Oil immersion device for rotating shaft production and processing

A technology of oil immersion and rotating shaft, which is applied to the device and coating of the surface coating liquid to achieve the effects of avoiding precipitation, enhancing flow, and enhancing the effect of oil immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

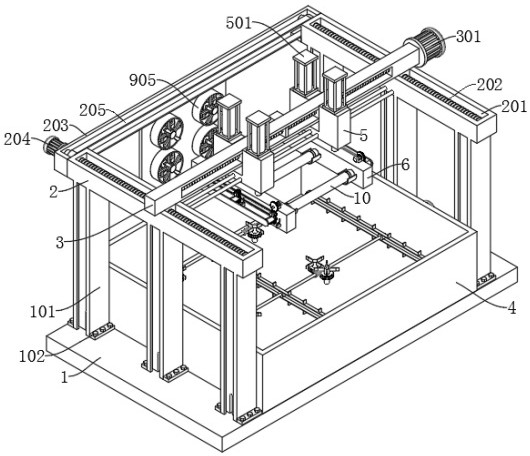

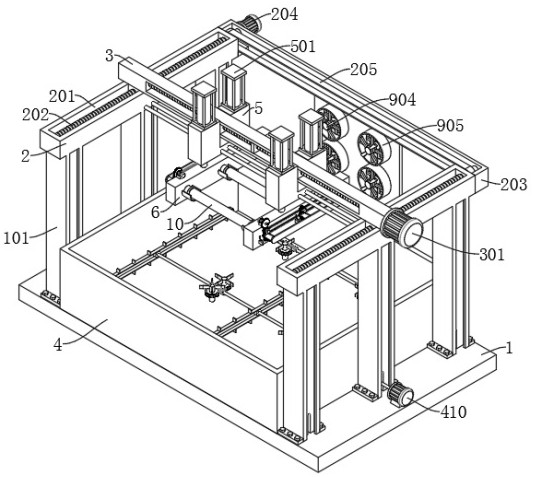

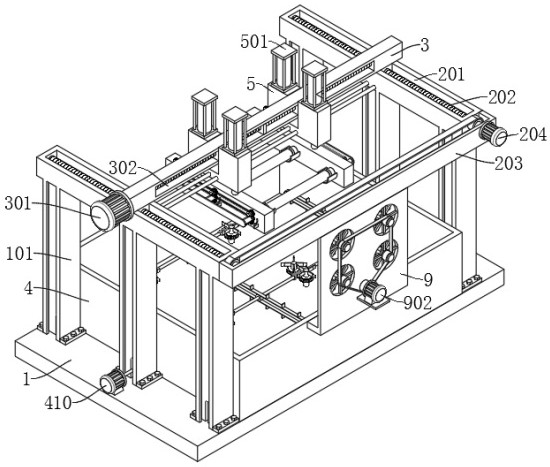

Image

Examples

Embodiment 1

[0044] The vertical board 6 is fixedly connected with a fourth motor 601, the output end of the fourth motor 601 is connected with a driving gear 602, the outer wall of the vertical board 6 is provided with a driven shaft 7, and the outer wall of the driven shaft 7 is fixedly connected with a driving gear 602 The second driven gear 802 meshed with the first driven gear 701 is provided on the threaded sleeve 801 to engage with the first driven gear 701 .

[0045]In this embodiment, after the shaft body 10 is placed on the arc backing plate 603, the auxiliary assembly is controlled to work at this time, and the shaft body 10 is clamped. The specific working process of the auxiliary assembly is: start the fourth motor 601 to drive the The driving gear 602 at the output end rotates, and the driving gear 602 will drive the first driven gear 701 meshed with it to rotate, thereby driving the driven shaft 7 to rotate, and the first driven gear 701 will drive the second driven gear 802 ...

Embodiment 2

[0047] Example 4:

[0048] The outer wall of the rotating shaft 401 is provided with a worm screw 405, the bottom inner wall of the oil immersion tank 4 is provided with a stirring shaft 406, the stirring shaft 406 is provided with a worm wheel 407 meshed with the worm screw 405, the top of the stirring shaft 406 is provided with a rotating plate 408, and the rotating plate The end of 408 away from the stirring shaft 406 is provided with a rubber sheet 409 .

[0049] In this embodiment, when the rotating shaft 4 rotates, it will drive the worm 405 to rotate, and further drive the worm wheel 407 meshed with it to rotate, so that the worm wheel 407 drives the stirring shaft 406 to rotate, so that the rotating plate 408 and the rubber sheet on the stirring shaft 406 Rotate at 409 to stir the liquid, enhance the flow of the liquid, and make the oil immersion effect of the shaft body 10 better.

[0050] Example 5:

[0051] A vertical plate 9 is provided between the frame plate 20...

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com