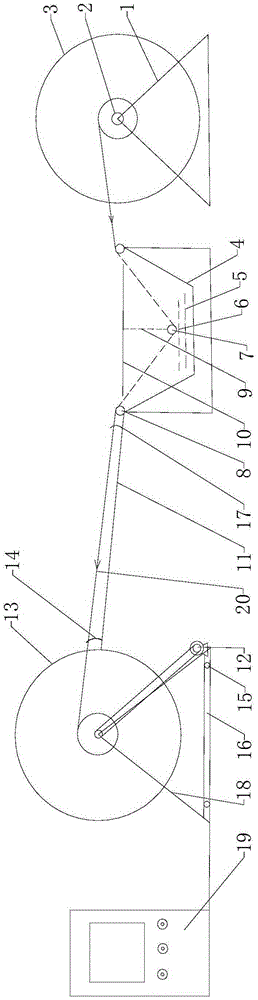

Lipophilic felt base cloth and production method thereof

InactiveCN108085873AImprove permeabilityImprove oil immersion effectSpinning head liquid feederArtificial thread manufacturing machinesPolyesterCrystallization

The invention discloses a lipophilic felt base cloth and a production method thereof. The production method comprises the following steps: successively carrying out crystallization and drying, screw extruding, melt filtering, spinning, cooling, drafting, wire placement and net pavement, needling reinforcement, hot rolling and chemical glue dipping and drying on polyester chips. Based on the totalweight of a glue solution, the glue solution for chemical glue dipping and drying comprises 6-8wt% of acrylate, 90-93wt% of water and 1-2wt% of a curing agent. The invention provides a production method of the brand-new lipophilic felt base cloth. According to the production method of the brand-new lipophilic felt base cloth, an acrylate solution which contains the curing agent is selected to be used as the glue solution to prepare the lipophilic felt base cloth, thus, the prepared lipophilic felt base cloth has good oil immersion property, and the problems that in a follow-up coiled materialproduction process, oil immersion uniformity of a coiled material is slightly poor, and the production efficiency is low are solved.

Owner:滁州天鼎丰非织造布有限公司

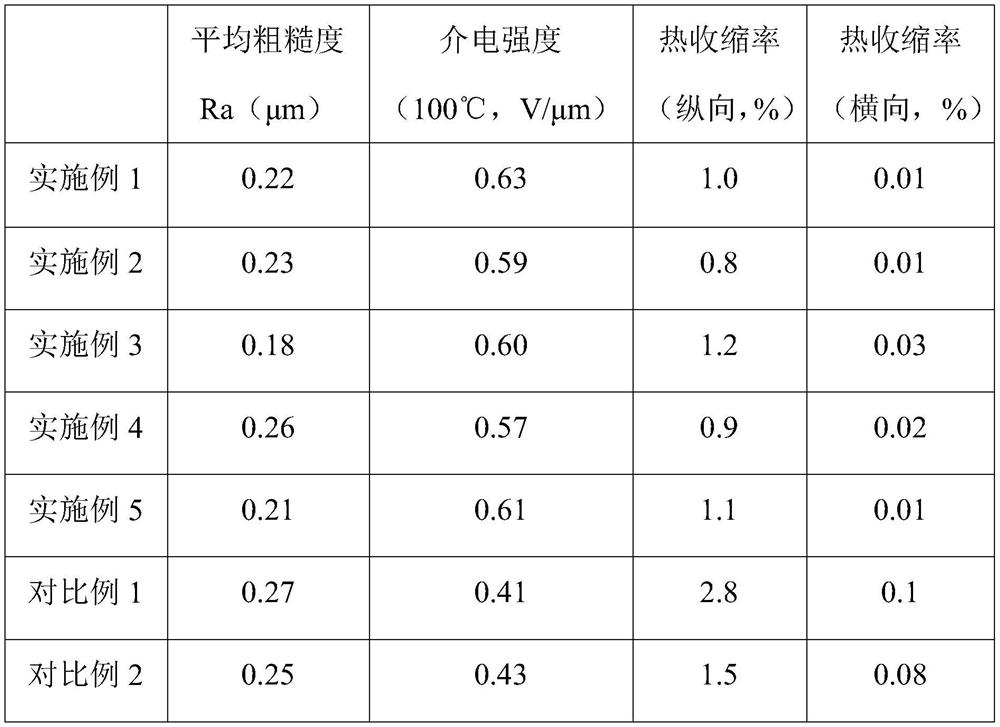

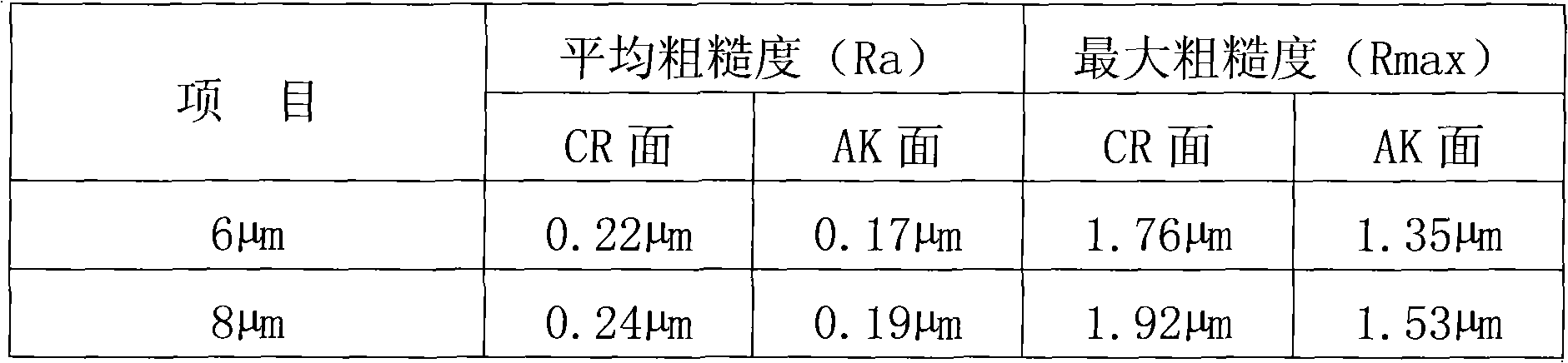

Biaxially oriented polypropylene film for capacitor

PendingCN114179341AImprove oil immersion effectMeet the requirements of withstand voltage under high field strengthSynthetic resin layered productsElectrical equipmentPolymer sciencePlasticulture

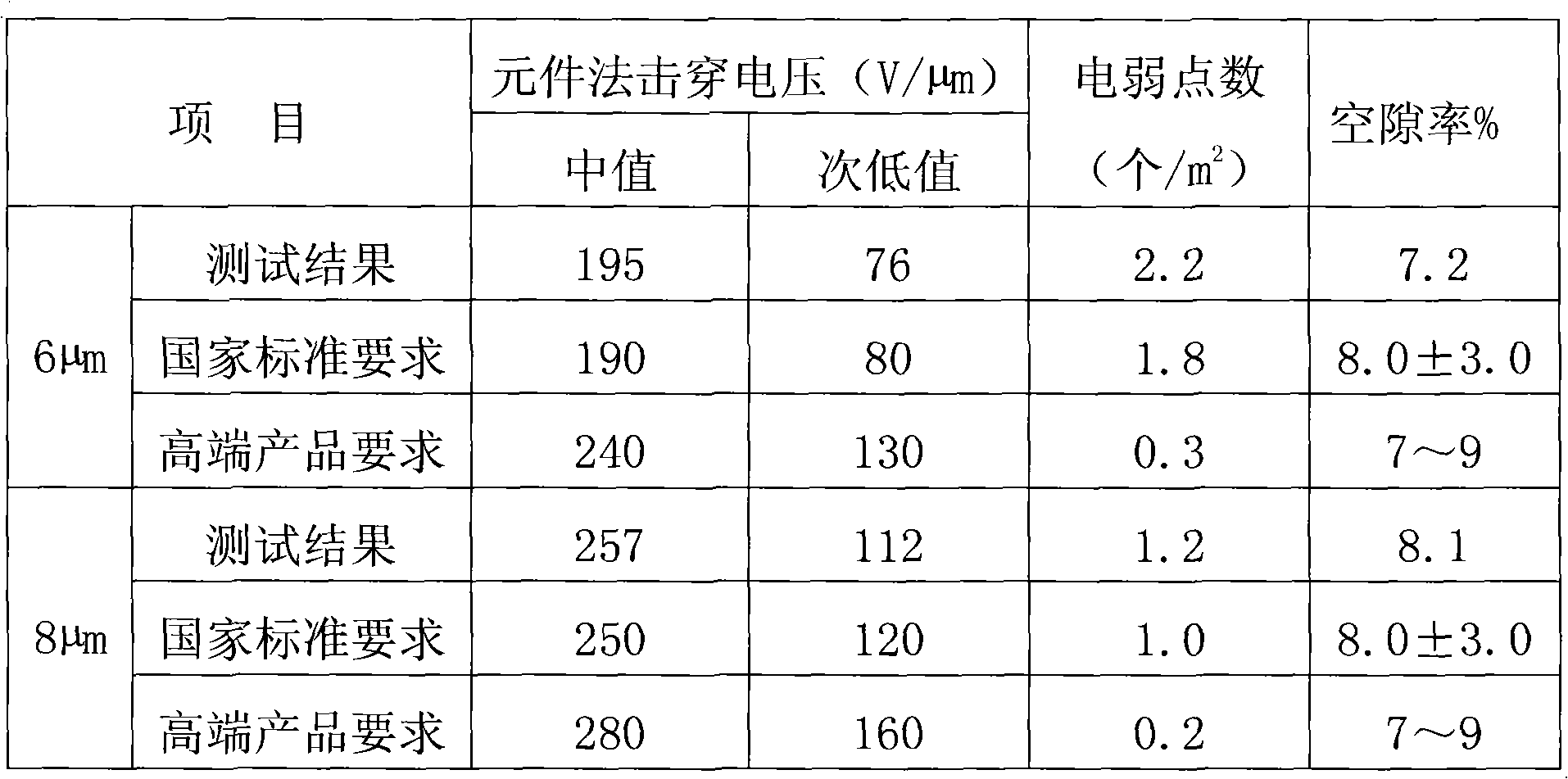

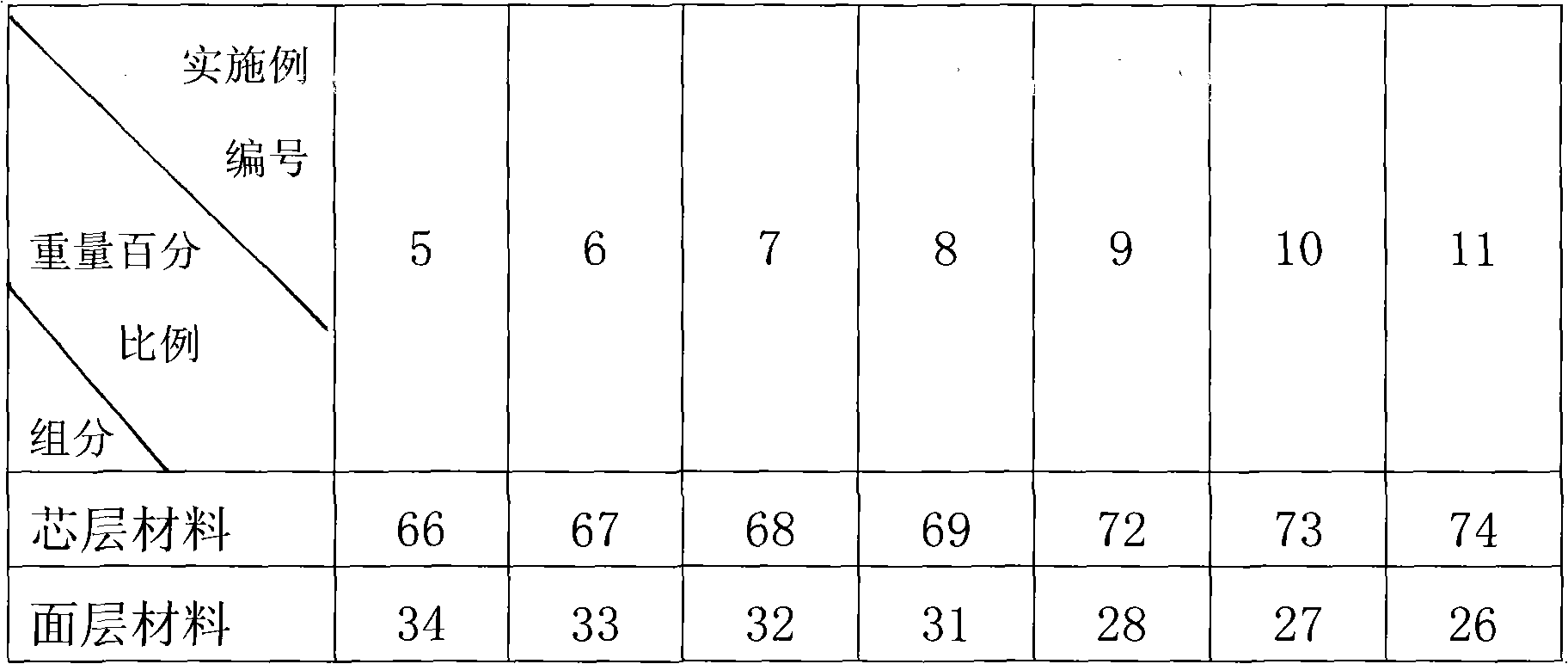

The film comprises an upper surface layer, a middle layer and a lower surface layer, and is prepared by the following steps: respectively feeding polypropylene resin A serving as a middle layer raw material and polypropylene resin B serving as a surface layer raw material into a main extruder and an auxiliary extruder for melting and plasticizing; extruding through a three-runner composite die head to obtain flaky fluid; the obtained sheet fluid is subjected to casting forming through a chilling roller and a high-pressure air knife, longitudinal stretching and transverse stretching are sequentially conducted through a longitudinal stretching machine and a transverse stretching machine, and the biaxially stretched polypropylene film for the capacitor is obtained. The polypropylene film provided by the invention is used in a capacitor, can meet the oil immersion requirement, and can also meet the electrical performance index requirements such as breakdown voltage and the like.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

