A kind of MBR film intelligent conveying system and using method thereof

A conveying system and casting membrane technology, which is applied in the field of MBR membrane intelligent conveying system, can solve the problems of insufficient stability of nanofiltration membranes, cumbersome preparation process, and poor oil immersion effect, so as to improve the overall oil immersion effect and improve the overall quality , improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

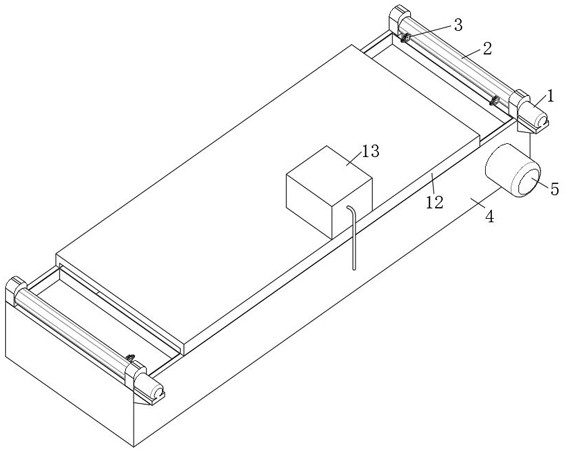

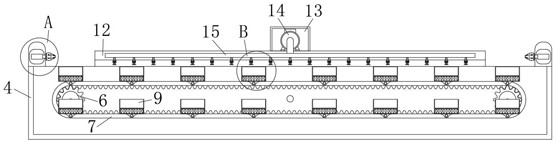

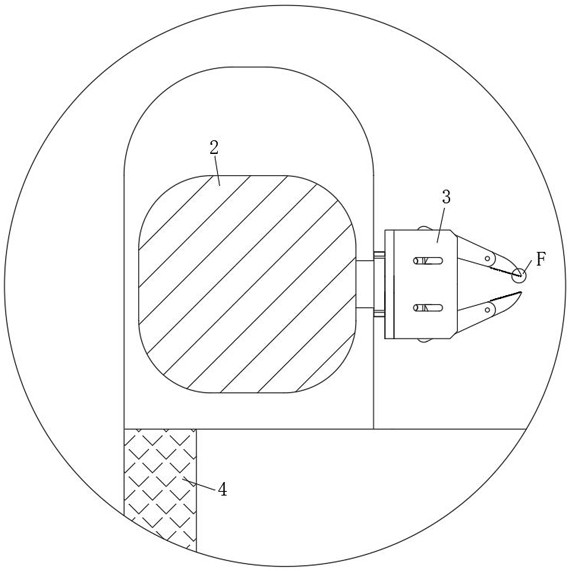

[0052] like Figure 1~9 Shown, a kind of MBR film intelligent conveying system, comprises, the stirring tank connected successively, film casting machine, gel cleaning all-in-one machine, post-processing equipment, drying machine, flat film cutting machine and ultrasonic welding machine; The processing equipment includes an oil immersion tank 4, a number of mechanical claws 3 that are rotated above the oil immersion tank 4, a timing belt 7 that is rotated on one side of the oil immersion tank 4, a basket 9 that is arranged on the timing belt 7, The top plate 12 arranged above the oil immersion tank 4 , the nozzle 17 arranged on the top plate 12 and the driving part for driving the synchronous belt 7 to rotate, wherein the nozzle 17 corresponds to the position of the basket 9 .

[0053] The oil immersion tank 4 is provided with a support beam 2, a plurality of mechanical claws 3 arranged on the support beam 2, and a motor one 1 connected to the support beam 2 in rotation, wher...

Embodiment 2

[0062] On the basis of the first embodiment, the second embodiment also provides an MBR film intelligent conveying system and its usage method, wherein an MBR film intelligent conveying system is the same as the first embodiment, and will not be repeated here. A specific method of using an MBR membrane intelligent delivery system is as follows:

[0063] S1. Preheating: dimethylacetamide is pumped into the mixing tank under airtight conditions through the feeding pump that comes with the mixing tank; 50°C, keep warm for 2h;

[0064] S2. Mixing and stirring: After dimethylacetamide is preheated, use the negative pressure pumping system that comes with the mixing tank to pump PVDF, porogen and modifier into the mixing tank respectively and heat it to 55°C. The internal stirring device is fully stirred until PVDF is completely dissolved in dimethylacetamide to obtain a casting solution;

[0065] S3. Flat film casting: The casting liquid is evenly scraped and coated on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com