Oil immersion machine

An oil immersion machine and oil immersion technology, which is applied in the direction of pretreatment surface, coating, and surface coating liquid device, etc., can solve the problems of low work efficiency, time-consuming and labor-intensive, etc., and achieve fast oil immersion speed and use The effect of long life and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

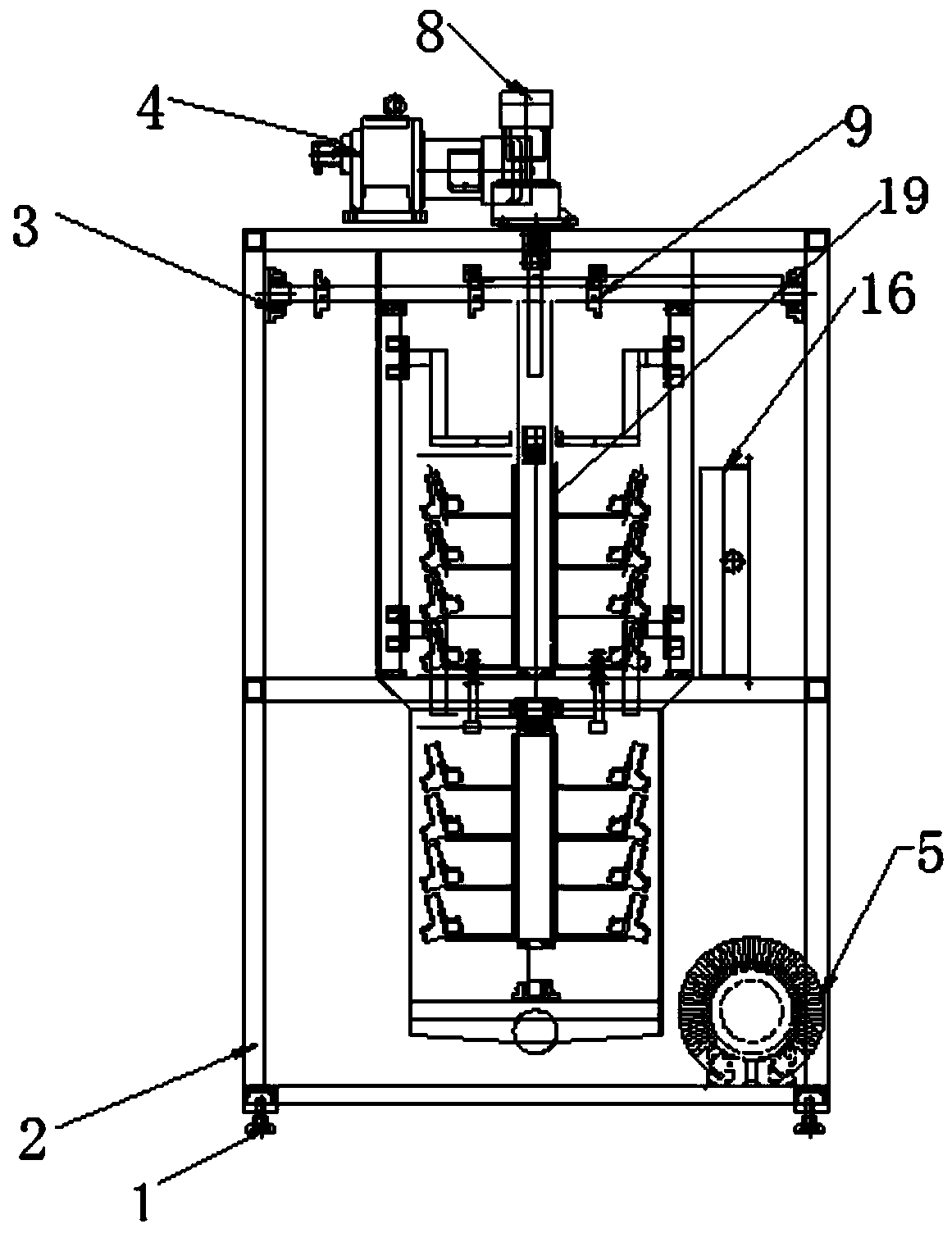

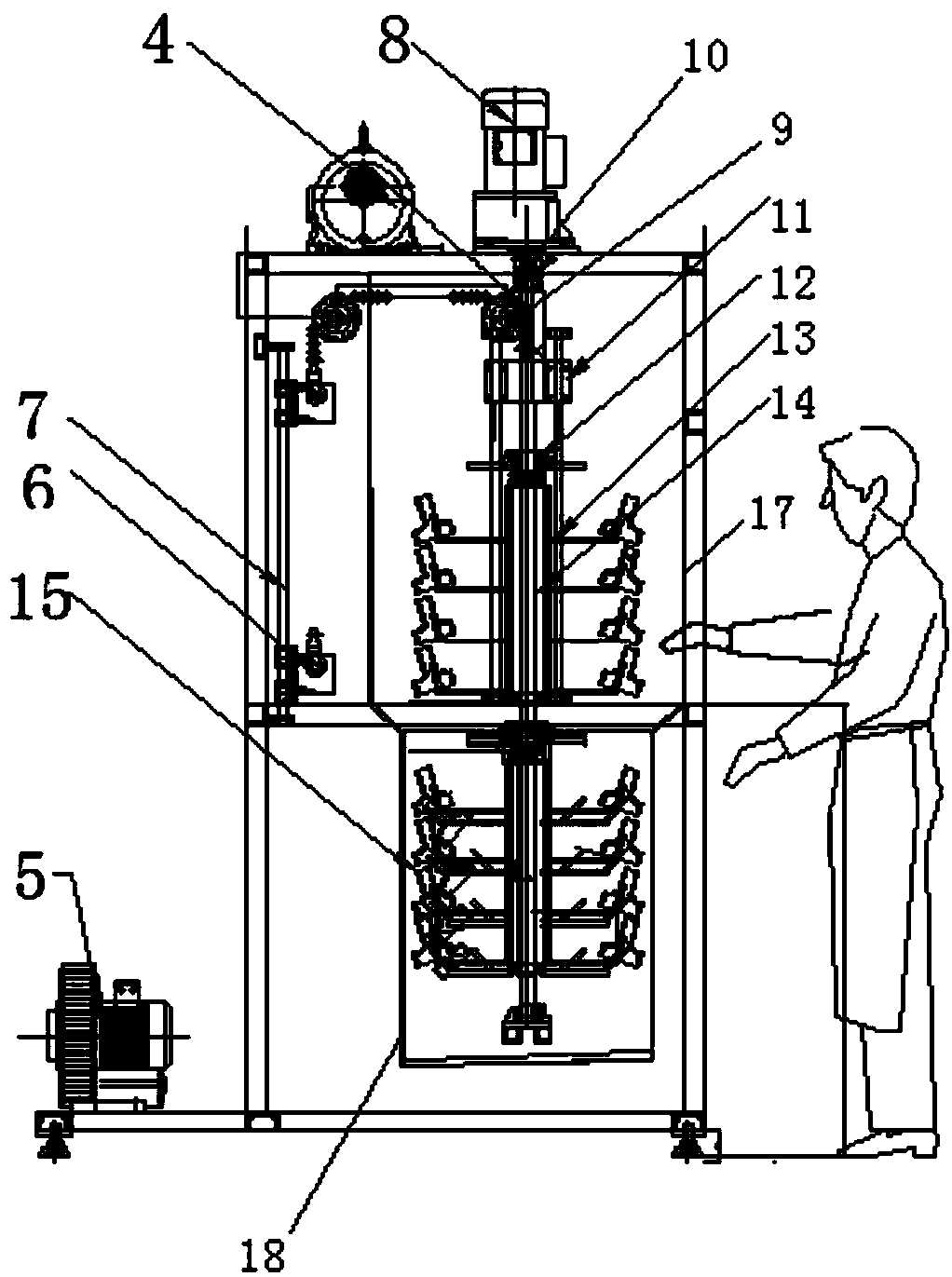

[0030] This embodiment discloses an oil immersion machine, which includes a lifting mechanism arranged at the top, a rotating mechanism, an oil immersion tank 18 arranged at the bottom, a blower mechanism, an observation window 17 and a frame 2 supporting the entire oil immersion machine;

[0031] The rotating mechanism includes a long shaft 19 that runs through the middle of the oil immersion machine from top to bottom, and multi-layer hooks 13 are longitudinally arranged on the long shaft 19, and the hooks 13 are used to place workpieces 15 to be cleaned;

[0032] Blowing mechanism comprises air knife 16 and air pump 5.

[0033] The hooks 13 are symmetrically distributed on both sides of the same cross-section of the long axis.

[0034] The lifting mechanism includes a lifting motor 4 and a lifting sprocket 9 arranged below it.

[0035] A slider 11 is sheathed on the long axis 19, and the slider 11 can move up and down along the optical axis 7, and a tapered roller bearing ...

Embodiment 2

[0041] This embodiment discloses a method of using the oil immersion machine described in Embodiment 1 to immerse a workpiece in oil, the method comprising the following steps:

[0042] S1: The operator hangs the workpieces on the hooks one by one, closes the observation window, and activates the one-key oil immersion key;

[0043] S2: The hook is lowered into the oil immersion tank for oil immersion treatment, and automatically rises to the designated position after the set time, and the rotating shaft starts to drive the hook to rotate and blow air;

[0044] S3: After the set time is up, the rotation and blowing will be stopped, and the equipment will alarm to remind the operator to unload the material, that is, the whole process of oil immersion and blowing is completed.

[0045] In S2, the set time for oil immersion treatment is 5-10 minutes.

[0046] In S3, the setting time of the rotation and blowing process is 3-8min.

[0047] The long axis can be rotated 360 degrees....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com