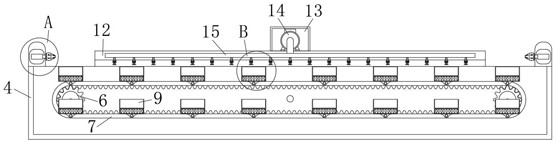

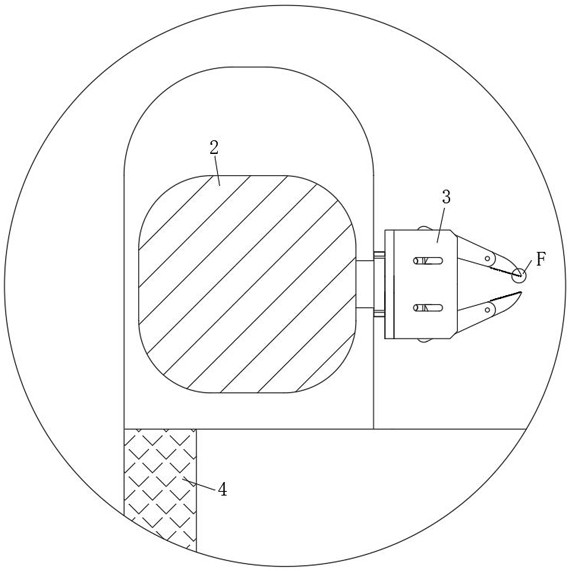

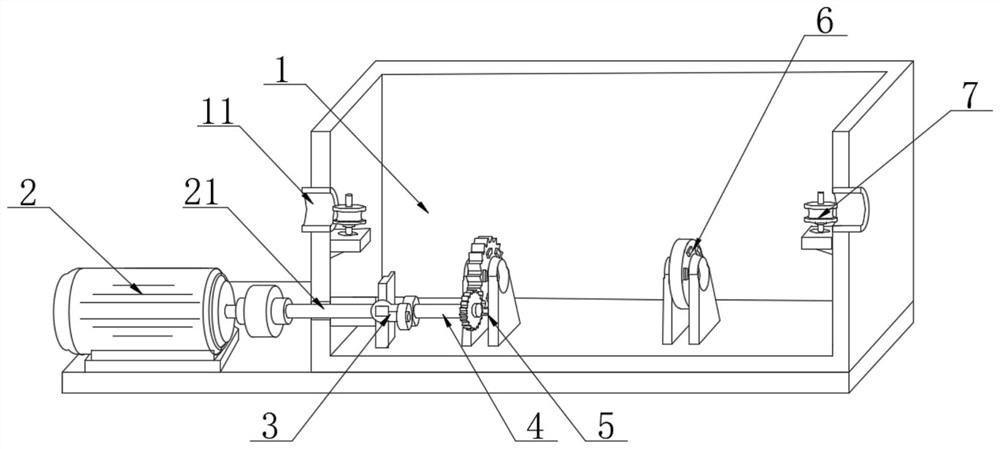

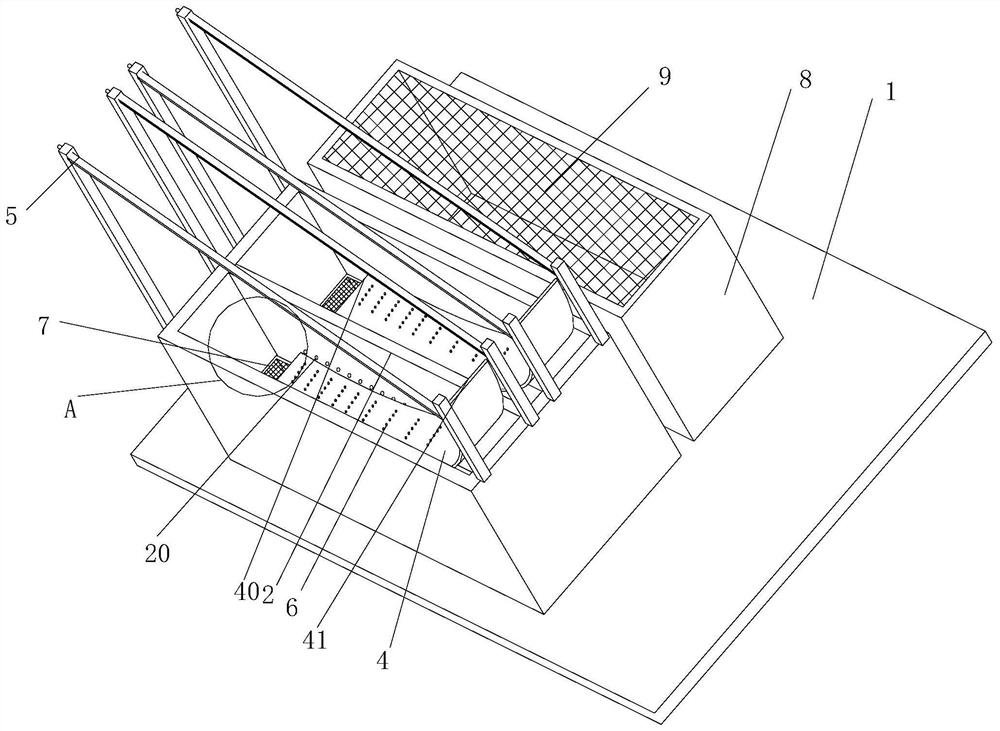

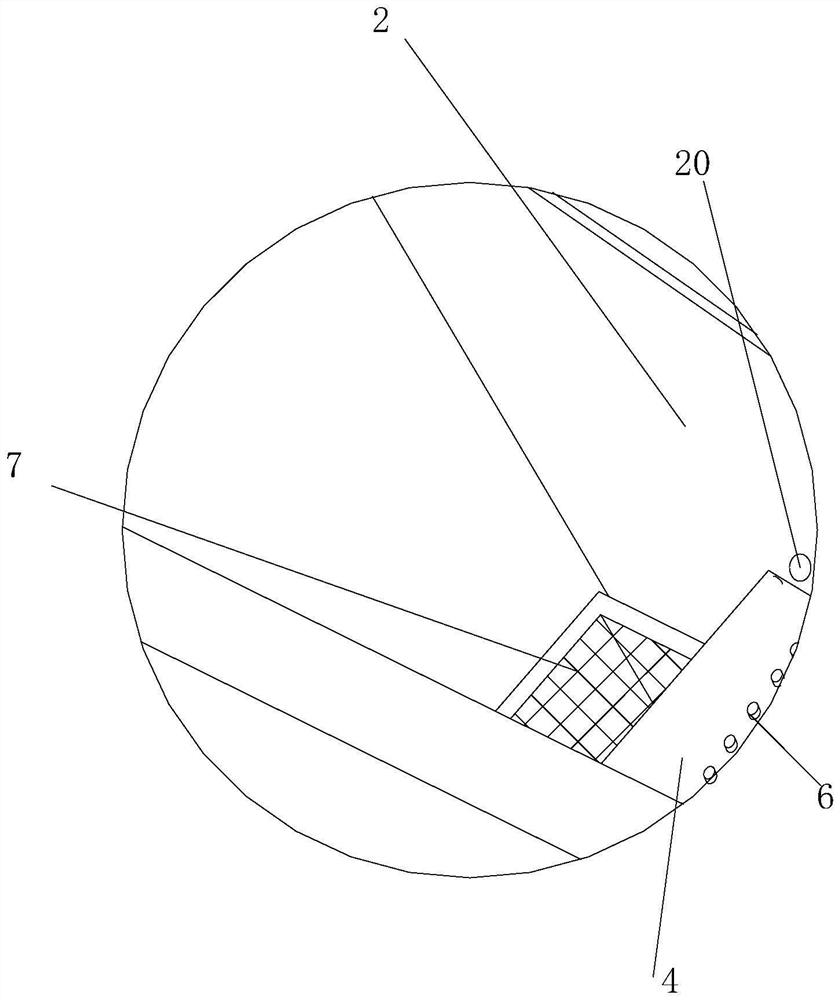

Full-automatic energy-saving type steel wire rope oil immersing machine

The invention provides a full-automatic energy-saving type steel wire rope oil immersing machine which comprises a disc to be subjected to oil immersion, an active oil immersing disc, an oil pool, a transmission device and a heating device. The disc to be subjected to oil immersion and the active oil immersing disc are distributed on the two sides of the oil pool respectively, and a steel wire rope released from the disc to be subjected to oil immersion is subjected to oil immersion of the oil pool and then wound on the active oil immersing disc. The transmission device comprises a speed adjusting motor installed on the active oil immersing disc, and drives the active oil immersing disc to rotate to pull the oil immersing steel wire rope to pass through the interior of the oil pool, and the heating device is installed at the bottom of the oil pool to heat oil. When the machine is used for carrying out the oil immersing work of the steel wire rope, the oil cannot be wasted, pollution is avoided, energy consumption is small, consumed electricity is little, the heat preservation effect is good, only one person is needed in the whole operation process, and the labor intensity is low; a rope core is included in a rope body, adsorption is full, the effect is good, efficiency is high, high durability is achieved, quality is stable, the service life of the steel wire rope can be prolonged, operation is convenient and safe, and cost is reduced.

Owner:STATE GRID CORP OF CHINA +1

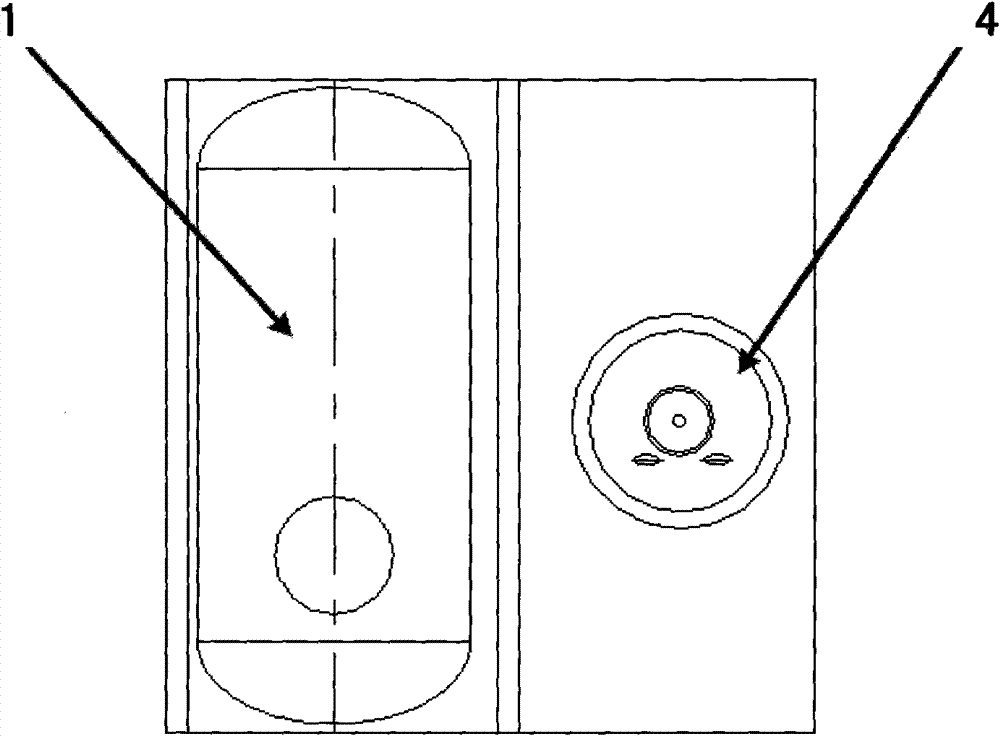

Improved gear oil immersion equipment

InactiveCN103977931AReduce labor intensityReasonable structureLiquid surface applicatorsCoatingsUltimate tensile strengthGear oil

The invention relates to oil immersion equipment of automobile parts, and particularly relates to improved gear oil immersion equipment. According to the adopted technical scheme, the improved gear oil immersion equipment comprises an oil tank and a bracket for supporting the oil tank, wherein the oil tank can move up and down along the bracket, a shelf for storing gears is arranged above the oil tank, and a driving device for driving the oil tank to move up and down is arranged below the oil tank and consists of a cylinder A and a cylinder arm A. The cylinder arm A is contacted with the bottom of the oil tank, a cylinder B and a cylinder arm B are arranged on one side of a tank body, an output end of the cylinder arm B is connected with an oil dripping plate, and a notch for the oil dripping plate to pass through is formed in a part where the oil tank corresponds to the oil dripping plate. The improved gear oil immersion equipment has the advantages of being reasonable in structure, convenient and practical, safe and reliable, good in oil immersion effect, and capable of lowering the labor intensity of workers and improving the working efficiency.

Owner:TAIZHOU AIGUO MACHINERY

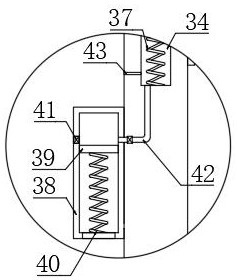

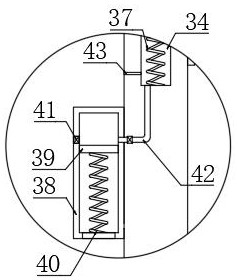

Automatic oil immersion device for automobile part production

InactiveCN112827742AImprove oil immersion effectAchieve jitterLiquid surface applicatorsCoatingsElectric machineryOil filter

The invention provides an automatic oil immersion device for automobile part production, and belongs to the technical field of automobile part production. The automatic oil immersion device comprises a bottom box, an oil storage tank and an oil filtering tank are formed in the upper part of the bottom box, and a conveying assembly for conveying automobile parts into the oil storage tank is arranged on the side, away from the oil filtering tank, of the oil storage tank on the upper part of the bottom box; a second support is fixedly arranged on the upper portion of the bottom box, a rotating wheel is rotationally arranged on one side of the second support through a rotating shaft and located above the oil storage tank, and a plurality of pushing assemblies are fixedly arranged on the circumferential side wall of the rotating wheel; and one end of the rotating shaft is connected to an external motor. The automatic oil immersion device has the advantages of being simple in structure, convenient to use and good in oil immersion effect; a screen plate is driven to rotate through a partition assembly, shaking of the screen plate is achieved in cooperation with a reset assembly, then automobile parts located in oil liquid are driven to be dispersed, so that the automobile parts make full contact with the oil liquid, the oil immersion effect of the automobile parts is improved, and comprehensive and uniform oil immersion of the automobile parts is realized.

Owner:范小伟

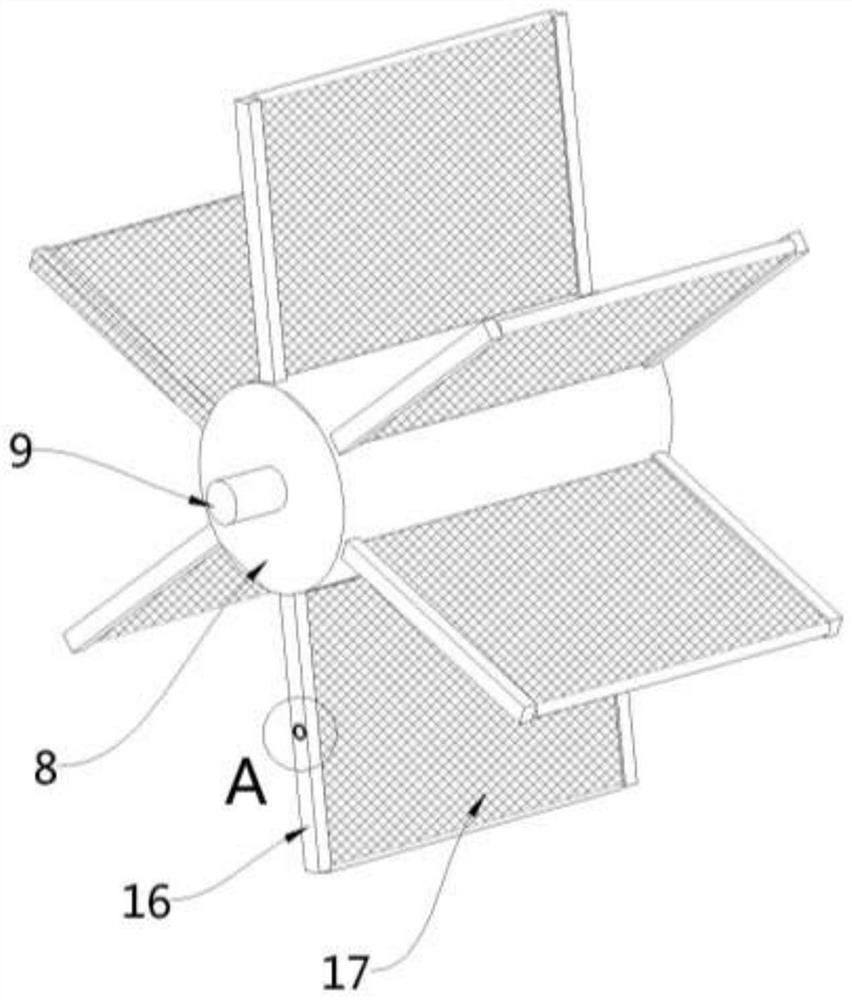

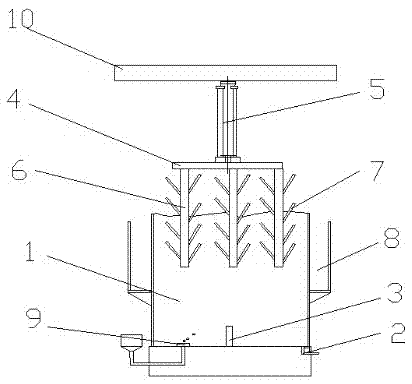

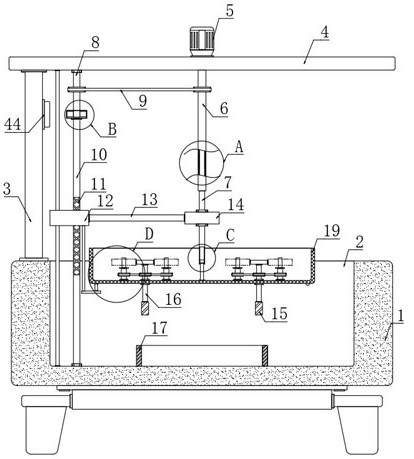

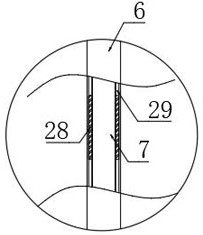

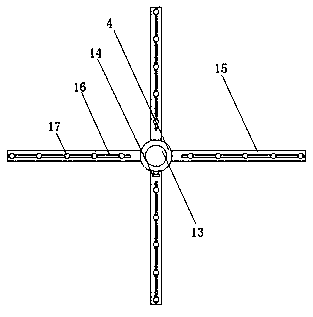

Oil immersion machine

InactiveCN109290121AIncrease production costReduce manufacturing costPretreated surfacesCoatingsPulp and paper industryMultiple layer

The invention relates to the technical field of workpiece oil immersion, in particular to an oil immersion machine. The oil immersion machine comprises a lifting mechanism arranged on the top part, arotating mechanism, an oil immersion groove formed in the bottom part, an air blowing mechanism, an observation window, and a rack for supporting the whole oil immersion machine, wherein the rotatingmechanism comprises a long shaft penetrating through the middle part of the oil immersion machine from top to bottom; multiple layers of pothooks are longitudinally arranged on the long shaft, and areused for placing workpieces to be cleaned; and the air blowing mechanism comprises an air knife and an air pump. According to the oil immersion machine, the rotating mechanism is arranged and is provided with the liftable long shaft, the long shaft can rotate, in short, the oil immersion machine is provided with a coaxial lifting and rotating mechanism, and oil immersion and air blowing operationcan be accomplished in one machine, so that the production efficiency is greatly improved; and the oil immersion machine has the characteristics of low production cost, fast oil immersion speed, goodoil immersion effect, convenience in use, attractive appearance, reasonable structure, long service life and the like, and is the ideal oil immersion equipment.

Owner:苏州司达夫超声科技有限公司

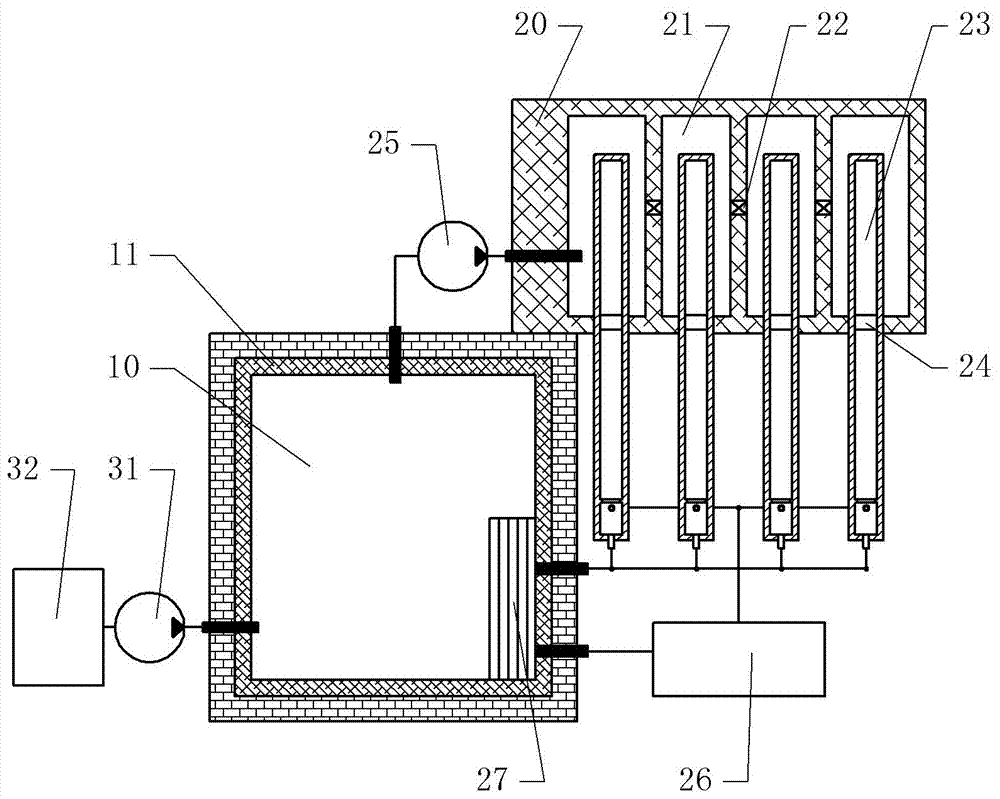

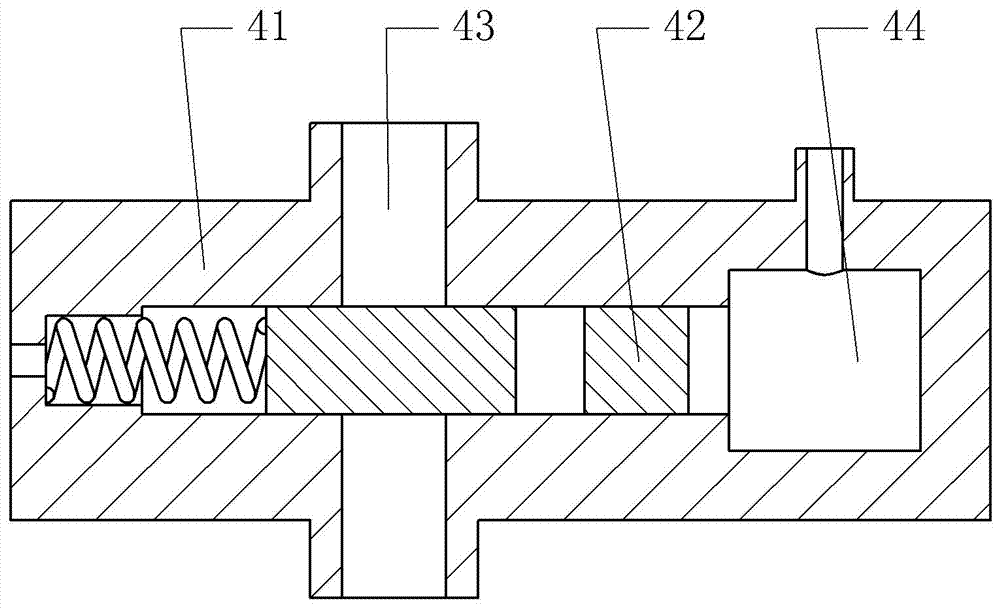

Gear oil immersing device of improved structure

InactiveCN107127104AControl oil immersion timeImprove oil immersion effectLiquid surface applicatorsCoatingsLiquid stateUltimate tensile strength

The invention relates to an oil immersing device, in particular to a gear oil immersing device of an improved structure. According to the technical scheme, the gear oil immersing device of the improved structure comprises an oil immersing tank for accommodating liquid-state infiltration oil; a liquid drain pipe is arranged at the bottom of the oil immersing tank; an electric heating pipe is arranged in the center in the oil immersing tank; a rail plate is arranged over the oil immersing tank; a pressing cylinder capable of driving the rail plate to enter the oil immersing tank is mounted on the rail plate; the other end of the pressing cylinder is fixed through a fixed frame; multiple vertical brackets are arranged below the rail plate; and multiple hanging frames are arranged on the vertical brackets at intervals in a upward slanting mode. The gear oil immersing device of the improved structure has the following advantages that the gear oil immersing device is reasonable in structure, high in automation degree and high in working efficiency, facilitates reduction of the working intensity of workers, and improves the product quality.

Owner:TAIZHOU XINGHUA GEAR MFG CO LTD

Automobile brake pad steel backing oil immersion device

InactiveCN108838024AReduce wasteAvoid the effects of oil immersionLiquid surface applicatorsCoatingsDrive shaftFuel tank

The invention discloses an automobile brake pad steel backing oil immersion device. The automobile brake pad steel backing oil immersion device comprises a sealing cover, a rotating drum, an oil immersion cylinder, oil immersion rods, a rotating disk, an oil storage tank, an oil pump and a separating sleeve; the oil immersion cylinder is fixed to the top of the oil storage tank through a bracket;one end of the oil immersion cylinder is connected with the sealing cover; a mechanical seal is arranged in the middle of the sealing cover; a driving shaft is erected in the mechanical seal; the inner end of the driving shaft is connected with the rotating drum; and the multiple oil immersion rods are welded to the outer side of the rotating drum circumferentially. Connected automobile brake padsteel backings are separated through the separating sleeve, the situation that oil immersion of the automobile brake pad steel backings is affected due to the fact that the adjacent automobile brake pad steel backings are closely attached is avoided, the automobile brake pad steel backings can be subjected to oil immersion in batch, the oil immersion effect is good, oil immersion is complete, excess oil can be removed, the quality of oil immersion is improved, waste of oil is reduced, and the cost of oil immersion is lowered.

Owner:YANCHENG LICHENG AUTO PARTS CO LTD

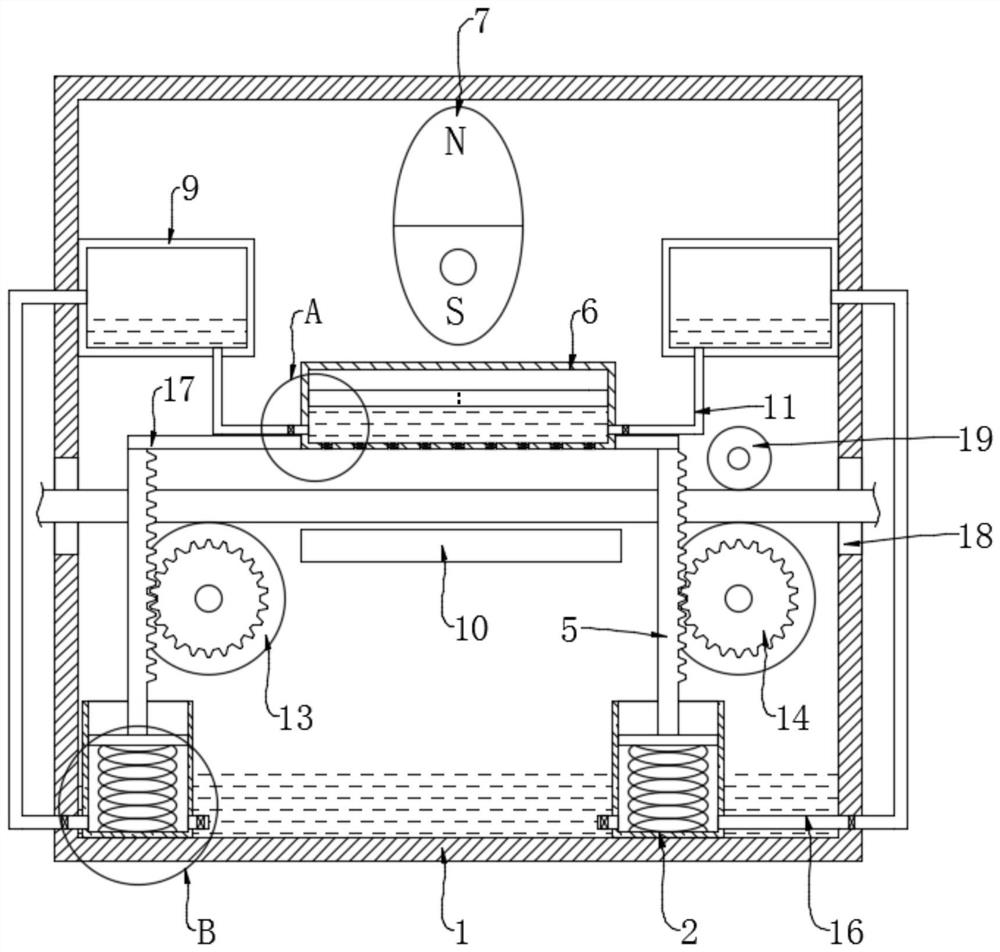

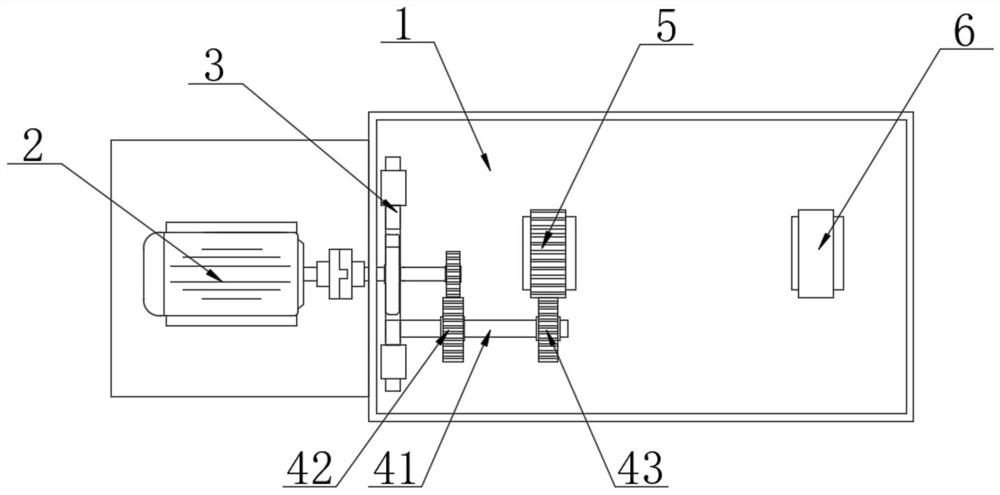

Automatic oil immersion device for fittings for machining

InactiveCN111804503AImprove oil immersion effectStrong oil immersion effectLiquid surface applicatorsCoatingsGear wheelMachining

The invention provides an automatic oil immersion device for fittings for machining, and belongs to the technical field of machining equipment. The automatic oil immersion device comprises an oil storage tank and a fitting containing component arranged above the oil storage tank, wherein a through opening is arranged in the upper wall of the oil storage tank, and a driving component for driving the fitting containing component to move from the through opening to the interior of the oil storage tank is arranged on the upper part of the oil storage tank; the fitting containing component comprises a containing outer box and a containing inner box arranged at the inner side of the containing outer box; each of the containing outer box and the containing inner box is provided with an upper opening and a lower opening; a bottom plate is fixedly arranged at the bottom of the containing inner box; a cover plate is hinged to the upper part of the containing inner box; a first rotating rod is fixedly arranged on the side wall of the containing inner box; and the first rotating rod penetrates through the containing outer box and is connected to a first gear. The embodiment of the invention has the advantages of being convenient to use and good in oil immersion effect, and particularly has a stronger oil immersion effect for the fittings with relatively complex structures.

Owner:范翠英

Device for soaking parts in anti-rust oil

ActiveCN113369081AAvoid dripping situationsAvoid the hassle of post-cleaningPretreated surfacesCoatingsStructural engineeringMechanical engineering

The invention discloses a device for soaking parts in anti-rust oil. The device comprises a shell, two treatment grooves are symmetrically formed in the upper end of the shell, a net frame is arranged in each treatment groove, a mounting frame is mounted on the inner wall of each treatment groove, the lower end of each net frame is fixedly connected with a vertical rod, the lower end of each vertical rod is rotationally connected with the corresponding mounting frame, the lower end of each vertical rod penetrates through the corresponding mounting frame and is fixedly connected with a worm wheel, and a rotating rod is rotationally connected between the inner walls of the two sides of each treatment groove. According to the device, through the arrangement of the two net frames, oil draining and oil soaking can be achieved synchronously, the net frames do not need to be moved many times, the situation that oil attached to the net frames drips all around is avoided while the oil soaking step is optimized, the overall oil soaking and oil draining efficiency is further improved through the arrangement of fans, and therefore the effect of improving the overall machining efficiency is achieved.

Owner:南通豪派金属制品有限公司

Efficient oil immersion method for spinning frame

InactiveCN111691027AImprove work efficiencyImprove oil immersion effectTextiles and paperYarnSpinning

The invention discloses an efficient oil immersion method for a spinning frame. The efficient oil immersion method mainly comprises the following steps of S1, oiling; S2, material placing; S3, oil immersion; and S4, oil recovery. An efficient oil immersion device for the spinning frame comprises a tank body, a plurality of piston cylinders are symmetrically arranged on the inner bottom wall of thetank body, a piston plate is elastically connected into each piston cylinder through a spring, the upper end of each piston plate is connected with a toothed plate, the upper ends of the multiple toothed plates are jointly connected with a movable box through a fixing plate, a driving motor is mounted on the tank body, an output shaft of the driving motor extends into the tank body and is connected with a cam, the cam is located above the movable box, and a pressure bearing plate corresponding to the movable box is horizontally arranged in the tank body. According to the efficient oil immersion method, rough yarn is subjected to intermittent extruded oil immersion when conveyed section by section, so that the working efficiency and oil immersion effect of oil immersion of the rough yarn are greatly improved, meanwhile, mineral oil can be recycled, and waste of resources is avoided.

Owner:杨和萍

Spherical metal product surface anti-rust oil soaking device

ActiveCN113522635AImprove oil immersion effectHigh speedLiquid surface applicatorsCoatingsMetallurgyEngineering

The invention discloses a spherical metal product surface anti-rust oil soaking device which comprises a bottom plate. A mounting frame is mounted at the upper end of the bottom plate, a hydraulic telescopic rod is mounted at the lower end of the mounting frame, a connecting plate is fixedly connected to the telescopic end of the hydraulic telescopic rod, a first rotating rod is rotatably connected to the lower end of the mounting frame, a second rotating rod is rotatably connected to the lower end of the connecting plate, a placing frame is fixedly connected to the lower end of the second rotating rod, multiple placing grooves are formed in the upper end of the placing frame, and a rectangular guide groove is formed in the lower end of the first rotating rod. In the using process of the device, a metal ball and anti-rust oil are in a moving state, so that the oil immersion quality and effect are improved; in the process, the ball is still in a rolling state, so that the contact range of the ball and moving oil is larger and more uniform; and a structure for taking out impurities and chippings is further arranged, so that the oil immersion quality is further improved.

Owner:南通市力行机械制造有限公司

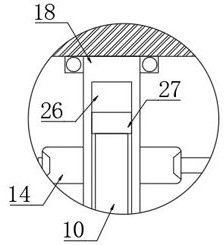

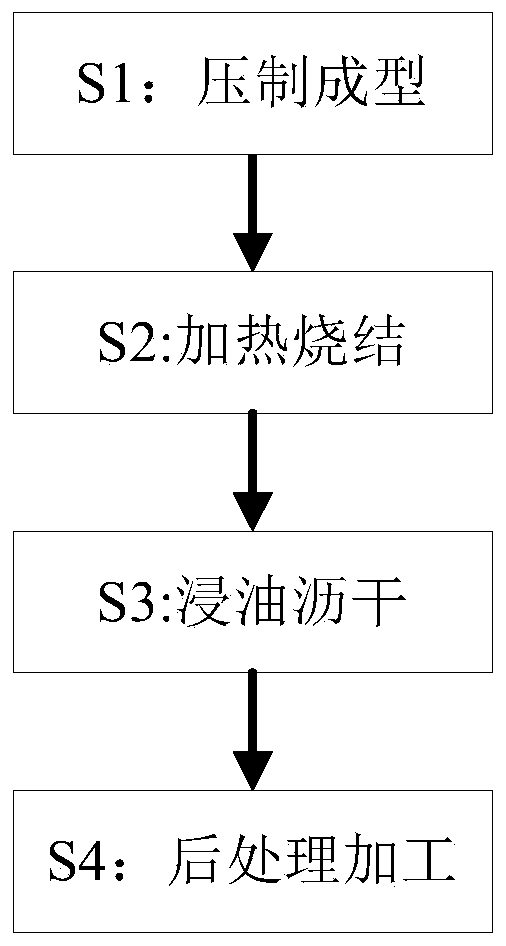

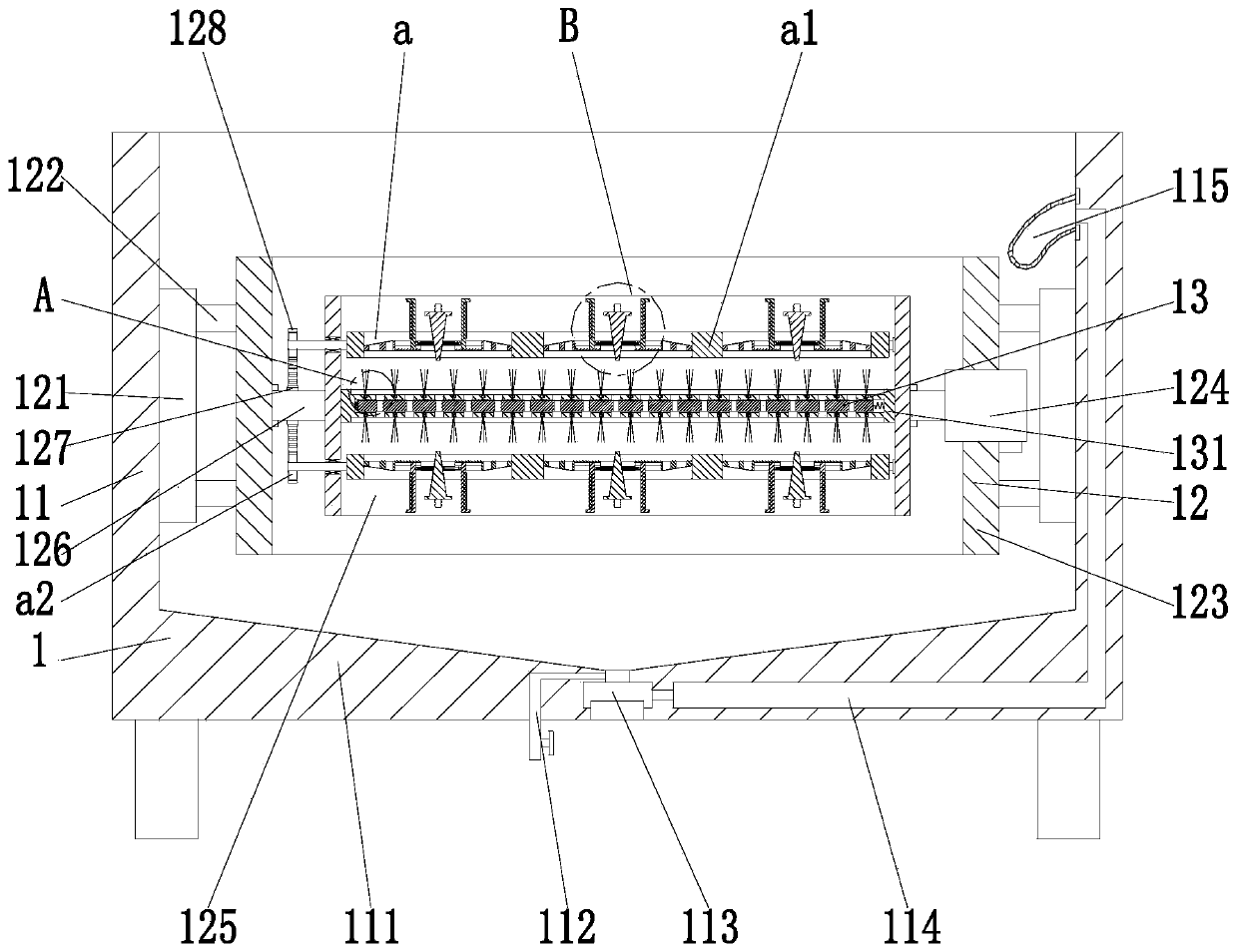

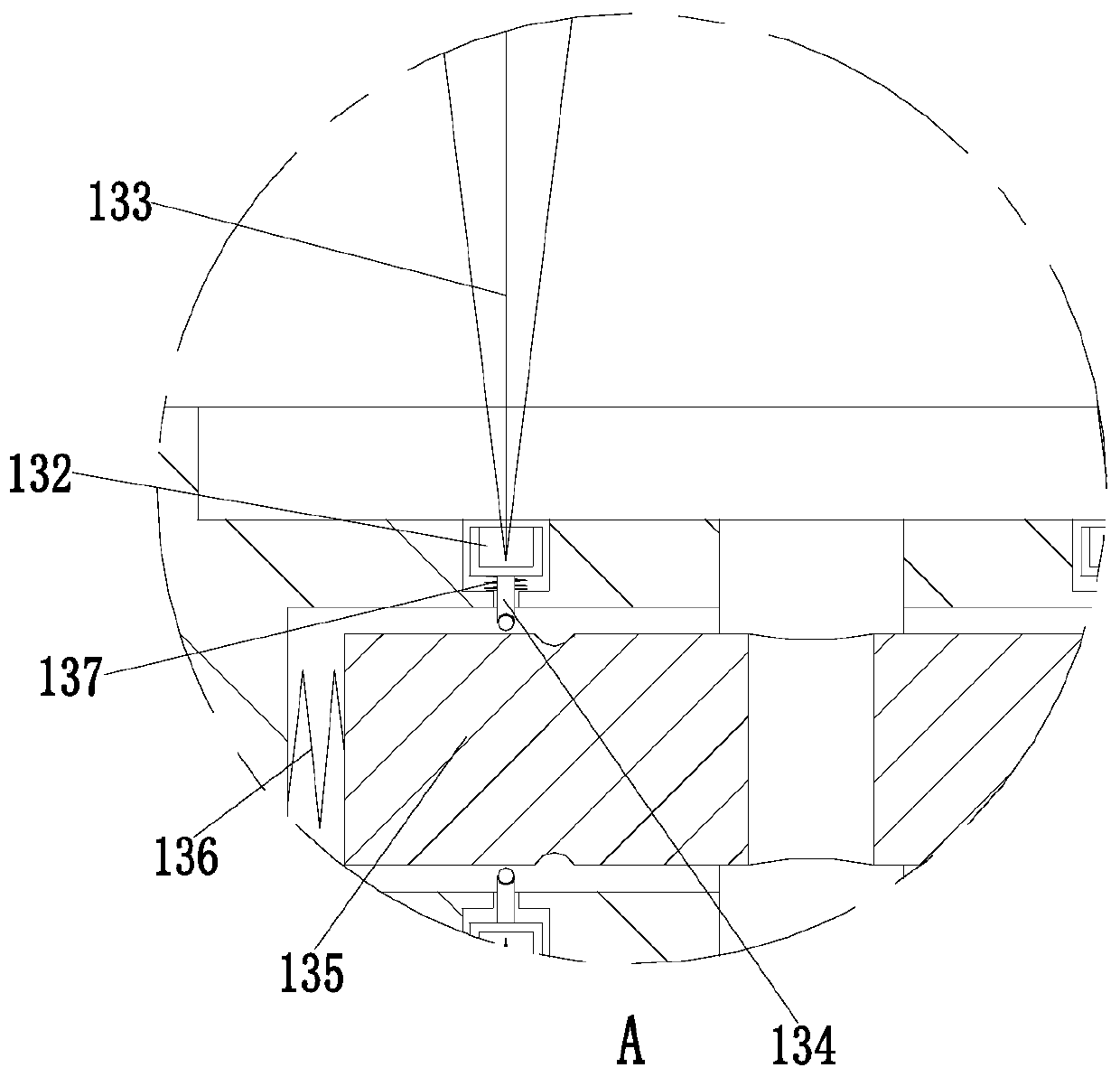

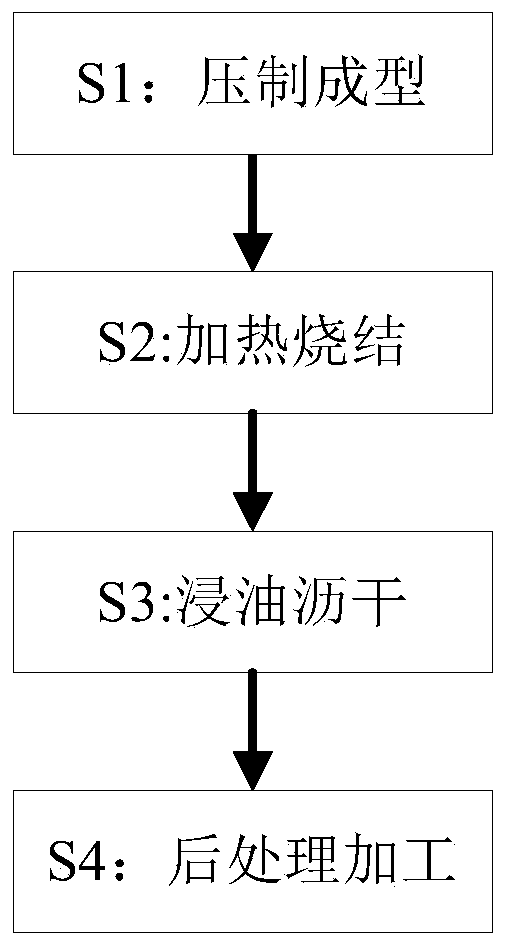

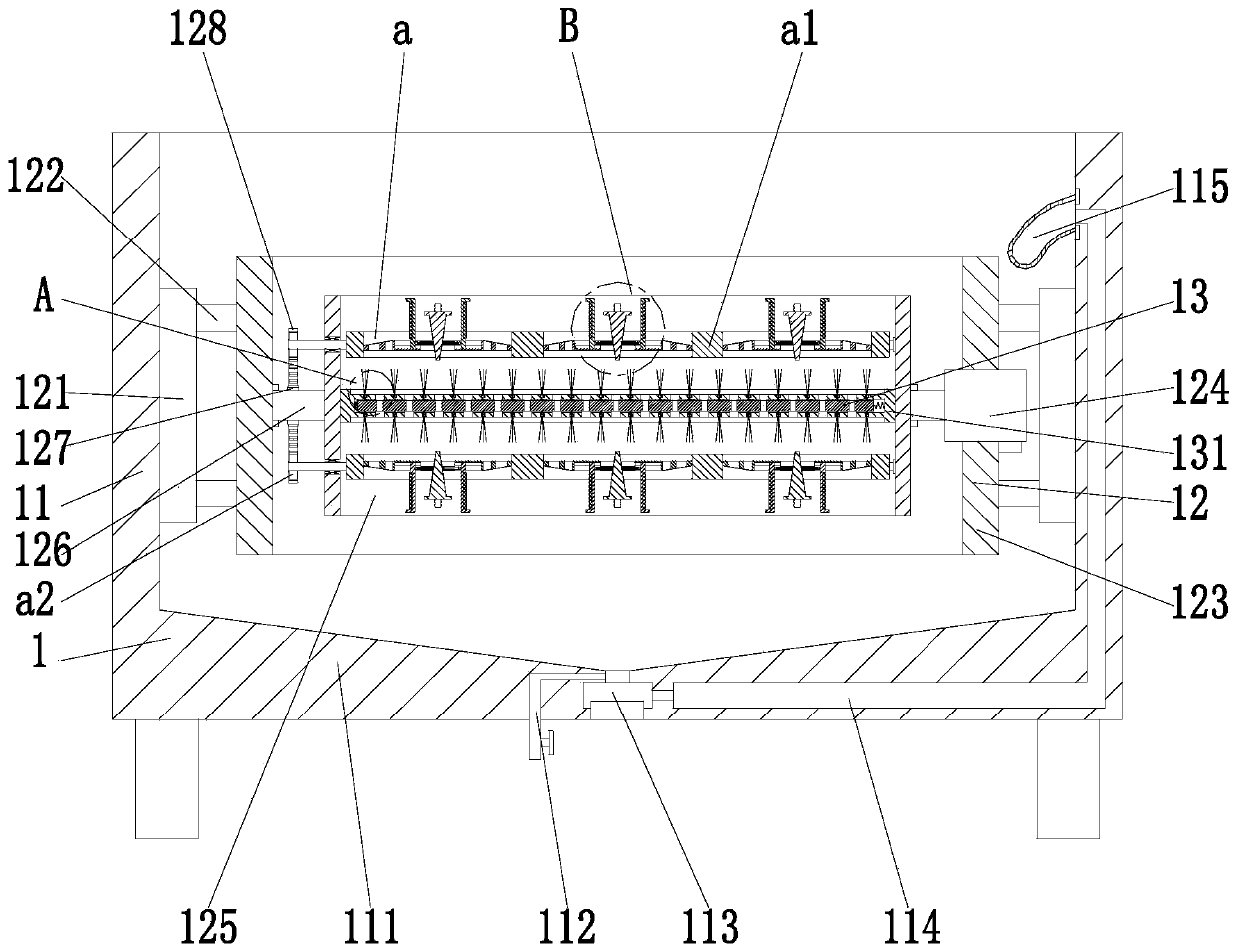

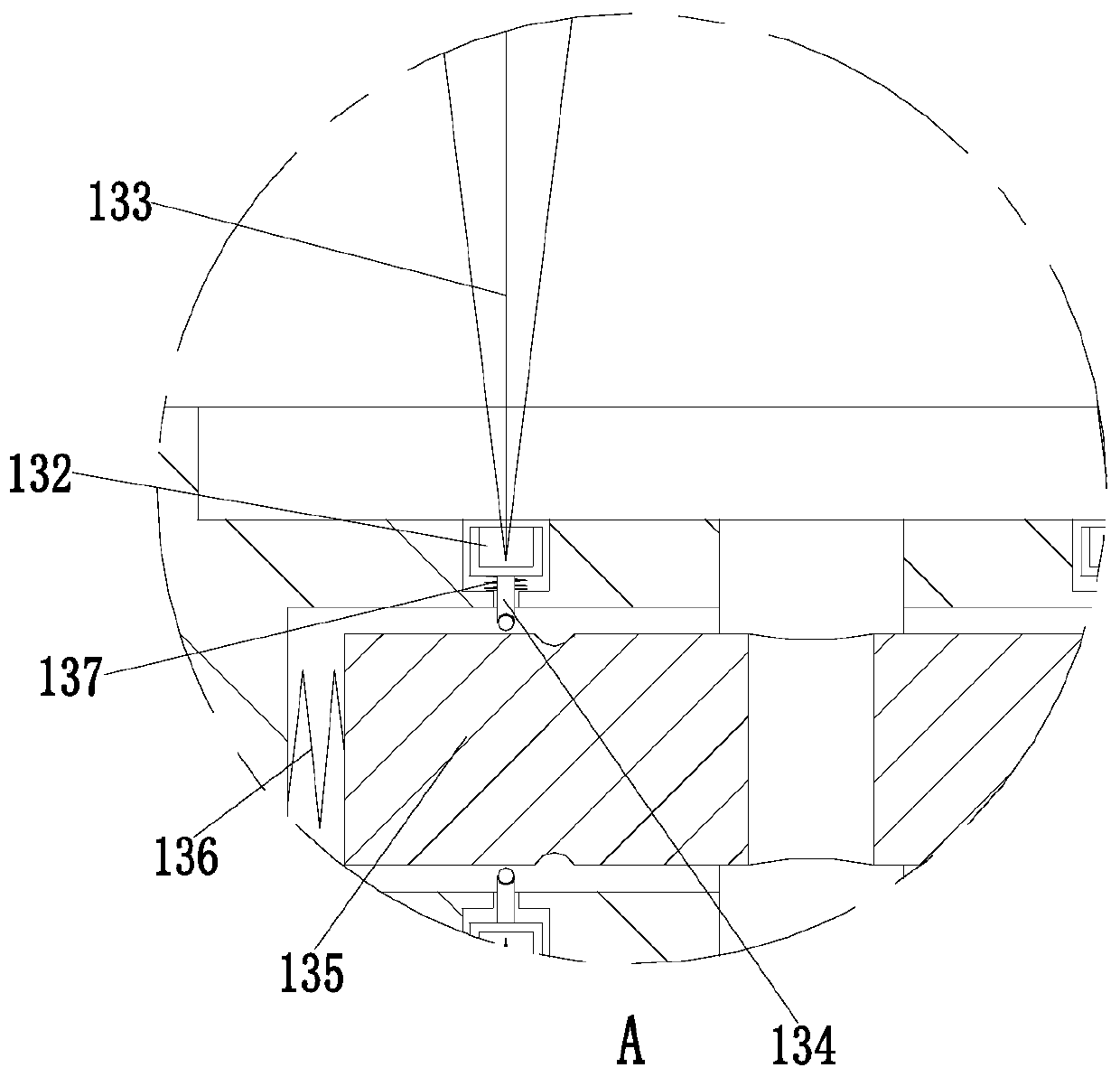

Manufacturing method for powder metallurgical gear

The invention provides a manufacturing method for a powder metallurgical gear. Manufacturing for the powder metallurgical gear is completed through the cooperation of a forming die, a vacuum sinteringfurnace, oil immersion equipment and the like; and the following problems are solved: the existing oil immersion for gears is mostly directly placing the pressed-formed gears in oil and carrying outimmersion, however, manual collision among the gears is easily caused by directly placing the gears in the oil, so that the outer walls of the gears are broken; moreover, solid particulate matters existing on the surfaces of the directly-placed gears are difficultly removed and easily mixed with the oil, so that the cleanliness degree of the oil is reduced, and the scratches of the outer walls ofthe gears are easily caused by the particulate matters in the oil; and moreover, the existing clamps for fixing the gears are low in practicability and incapable of fixing the gears with many hole diameters, and easily cause the damage of the gears in the process of fixing the gears.

Owner:圣航粉末冶金河北有限公司

Automatic oil immersion device for rope head of rope winding frame

PendingCN112474182AReduce dependence on experienceReduce manual involvementLiquid surface applicatorsCoatingsClassical mechanicsMechanical engineering

The invention discloses an automatic oil immersion device for a rope head of a rope winding frame. The automatic oil immersion device for the rope head of the rope winding frame comprises a supportingmechanism, a rope winding frame hanging mechanism, a rope head oil immersion mechanism and a position detection mechanism, wherein the rope head oil immersion mechanism comprises an oil immersion part and a driving part; the oil immersion part or the rope winding frame hanging mechanism is movably connected to the supporting mechanism, and the oil immersion part is positioned below the hanging part; the driving part is connected to the oil immersion part or the rope winding frame hanging mechanism and is used for driving the oil immersion part or the rope winding frame hanging mechanism to move, so that the distance between the oil immersion part and the rope winding frame hanging mechanism is reduced or reset; the oil immersion part is provided with an oil immersion groove; an opening ofthe oil immersion groove faces the hanging part; and the position detection mechanism is arranged on the supporting mechanism and is used for detecting whether the position of the position detectionmechanism and the liquid level position in the oil immersion groove reach a preset distance or not. The automatic oil immersion device for the rope head of the rope winding frame is good in oil immersion treatment effect, and the oil immersion quality among batches is stable.

Owner:广东康派环创科技有限公司

Bearing inner and outer ring synchronous oil immersion device for machining

ActiveCN113663865ASimplify the operation processReduce labor intensityLiquid surface applicatorsCoatingsPhysicsEngineering

The invention discloses a bearing inner and outer ring synchronous oil immersion device for machining. The device comprises a shell, wherein an oil immersion groove is formed in the upper end of the shell, a vertical plate is fixedly connected to the upper end of the shell, a transverse plate is installed at the upper end of the vertical plate, a motor is installed at the upper end of the transverse plate, the tail end of an output shaft of the motor penetrates through the transverse plate, the motor is fixedly connected with a rotating pipe, a first rotating rod is arranged below the rotating pipe, the upper end of the first rotating rod extends into the rotating pipe, a second rotating rod is arranged below the first rotating rod, and a rectangular sliding cavity is formed in the first rotating rod. According to the oil immersion device, on the basis that a good oil immersion effect is achieved, the operation process is simplified, the labor intensity of workers is reduced, and meanwhile in the oil throwing process, the good oil throwing effect is achieved through cooperation of a shaking structure and centrifugal force.

Owner:南通腾华新材料科技有限公司

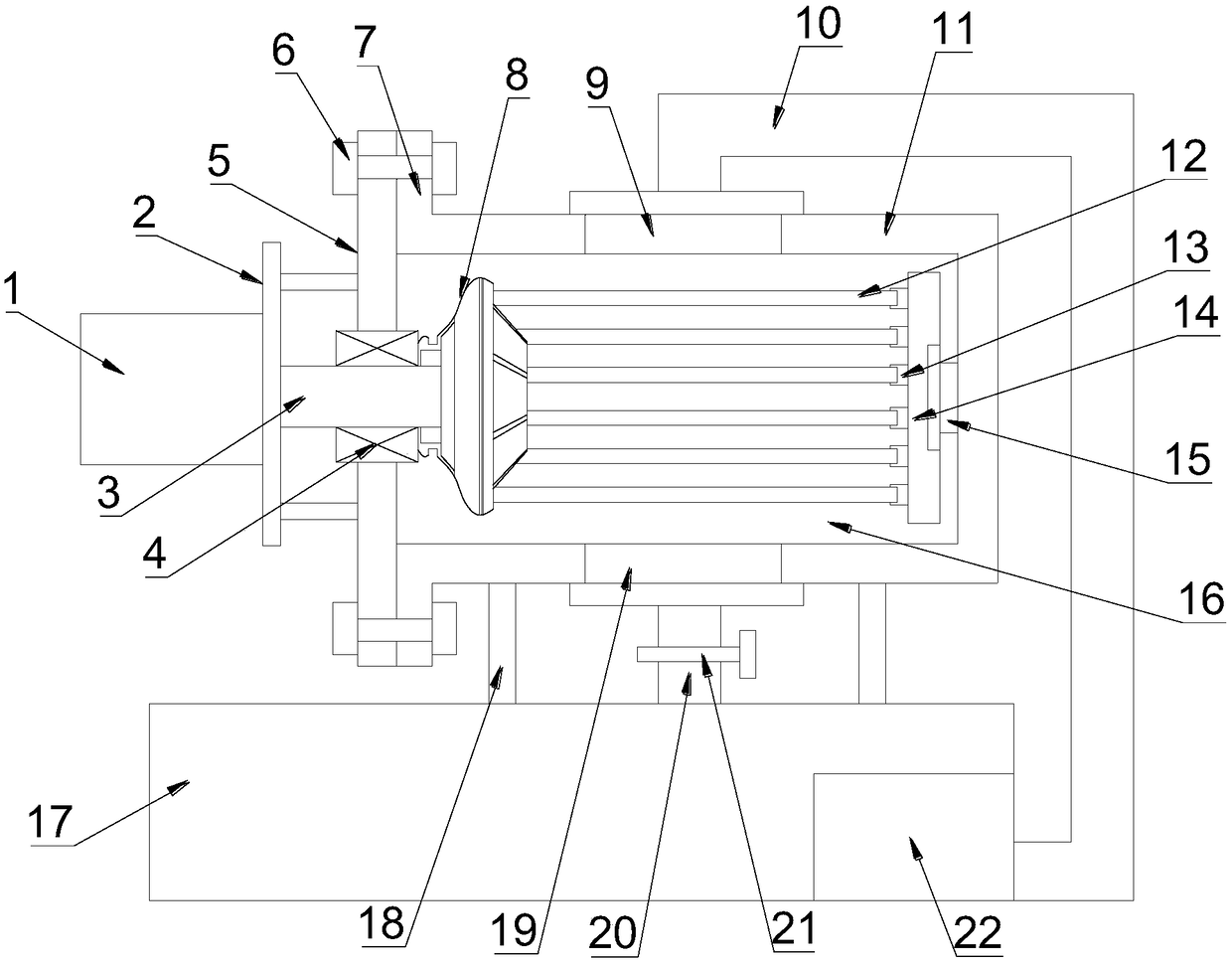

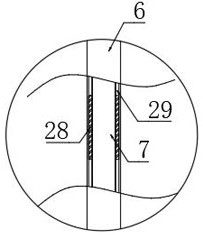

Extrusion-type efficient oil immersion equipment for spinning

InactiveCN112048855AImprove oil immersion effectFast absorptionTextile treatment machine arrangementsTextile treatment by spraying/projectingInterference fitGear wheel

The invention discloses extrusion-type efficient oil immersion equipment for spinning. The extrusion-type efficient oil immersion equipment comprises an oil immersion cylinder; a motor is fixedly installed on the side wall of the oil immersion cylinder, an output shaft of the motor penetrates through the side wall of the oil immersion cylinder and is fixedly connected with a rotating rod through acoupling, and the end, away from the motor, of the rotating rod is rotationally connected with the inner side wall of the oil immersion cylinder through a bearing; a driving gear and a plurality of cams are arranged on the rotating rod in an interference fit mode, the driving gear is a half gear, the driving gear is located in the middle of the rotating rod, the multiple cams are symmetrically distributed on the two sides of the driving gear, a permanent magnet block is embedded in the edge of each cam, and a cover plate is fixedly arranged on the oil immersion cylinder; and a fixed plate anda plurality of extrusion side plates are fixedly arranged on the lower surface of the cover plate through a mounting plate, a driven gear is rotationally mounted on the fixed plate, and the driven gear is engaged with the driving gear. The structure of a hemp thread can be converted to be tightened or loosened, and the oil immersion efficiency of the hemp thread is improved in an intermittent pressurizing mode.

Owner:王鹏

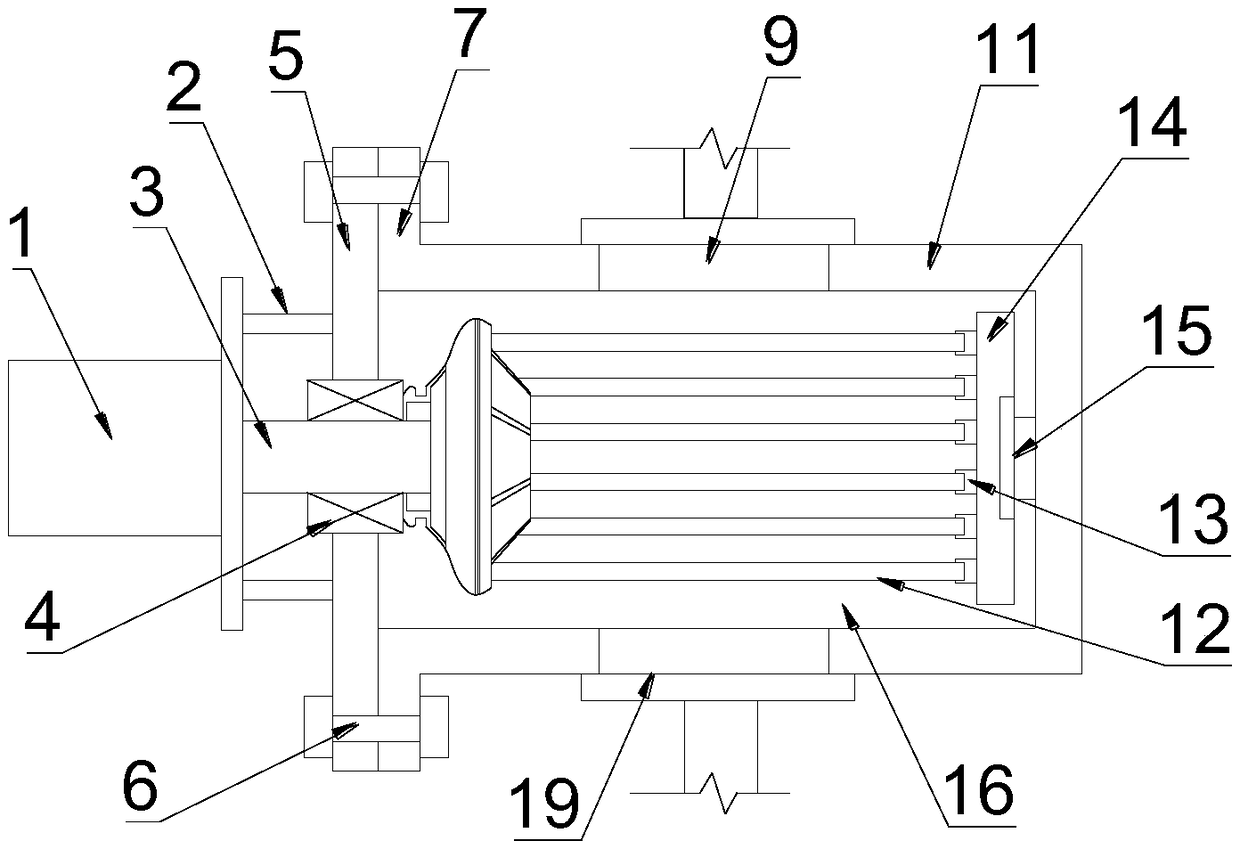

Oil immersion rust prevention device for motor stator machining and operation method thereof

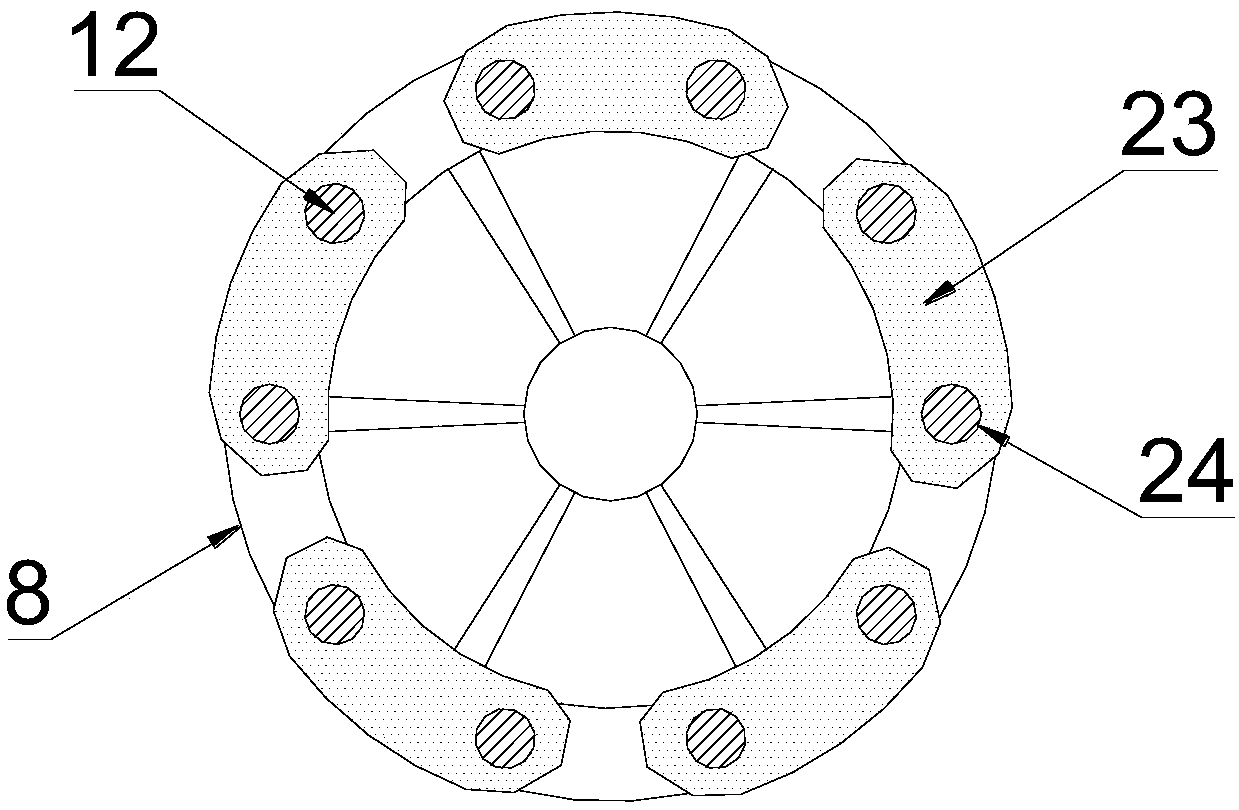

PendingCN108745768AAdequate drainageImprove oil immersion effectLiquid surface applicatorsCoatingsRotational axisBiochemical engineering

The invention discloses an oil immersion rust prevention device for motor stator machining. The oil immersion rust prevention device comprises an oil tank, an ejection plate, an air cylinder, an installing ring, a motor and a rotating shaft; and the oil immersion rust prevention device is characterized in that the oil tank is arranged on a support, a vertical plate is arranged on the top of the oil tank, the ejection plate is arranged on the vertical plate, the air cylinder is arranged on the vertical plate and is provided with a power line and a piston rod, the installing ring is arranged onthe piston rod through a fastening bolt, a fixing plate is arranged on the installing ring, the motor is arranged on the side wall of the oil tank, the power line is arranged on the motor, one end ofthe rotating shaft is arranged in a bearing, the other end of the rotating shaft is connected with the motor, and a stirring plate is arranged on the rotating shaft. By means of the oil immersion rustprevention device, a through groove is formed in the fixing plate, a bearing rod is vertically arranged on the fixing plate, liquid in the oil tank conveniently flows to the position above the fixingplate from the position below the fixing plate through the through groove, liquid oil can be in sufficient contact with a motor stator, and the oil immersion effect of the motor stator is improved.

Owner:NANLING LIANG POWER TOOLS

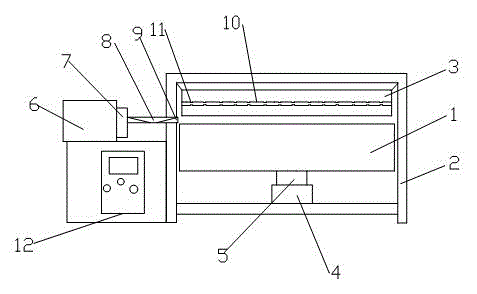

Energy-saving sintering furnace

The invention discloses an energy-saving sintering furnace, and relates to a heating device. The energy-saving sintering furnace comprises a furnace body, a heat preservation layer fixed to the innerwall of the furnace body, a heating device and a cooling device, wherein the heating device is arranged in the furnace body. The cooling device comprises a transition box, an air pump and a cooling part, wherein the furnace body is connected with the transition box through the air pump, the air inlet end of the air pump communicates with the furnace body, and the air outlet end of the air pump communicates with the transition box. The cooling part comprises a cylinder, a piston arranged in the cylinder and capable of sliding in the axial direction of the cylinder, and an evaporator fixed to the side wall of the furnace body and located in the furnace body. The cylinder is fixed to the transition box, one end of the cylinder is a heated end arranged in the transition box, and the other endof the cylinder is a compression end arranged outside the transition box. The heated end and the compression end are isolated through the piston, expandable liquid is arranged in the heated end, and arefrigerant is arranged in the compression end. The compression end communicates with the evaporator through a first pipeline, and the first pipeline is provided with a first pressure valve. The sintering furnace has an energy saving function.

Owner:CHONGQING HEHAI CARBON PROD

A device for immersing anti-rust oil on the surface of spherical metal products

ActiveCN113522635BImprove oil immersion effectHigh speedLiquid surface applicatorsCoatingsMetal sphereEngineering

The invention discloses a device for immersing the surface of a spherical metal product in antirust oil, which comprises a bottom plate. A connecting plate is connected, the lower end of the installation frame is rotatably connected with a first rotating rod, the lower end of the connecting plate is rotatably connected with a second rotating rod, the lower end of the second rotating rod is fixedly connected with a placement frame, and the placing The upper end of the frame is provided with a plurality of placement slots, and the lower end of the first rotating rod is provided with a rectangular guide slot. During the use of the device, the metal ball and the anti-rust oil are in motion, thereby increasing the quality and effect of oil immersion, and in this process, the ball is still in a rolling state, making it in contact with the moving oil The range is larger and more uniform, and a structure for removing impurities and debris is also provided to further improve the quality of immersion oil.

Owner:南通市力行机械制造有限公司

Oil immersion device for rotating shaft production and processing

ActiveCN114602721AExtended service lifeImprove oil immersion effectLiquid surface applicatorsCoatingsEngineeringMachining

Owner:DALIAN DEMAISHI PRECISION TECH CO LTD

Full oil immersing oil immersion device for automobile part

PendingCN112452640AEasy to take outImprove oil immersion effectLiquid surface applicatorsCoatingsElectric machineryMechanical engineering

The invention is applicable to the technical field of automobile part production, and provides a full oil immersing oil immersion device for an automobile part. The device comprises a supporting plateand a mounting column, wherein the lower end of the supporting plate is fixedly connected with a placement groove, the mounting column is mounted in a positioning groove, a motor fixedly connected with the upper surface of the supporting plate is arranged on the rear side of the mounting column, a limiting plate is mounted on the outer surface of the mounting column, a connecting block is arranged on the lower side of the limiting plate, a mounting block is mounted at the inner end of the connecting block, a limiting pin is arranged in the mounting block, a mounting plate is arranged on the lower side in the supporting plate, a motor is arranged in the mounting plate, and a rotary stirring rod is mounted at the upper end of the motor. According to the full oil immersing oil immersion device for the automobile part, a better oil immersion effect can be achieved conveniently, the use stability can be improved conveniently, and automobile parts can be better taken out conveniently.

Owner:泰州硕甫机械科技有限公司

A method for manufacturing powder metallurgy gears

Owner:圣航粉末冶金河北有限公司

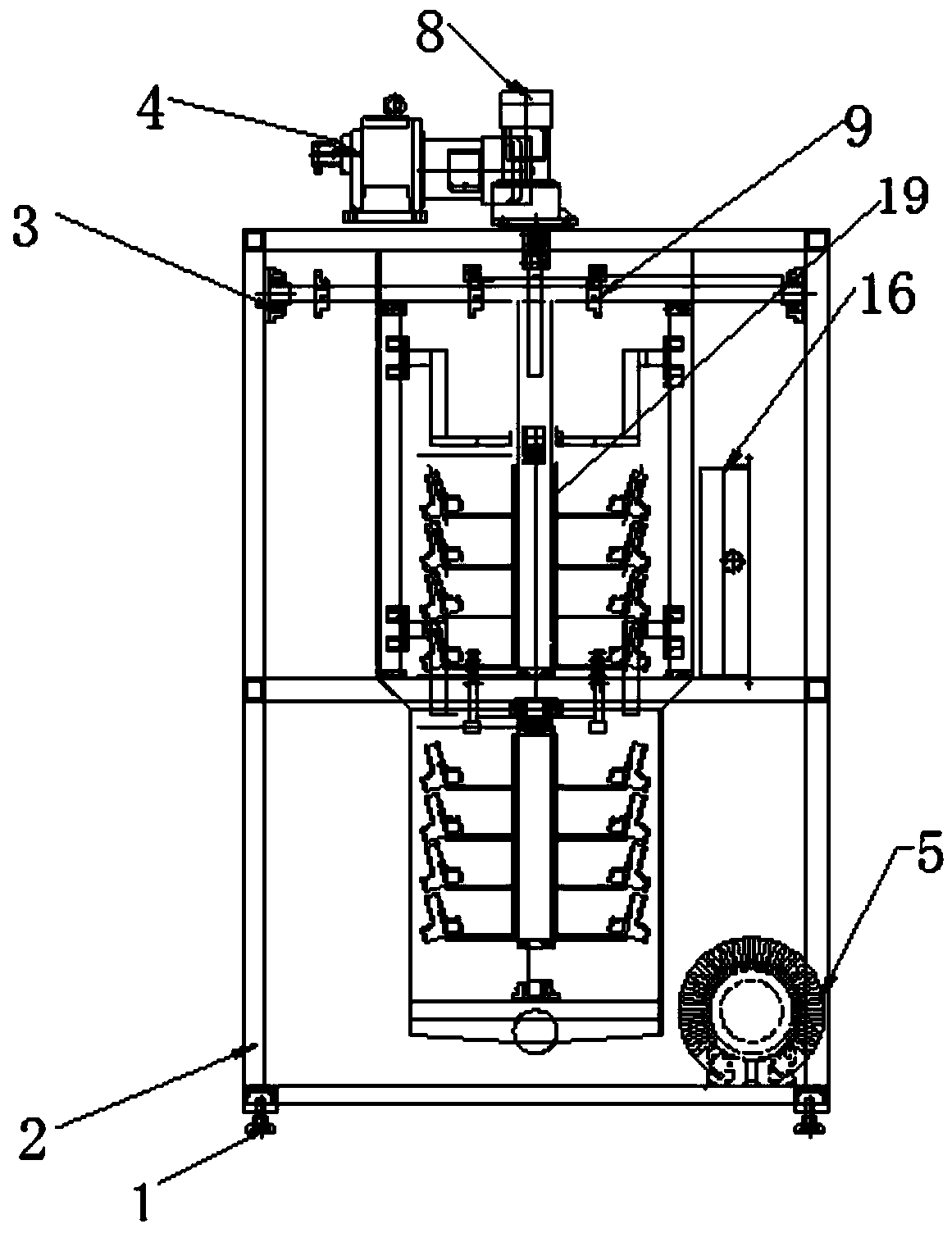

A kind of MBR film intelligent conveying system and using method thereof

ActiveCN114042381BReduce the probability of not being able to immerse in oilImprove oil immersion effectMembranesSemi-permeable membranesUltrasonic weldingElectric machinery

The present invention relates to the technical field of ultra-nanofiltration membranes, in particular to an MBR membrane intelligent conveying system and its use method, including a stirring tank, a film casting machine, a gel cleaning machine, post-processing equipment, a drying machine, Flat film cutting machine and ultrasonic welding machine; the post-processing equipment includes an oil immersion tank, a number of mechanical claws that are rotated and arranged above the oil immersion tank, a timing belt that is rotated and arranged on one side of the oil immersion tank, and a timing belt that is arranged on the The upper basket, the top plate set above the oil immersion tank, the nozzle set on the top plate and the driving part for driving the synchronous belt to rotate, wherein the position of the nozzle corresponds to the position of the basket. The invention reduces the probability that the part of the workpiece held by the mechanical claw cannot be soaked in oil by setting the first motor, the support beam and the mechanical claw, and improves the oil immersion effect of the workpiece.

Owner:波塞冬(江苏)新材料科技有限公司

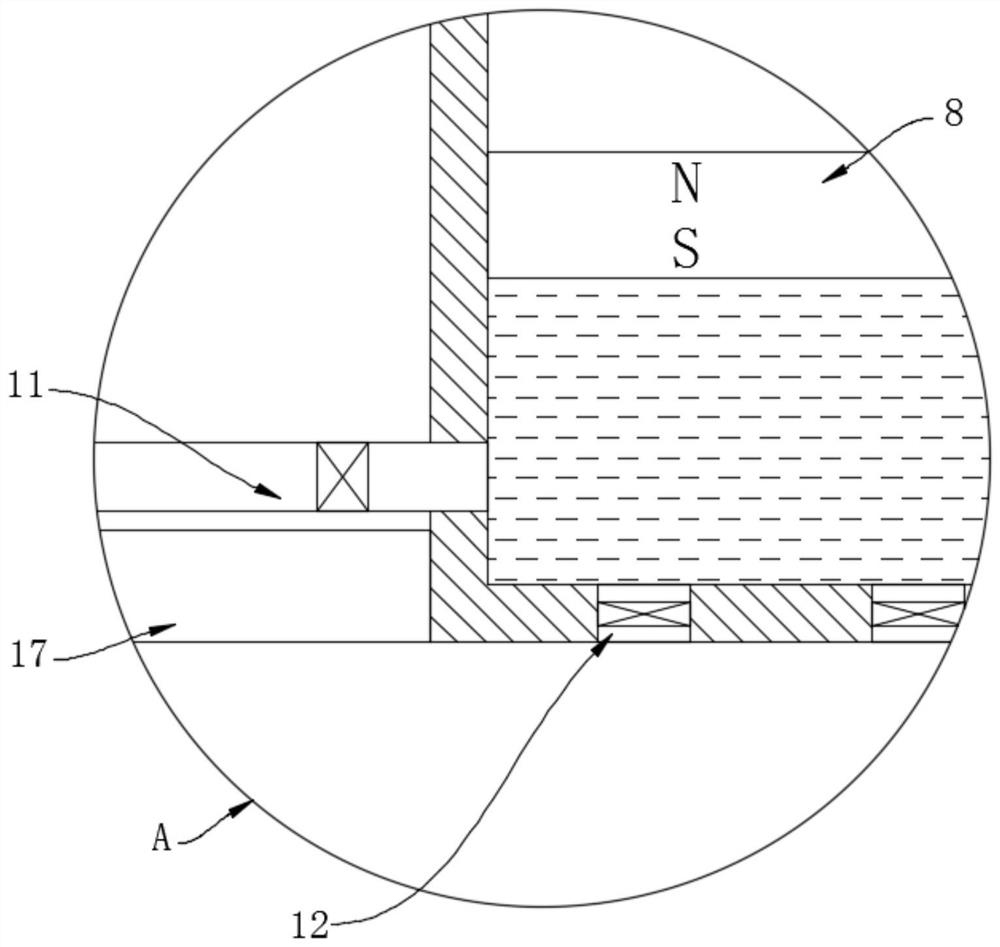

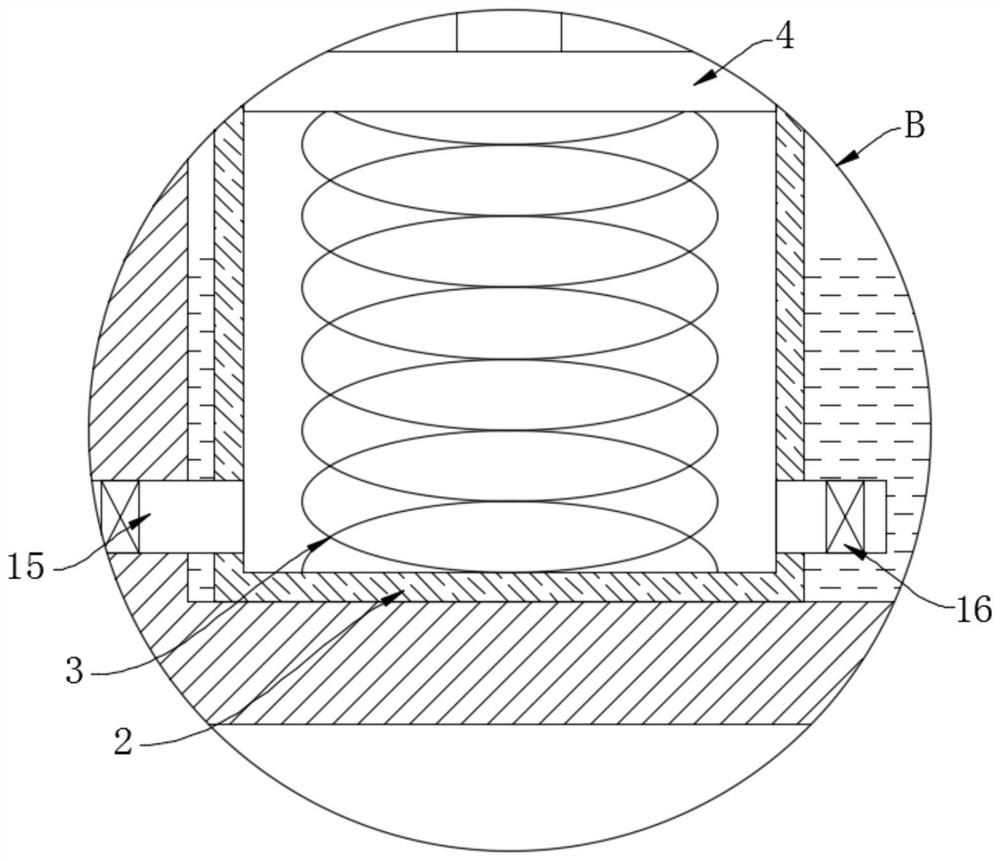

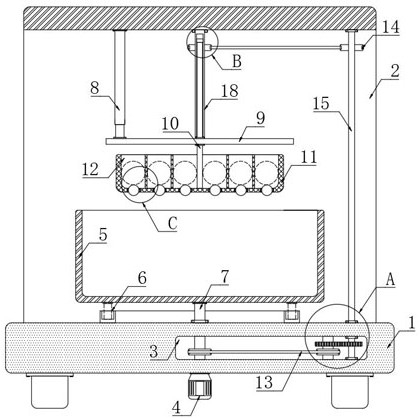

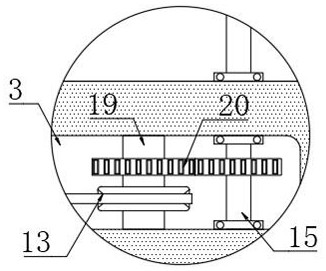

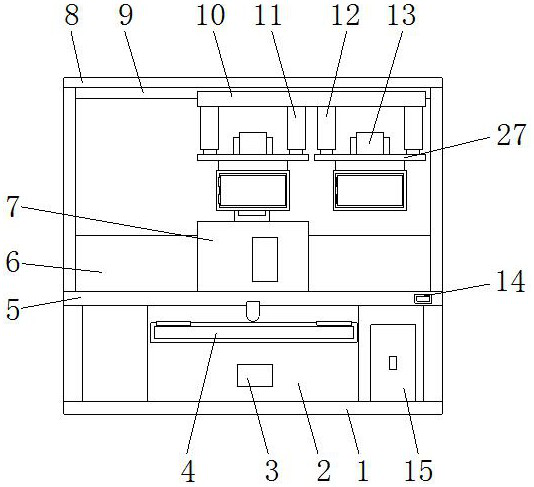

Automatic production robot for magnet oil immersion process

InactiveCN113769967AImprove oil immersion effectImprove work efficiencyLiquid surface applicatorsCoatingsElectric machineryProcess engineering

The invention discloses an automatic production robot for a magnet oil immersion process. The automatic production robot comprises a bottom plate, the top of the bottom plate is fixedly connected with a workbench through a support, the top of the workbench is fixedly connected with a top plate through a support, the bottom of the top plate is fixedly connected with a guide rail, and the outer surface of the guide rail is slidably connected with an electric sliding table; and first electric telescopic rods are fixedly mounted at the periphery of the left end of the bottom of the electric sliding table, and second electric telescopic rods are fixedly connected to the periphery of the right end of the bottom of the electric sliding table. Through mutual cooperation of an oil tank, an oil collecting box, an oil immersion box, the guide rail, the electric sliding table, the first electric telescopic rods, the second electric telescopic rods, a motor, a net cage, a flow guide pipe, a filter screen, a pump machine, a long pipe, third electric telescopic rods, a spray head, an annular sliding groove, an annular sliding block and a connecting plate, the problems that an existing automatic production robot for the magnet oil immersion process is single in function, and the use by people is inconvenient are solved.

Owner:广东桂荣永磁新材料科技有限公司

Manufacturing method of super thin bidirectional stretched polypropylene coarse thin film for capacitor

The invention discloses a manufacturing method of a super thin bidirectional stretched polypropylene coarse thin film for a capacitor. The manufacturing method is characterized by comprising the following steps of: adopting two polypropylene resin materials with degree of isotacticity of 95-98%, ash content being smaller than 30ppm and different melt indexes, melting by a primary extruder and an auxiliary extruder, extruding by a three-layered compound die head, cooling and forming at 95-105 DEG C via a cooling roller and a casting piece air knife; then stretching longitudinally with 4.5-5.0 fold of draw ratio, and forming the coarse thin film product with three-dimensional netty groove structures which are communicated with each other after stretching horizontally with 8-9 fold of draw ratio. The polypropylene coarse thin film prepared by using the invention can not only ensure good oil immersion property of the capacitor, but also satisfy the voltage resisting requirements of the capacitor under high field intensity, and is particularly suitable for being used as an electrical medium in power capacitors with large capacity, small volume and high power and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

A synchronous oil immersion device for inner and outer rings of bearings for mechanical processing

ActiveCN113663865BReduce labor intensityImprove oil immersion effectLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention discloses a synchronous oil immersion device for the inner and outer rings of a bearing used for mechanical processing, which comprises a housing, an oil immersion tank is arranged at the upper end of the housing, a vertical plate is fixedly connected to the upper end of the housing, and the upper end of the vertical plate is A horizontal plate is installed, and a motor is installed on the upper end of the horizontal plate. The end of the output shaft of the motor passes through the horizontal plate, and is fixedly connected with a rotating tube. A first rotating rod is arranged below the rotating tube. The upper end of the rotating rod extends to the inside of the rotating tube, a second rotating rod is arranged below the first rotating rod, and a rectangular sliding chamber is arranged inside the first rotating rod. The oil immersion device, on the basis of achieving a better oil immersion effect, simplifies the operation process and reduces the labor intensity of the staff. oil effect.

Owner:南通腾华新材料科技有限公司

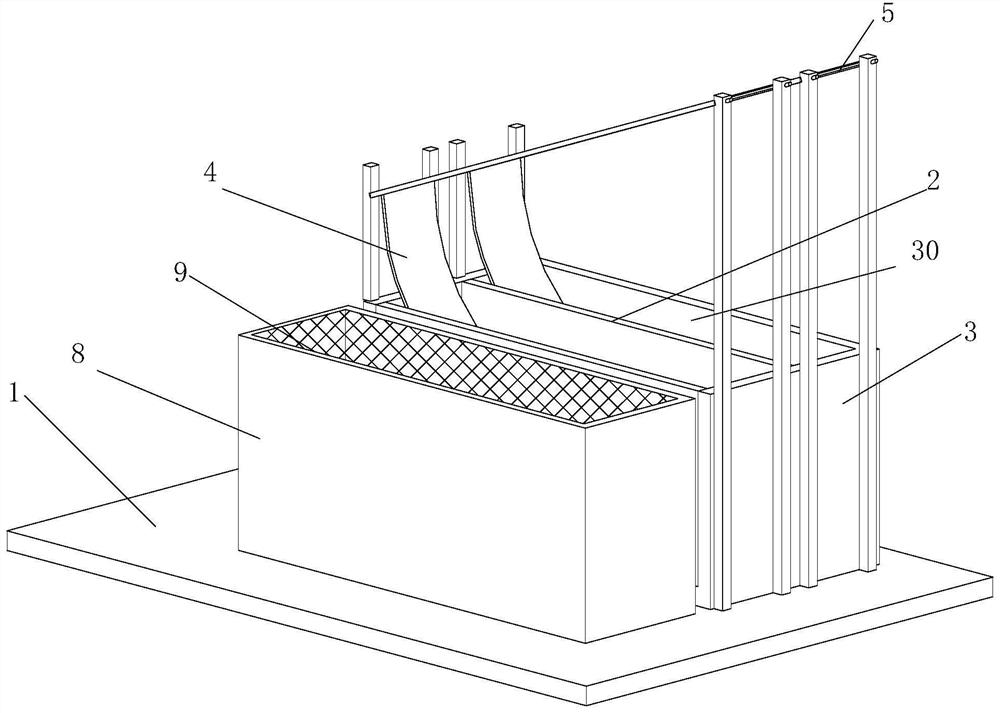

Reciprocating type oil immersion equipment for textile thread processing and use method thereof

InactiveCN113417099AIncrease contact areaImprove wettabilityTextile treatment containersTextile treatment machine arrangementsWire rodElectric machinery

The invention discloses reciprocating type oil immersion equipment for textile thread processing and a use method thereof, and particularly relates to the field of textile processing. The reciprocating type oil immersion equipment comprises an infiltration liquid box and a driving motor; thread guide holes are formed in the two sides of the infiltration liquid box; a reciprocating twisting thread passing mechanism and a fixed thread passing frame are fixedly installed on the bottom face of an inner cavity of the infiltration liquid box; a reciprocating driving mechanism is arranged in the infiltrating liquid box; an intermittent transmission rod is rotationally installed on one side of the reciprocating driving mechanism; and floating guide wheel mechanisms located on the inner sides of the thread guide holes are fixedly installed on the inner side of the infiltrating liquid box. According to the scheme, a reciprocating type twisting structure is adopted for the thread oil immersion equipment; reciprocating type rotation of a twisting wheel is achieved through intermittent rotation transmission and elastic recovery of the reciprocating twisting thread passing mechanism; weaving threads are twisted in a reciprocating mode; and spirals of infiltrated sections of flax threads are unfastened, so that fiber tissue spirals are unfastened, then the interiors of the flax threads are subjected to oil immersion, and the contact area between the threads and oil is increased to obtain a better infiltration effect.

Owner:嘉兴鼎澳纺织科技有限公司

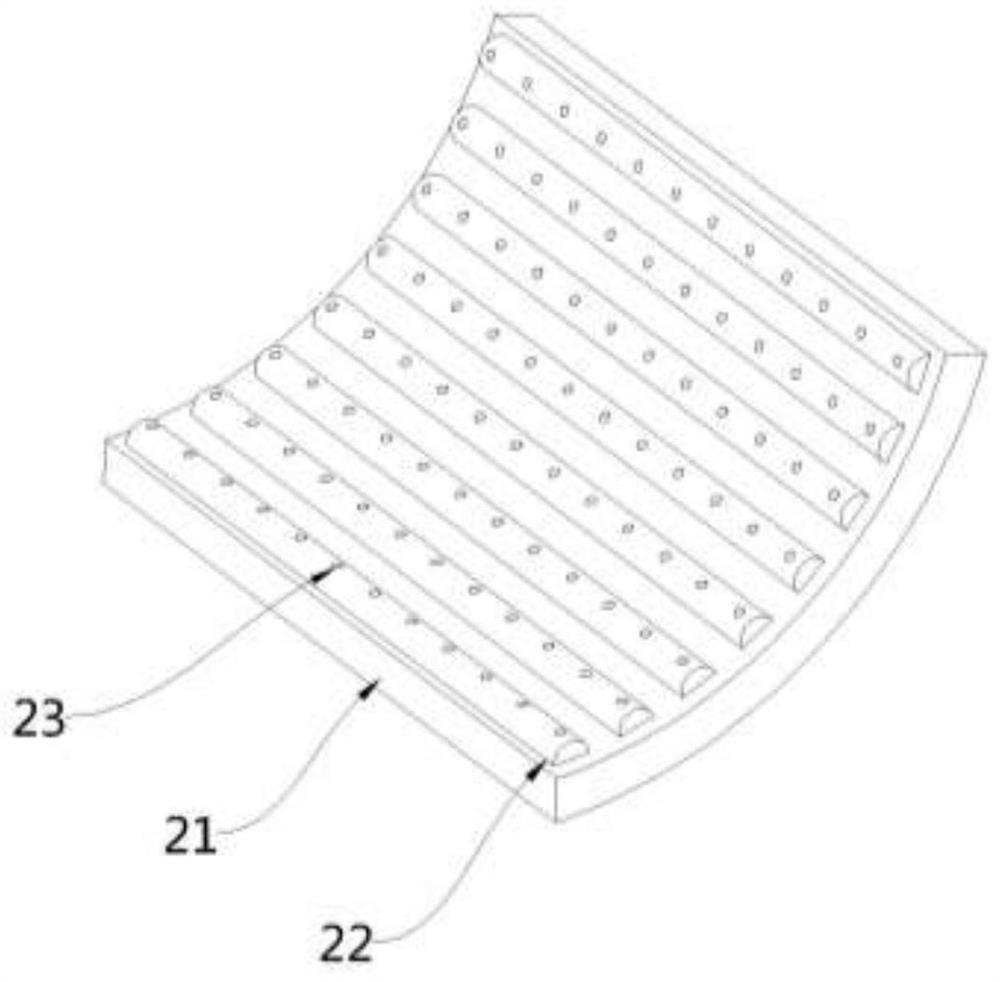

Device for chain oil immersion

InactiveCN114100955AImprove oil immersion effectLiquid surface applicatorsCoatingsEngineeringChain link

The invention discloses a device for chain oil immersion, which comprises a workbench, an oil storage tank, a flexible oil immersion belt and a driving mechanism, and is characterized in that the oil storage tank is arranged on the workbench and is provided with an oil immersion groove; the flexible oil immersion belt is of a belt-shaped structure with certain flexibility and can be made of a mesh or Oxford cloth or other materials, the flexible oil immersion belt is provided with an installation end and a sliding end, the installation end of the flexible oil immersion belt is installed in the oil immersion groove of the oil immersion box, and the sliding end of the flexible oil immersion belt is installed on the workbench in a sliding mode. The sliding end of the flexible oil immersion belt can move towards the end close to or away from the installation end, and the smaller the horizontal distance between the sliding end and the installation end is, the larger the vertical position between the sliding end and the installation end is. According to the device for chain oil immersion, the chain rolls on the oil immersion belt, so that mutual rotation of the connecting positions of chain links on the chain is achieved, and the oil immersion effect is improved.

Owner:WUHU JINGFENG GARDEN MACHINERY TECH

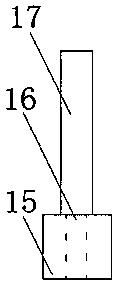

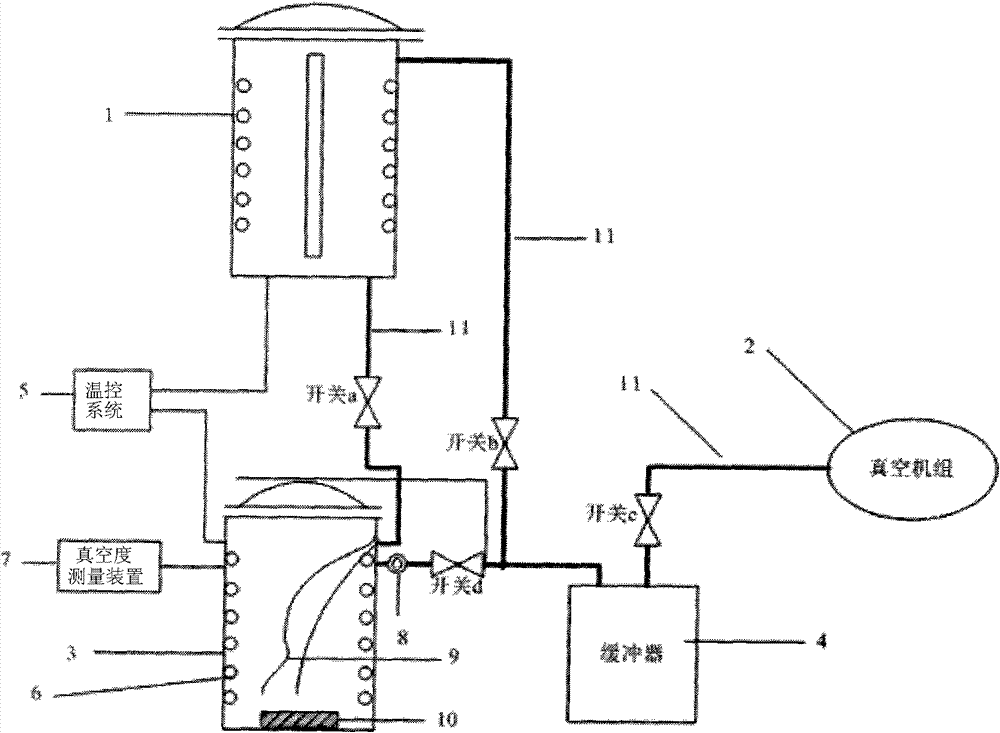

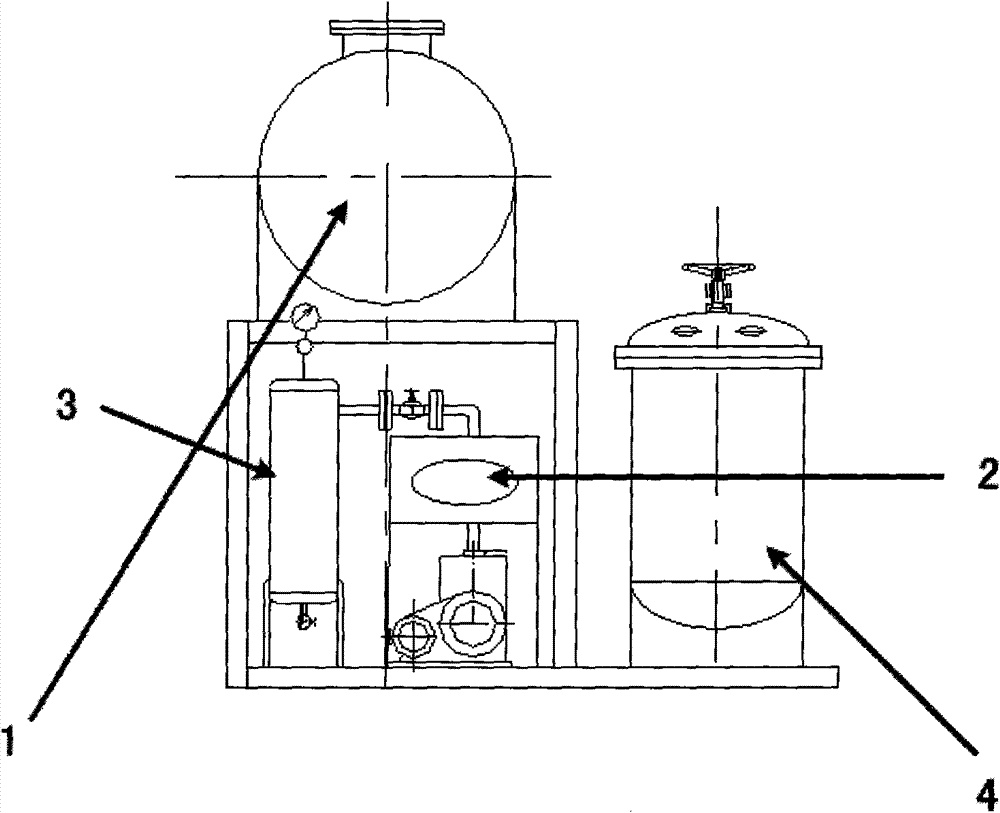

Vacuum insulation oil impregnating device and method thereof

ActiveCN101950642BFull overflowPrevent secondary entryInsulatorsCoils manufactureCardboardTherapeutic effect

Owner:CHINA ELECTRIC POWER RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com